Li-ion secondary battery and its making method

A secondary battery and lithium-ion technology, which is applied in the manufacture of secondary batteries, secondary battery components, and electrolyte batteries, and can solve problems such as leakage and uneven distribution of electrolyte

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

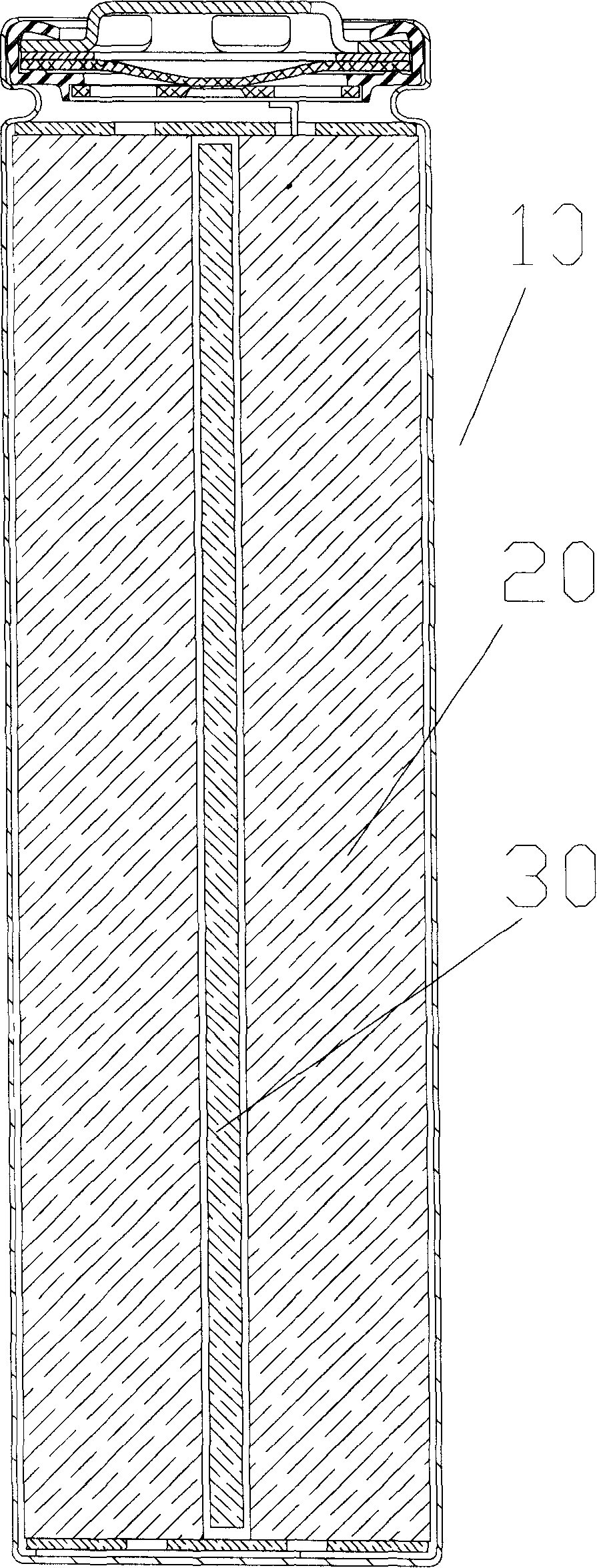

[0023] Such as figure 1 and figure 2 As shown, a cylindrical lithium ion secondary battery includes a cylindrical cylinder 10 and an electrode group 20 housed in the cylinder, the electrode group is wound into a cylindrical shape and has a space defined in its center, A central pin 30 of a polyvinylidene fluoride physical gel with a microporous structure, specifically a PVDF-HFP gel, is arranged in the space defined by the center of the electrode group. When the electrolyte solution enters the gel center pin 30 with a microporous structure, a lateral force is generated due to swelling to press against the electrode assembly 20 . The center pin 30 is a solid cylinder and has an "I" shape as a whole. The outer diameter of the polyvinylidene fluoride physical gel 30 is not greater than the diameter of the cylindrical space at the center of the electrode assembly 30 . Preferably, the outer diameter of the cylinder of the polyvinylidene fluoride physical gel is 50%-99% of the d...

Embodiment 2

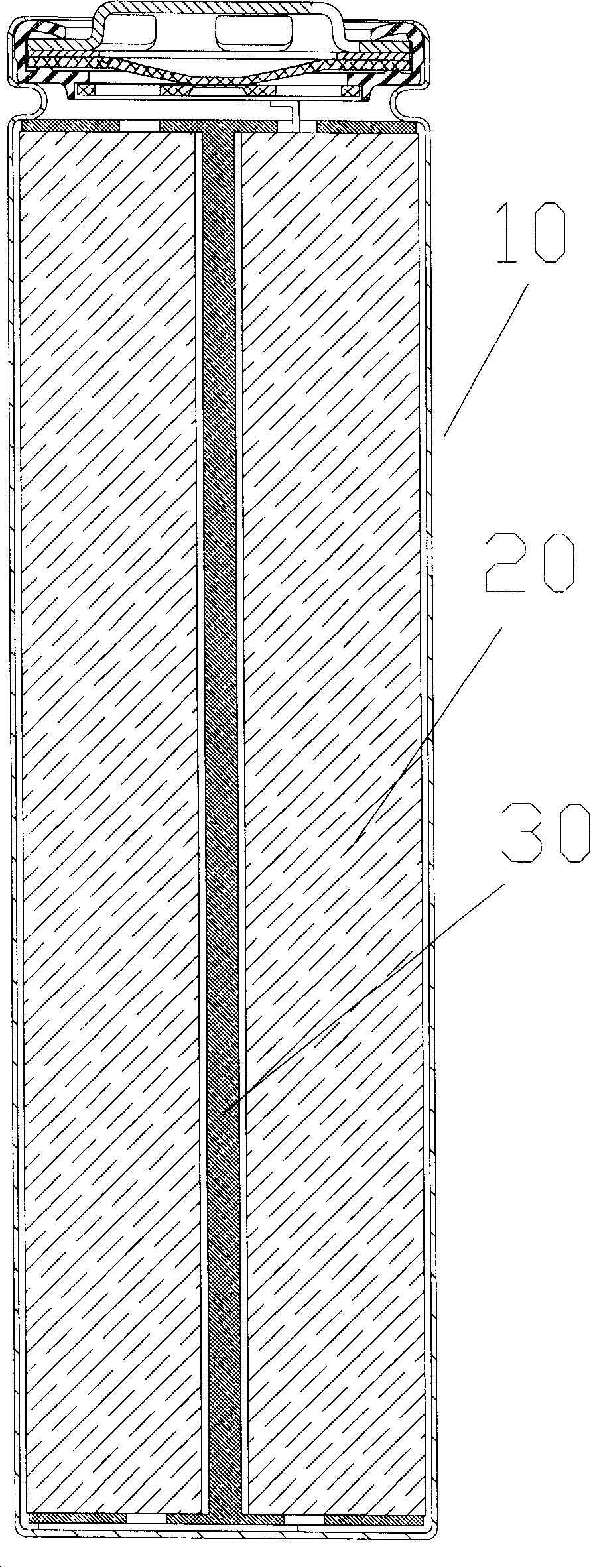

[0026] Such as Figure 3-Figure 4 As shown, another cylindrical lithium-ion secondary battery, the difference between this embodiment and embodiment 1 is that the polyvinylidene fluoride physical gel used in the center pin 30 is a mixture of PVDF-HFP and homopolymerized PVDF gel. The polyvinylidene fluoride physical gel uses polyvinylidene fluoride copolymers with a melting point of 130-145° C. as raw materials, and the comonomers are copolymerized with hexafluoropropylene. The upper and lower ends of the cylindrical center pin 30 have a disc-shaped structure, wherein the upper disc-shaped structure 31 is provided with a groove 32 to facilitate the extraction of the tab (according to requirements, if the tab is drawn from the lower disc-shaped structure 31, it can also be Offer the groove 32 that draws tab on the disc structure 31 of lower end. So that it is easier to absorb electrolyte, battery liquid retention is better, and battery is not easy to leak. Other structures and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com