Multistage triggering fabricated seismic-isolation support for connection of skirt steel roof and high-rise building

A technology of high-rise buildings and seismic isolation bearings, applied in buildings, building components, building types, etc., can solve the problems of inability to resist large overturning moments of steel roofs, low shock absorption rate of seismic isolation bearings, weak seismic performance, etc. , to achieve the effect of reliable performance, convenient performance and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with specific embodiments.

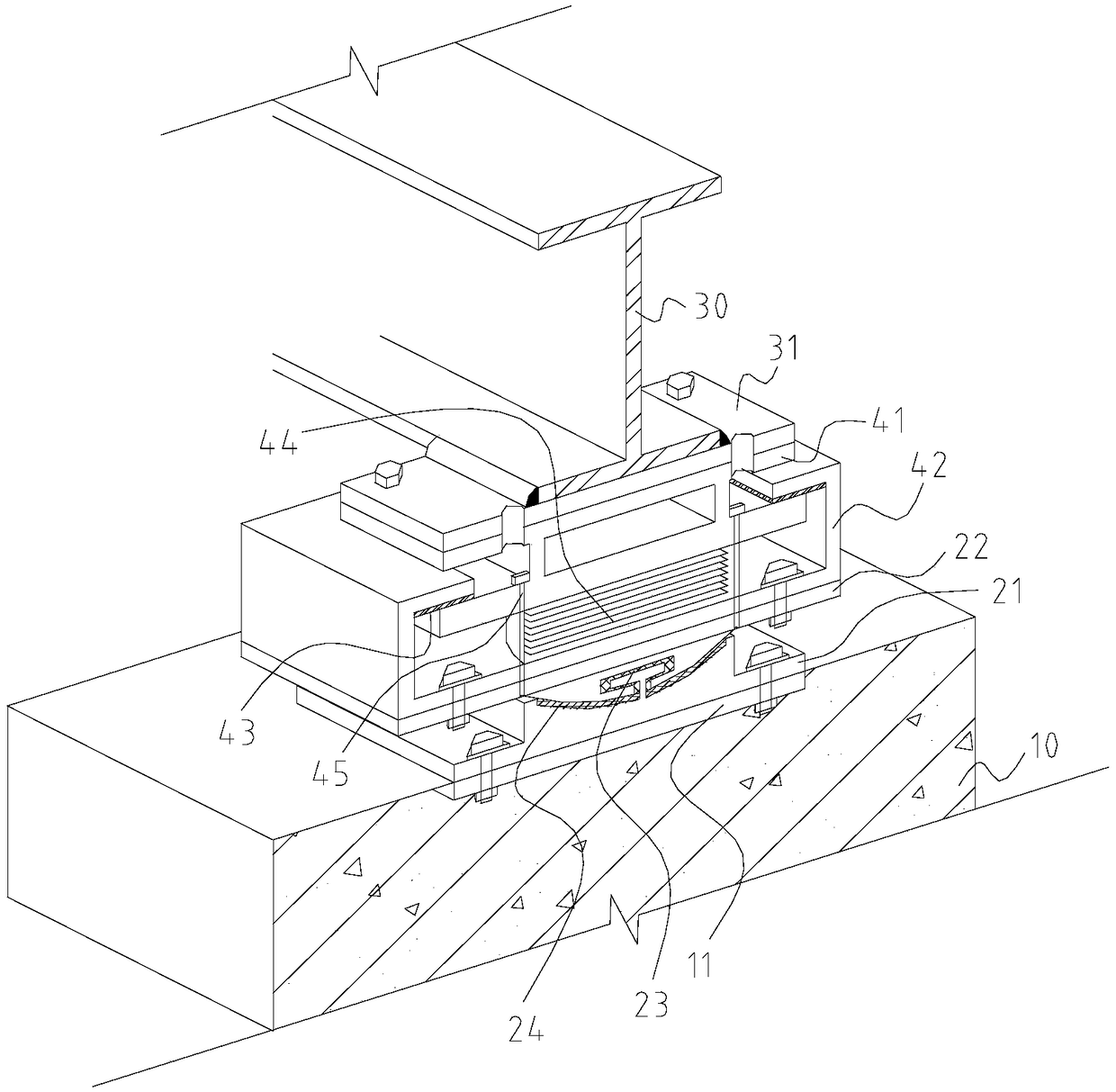

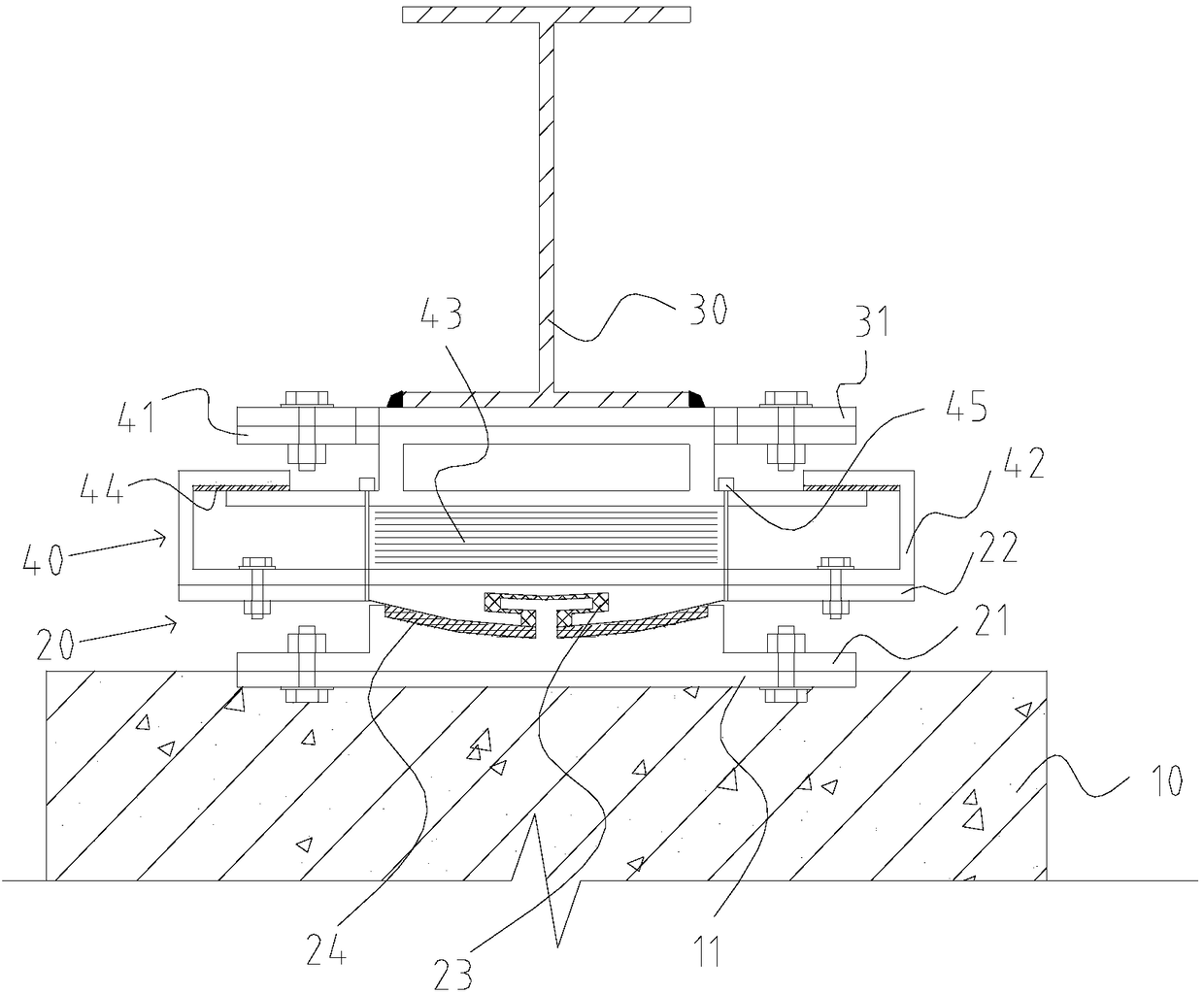

[0045] Such as figure 1 ,2 As shown, a multi-stage trigger assembly type seismic isolation support for the connection between the skirt steel roof and the high-rise building, the vibration isolation support includes a sliding part 20 fixed on the pre-embedded steel plate 11 of the high-rise building 10 and a fixed The shock-isolating part 40 on the bottom end plate of the skirt steel roof 30, the sliding part 20 and the shock-isolating part 40 are assembled to form a multi-stage triggered assembly structure.

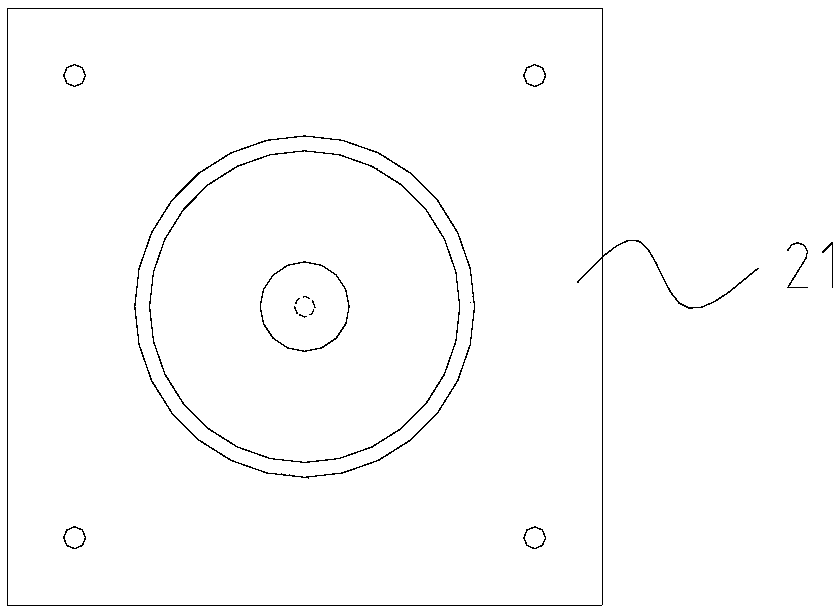

[0046] In a preferred embodiment, as figure 1 , 2 , 3A, 3B, 4A, and 4B, the sliding part 20 includes a lower support plate 21 fixed on the embedded steel plate 11 of the high-rise building 10 and a sliding support plate 22 that forms a fixed connection with the middle support plate 42 of the shock-isolating part 40 , the upper surface of the lower support plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com