Device for suction and decantation of a crankcase gas and associated installation

A crankcase and equipment technology, which is applied in the field of motor crankcase gas recovery and processing systems, can solve the problems of the lower motor and the upper motor being heavy, and achieve the effects of saving efficiency gains, improving discharge capacity, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

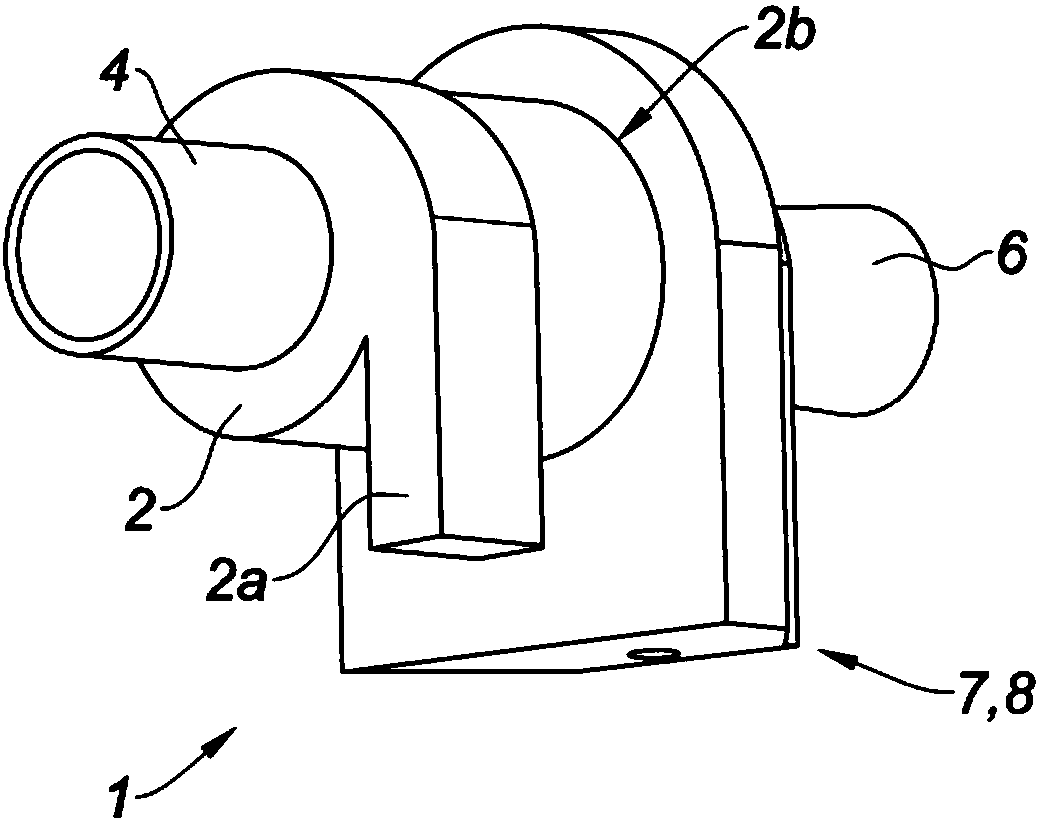

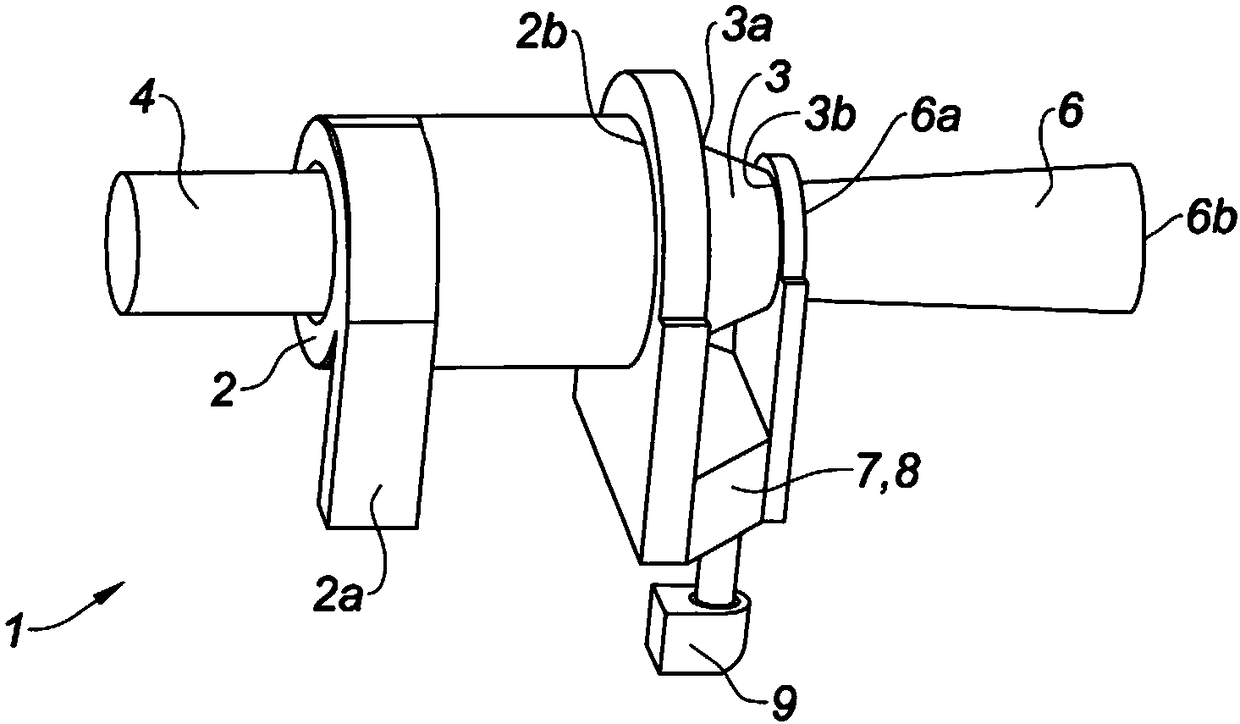

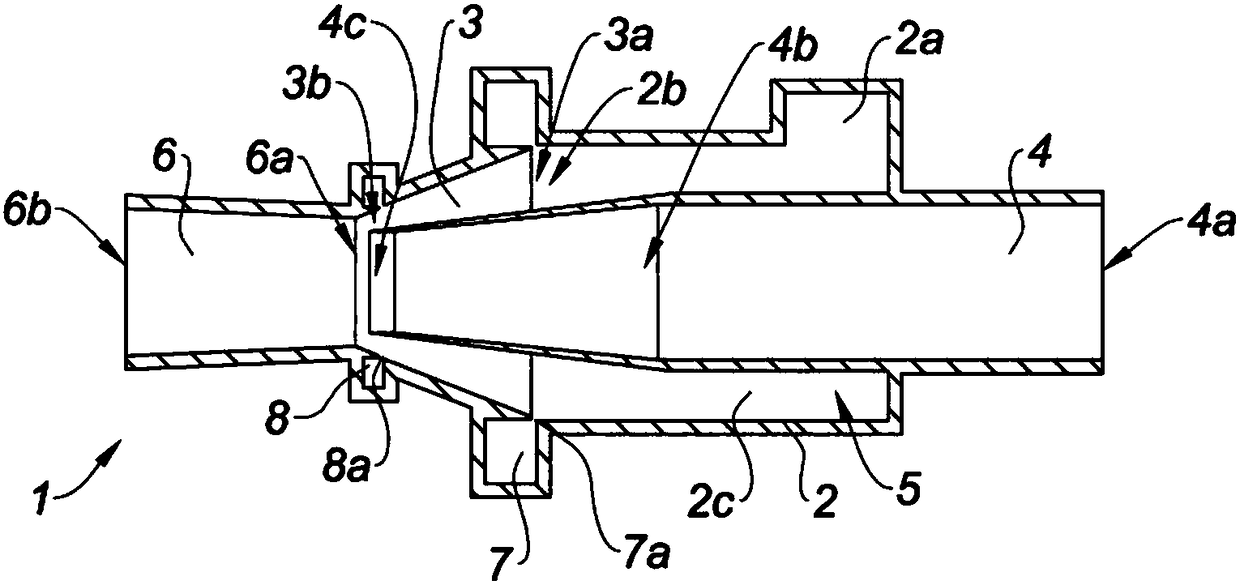

[0051] The elements common to all embodiments of the suction and decanting apparatus 1 according to the invention are described below.

[0052] as in Figure 1 to Figure 9 and Figure 13 As exemplified in , the crankcase gas suction and decanting device 1 according to the invention comprises a crankcase gas collection cylinder 2 having a cylinder inlet 2a and a cylinder outlet 2b, said cylinder inlet 2a being shaped as a cut The cylinder inlet 2 a is arranged tangentially to the cylinder 2 to deliver crankcase gases.

[0053] Furthermore, the suction and decanting device 1 comprises a first conical portion 3 comprising a first end 3a and a second end 3b arranged at the cylinder outlet 2b. as in image 3 and Figure 9 As clearly shown in , the first conical portion 3 converges from its first end 3a towards its second end 3b.

[0054] as in image 3 and Figure 9 in and in figure 1 , figure 2 , Figure 4 to Figure 8 and Figure 13 As shown in , the suction and decant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com