Stainless steel radiator without water

A stainless steel and radiator technology, applied in indirect heat exchangers, heat exchanger shells, heat exchanger types, etc., can solve the problems of oxidation corrosion, high production energy consumption, shortened service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

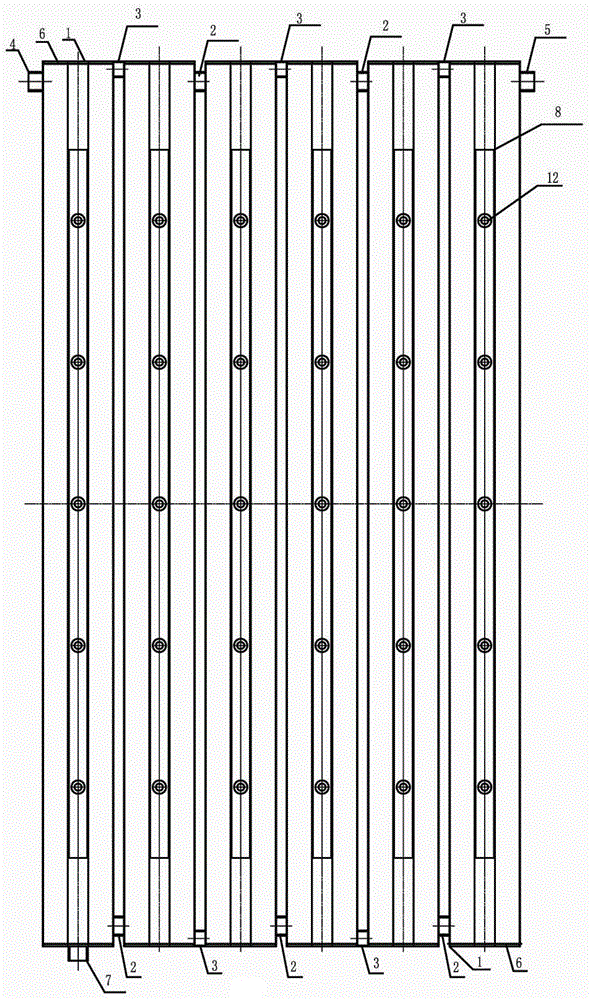

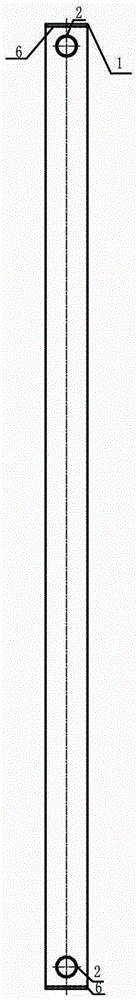

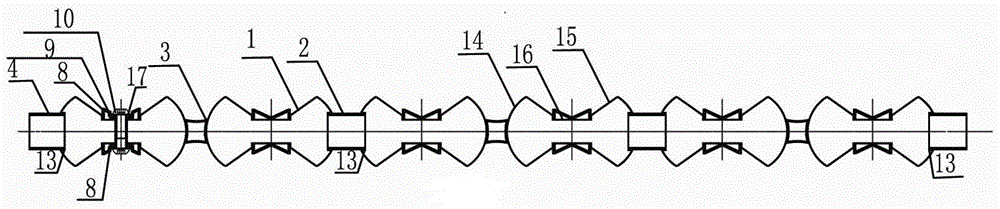

[0024] The present invention as Figure 1 to Figure 4 , Pic 4-1 , Figure 5 , Figure 5-1 As shown, the stainless steel radiator without stringing water is composed of stretched heat pipe 1, connecting pipe 2, connector 3, water inlet 4, water outlet 5, bow-knot-shaped flanged head 6, air release valve 7, M bead 8 , sealing gasket 9, plywood bolt 10, circular seam welding 11, plywood bolt hole 12, inner flange circular seam welding 13, characterized in that:

[0025] A plurality of said series-connected tensile heat pipes 1 are welded at the arc surfaces 14 at both ends of a plurality of connecting pipes 2 and a plurality of connectors 3 to form a rectangle or a square shape;

[0026] The arc surfaces 14 at both ends of the plurality of series-connected tensile heat pipes 1, the front and back surfaces are concave to form an arc surface 15, and the middle part of the front and back surfaces is a plane concave step 16;

[0027] The welded part 13 of the stretched heat pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com