Patents

Literature

36results about How to "Save efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deep purification and reclaiming device and method for dyeing waste water

InactiveCN1569694AImprove biochemical treatment efficiencyMeet process water requirementsMultistage water/sewage treatmentFiberChlorine dioxide

The invention discloses a deep purification and reclaiming device and method for dyeing waste water, wherein the device comprises a regulating reservoir, an naerobic tank, an aerobic aeration tank, a sedimentation tank, a chlorine peroxide oxidation tank, a medicament administration and coagulation tank, a biologically active charcoal tank and a fiber ball filter. The waste water treatment method integrates a biochemical treatment process and a physical-chemical treatment method.

Owner:东莞市天虹实业投资有限公司

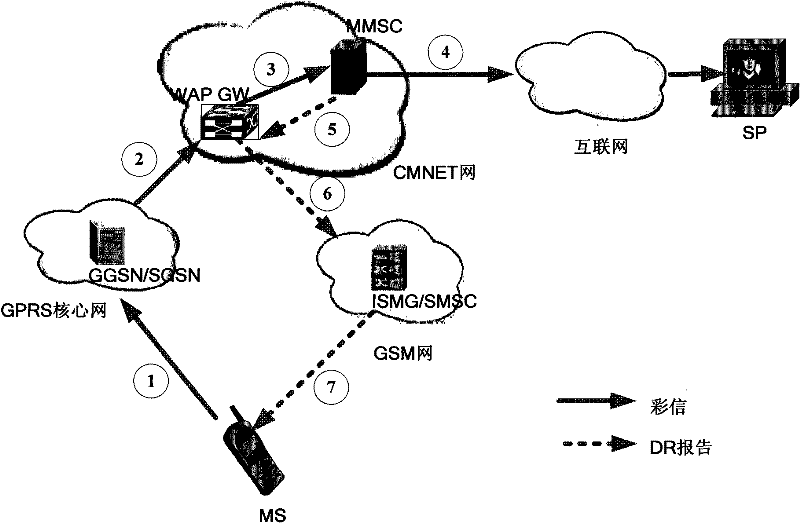

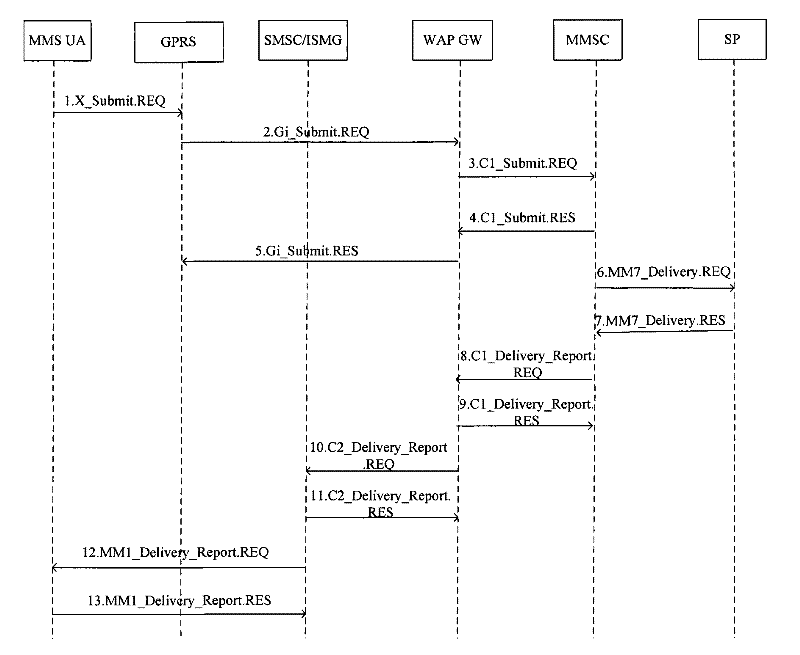

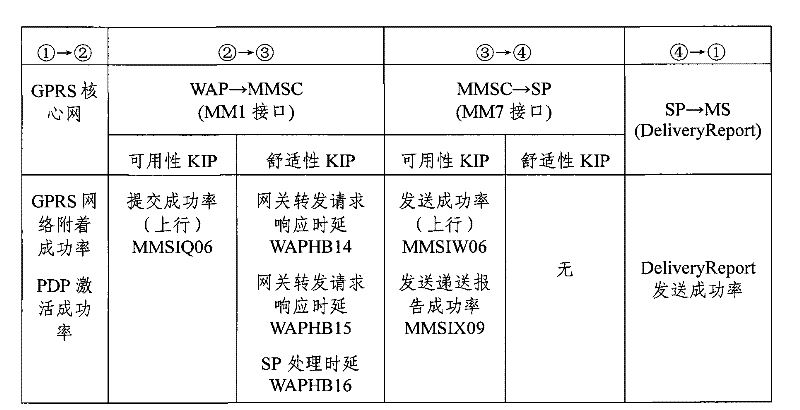

Mobile data service end-to-end quality analysis method and system

ActiveCN102238465AQuickly adapt to the actual situationShorten the timeWireless commuication servicesAnalysis methodBusiness metrics

The invention discloses a mobile data service end-to-end quality service method, which is characterized by comprising the following steps of: configuring different data service systems according to the source-end-to-destination-end flow of a mobile data service to be analyzed; configuring influence relationships between service indexes of previous and next data service systems according to interaction relationships between the previous and next data service systems in the flow of the data service, and marking the service indexes with the influence relationships with identical identifiers; and monitoring the service indexes according to the influence relationships in real time to judge whether the service indexes are normal or not. The invention also discloses a mobile data service end-to-end quality analysis system, which comprises a service system configuration module, a service index configuration module and a service index analysis module. By the method and the system, the configurability of the service systems and the service indexes is achieved, 'lateral' influence relationships among the service indexes are established, development time is greatly saved, development efficiency is greatly improved, abnormal service indexes can be positioned at any time, and problems can be timely discovered.

Owner:ULTRAPOWER SOFTWARE

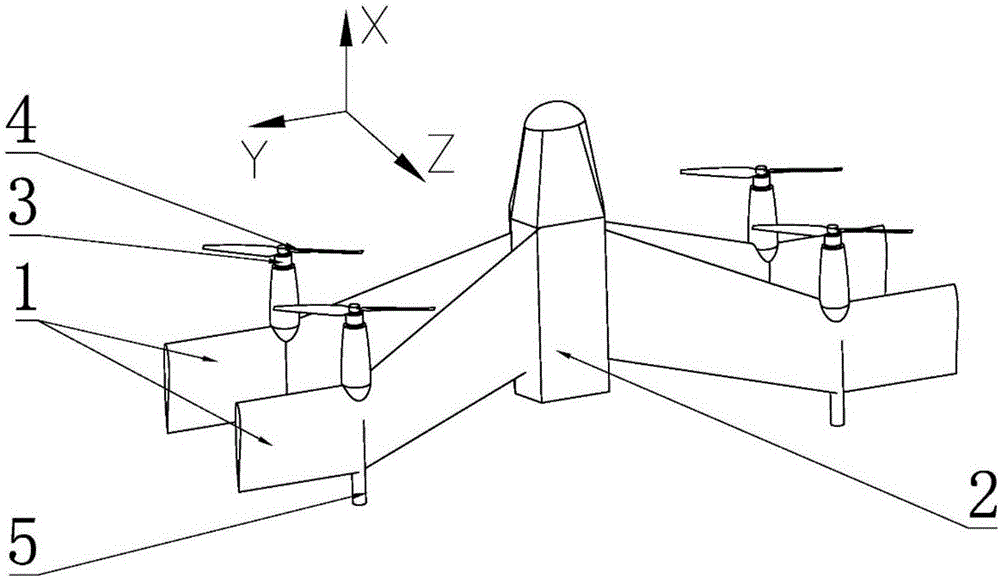

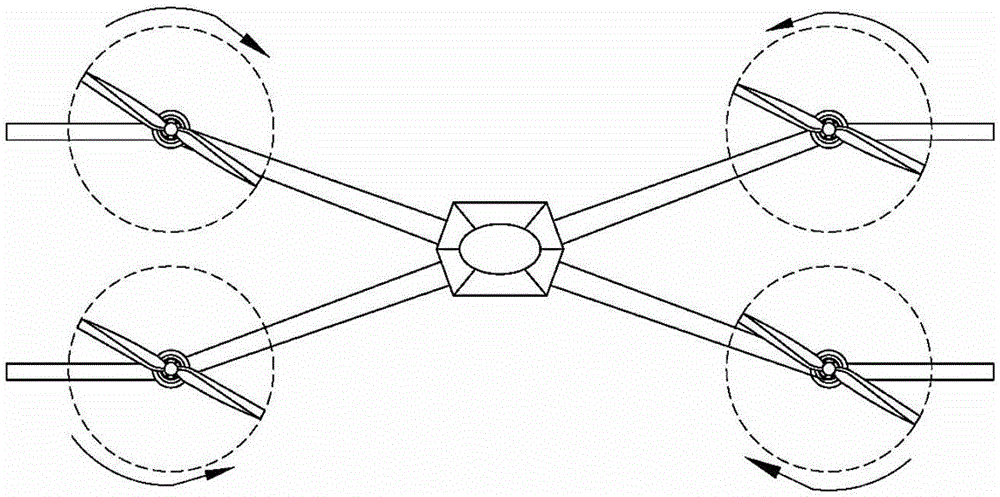

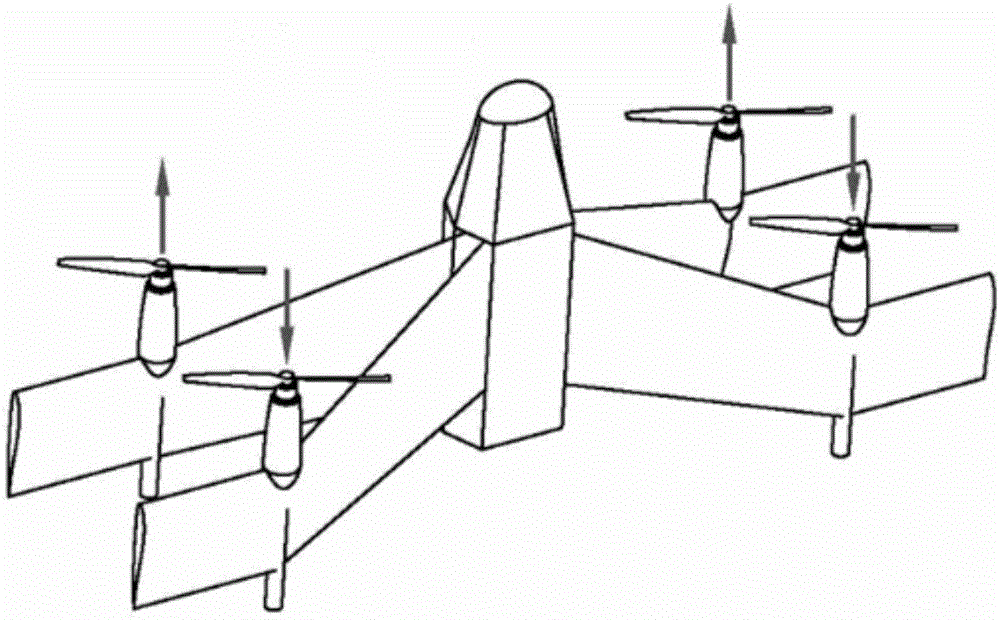

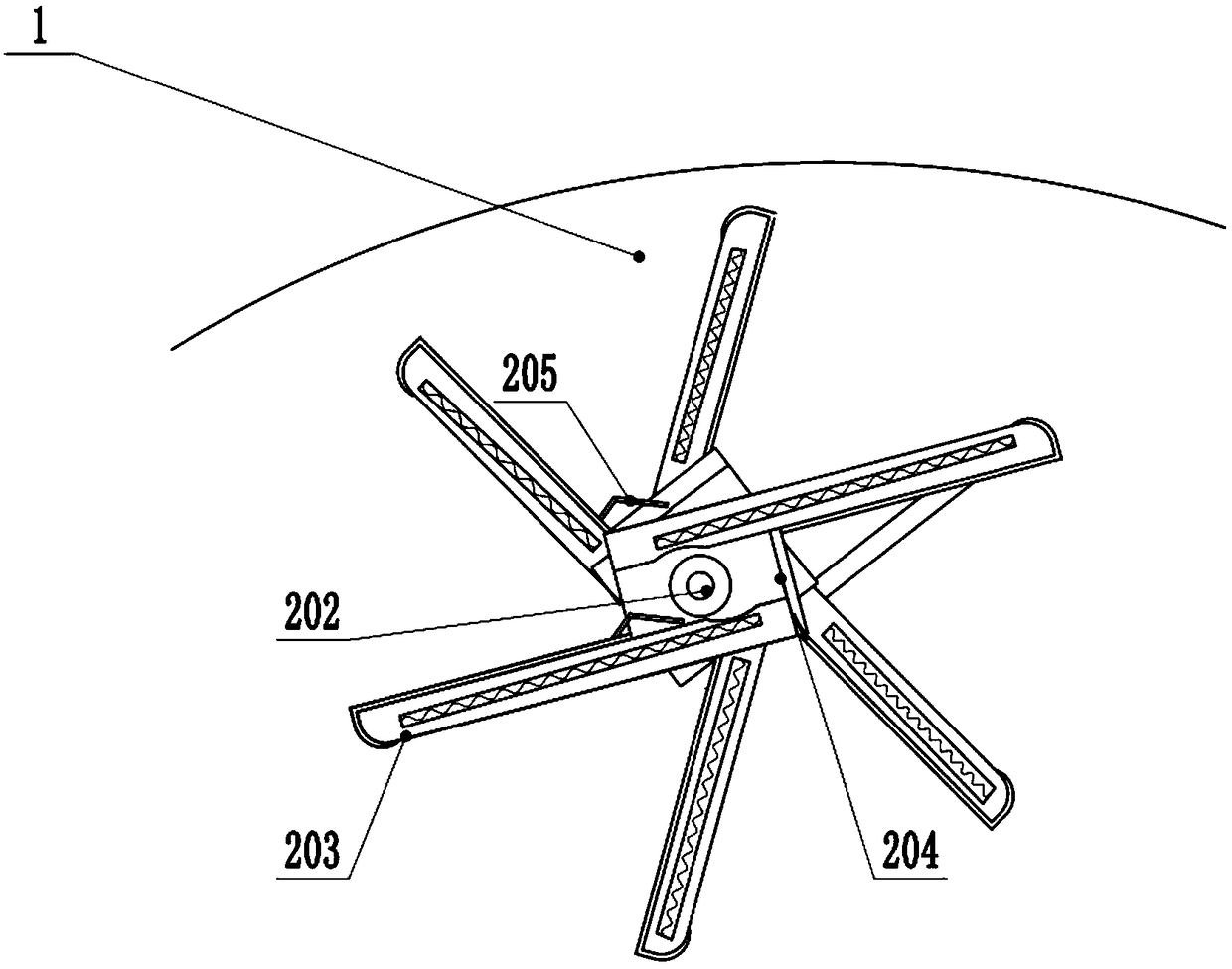

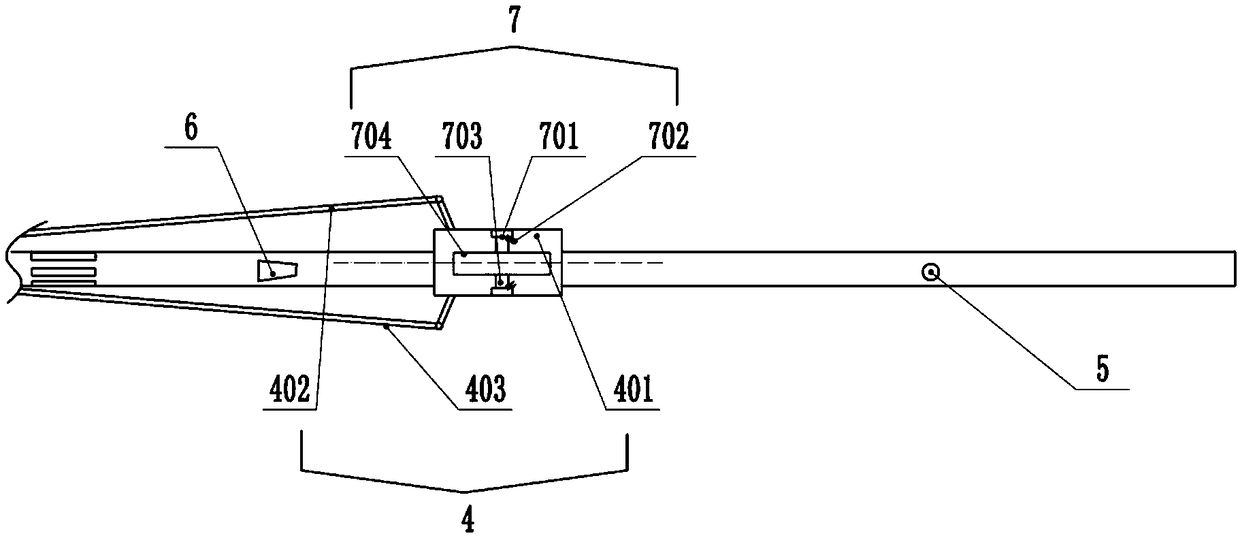

Power-operated tail-sitting type mixed layout vertical take-off and landing aircraft

InactiveCN106240814AStable and efficient vertical take-off and landingStable and efficient hoveringVertical landing/take-off aircraftsRotocraftRotary wingDihedral angle

The invention discloses a power-operated tail-sitting type mixed layout vertical take-off and landing aircraft. The power-operated tail-sitting type mixed layout vertical take-off and landing aircraft is composed of a fuselage, airfoils, motors, propellers and landing gears; the fuselage axis coincides with the OX axis of a body axial system, the projections of the fuselage axis and the OX axis in an XOY plane of the body axial system are distributed in an X shape; each airfoil on the fuselage is divided into several sections, sweepback angles and dihedral angles of all the sections are different from one another, and excellent pneumatic performance and maneuvering performance are achieved through positively-curved airfoil profiles and negatively-curved airfoil profiles; four sets of propeller-motor power systems are installed on the four airfoils correspondingly, and the distances between the positions where the propeller-motor power systems are located and the OX axis of the body axial system are the same; and four power devices take off in an X-shaped quad-rotor mode in the vertical take-off and landing processes and complete conversion operation to enter a cruising state through different tensile forces of the motors or by being matched with maneuvering surfaces, and required maneuvering is completed through tensile force changing of the motors in the whole process. The power devices of the aircraft are simple, the control mode is reliable, propeller slipstreams can be effectively utilized, and the aircraft is suitable for serving as flying platforms of a tail-sitting type vertical take-off and landing unmanned aerial vehicle.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

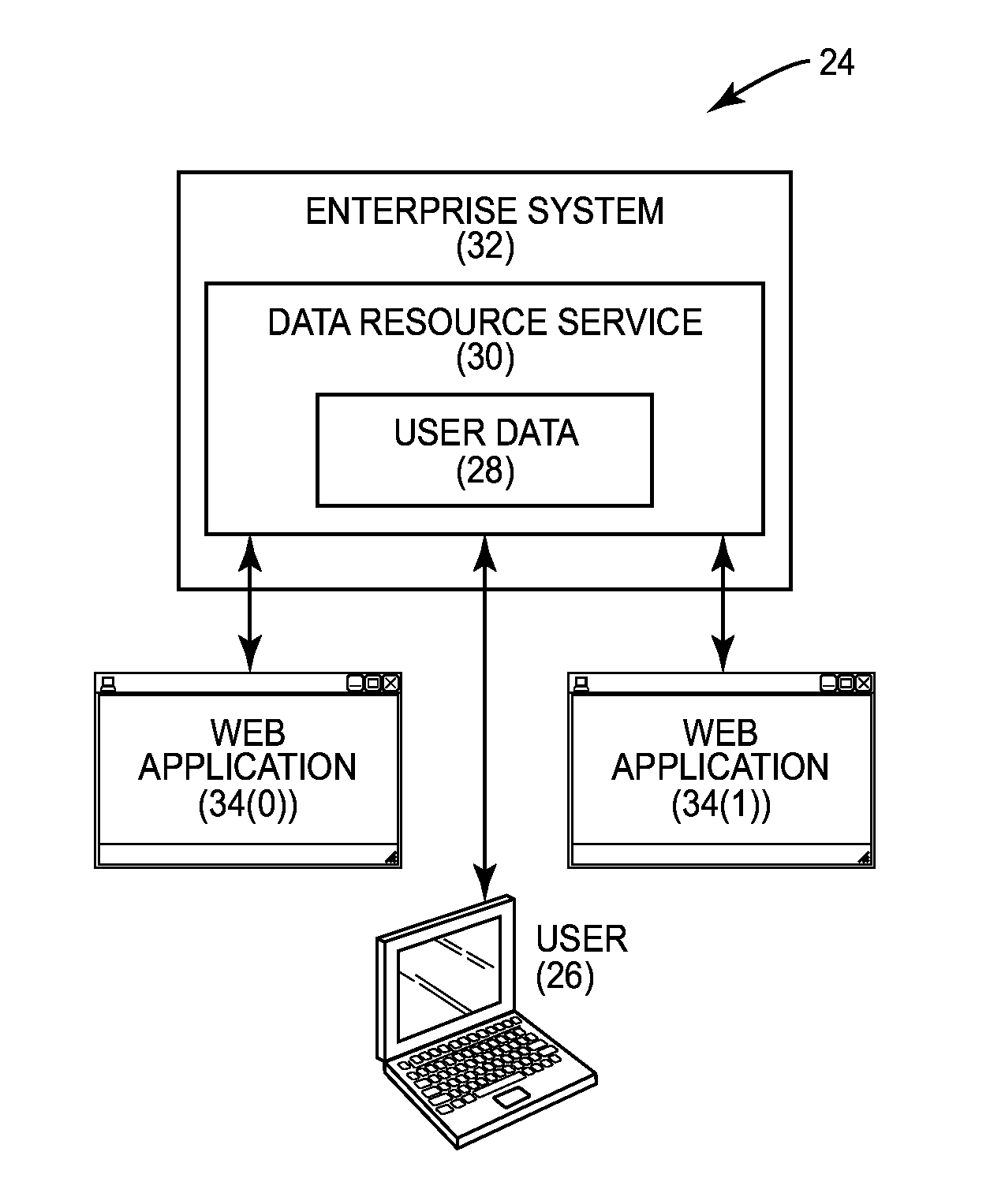

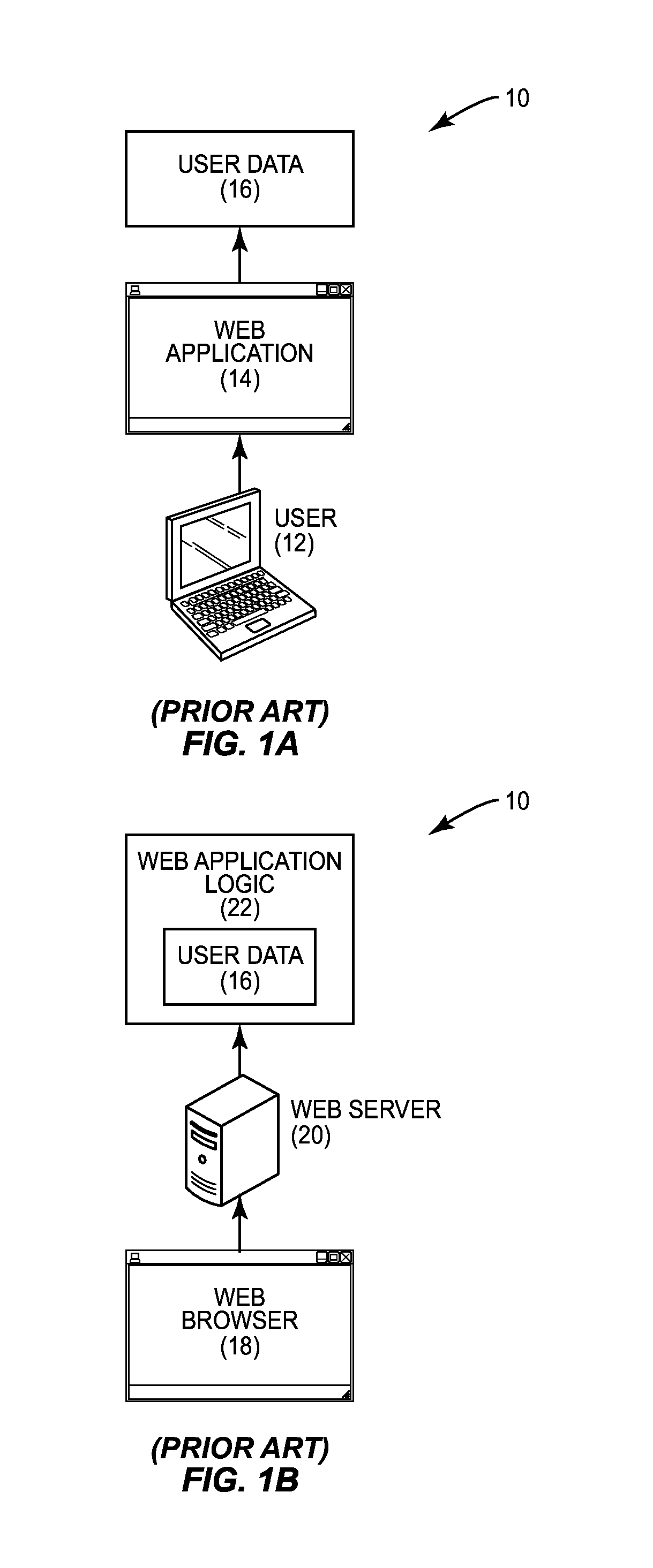

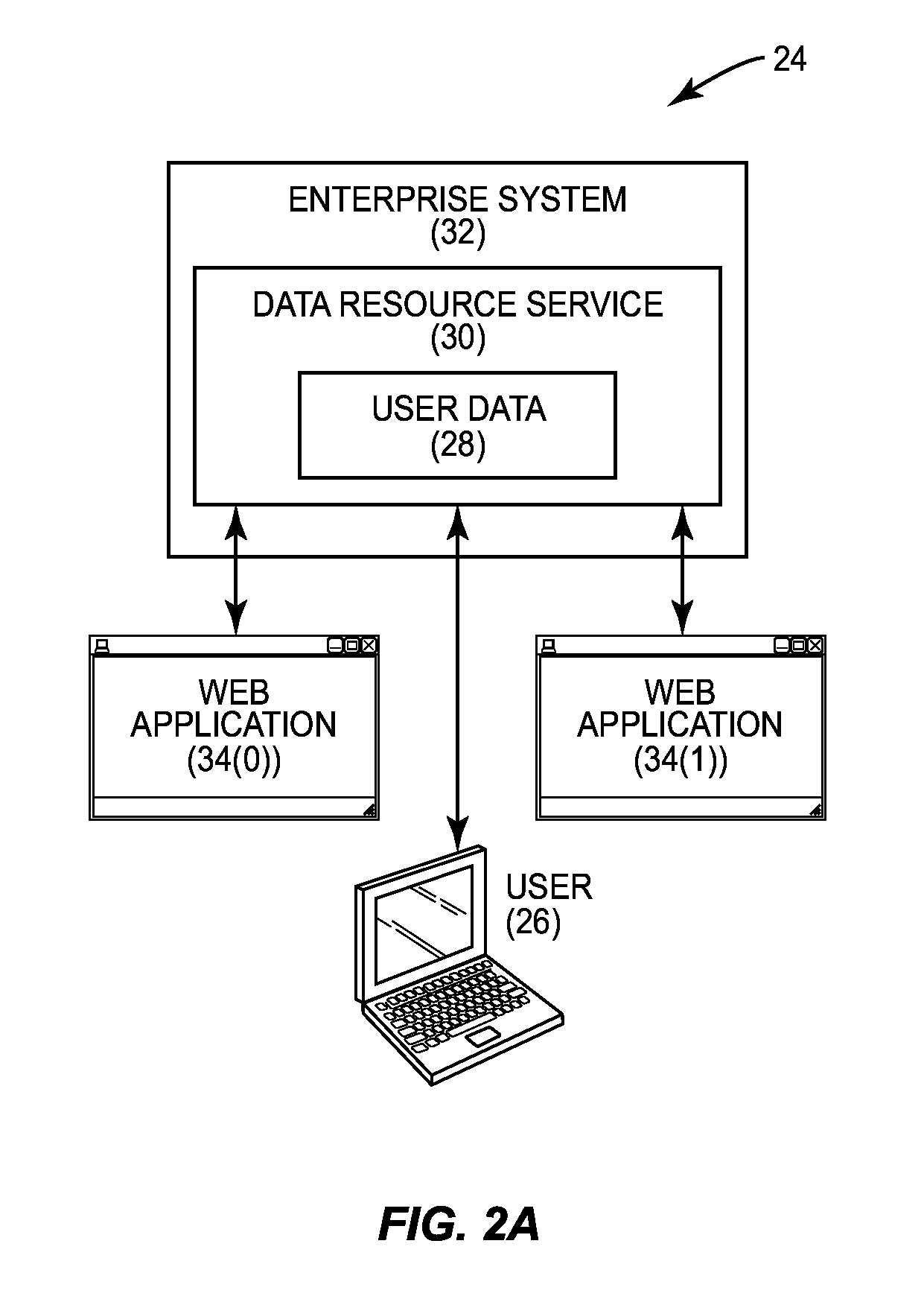

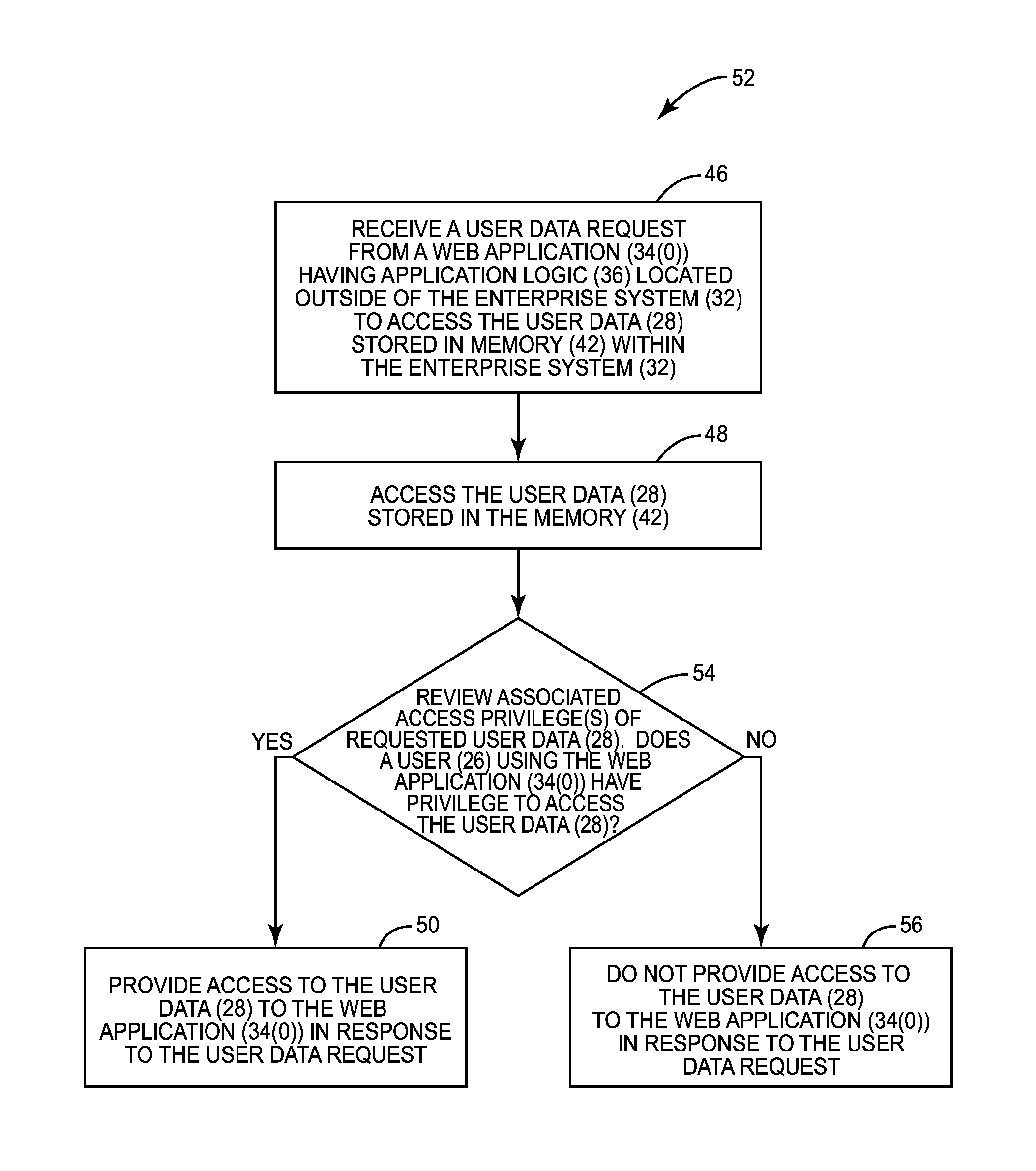

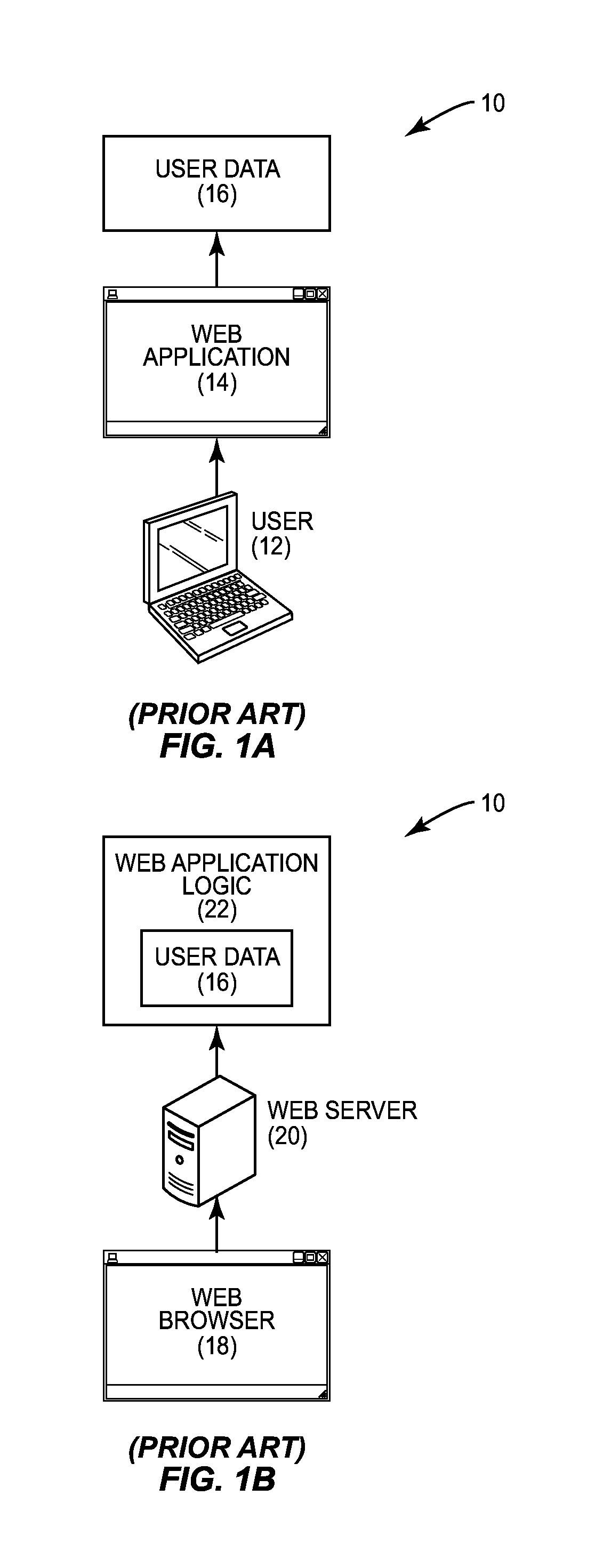

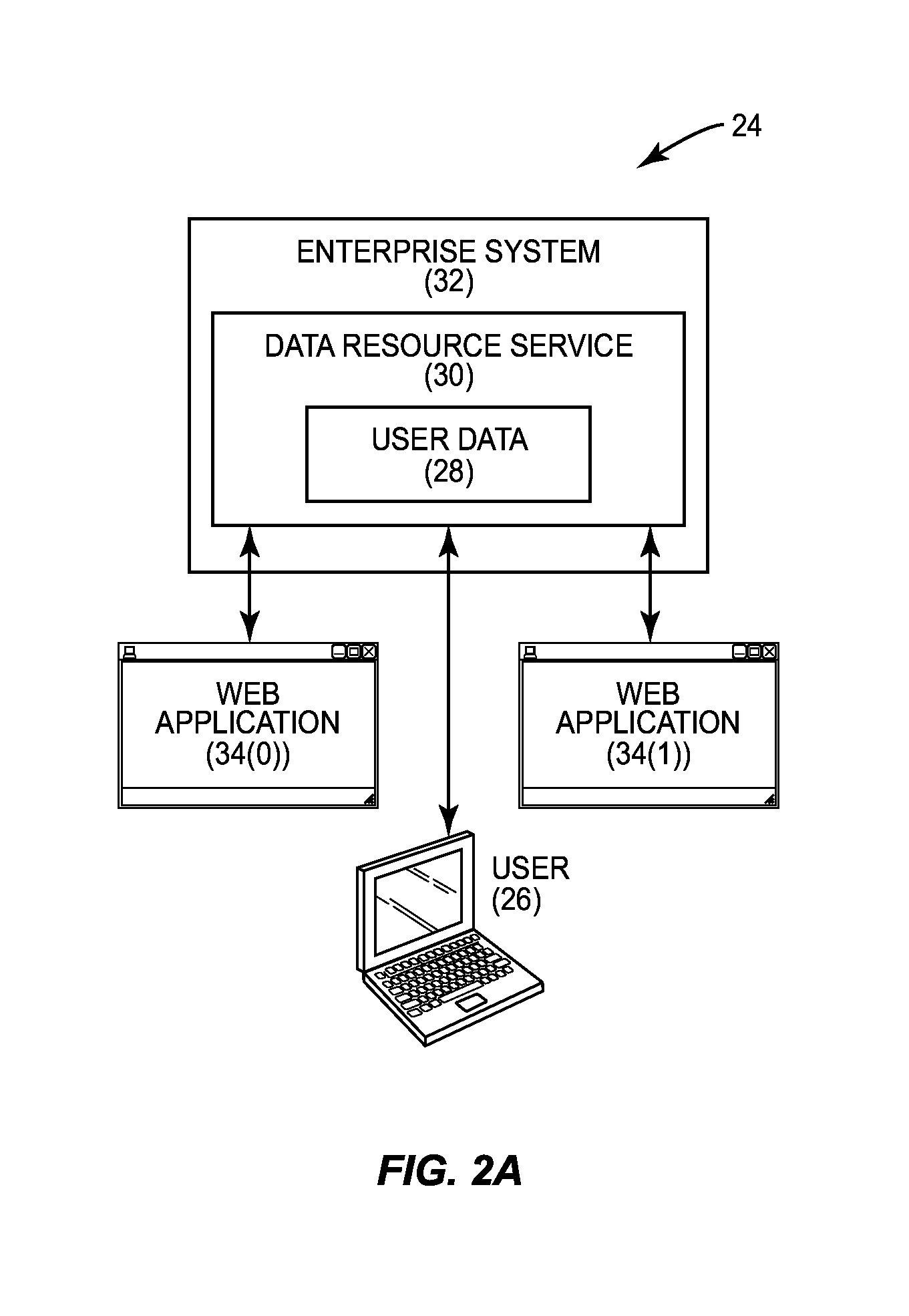

Providing data resource services within enterprise systems for resource level sharing among multiple applications, and related methods, systems, and computer-readable media

ActiveUS20150058418A1Save efficiencyShorten the timeComputer security arrangementsTransmissionWeb applicationEnterprise system

Providing data resource services within enterprise systems for resource level sharing among multiple applications, and related methods, systems, and computer-readable media are disclosed. In one embodiment, a method for providing a data resource service within an enterprise system is provided. The method includes receiving a user data request from a web application having application logic located outside of an enterprise system to access user data stored in memory within the enterprise system. The method further includes accessing the user data stored in the memory within the enterprise system in response to the user data request from the web application. The method also includes providing access to the user data stored in the memory within the enterprise system to the web application in response to the user data request.

Owner:AVAYA INC

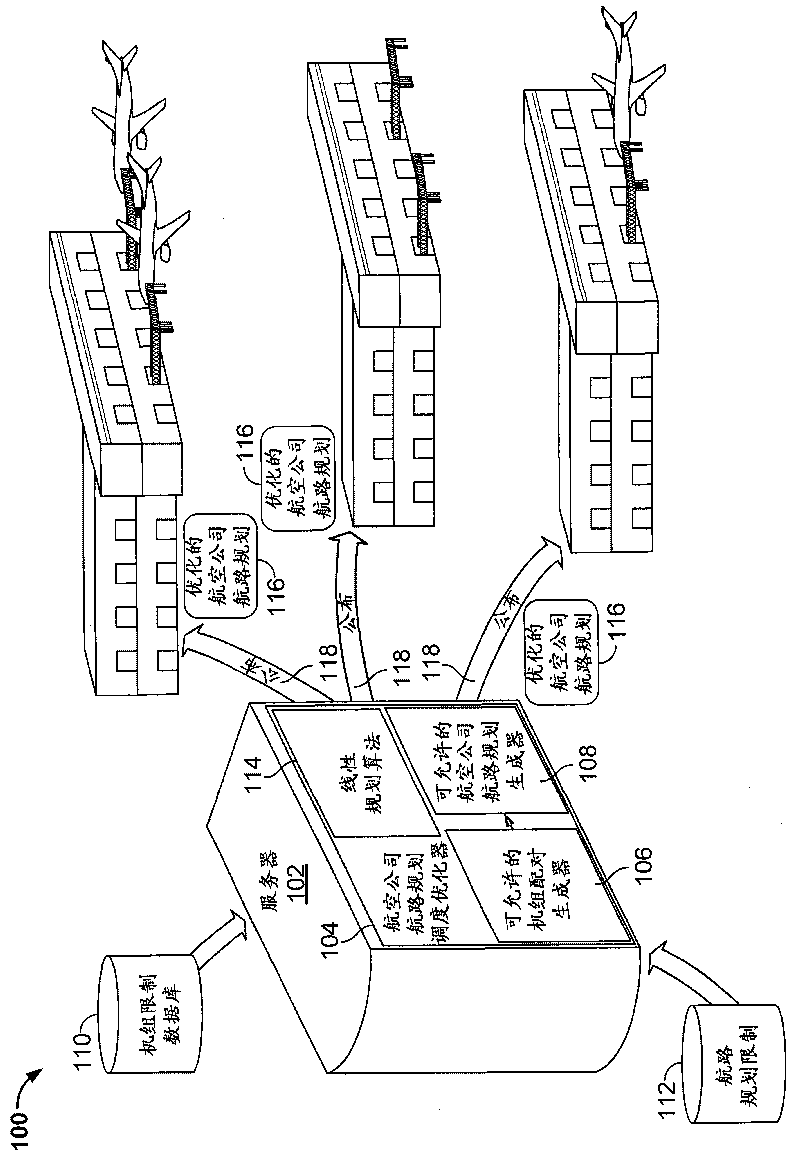

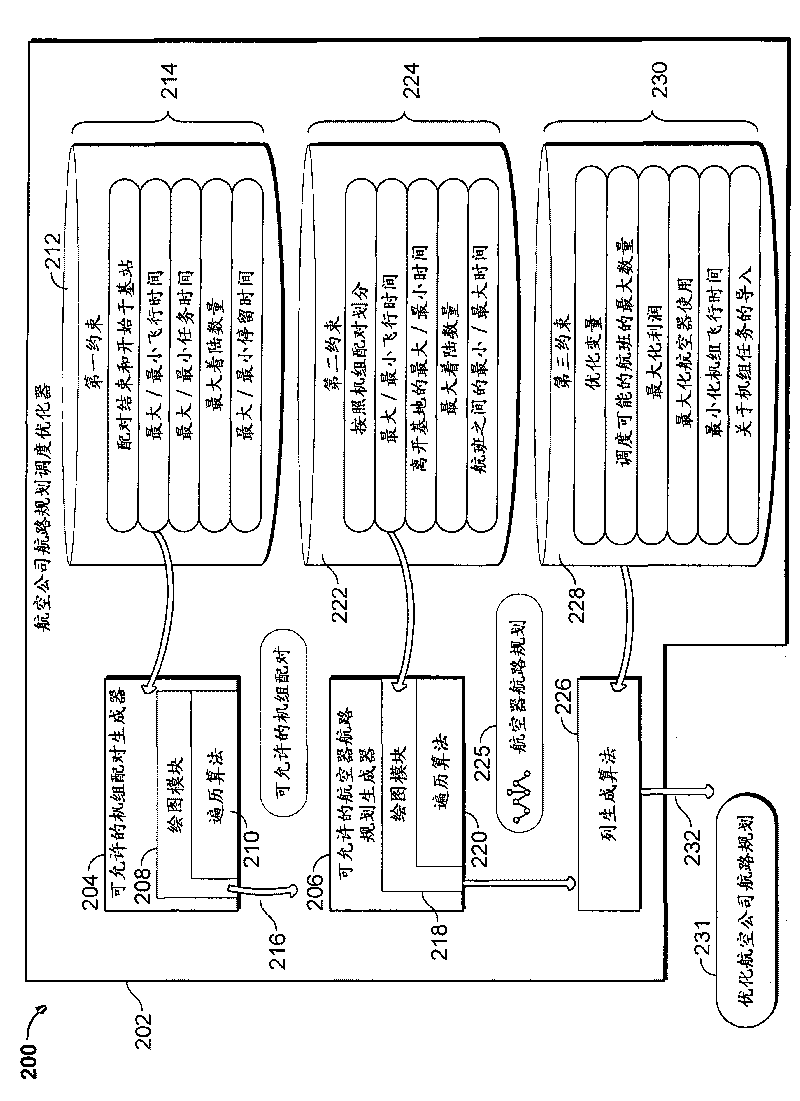

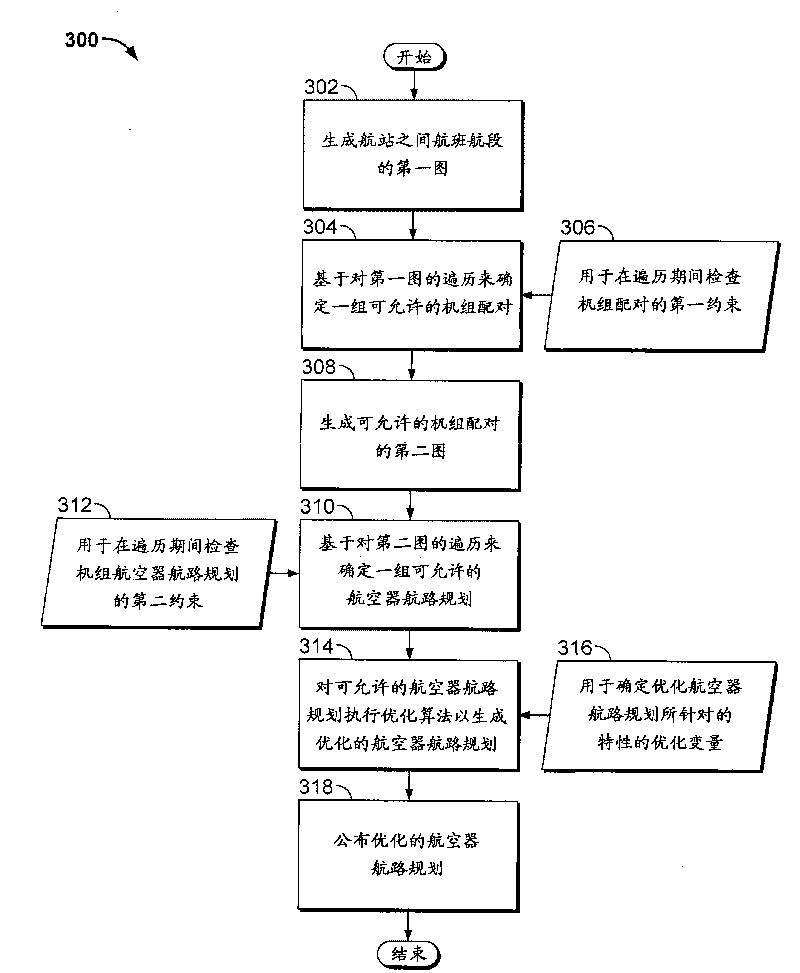

Flight schedule constraints for optional flights

InactiveCN101714237AEasy to createGuaranteed feasibilityReservationsAircraft traffic controlModel selectionSubject matter

The present invention relates to flight schedule constraints for optional flights. The subject matter of this specification can be embodied in, among other things, a method that includes receiving a number N m of optional flights available to fly a flight route. The method also includes receiving a minimum number I m of the optional flights to fly the flight route, receiving a maximum number u m of the optional flights to fly the flight route, and generating one or more constraints for an optimization model that are configured to cause the optimization model to favor the selection of at least I m flights and to favor the selection of at most u m flights from the N m optional flights to fly the flight route. The method includes selecting, using the optimization model, an optimized subset of the N m optional flights, where the selection is based on the one or more constraints.

Owner:埃森哲国际责任有限公司

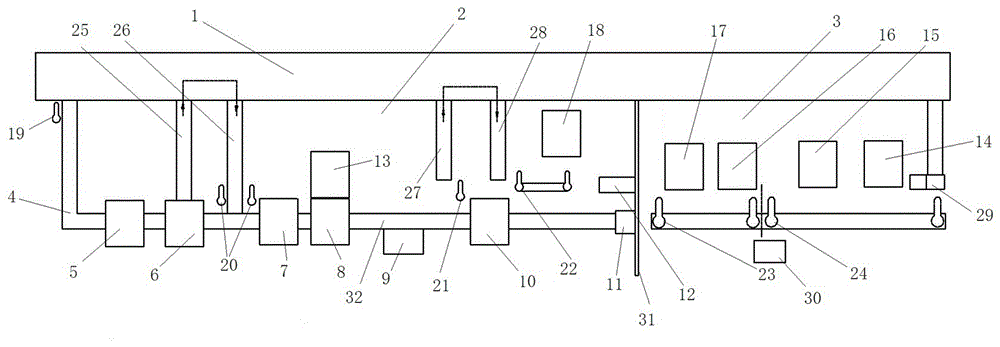

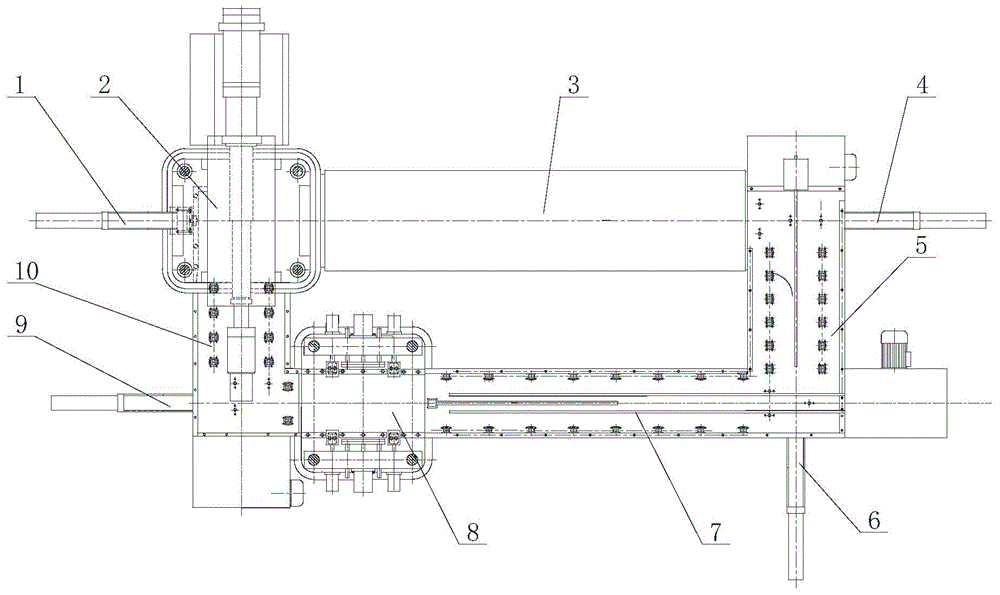

Production method of combiner box and production line of combiner box implementing method

ActiveCN106271671ARealize automated productionEliminate labor-intensive problemsOther manufacturing equipments/toolsMetal working apparatusProduction linePunching

The invention relates to a production method of a combiner box and a production line of the combiner box implementing the method. The production method of the combiner box comprises the following steps of enabling punching and cutting equipment to punch and cut a metal sheet which is conveyed from a material warehouse; enabling a bending machine to bend the four edges of the punched and cut metal sheet; enabling sheet joint welding equipment to weld and connect the sheet joint of the bent workpiece; punching screws into the workpiece after the welding of the sheet joint; enabling bulk welding equipment to position the workpiece after screw punching, and welding a bulk part on the positioned workpiece; enabling grinding equipment to grind the welding seam of the to-be-ground workpiece after the welding of the bulk part; enabling a stacking machine to stack the ground workpiece, and downloading. The production method has the advantages that the automation production of a box body and a box cover of the combiner box is realized, and the problems of low efficiency and high labor intensity of workers due to artificial or forklift hauling between different workshops and different equipment in the prior art are solved.

Owner:HENAN SENYUAN ELECTRIC CO LTD

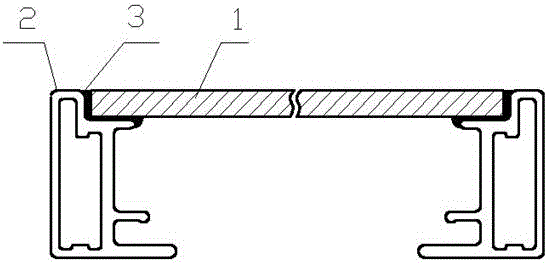

Novel non-metallic photovoltaic module and assembling method thereof

InactiveCN106026888ALow costExtended service lifePhotovoltaicsPhotovoltaic energy generationMechanical engineeringMaterials science

The invention provides a novel non-metallic photovoltaic module and an assembling process thereof. The novel non-metallic photovoltaic module comprises a photovoltaic module and a solar module insulated frame for fixing the photovoltaic module, wherein a composite material is adopted to be subjected to pultrusion to form the solar module insulated frame; and the photovoltaic module and the solar module insulated frame are bonded into an integrated structure by adopting an adhesive layer at the joint place. The structure is delicate; the process is concise; the photovoltaic module and the insulated frame formed by adopted the composite material through pultrusion are combined to form the photovoltaic module, no stop bar exists on the front face of the module frame, no accumulated dust exists in the bottom of the front face of the module, no hot spot effects are generated, and the service life of the module is prolonged, and the power generation amount of the module is ensured; and, as the insulated frame of the module adopts the composite material, no PID phenomenon is generated, the module efficiency and the service life are not reduced in the case of long-time power generation work of the module, and the cost of the whole system is reduced.

Owner:JIANGYIN UTT SOLAR EQUIP

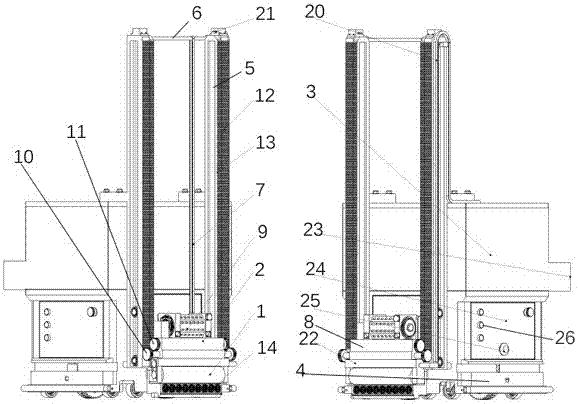

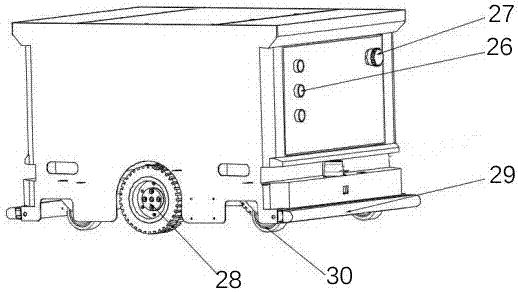

Intelligentized building painting equipment

ActiveCN107327131ARealize brushing and polishingRealize sanding and brushingBuilding constructionsArchitectural engineeringMaterial resources

The invention provides intelligentized building painting equipment. The intelligentized building painting equipment comprises a rotatable painting device, a polishing device, a lifting device, a material conveying device and a base frame device. According to the intelligentized environment-friendly building painting equipment, manpower and material resources are saved, and the accident rate is reduced.

Owner:隽秀新材料科技(苏州)有限公司

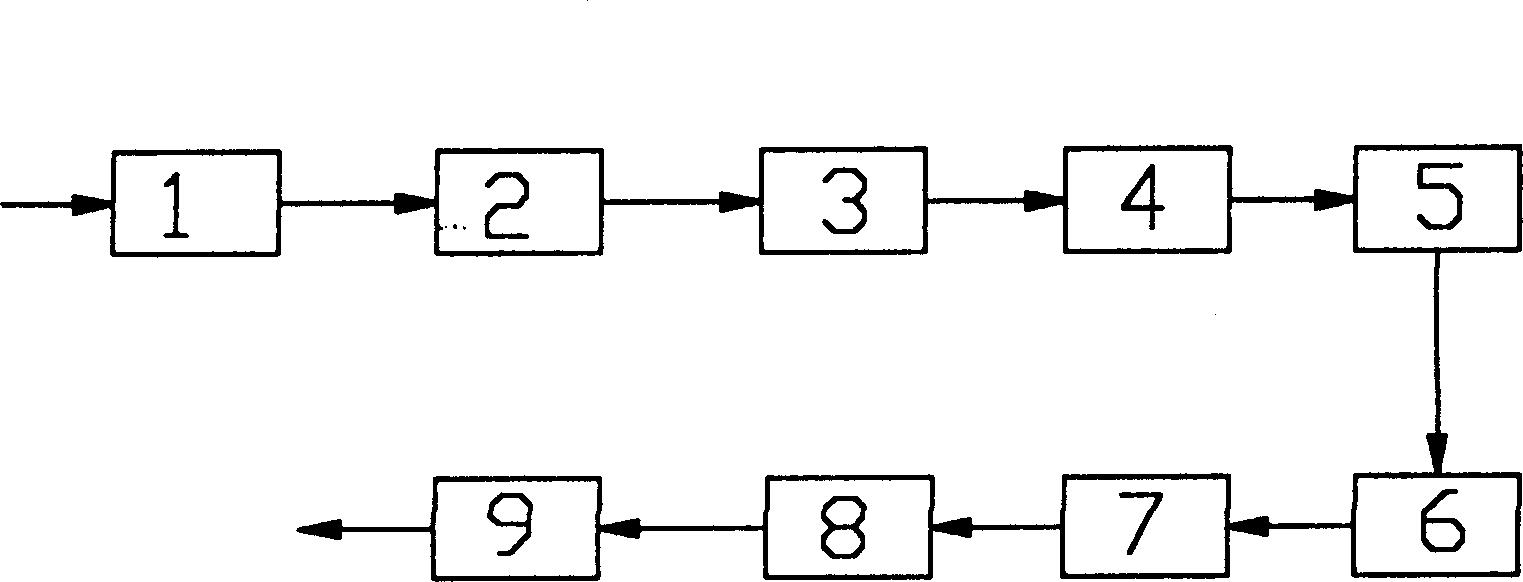

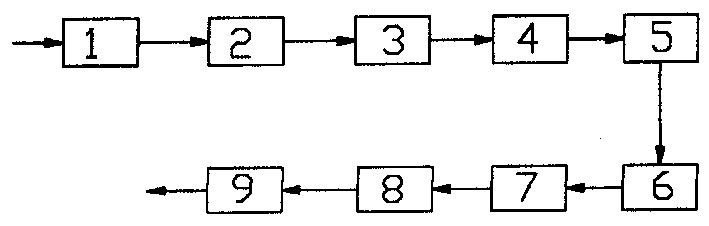

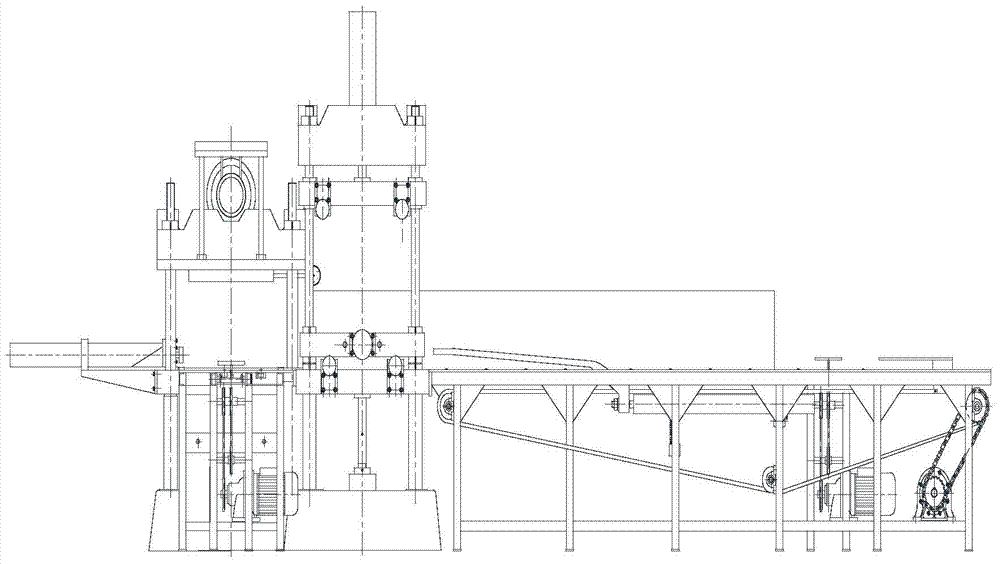

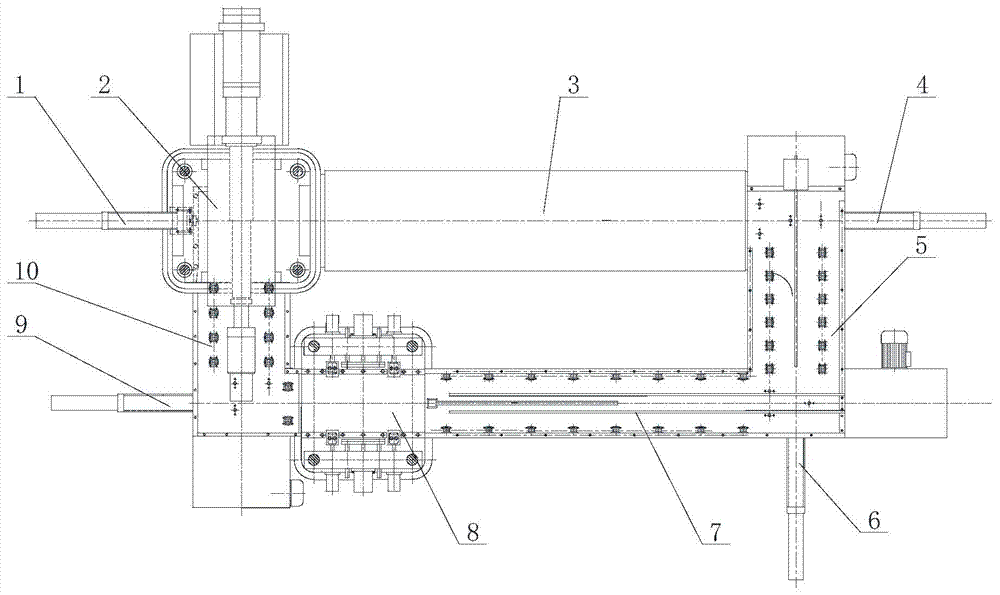

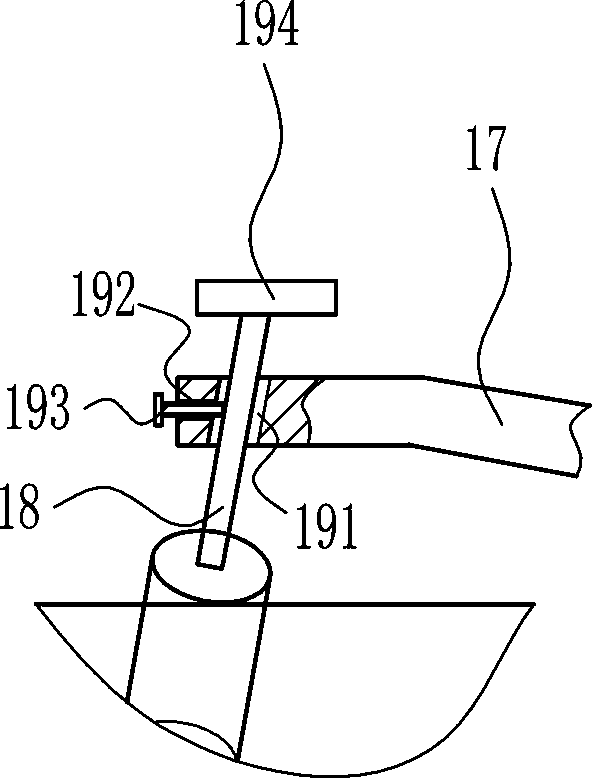

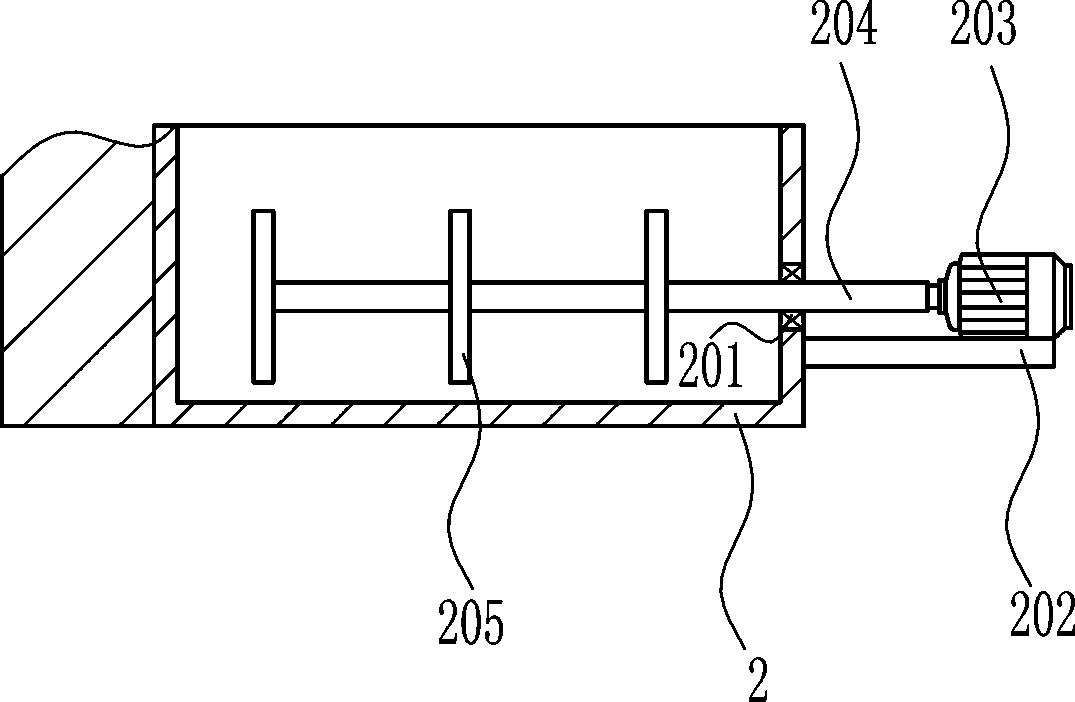

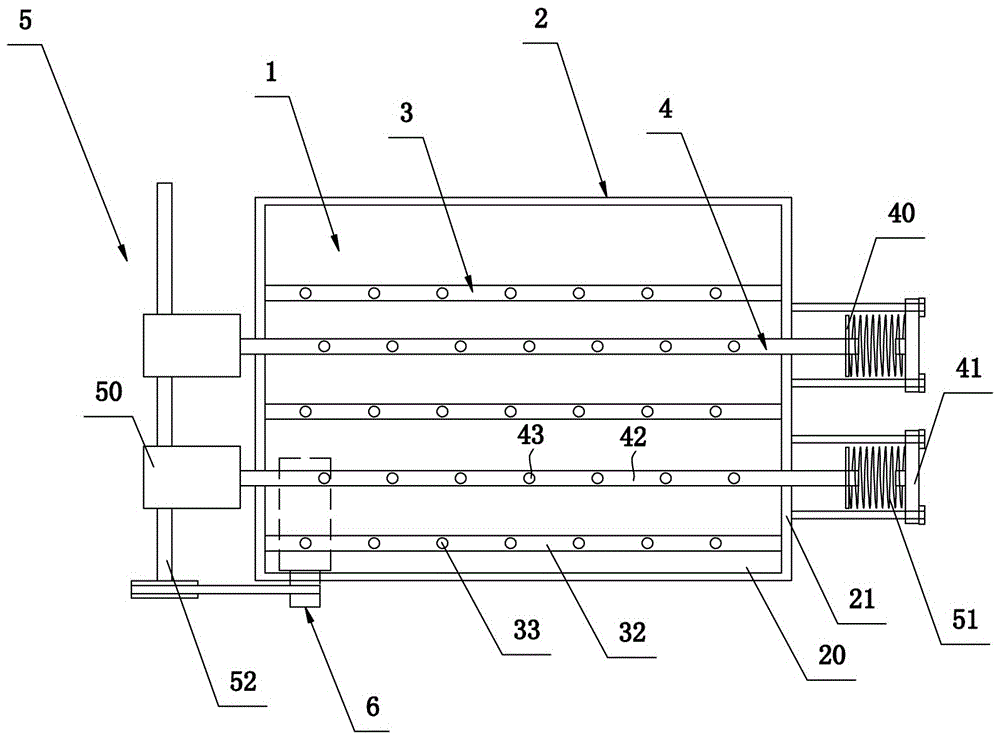

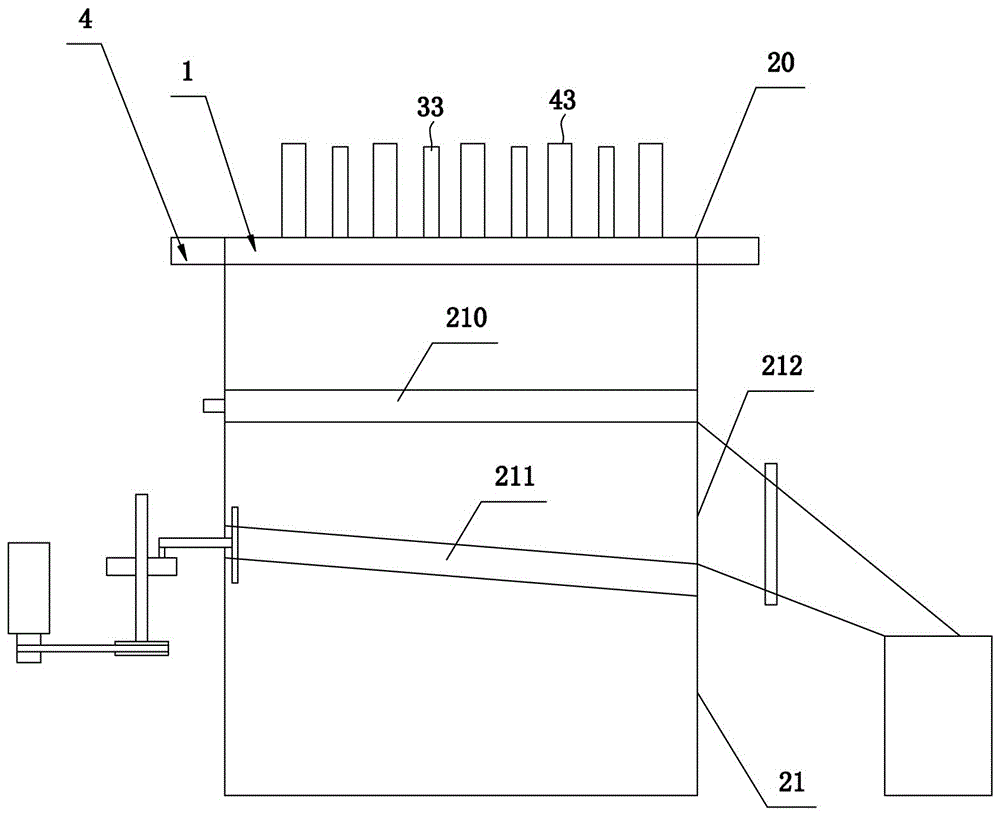

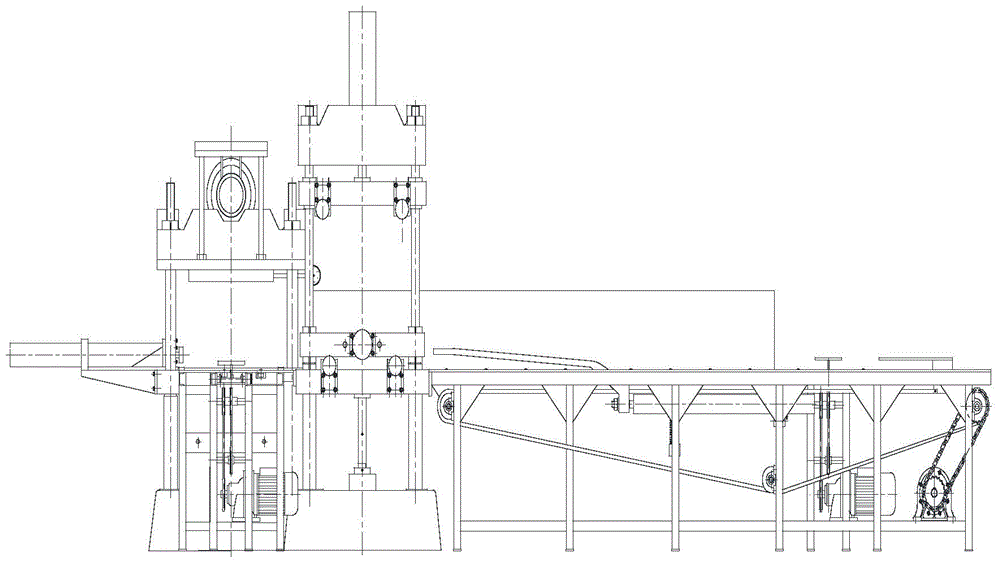

Rubber product production process flow and automatic streamline

The invention relates to a rubber product production process flow and an automatic streamline. The process flow comprises the processes of rubber vulcanization, die opening and locking, taking and peeling of a piece from an injection molding machine or an injection pressing molding machine, and the processes are completed by a vulcanization drying tunnel and a die opening and locking machine respectively; and the automatic streamline comprises the injection molding machine, the vulcanization drying tunnel, the die opening and locking machine, a conveyer belt and an oil cylinder, the injection molding machine is connected with the vulcanization drying tunnel, the vulcanization drying tunnel, the die opening and locking machine and the injection molding machine are sequentially connected through the conveyer belt, the oil cylinder is connected with the conveyer belt, and a locked product die is arranged in the injection molding machine. Compared with the prior art, the process flow and the automatic streamline have the advantages of high productivity, substantial energy saving, low cost, less labor and the like.

Owner:上海昀泰机电科技有限公司

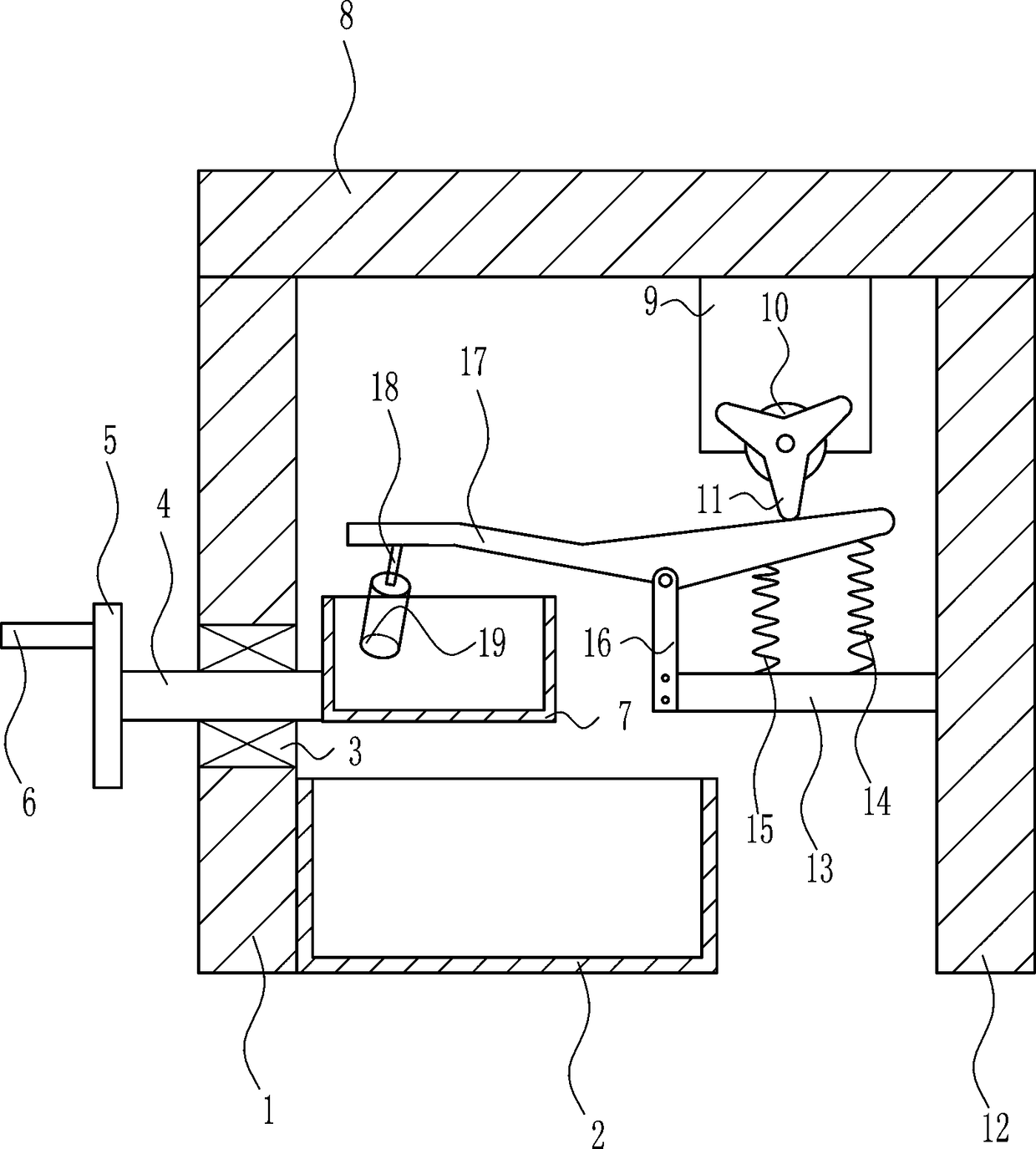

Veterinary herbal mashing device

ActiveCN108212287AAchieving stirringEasy to take outGrain treatmentsHerb medicineVeterinary medicine

The invention relates to a mashing device, in particular to a veterinary herbal mashing device. The invention aims at providing the veterinary herbal mashing device which replaces manual work with a machine. The invention provides the veterinary herbal mashing device; the device comprises a first support, a medicine storage box, a first bearing, a first rotating shaft, a first connecting rod, andthe like, the medicine storage box is fixedly installed at the left side under the first support; the first bearing is fixedly installed on the first support; the first bearing is internally connectedwith the first rotating shaft in an interference fitting way; the first connecting rod is fixedly installed at the left end of the first bearing; a handle is fixedly installed on the first connectingrod. The veterinary herbal mashing device realizes a veterinary herbal mashing function, is rapid in herbal mashing speed and high in efficiency, effectively reduces the raw material waste caused bymanually mashing, and greatly lowers the labor cost; the veterinary herbal mashing device is convenient and safe to use, simple to operate, low in manufacturing cost, and the like.

Owner:徐先平

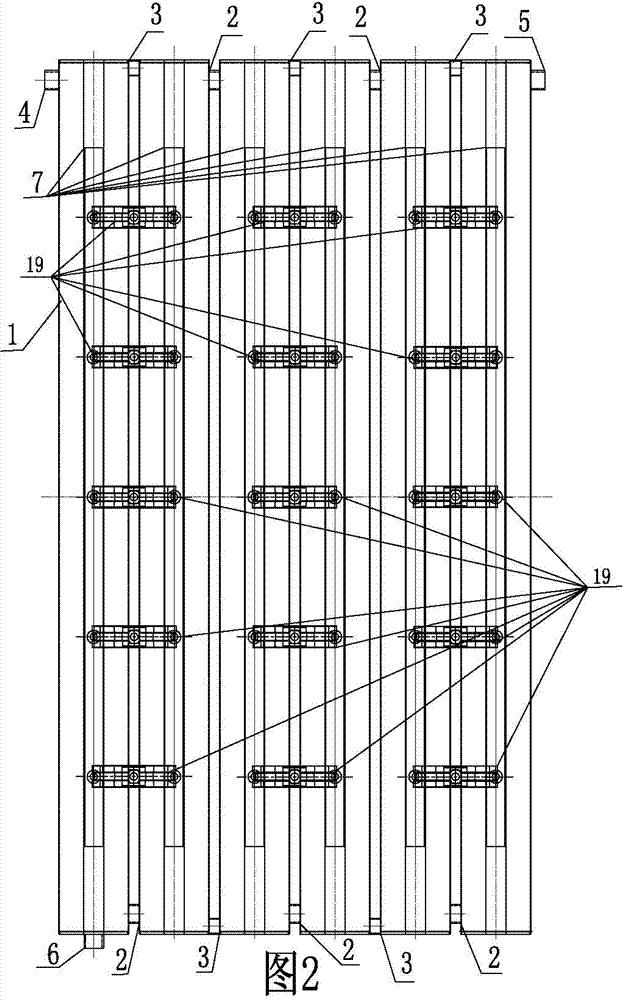

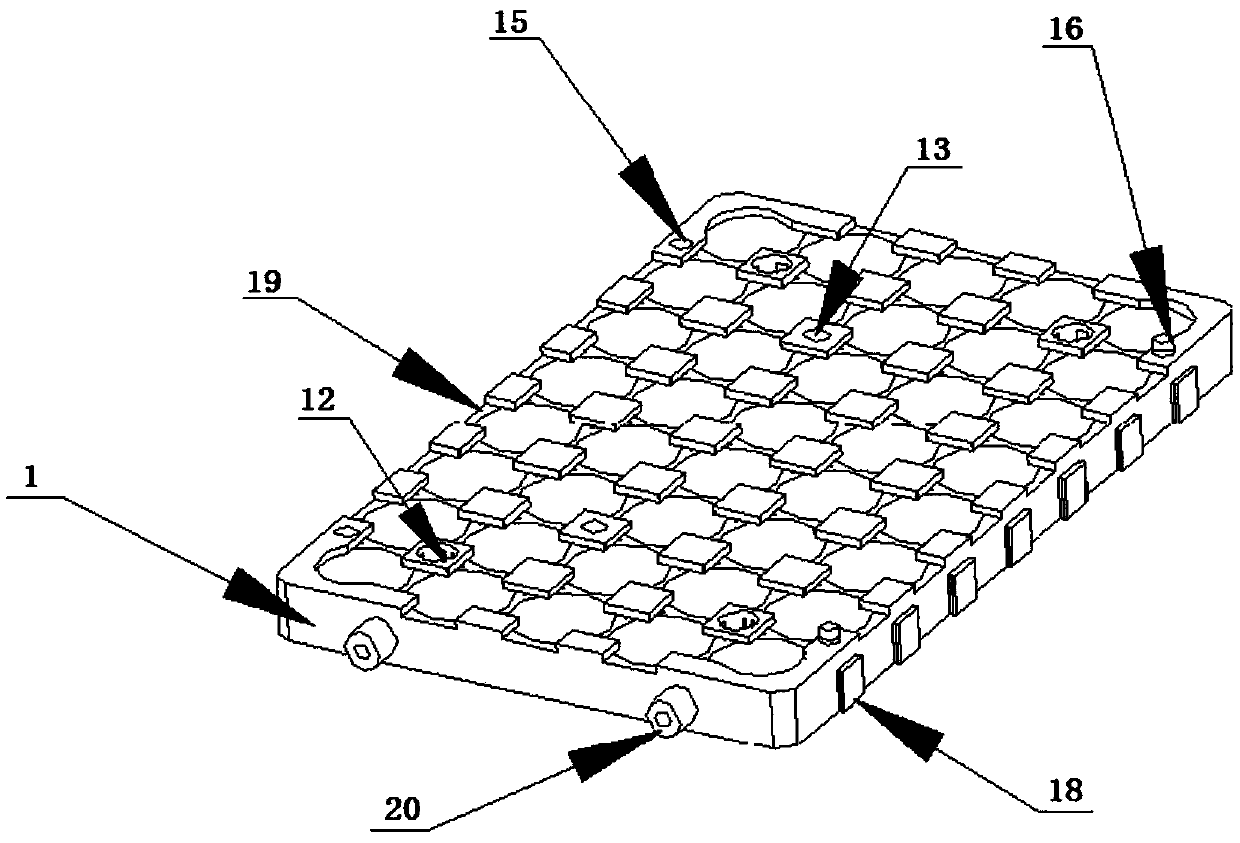

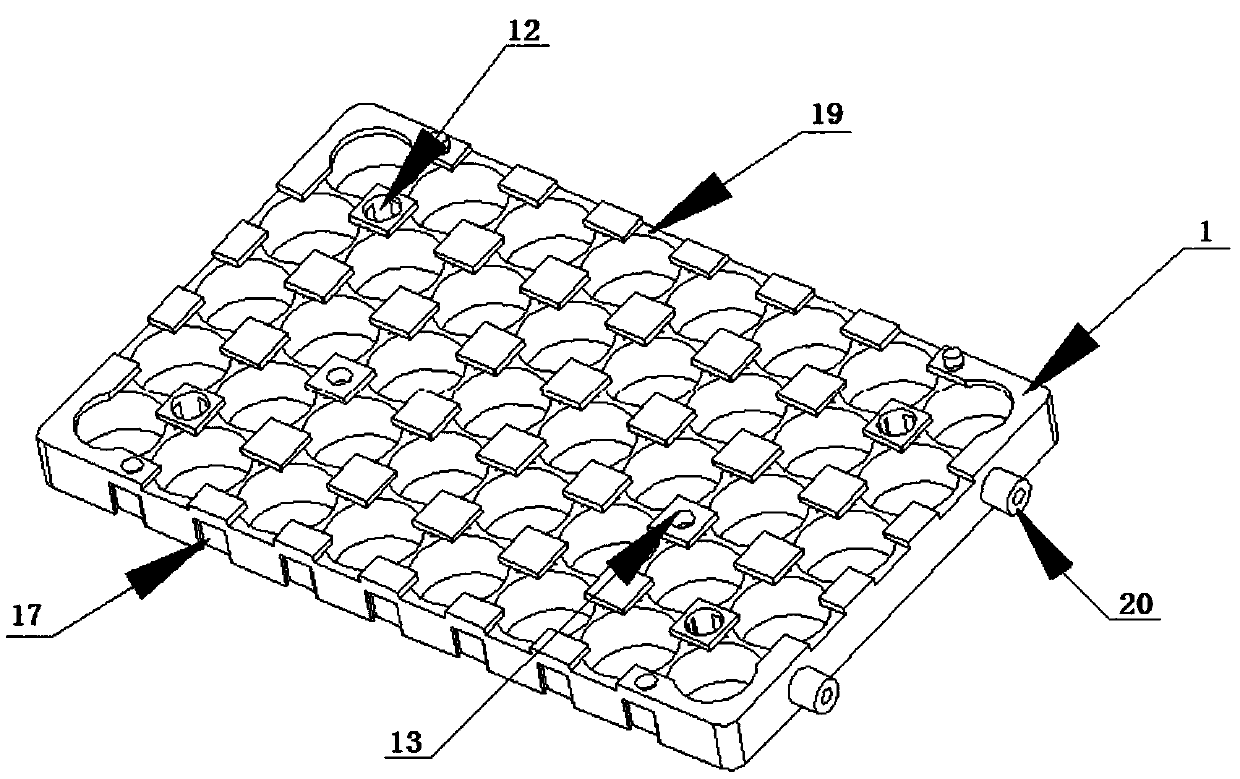

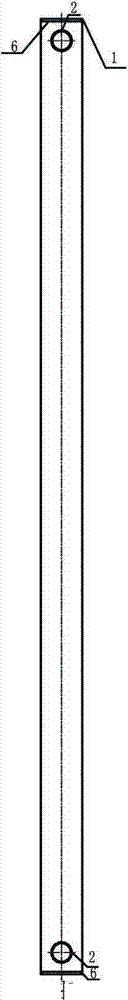

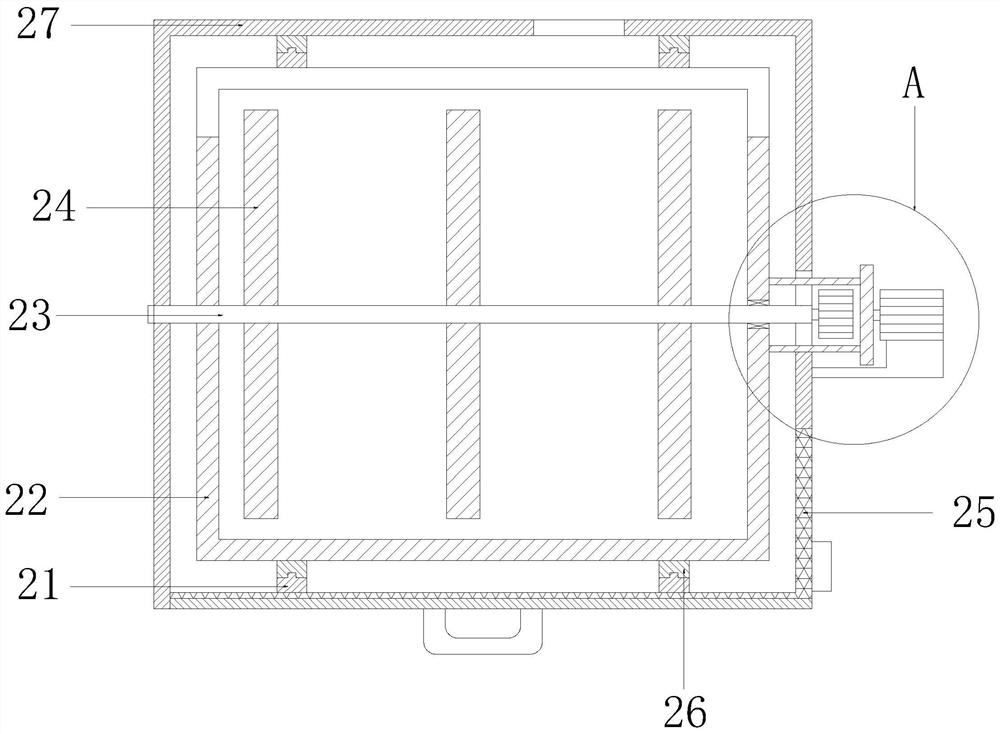

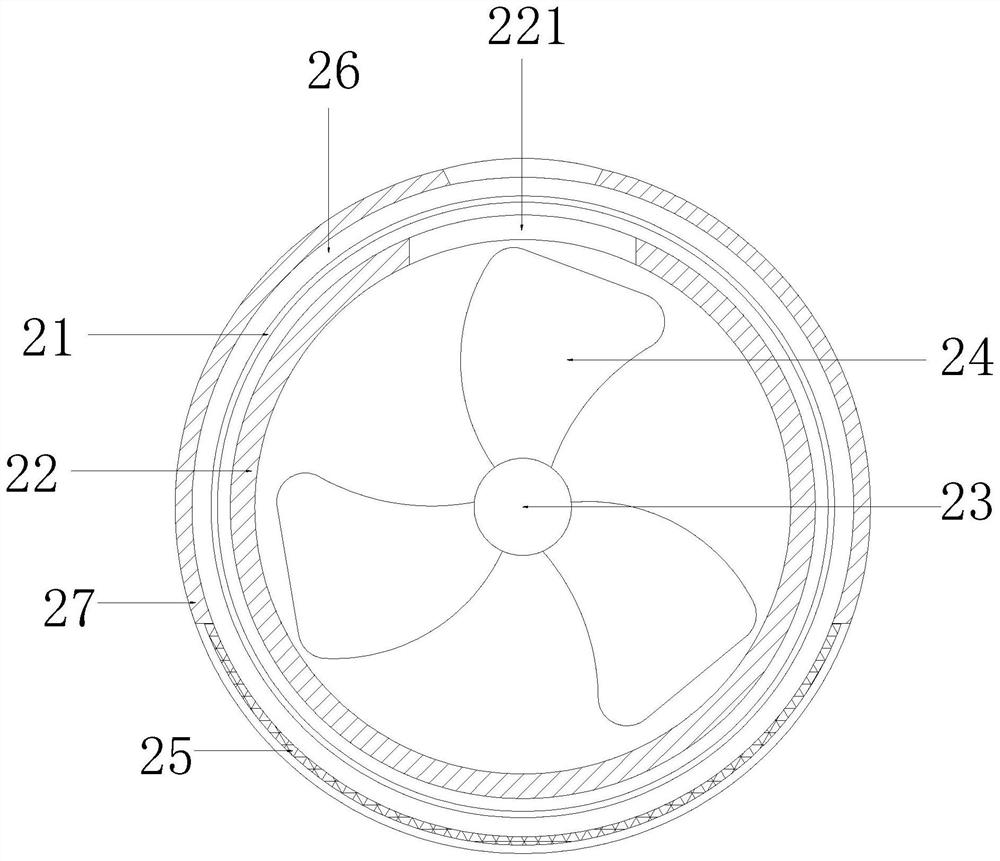

Stretching arc-shaped pressure plate used for radiator

ActiveCN104329724ALow costSave efficiencyStationary conduit assembliesSpace heating and ventilation detailsEngineeringMechanics

The invention discloses a stretching arc-shaped pressure plate used for a radiator. The stretching arc-shaped pressure plate is characterized in that the arc shape of the stretching arc-shaped pressure plate is similar to the shape of a butterfly joint of a stretching heat conduction tube, the stretching heat conduction tube is controlled to have no deformation, and the stretching arc-shaped pressure plate comprises the stretching heat conduction tube, a communicating tube, a connecting piece, a water inlet, a water outlet, a deflation valve, an M-shaped depression bar and a plurality of stretching arc-shaped pressure plate bodies, and is welded to be rectangular or square. The two sides of the strip direction of a rectangular plate are downwards turned by 90 degrees, the middle part of the strip direction of the rectangular plate is subjected to downward stretch flanging to form an inner boss shape, the two straight ends of the middle section of each stretching arc-shaped pressure plate body are in an arc boss shape and are downwards stretched to form a slope at an angle of 30 degrees, the two ends are straight, the two ends in the direction of the rectangular plate are downwards turned by 90 degrees, the middle part of each stretching arc-shaped pressure plate is subjected to downward stretch flanging, two sides of a boss are semicircular, the shape of the rectangular plate after stretching is similar to the shape of the butterfly joint of the stretching heat conduction tube, and the stretching arc-shaped pressure plate bodies are crossly and uniformly distributed in a plurality of adjacent gap spaces which are fixedly connected and are communicated with the stretching heat conduction tube in series, so that a cooling fin is guaranteed to have internal pressure without expansion, the material is thin, the cost is reduced and the purposes of attractive appearance and practicability are achieved.

Owner:ZAOZHUANG FUYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING MACHINERY MFG CO LTD

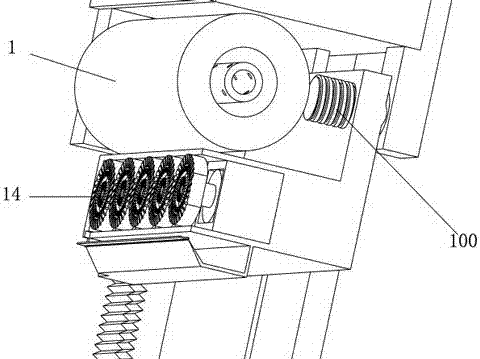

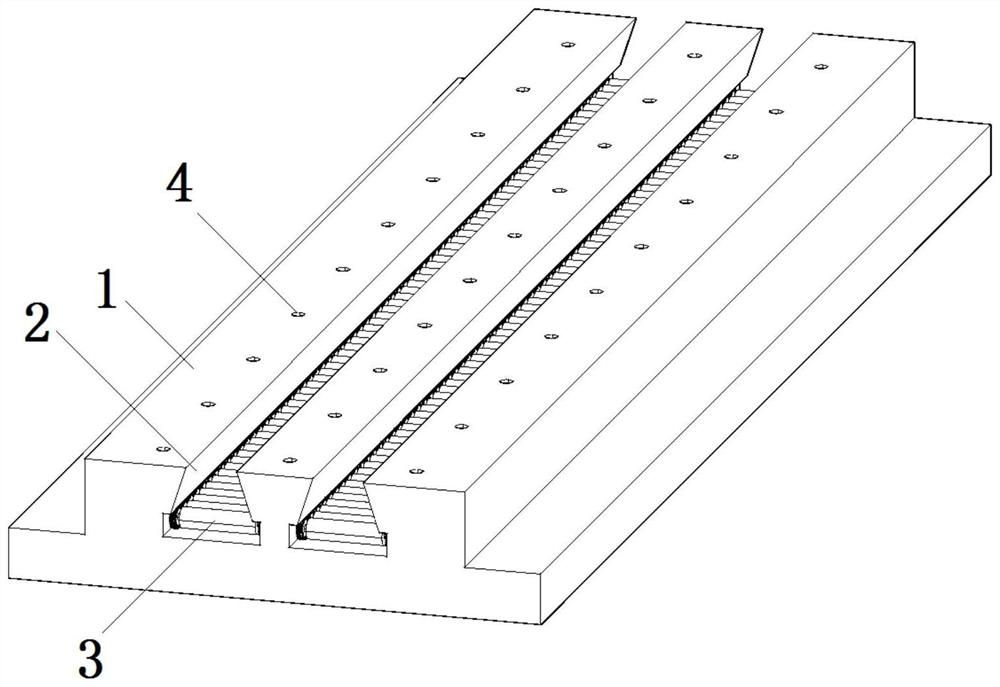

Linear motor permanent magnetic brake

ActiveCN105978291AReduce volumeReduce weightPermanent-magnet clutches/brakesMechanical energy handlingAutomatic controlLinear motor

The invention discloses a linear motor permanent magnetic brake. The linear motor permanent magnetic brake comprises a static iron core assembly and a moving plate assembly, wherein the static iron core assembly comprises multiple coils embedded in the static iron core; the upper portion of each coil is provided with a magnet yoke and magnet steel; the moving plate assembly comprises a fixed plate and a movable plate which are spaced by a spring sheet; and the fixed plate is placed above the magnet yokes and the magnetic steel. The linear motor permanent magnetic brake has the following advantages: 1, linear internal contracting brake is realized, the volume is small, and the weight is light; 2, the processing is simple, and the installation and maintenance are simple; 3, the connection is reliable, the brake is flexible, automatic control and long-distance operation of a work mechanism can be realized, and the brake time is extremely short; 4, the control power is small, and the service life is long; 5, the performance is stable, and the safety and reliability are high; 6, the structure is simple and compact, the operation is simple, and accurate combination can be guaranteed in quite short time; 7, diversified combination and application can be realized through adjusting features of the coils and the magnetic steel; and 8, the linear electromagnetic brake does not need motion at all, apart from an electromagnet, a brake using a permanent magnet does not need electric power, and thus the space and the efficiency can be reduced.

Owner:KEDE NUMERICAL CONTROL CO LTD

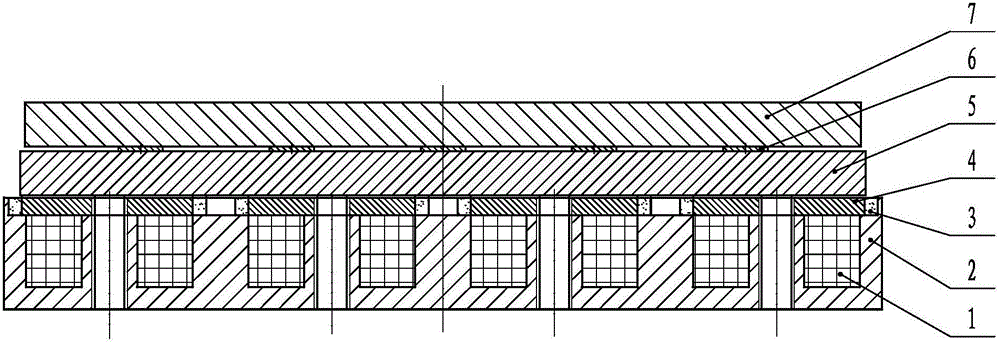

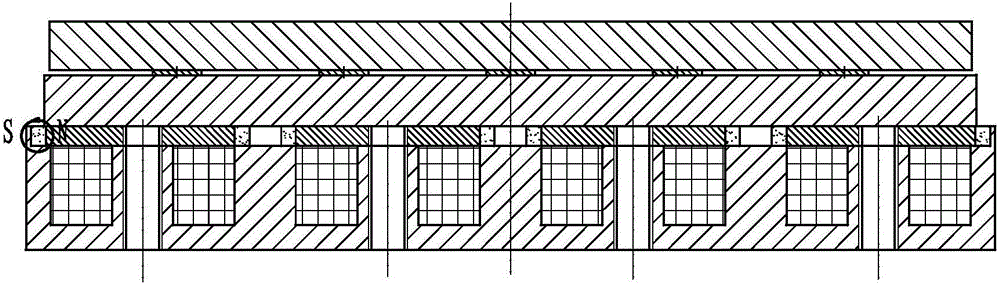

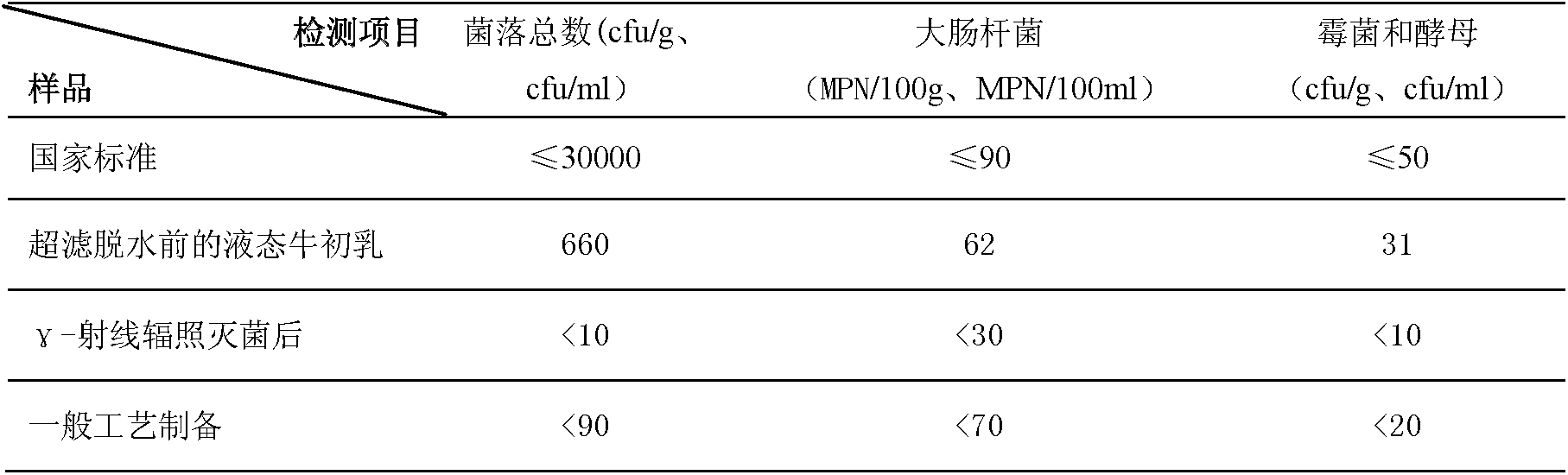

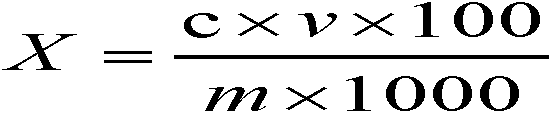

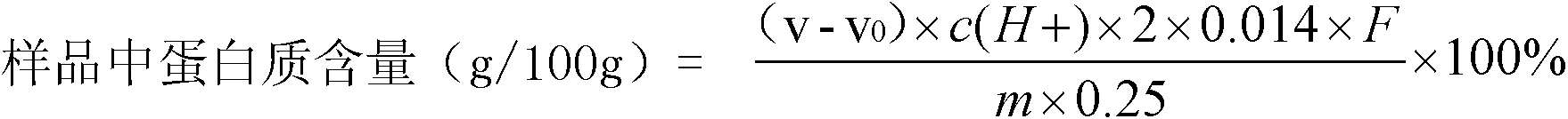

Organic bovine colostrum powder and preparation method thereof

InactiveCN103053687AActivity will not be reducedReduced activityMilk preparationMilk preservationUltrafiltrationClinical tests

The invention discloses organic bovine colostrum powder and a preparation method of the organic bovine colostrum powder. According to the preparation method, procedures of low-temperature freezing and drying and high-temperature powder ejection in the ordinary bovine colostrum powder production process are avoided; and in the bovine colostrum powder preparation procedures, ultrafiltration concentration dehydration and gamma-ray radiation sterilization are adopted. By utilizing the production process, both the purpose of dehydration concentration is achieved and the activation of immune globulin is not reduced; and meanwhile the gamma-ray radiation sterilization ensures complete nutrition components and ensures the thoroughness in sterilization. Clinical tests show that when compared with bovine colostrum powder prepared by using the conventional high-temperature powder ejection method, the bovine colostrum powder disclosed by the invention is high in IgG content and excellent in physicochemical indexes of protein, fat, moisture, acidity and various microbiological indicators.

Owner:山东银香大地乳业有限公司 +1

Providing data resource services within enterprise systems for resource level sharing among multiple applications, and related methods, systems, and computer-readable media

ActiveUS9531808B2Save efficiencyShorten the timeDigital data protectionTransmissionWeb applicationApplication software

Providing data resource services within enterprise systems for resource level sharing among multiple applications, and related methods, systems, and computer-readable media are disclosed. In one embodiment, a method for providing a data resource service within an enterprise system is provided. The method includes receiving a user data request from a web application having application logic located outside of an enterprise system to access user data stored in memory within the enterprise system. The method further includes accessing the user data stored in the memory within the enterprise system in response to the user data request from the web application. The method also includes providing access to the user data stored in the memory within the enterprise system to the web application in response to the user data request.

Owner:AVAYA INC

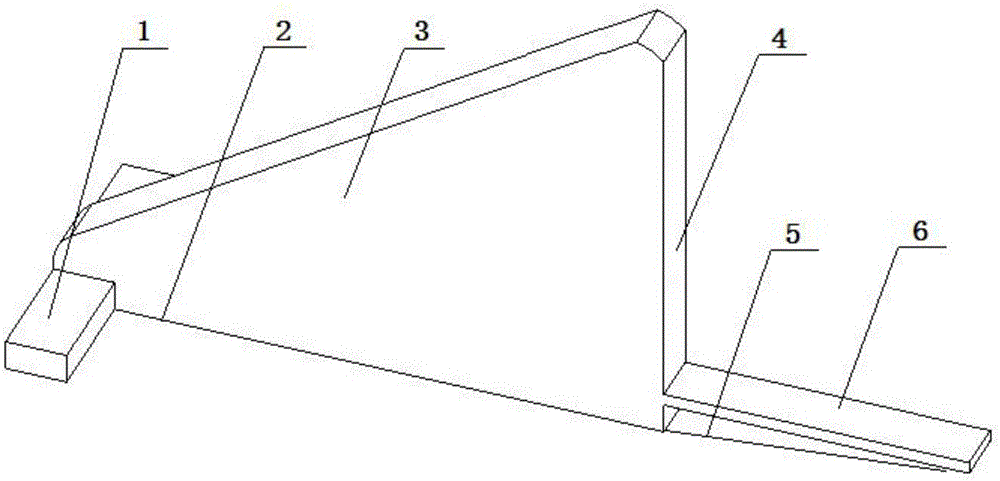

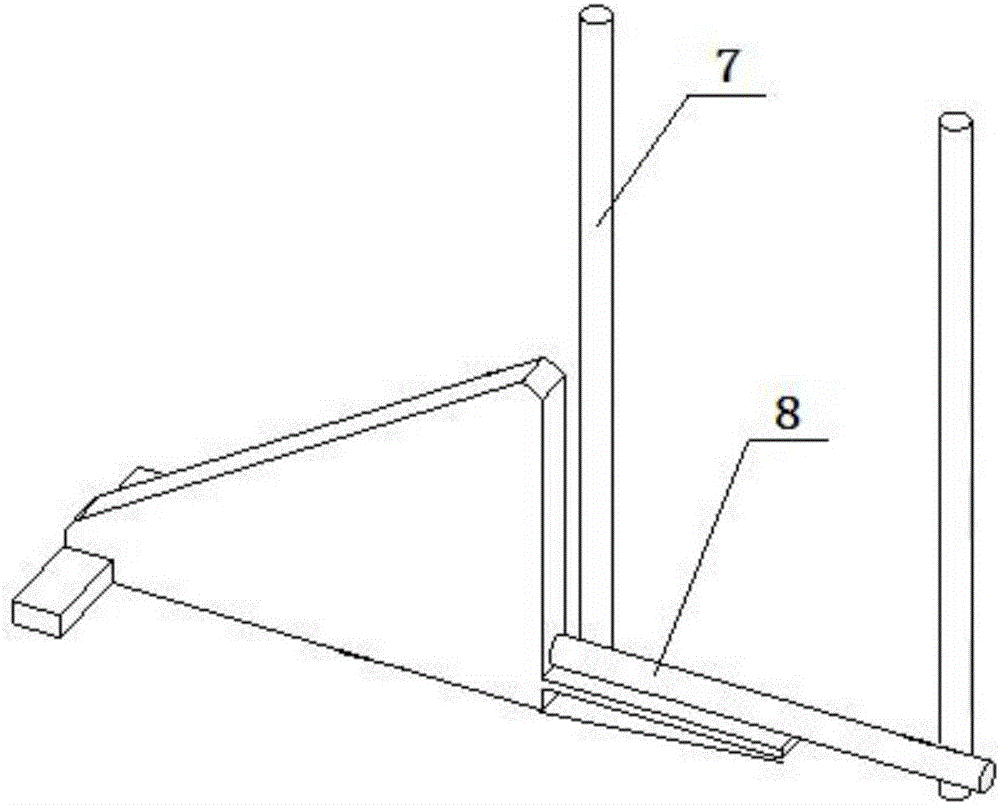

Poisoning reinforcement calibration welding tool and using method thereof

The invention relates to a positioning reinforcement calibration welding tool characterized by comprising a triangular positioning block, a measure gauge and a support pallet, and a measure gauge embedded at the corner between front edge bevel and level square edge of triangle poisoning block, and a support plate vertical to the back-end vertical square edge of triangle poisoning block. The invention also relates to a using method for positioning reinforcement calibration welding tool, which comprises the following steps: a. Place the positioning reinforcement calibration welding tool; b. Place the positioning reinforcement; c. welding. The structure of the invention is scientific and reasonable, and has the advantages of improving the construction efficiency, ensuring the construction quality, convenient operation and easy realization. It is a high-innovation poisoning reinforcement calibration welding tool and using method thereof.

Owner:ZHONGTIAN CONSTR GROUP

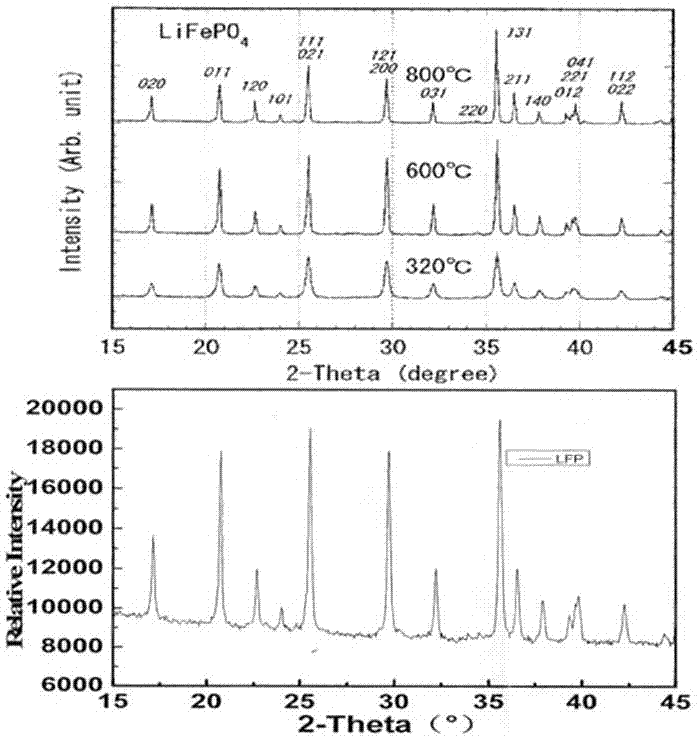

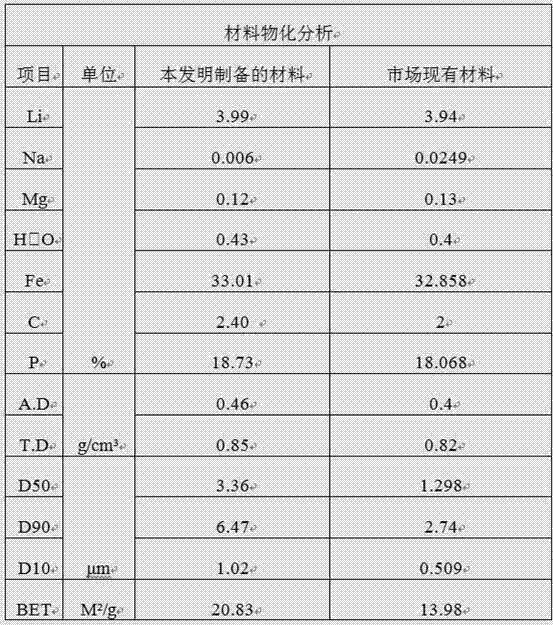

Preparation method of lithium iron phosphate cathode material

InactiveCN107154494ARaw materials are easy to getReasonable formulaCell electrodesMetallurgyDischarge rate

The invention discloses a preparation method of a lithium iron phosphate cathode material. The preparation method comprises the following steps of firstly, accurately weighing four raw materials in percentage by weight: 8 to 10% of lithium carbonate, 50 to 54% of ferrous oxalate, 28 to 30% of ammonium dihydrogen phosphate, and 6 to 8% of glucose, uniformly mixing, pressing into a powder cake, coating by pure carbon powder, placing into a high temperature furnace, sintering according to certain temperature gradient, and blowing out the furnace and cooling; after the carbon powder is recycled, processing into the used granularity, so as to obtain a finished product of the lithium iron phosphate cathode material with density of 2.4+ / -1g / cm<3>, specific surface area of 15.5+ / -2.5m<2> / g, and capacity more than or equal to 160 to 170MAh / g. The preparation method has the advantages that the obtaining of raw materials is easy, the formula is reasonable, the production process is simple, the production cost is low, and the rate of finished product is high; by detecting the lithium iron phosphate finished product material through the battery manufacturer and Dalian Institute of Chemical Physics of Chinese Academy of Sciences, the gram capacity is more than or equal to 155, the discharging rate is 98%, the diffraction peak of crystal form LiFePO4 is consistent with the literature comparison standard, and the performance of the current lithium iron phosphate cathode material is completely reached.

Owner:河南圣起机械集团有限公司

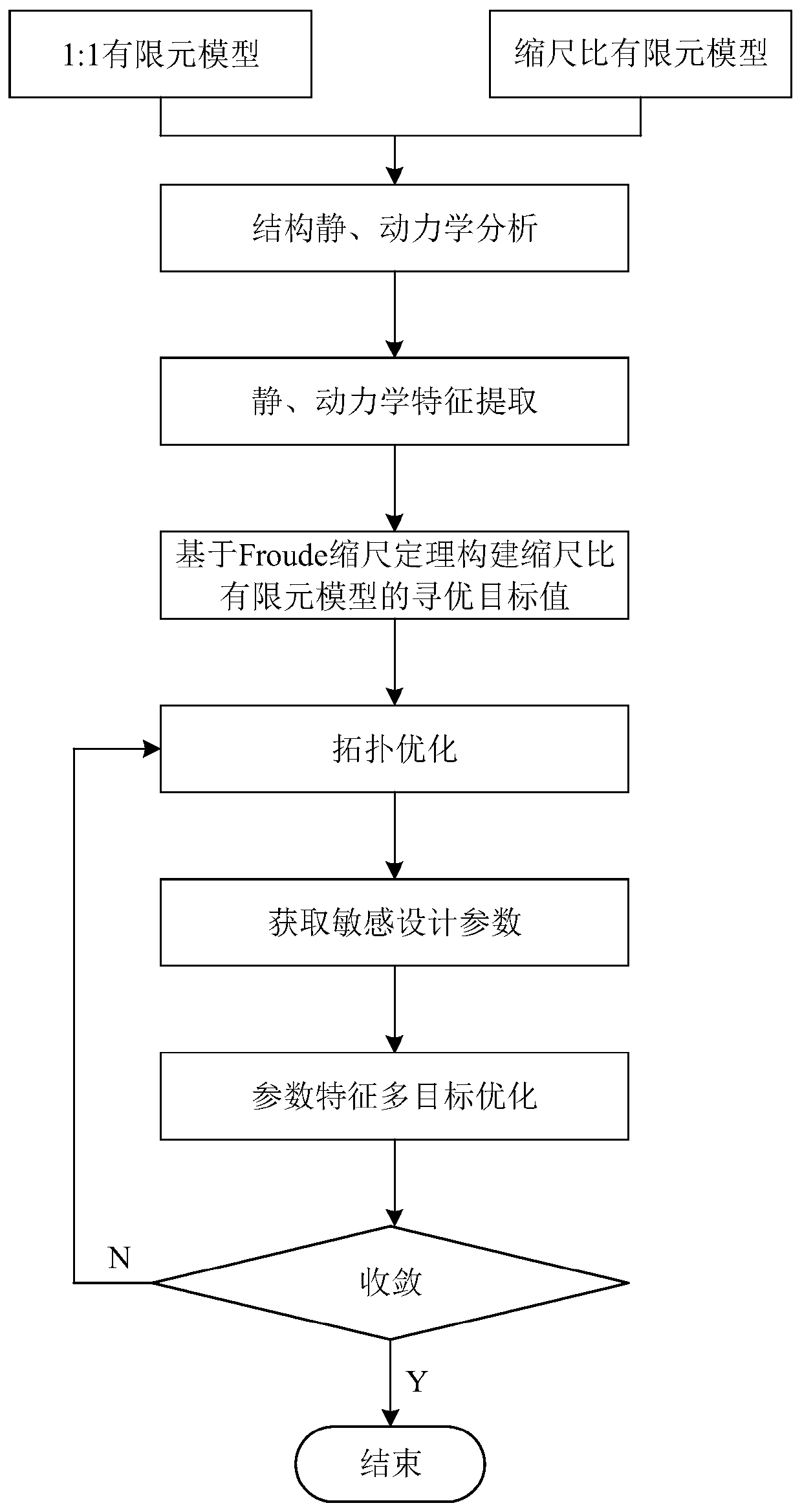

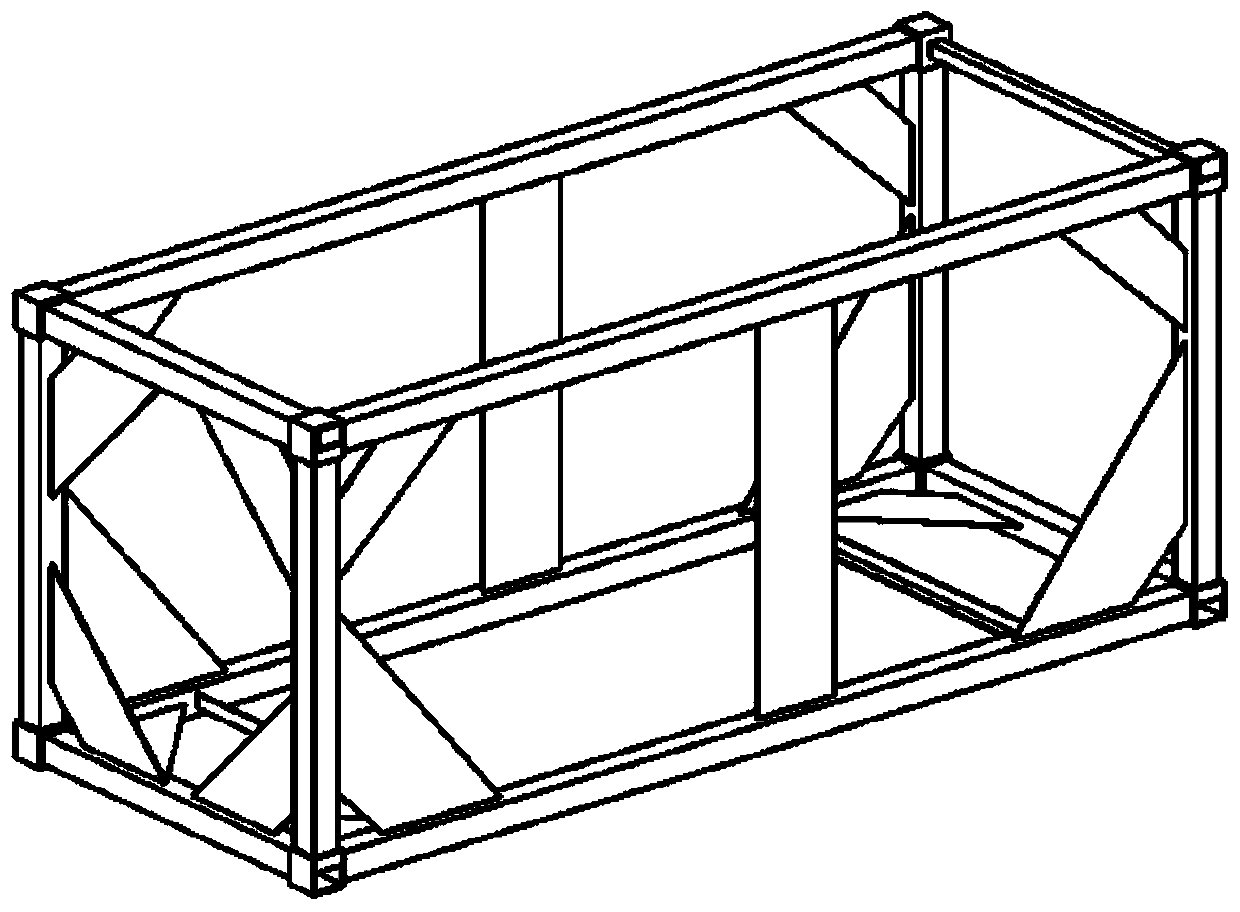

Container similarity model construction method based on multi-objective optimization and topological optimization

InactiveCN110309559ASimilar physical characteristicsGuaranteed characteristic performanceGeometric CADDesign optimisation/simulationApplicability domainTruth value

The invention relates to a container similarity model construction method based on multi-objective optimization and topological optimization. The container similarity model construction method comprises the following steps: (1) constructing a container 1: 1 finite element model and a scale ratio finite element model; (2) determining an optimization target, wherein the optimization target comprisesstatic characteristics and dynamic characteristics; (3) acquiring static characteristics and dynamic characteristic parameters of the 1: 1 finite element model; (4) constructing an optimization target value of the scale ratio finite element model based on the Froude scale theorem; (5) performing topological optimization on the wall structure of the scale ratio finite element model to obtain the shape of the wall structure; (6) obtaining sensitive design parameters of the scale ratio finite element model; and (7) optimizing the sensitive design parameters of the scale ratio finite element model until the optimization target true value converges to the optimization target value, and obtaining the container scale ratio finite element model determined by optimization as the container similarity model. Compared with the prior art, the container similarity model construction method is simple, practical, effective and wide in application range.

Owner:SHANGHAI JIAO TONG UNIV

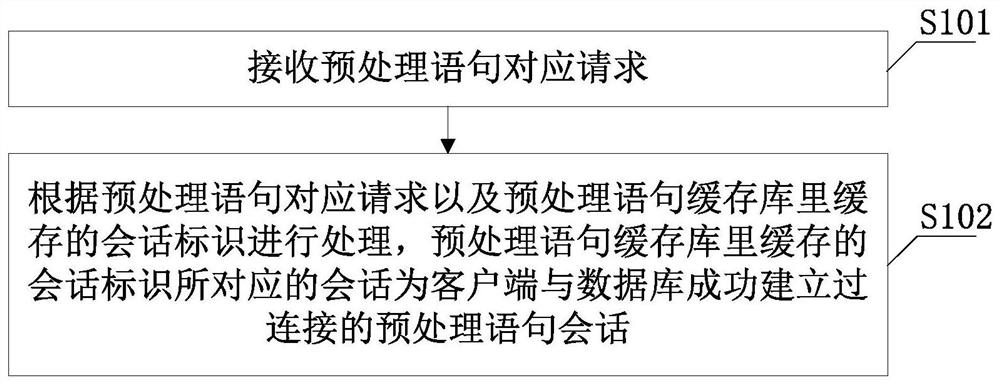

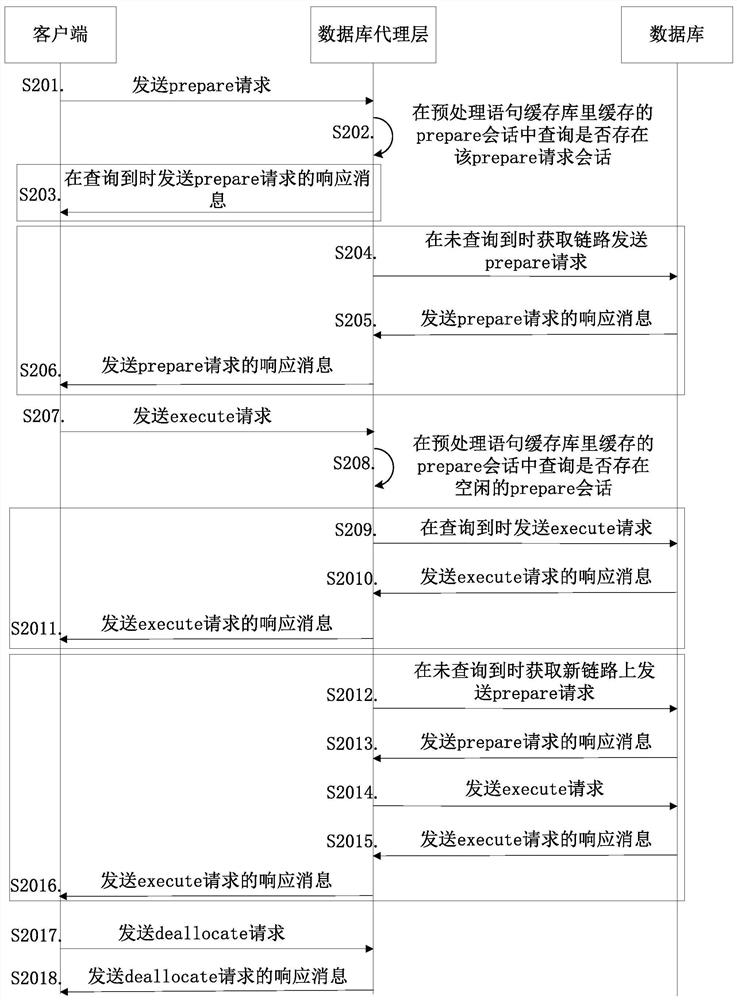

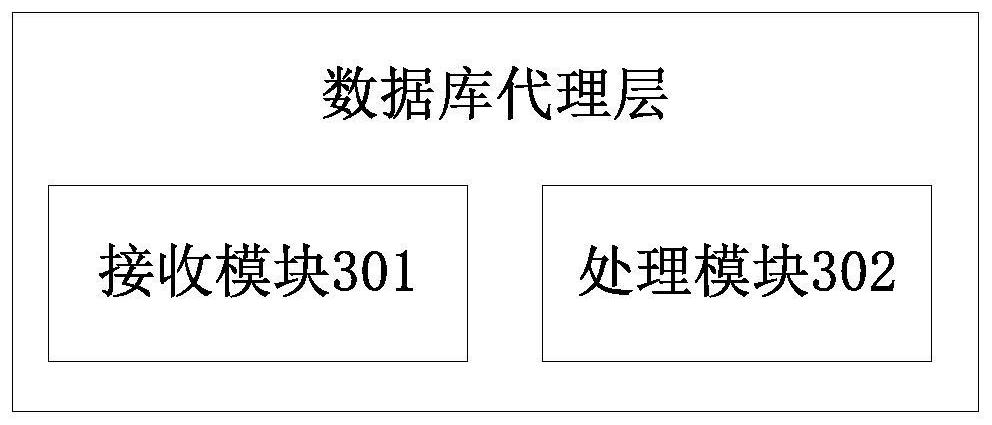

Distributed database preprocessing method, agent layer, system and storage medium

ActiveCN112241418ASolve processingSolve efficiency problemsDatabase distribution/replicationTransmissionTheoretical computer scienceEngineering

The invention provides a distributed database preprocessing method, a database agent layer, a system and a storage medium, and the method comprises the steps: receiving a preprocessing statement corresponding request, and carrying out the processing according to the preprocessing statement corresponding request and a session identification cached in a preprocessing statement cache library, whereinthe session corresponding to the session identifier cached in the preprocessing statement cache library is a preprocessing statement session with successfully established connection between the client and the database; the problem that in the prior art, the performance and efficiency of distributed database preprocessing are low is solved, the load of the database is reduced to a certain extent,the performance and efficiency of distributed database preprocessing are improved, and resources are saved.

Owner:金篆信科有限责任公司

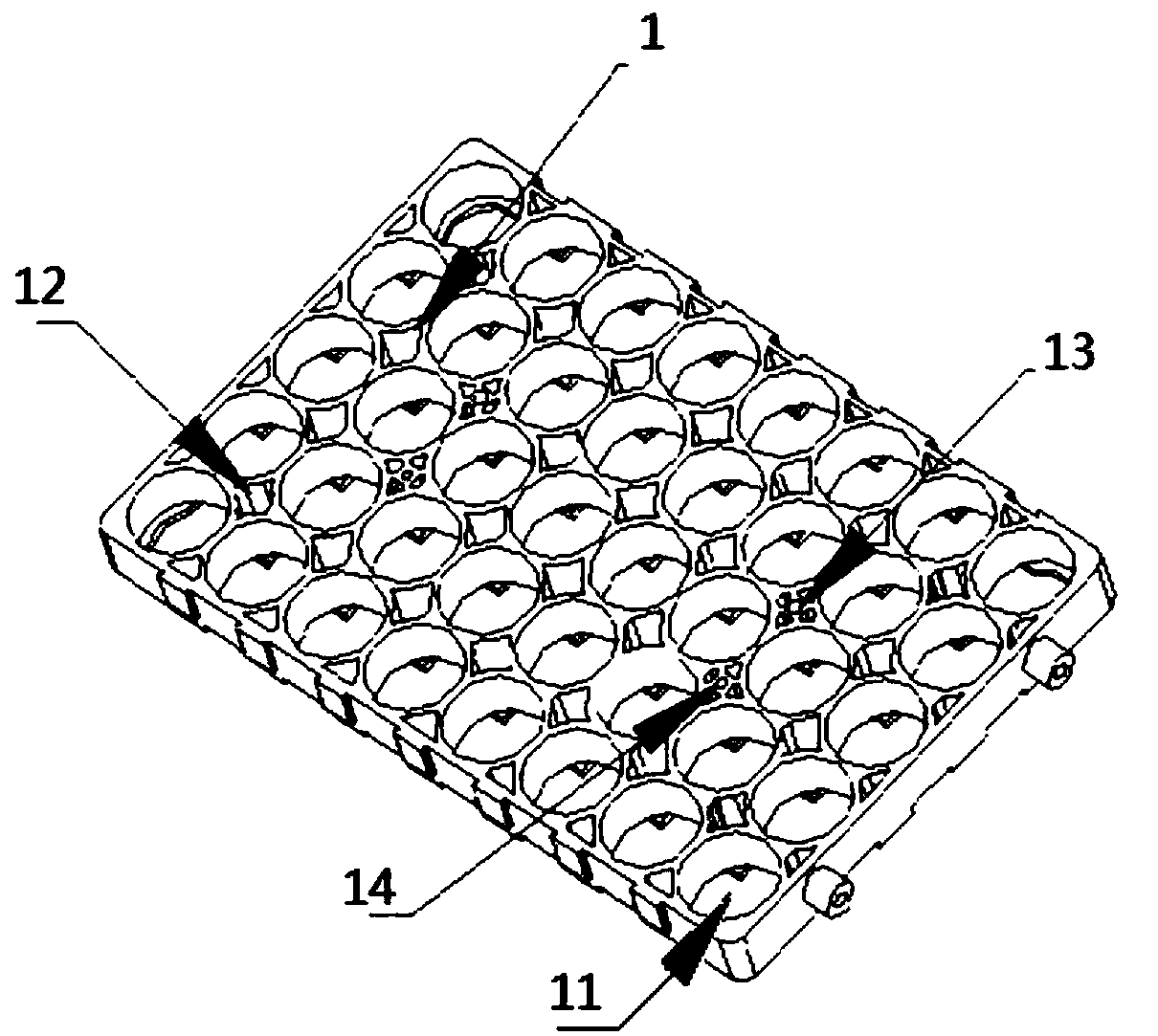

Fixing frame of lithium ion battery pack for AGV (Automatic Guided Vehicle) and lithium ion battery pack structure for AGV

PendingCN109664744AMeet different series and parallel requirementsLow costElectric propulsion mountingCells structural combinationEngineeringBattery cell

The invention provides a fixing frame of a lithium ion battery pack for an AGV (Automatic Guided Vehicle) and a lithium ion battery pack structure for the AGV. The fixing frame comprises a main body,wherein the main body comprises multiple battery cell accommodating parts, at least one first through hole for installing a fastener, at least one second through hole for installing the fastener, blind hole(s), at least one pair of positioning hole and positioning column, multiple dovetail grooves, and dovetail blocks, wherein the blind holes are arranged on the back face of the main body, and symmetrical with the second through hole relative to a central line in a length direction of the main body, and the number of the blind holes is the same as that of the second through holes; at least onepair of positioning hole and positioning column is arranged on the front face of the main body, and the positioning hole is symmetrical with the positioning column relative to the central line in thelength direction of the main body; multiple dovetail grooves are formed at the left side face of the main body; dovetail blocks are formed at the right side face of the main body; positions of the dovetail blocks correspond to positions of the dovetail grooves; and the number of the dovetail blocks is the same as that of the dovetail grooves. The reliability, rapidity, and convenience of batterygrouping are improved; the structure is simple and compact; the cost is low; and maintenance is convenient.

Owner:天津蓝天特种电源科技股份公司

Threshing machine convenient to use

A threshing machine convenient to use comprises a threshing mechanism and a grain containing box arranged under the threshing mechanism. The threshing mechanism comprises a plurality of fixed threshing rods which are arranged at intervals, movable threshing rods which are arranged between every two adjacent fixed threshing rods and can do axial back-and-forth movement and an intermittent driving assembly for driving the movable threshing rods to do back-and-forth movement. Due to the fact that the reciprocating translation type threshing machine is adopted, the equipment size and the occupied space are both smaller than those of an existing drum-type threshing machine, the cost is greatly reduced, and the carrying convenience of a user is improved; in addition, due to the fact that stems always stay over the threshing mechanism in the threshing process, grain impurities obtained in threshing are effectively reduced, and the threshing efficiency and quality are greatly improved; furthermore, misoperation basically cannot occur, and therefore injuries to the user in the threshing process can be effectively reduced.

Owner:张克泵

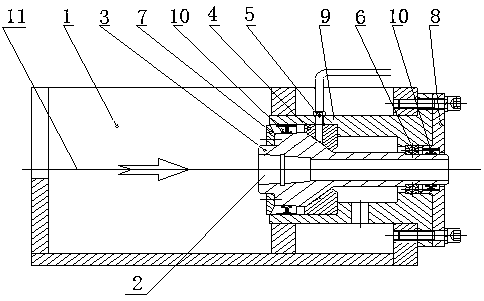

Passive high-speed rotary die box

The invention discloses a passive high-speed rotary die box. The passive high-speed rotary die box comprises a rotary device mounted in a box body, wherein the rotary device comprises a spiral die, a hollow shaft, a tapered sliding bearing, an oil pipe which is externally connected with a hydraulic station, a second bearing, front and rear covers and a shell, wherein the spiral die is mounted in the hollow shaft; the front part of the hollow shaft is suspended in the tapered sliding bearing; the oil pipe penetrates through the tapered sliding bearing to be contacted with the hollow shaft; the rear part of the hollow shaft is mounted in the second bearing; the front end of the hollow shaft is sleeved with the front cover and is connected with the shell; the rear end of the hollow shaft is sleeved with the front cover and is connected with the shell and the box body. The passive high-speed rotary die box is simple in structure; the tapered sliding bearing which can operate at the high speed and has high bearing capability is adopted and a main stress of a rotary die is borne by the tapered sliding bearing, so that the rotary die is not limited by a rotary speed, the service life is long and the problems that the bearings are replaced usually so as to influence the production and the efficiency are solved.

Owner:HUAIAN JINXIN TRANSMISSION MACHINERY

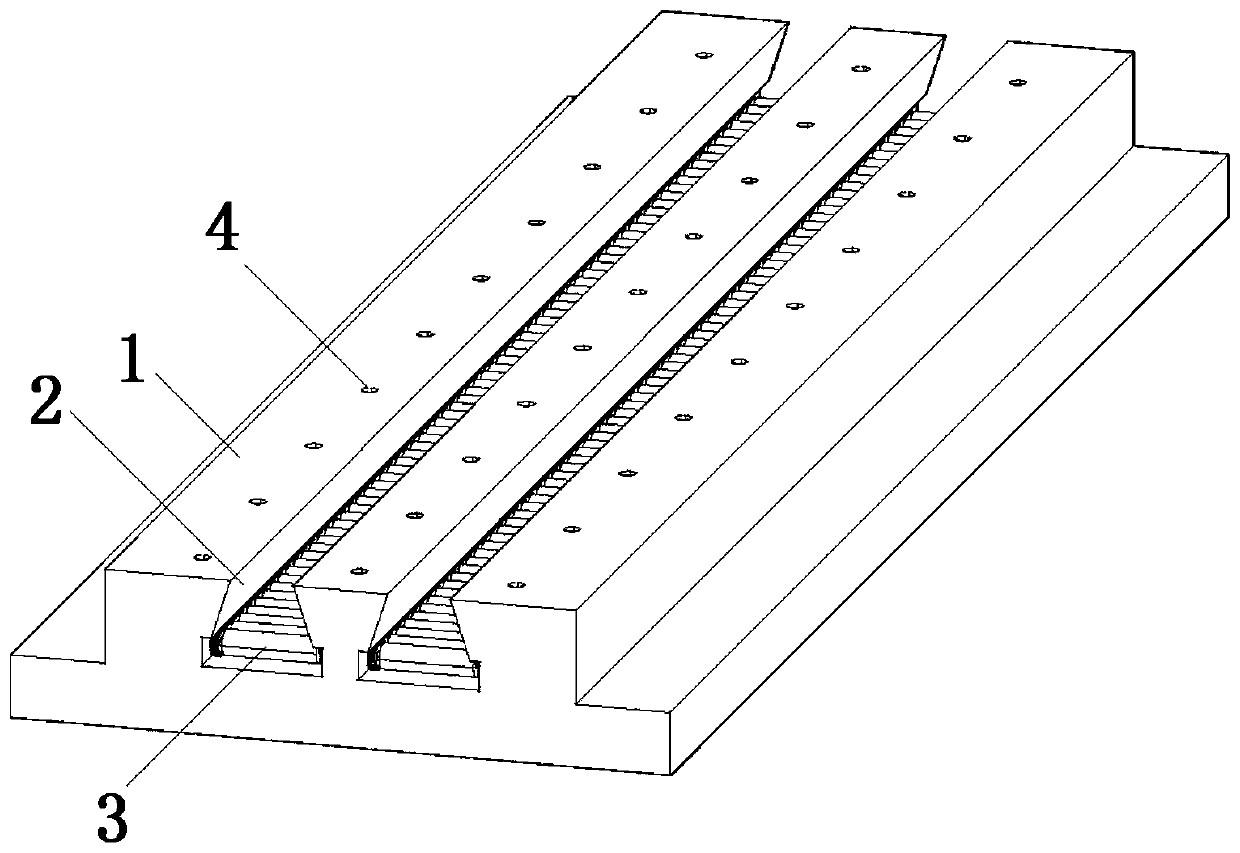

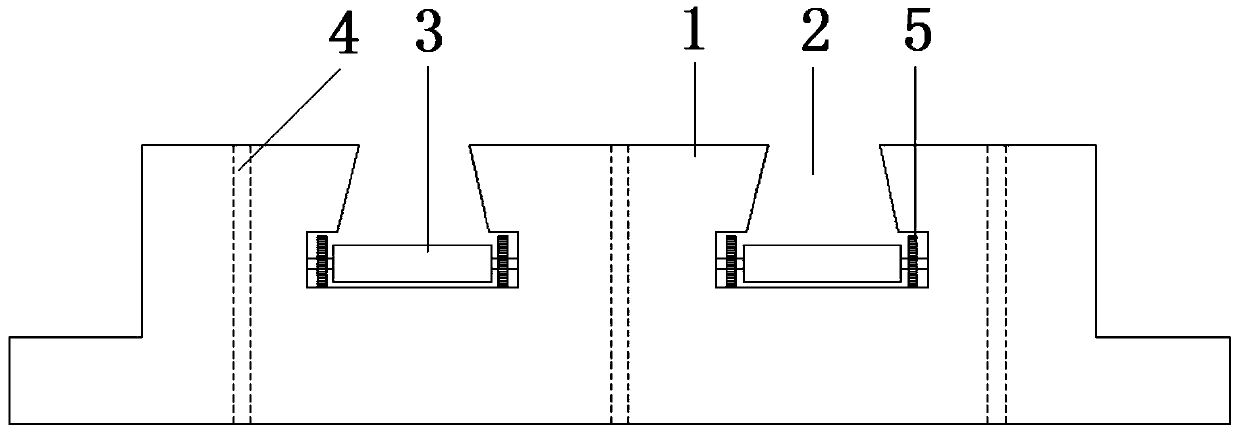

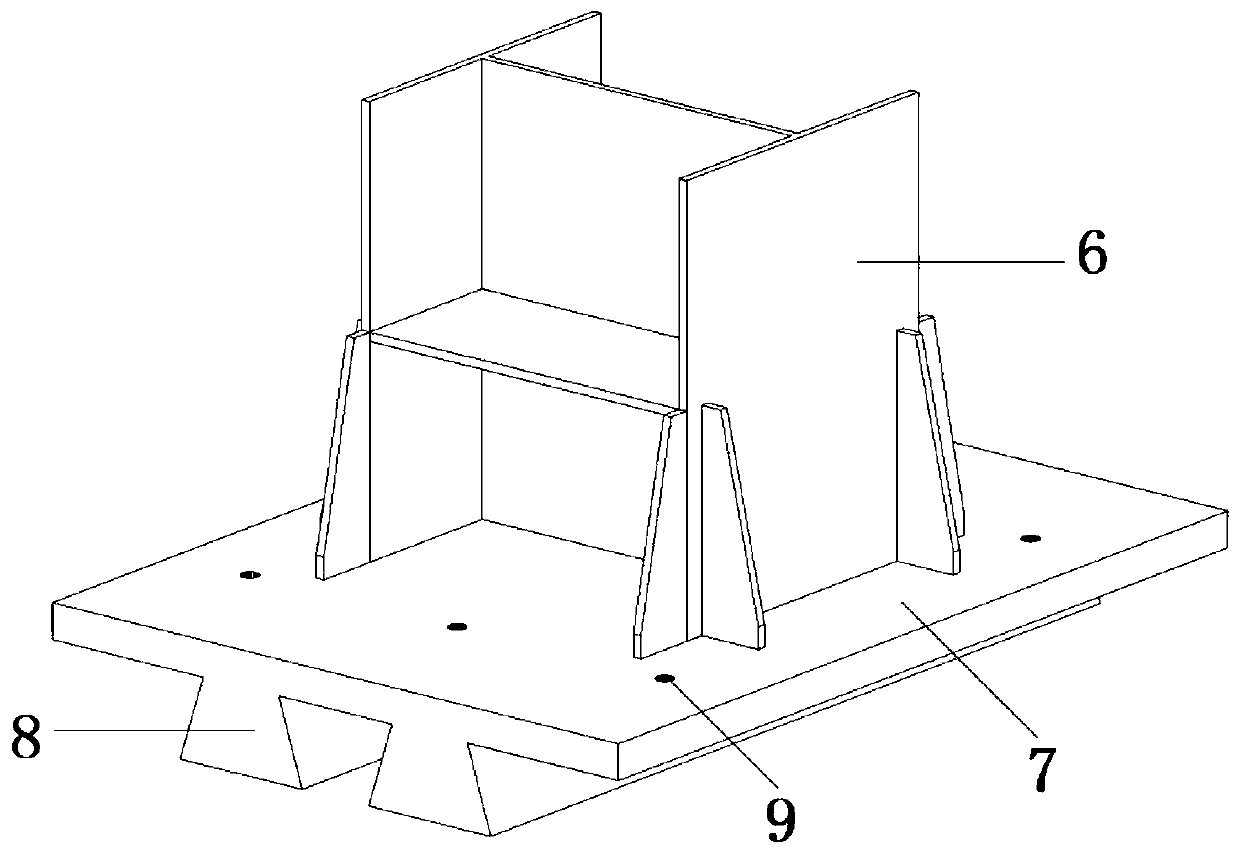

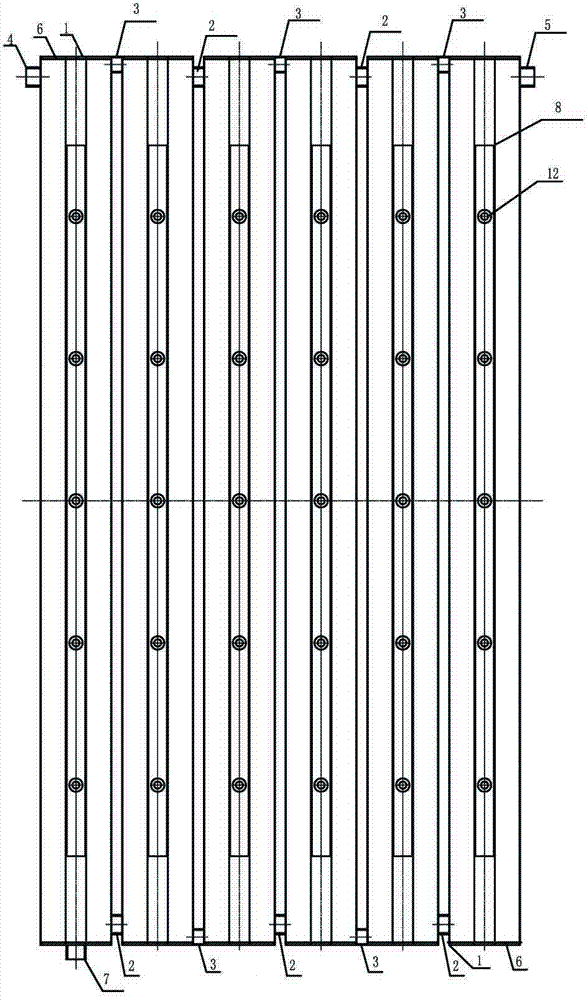

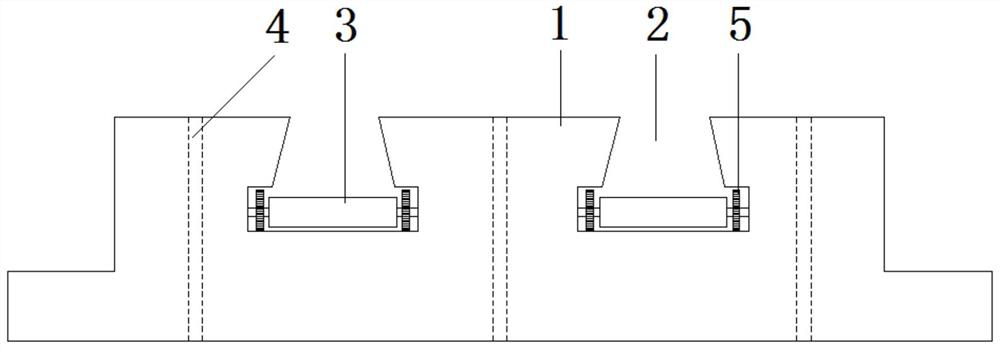

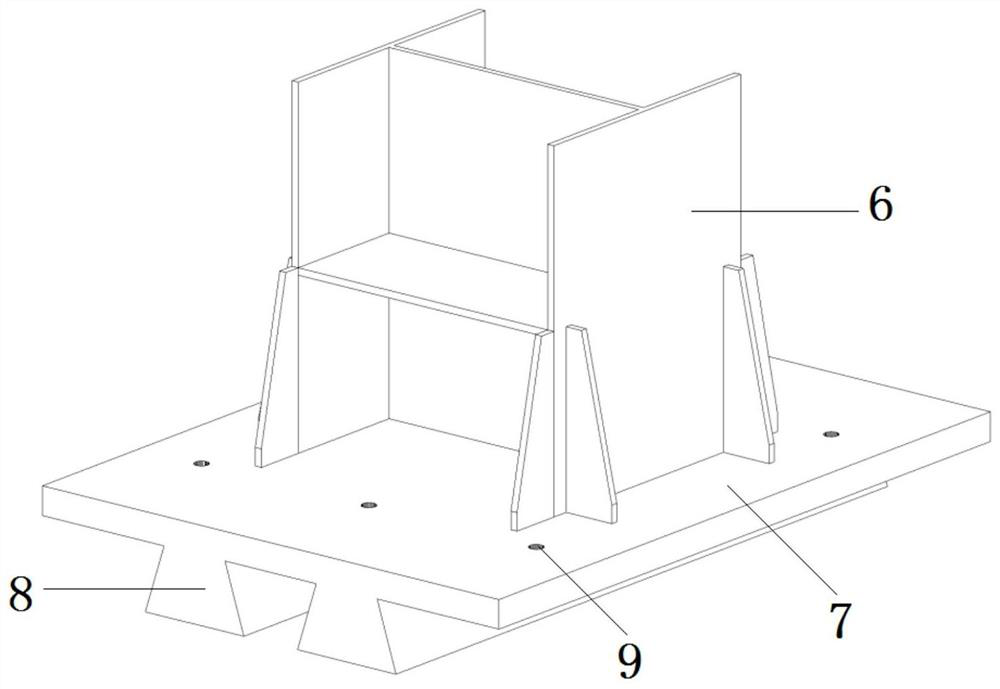

Track foundation for assembly type light steel structure building

ActiveCN111441378AMeet the requirements of rapid assemblyWith detachableFoundation engineeringArchitectural engineeringBolt connection

The invention relates to a track foundation for an assembly type light steel structure building. A plurality of second through holes which are through up and down are reserved in a column base bottomplate matched with the track foundation, a plurality of transverse strip-shaped sliding blocks are integrally arranged on the lower end surface of the column base bottom plate, and the plurality of strip-shaped sliding blocks are uniformly arranged at intervals. Sliding grooves which are equal to the strip-shaped sliding blocks in number and are matched with the strip-shaped sliding blocks in a one-to-one correspondence mode are formed in the upper end face of the track foundation, and each sliding groove is through front and back. Rows of first through holes used for being fixedly connected with the column base bottom plate are formed in the track foundation in the length direction, and each first through hole is through up and down. After being inserted into a set position in the track foundation, the column base bottom plate is fixedly connected with the track foundation through bolts. According to the track foundation, the column base bottom plate and the track foundation are in sliding fit and are connected through the bolts, and the column base arrangement has high flexibility. Meanwhile, a light steel structure foundation part has the advantages of being detachable and recyclable, damage to the construction site environment can be reduced, and the track foundation is environmentally friendly, economical and efficient.

Owner:JINLING INST OF TECH

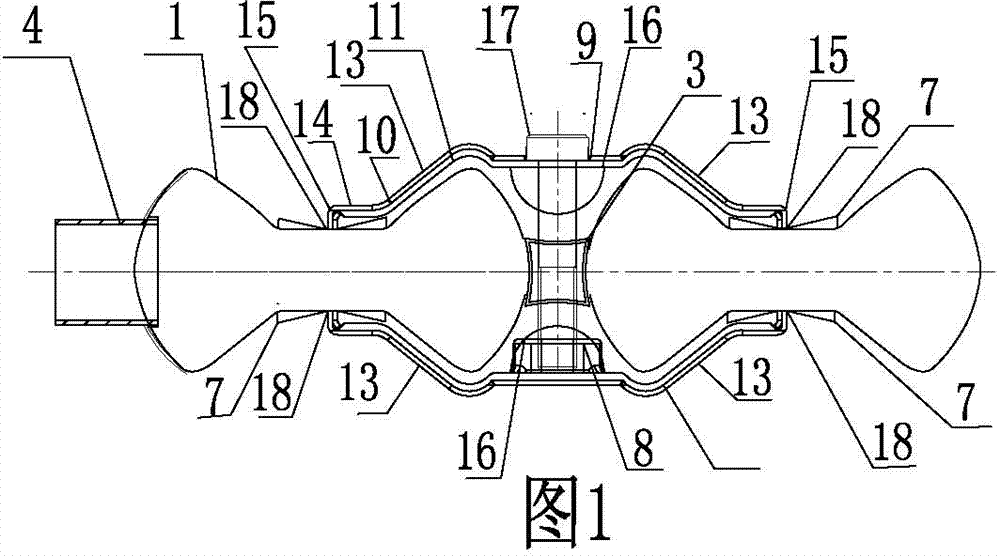

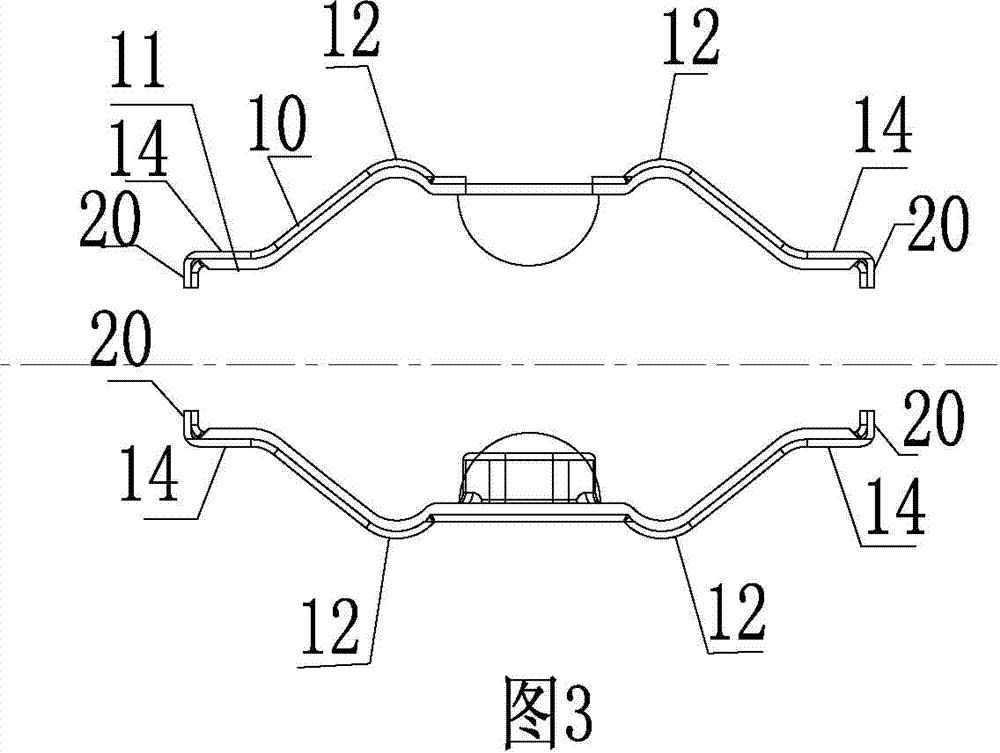

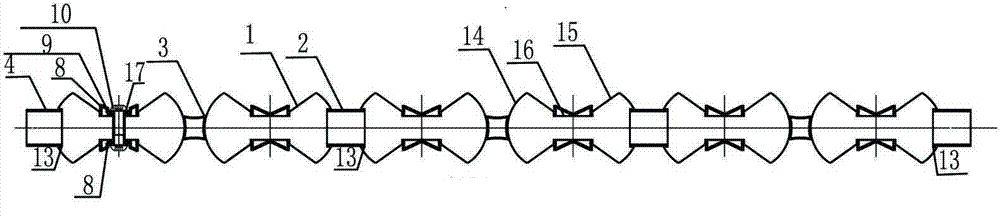

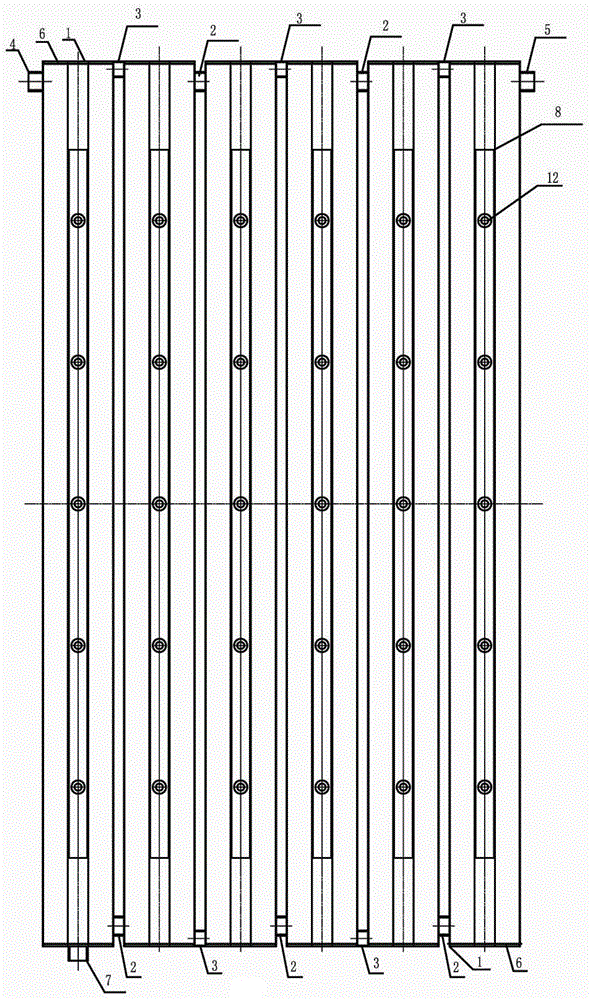

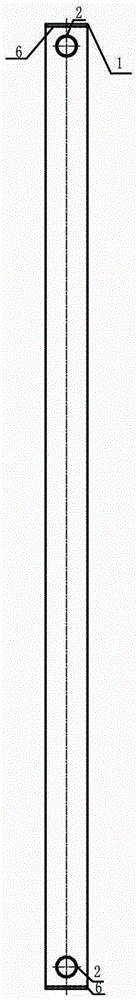

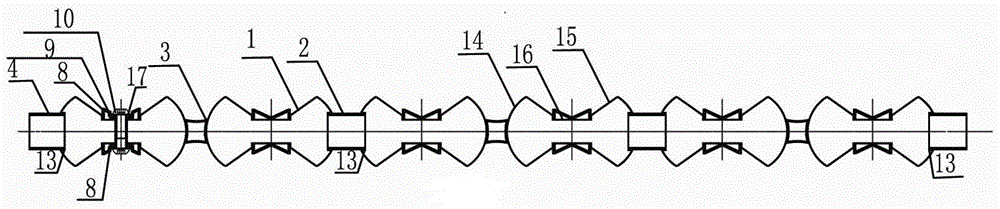

Water leakage preventing stainless steel radiator

ActiveCN103884044AIncrease the areaIncrease cooling areaStationary conduit assembliesSpace heating and ventilation detailsWater leakageEngineering

The invention relates to a water heating radiator, and belongs to indoor heating devices. A water leakage preventing stainless steel radiator is composed of stretching heat conduction pipes 1, communicated pipes 2, connecting pieces 3, bow-shaped folded edge end sockets 6, a splint bolt 10 and an inner folded edge girth welding part 13, and is characterized in that a rectangle or square is formed by welding the communicated pipes 2 and the connecting pieces 3 at the circular arc faces 14 at the two ends of the stretching heat conduction pipes 1, the stretching heat conduction pipes 1 are connected in series in a communicated mode, the front faces and the back faces of the circular arc faces 14 at the two ends of the stretching heat conduction pipes 1 connected in series in the communicated mode are concaved inwards to form circular arc faces 15, and the middle portions of the front faces and the back faces of the circular arc faces 14 are concaved inwards to form steps 16. The bow-shaped folded edge end sockets 6 are matched with the stretching heat conduction pipes 1 in shape, are inserted into the two ends of the stretching heat conduction pipes and are fixedly connected with an external girth welding part 11. The water leakage preventing stainless steel radiator is characterized in that the cylinder is changed into an inward-concaved cuboid, the heating water area is widened, the heat dissipation area is enlarged, the weight is low, and the water leakage preventing stainless steel radiator is attractive.

Owner:ZAOZHUANG FUYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING MACHINERY MFG CO LTD

A rubber product production process and automatic assembly line

The invention relates to a rubber product production process flow and an automatic streamline. The process flow comprises the processes of rubber vulcanization, die opening and locking, taking and peeling of a piece from an injection molding machine or an injection pressing molding machine, and the processes are completed by a vulcanization drying tunnel and a die opening and locking machine respectively; and the automatic streamline comprises the injection molding machine, the vulcanization drying tunnel, the die opening and locking machine, a conveyer belt and an oil cylinder, the injection molding machine is connected with the vulcanization drying tunnel, the vulcanization drying tunnel, the die opening and locking machine and the injection molding machine are sequentially connected through the conveyer belt, the oil cylinder is connected with the conveyer belt, and a locked product die is arranged in the injection molding machine. Compared with the prior art, the process flow and the automatic streamline have the advantages of high productivity, substantial energy saving, low cost, less labor and the like.

Owner:上海昀泰机电科技有限公司

A track foundation for prefabricated light steel structure buildings

ActiveCN111441378BMeet the requirements of rapid assemblyWith detachableFoundation engineeringTrackwayArchitectural engineering

The invention relates to a track foundation for a prefabricated light-weight steel structure building, wherein a plurality of second through holes penetrating up and down are reserved on the base plate of the column base matched with the track base, and a plurality of transverse holes are integrally arranged on the lower end surface of the base plate of the base The bar-shaped sliders, multiple bar-shaped sliders are evenly spaced. The end surface of the track foundation is provided with chute slots equal in number to the strip sliders and matched one by one, and each chute runs through front and back. Along the length direction, the track foundation is provided with a row of first through holes for fixing and connecting the bottom plate of the column feet, and each first through hole penetrates up and down. After the base plate of the column foot is inserted into the track foundation at a set position, it is fixedly connected with the track foundation by bolts. In the present invention, the bottom plate of the column feet is slidably matched with the track foundation and connected by bolts, and the arrangement of the column feet has a high degree of flexibility. At the same time, the basic part of the light steel structure has the advantages of disassembly and recycling, which can reduce the damage to the construction site environment, be green and environmentally friendly, save and increase efficiency.

Owner:JINLING INST OF TECH

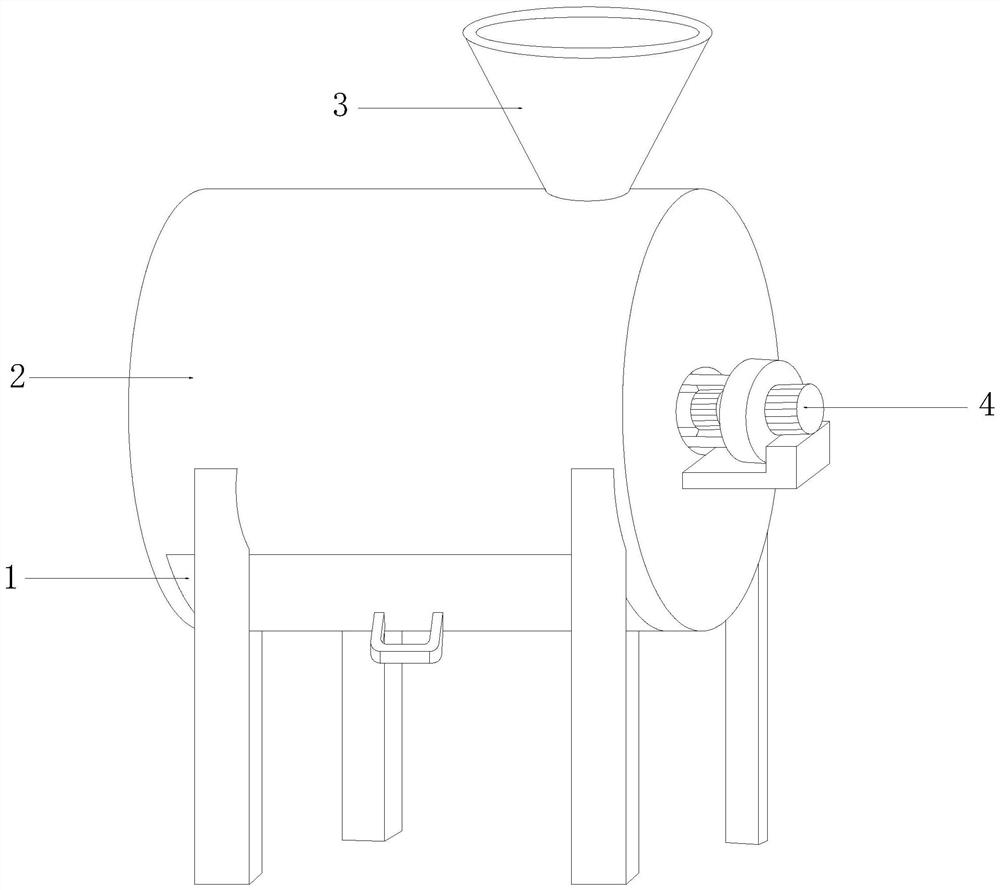

Building concrete mixer

InactiveCN113942113AEasy dischargeAvoid pollutionDischarging apparatusHollow article cleaningArchitectural engineeringMechanical engineering

The invention relates to the technical field of building machinery, in particular to a building concrete mixer. The building concrete mixer structurally comprises a discharging device, a mixing barrel, a feeding hopper and a transmission mechanism; the discharging device is arranged at the bottom of the mixing barrel, and the discharging device is movably connected with the mixing barrel; and the top of the mixing barrel is connected with the bottom of the feeding hopper. The building concrete mixer has the beneficial effects that: the stirred concrete can fall and be poured out more easily by means of the arc-shaped inner wall; the time cost is saved; a high-pressure spray head and a filter plate are additionally arranged, and the high-pressure spray head is arranged in the main shaft, so that the concrete residues remaining on the blades and the main shaft can be cleaned away at the first time through the high-pressure spray head after stirring of the building concrete mixer is completed, concrete residues are avoided, the use efficiency and the service life of the blades and the main shaft are guaranteed, the time and the cost for manual cleaning are saved, the working efficiency is improved, and land pollution is effectively avoided.

Owner:王仁达

Stainless steel radiator without water

ActiveCN103884044BIncrease the areaIncrease cooling areaStationary conduit assembliesSpace heating and ventilation detailsWater leakageWater heating

The invention relates to a water heating radiator, and belongs to indoor heating devices. A water leakage preventing stainless steel radiator is composed of stretching heat conduction pipes 1, communicated pipes 2, connecting pieces 3, bow-shaped folded edge end sockets 6, a splint bolt 10 and an inner folded edge girth welding part 13, and is characterized in that a rectangle or square is formed by welding the communicated pipes 2 and the connecting pieces 3 at the circular arc faces 14 at the two ends of the stretching heat conduction pipes 1, the stretching heat conduction pipes 1 are connected in series in a communicated mode, the front faces and the back faces of the circular arc faces 14 at the two ends of the stretching heat conduction pipes 1 connected in series in the communicated mode are concaved inwards to form circular arc faces 15, and the middle portions of the front faces and the back faces of the circular arc faces 14 are concaved inwards to form steps 16. The bow-shaped folded edge end sockets 6 are matched with the stretching heat conduction pipes 1 in shape, are inserted into the two ends of the stretching heat conduction pipes and are fixedly connected with an external girth welding part 11. The water leakage preventing stainless steel radiator is characterized in that the cylinder is changed into an inward-concaved cuboid, the heating water area is widened, the heat dissipation area is enlarged, the weight is low, and the water leakage preventing stainless steel radiator is attractive.

Owner:ZAOZHUANG FUYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING MACHINERY MFG CO LTD

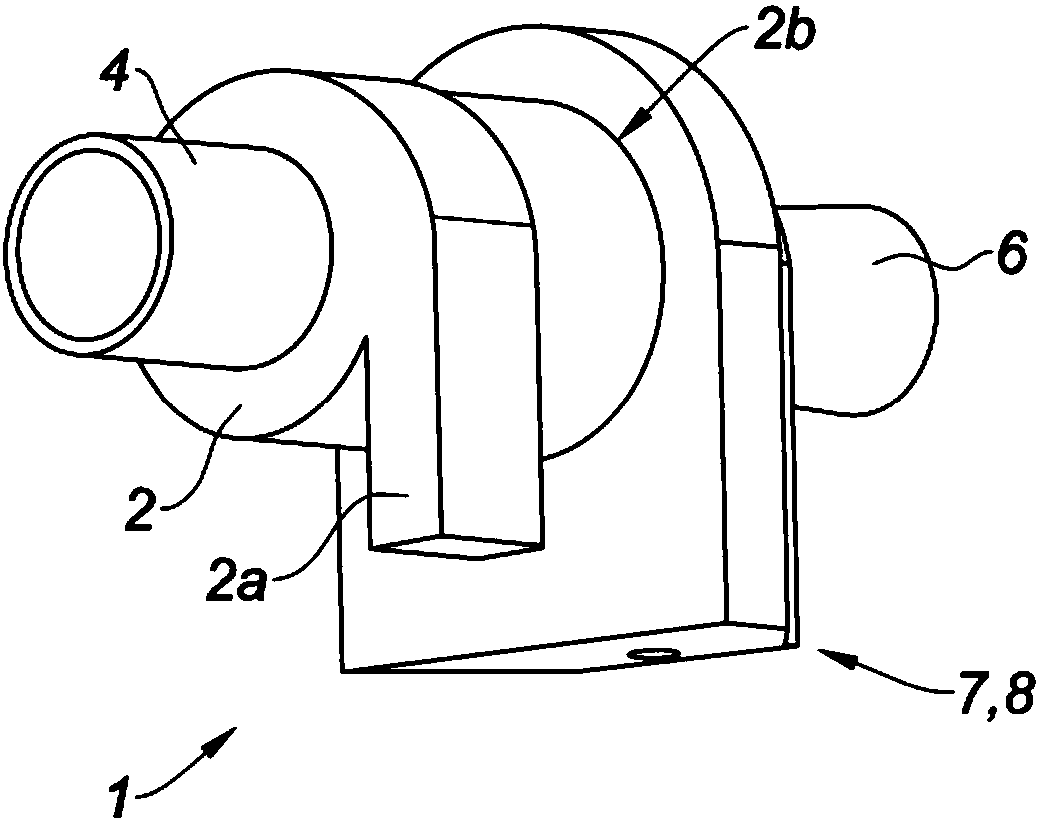

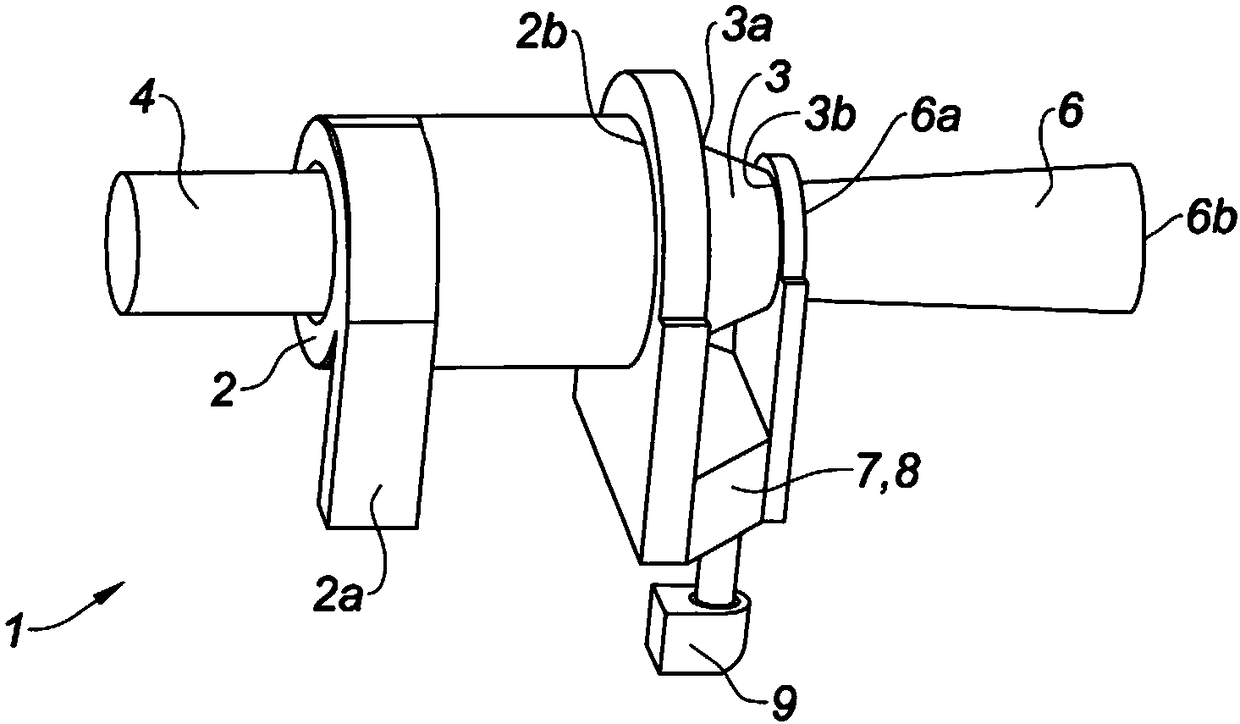

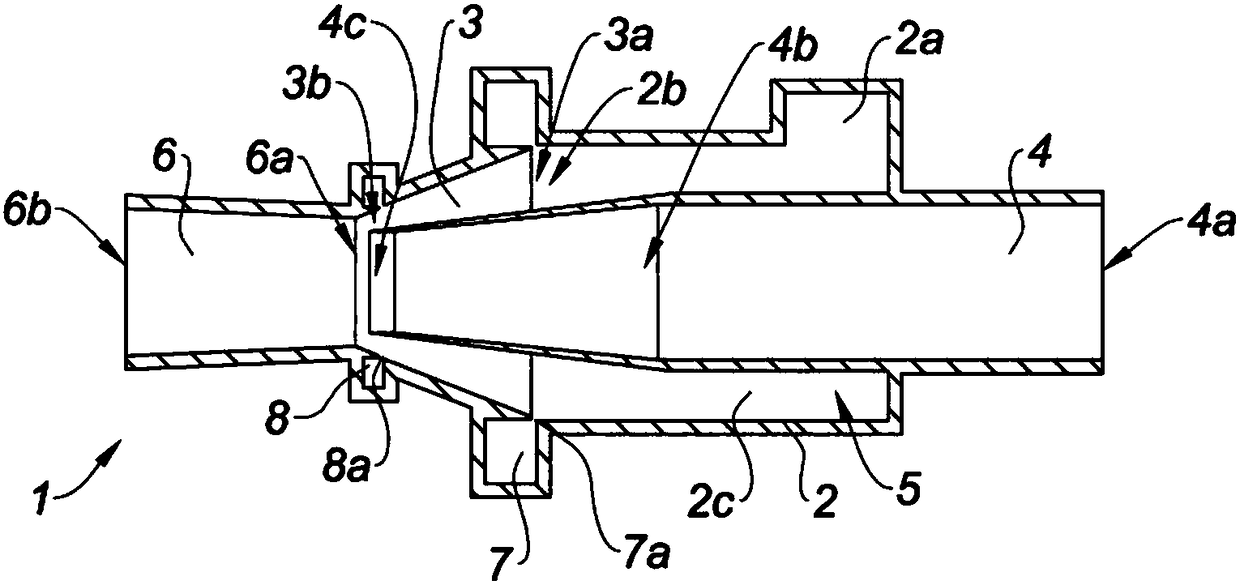

Device for suction and decantation of a crankcase gas and associated installation

ActiveCN108506066ASave efficiencySave spaceDispersed particle separationJet pumpsCombustionCrankcase

The invention discloses a device for suction and decantation of a crankcase gas and associated installation. The subject of the invention is a crankcase gas suction and decanting device (1) comprisingat least a combustion gas and engine oil, The suction and decanting device (1) comprising a crankcase gas collecting cylinder (2) comprising a cylinder inlet (2a) shaped to supply a crankcase gas anda cylinder outlet (2b) arranged tangentially to the cylinder (2); a first conical portion (3) comprising a first end (3a) and a second end (3b), the first end (3a) being arranged at the cylinder outlet (2b), the first conical portion (3) being convergent from its first end (3a) to its second end (3b), characterized in that the suction and decanting device (1) further comprises a second conical portion (6) having a first end (6a) and a second end (6b), the first end (6a) of the second conical portion (6) being positioned opposite the second end (3b) of the first conical portion (3), the secondconical portion (6) being divergent from its first end (6a) towards its second end (6b).

Owner:AKWEL SA

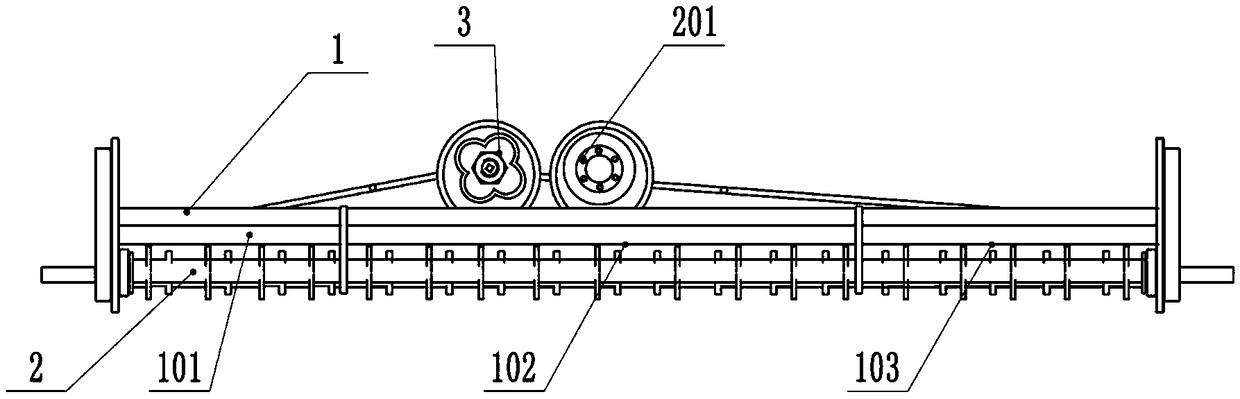

Foldable paddy field flattening machine

ActiveCN109479396AEasy to shrinkImprove scalabilityTilling equipmentsDrive shaftAgricultural engineering

The invention discloses a foldable paddy field flattening machine, and belongs to the field of agricultural machinery. The device comprises a shell of the flattening machine, wherein a transmission shaft which is connected with a tractor is arranged in the shell; the shell is successively divided into a left portion, a middle portion and a right portion from left to right; the middle portion is connected with an axial supporting shaft; each of the left portion and the right portion is connected with a folding portion; each folding portion comprises a sliding sleeve and a connecting rod; each sliding sleeve is slidably connected with the supporting shaft; each connecting rod comprises a first connecting rod body, a second connecting rod body and a third connecting rod body; each first connecting rod body is connected with the left portion and the corresponding sliding sleeve; each second connecting rod body is connected with the right portion and the corresponding sliding sleeve; and each third connecting rod is transversely serially connected with the left portion, the middle portion and the right portion. Compared with a traditional paddy field flattening machine, the foldable paddy field flattening machine has the advantages that an operator upwards slides a slider at the supporting shaft, at the moment, the slider moves upwards, in the upward movement process, the slider drives the first connecting rod and the second connecting rod to expand outwards, and at the moment, the paddy field flattening machine is unfolded. Contraction and expansion of the paddy field flattening machine are facilitated, and storage of the paddy field flattening machine is facilitated.

Owner:NAN COUNTY WEIYE MACHINERY MFG

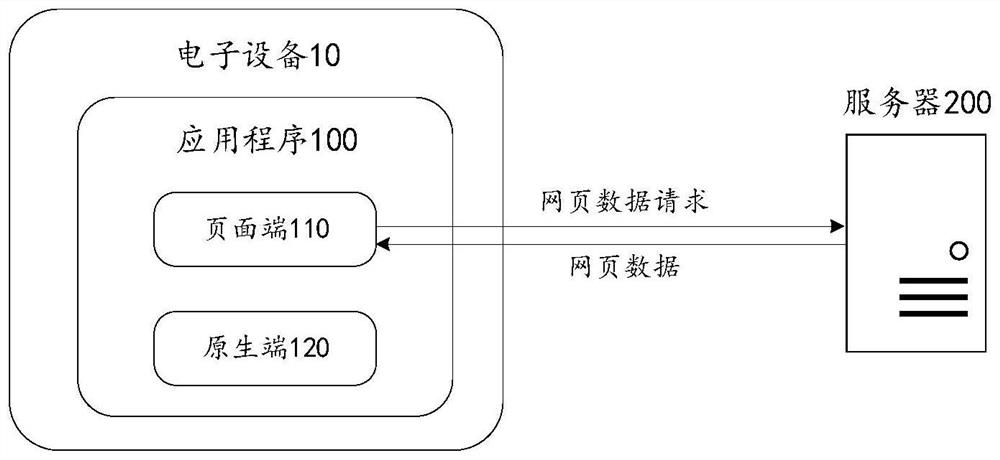

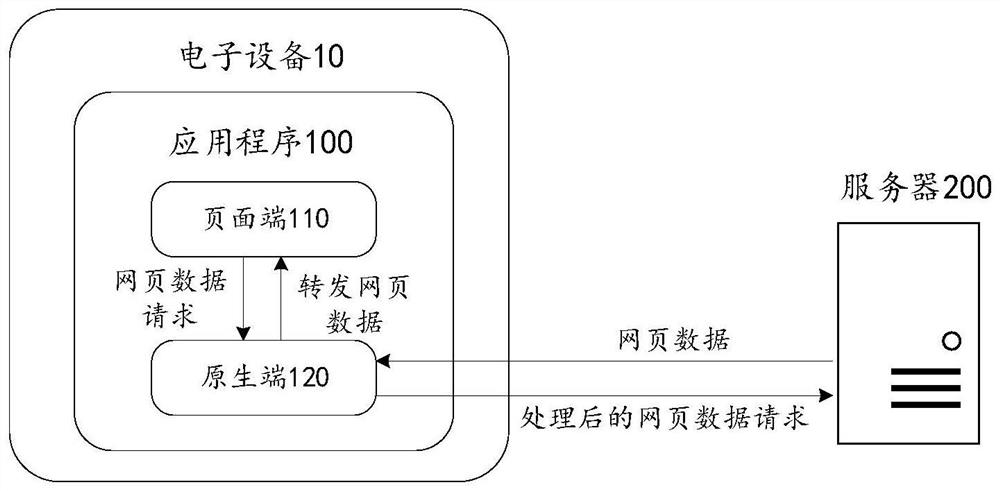

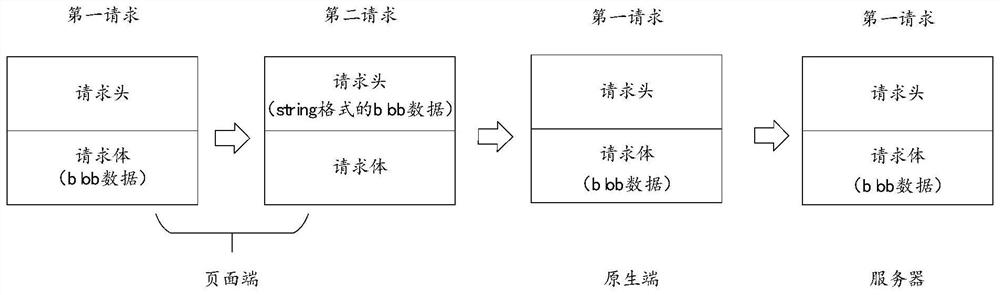

Webpage data request method, system, device, equipment and medium

PendingCN114816802ASolve the lost problemShorten the timeInterprogram communicationWebsite content managementEngineeringSerialization

The invention provides a webpage data request method, which comprises the following steps of: serializing blob data of a request body in a webpage data request into a character string format through a first process, adding the character string format into a request header, sending the request header to a second process, recovering the character string in the request header into blob data in the request body through the second process, and forwarding the blob data to a server. Therefore, the problem that the blob data of the request body in the webpage data request sent by the first process to the second process is discarded is solved, and for the server, the received webpage data request is the same as the previous format, the blob data does not need to be recovered by the server, the program code of the server does not need to be modified, the time is saved, and the efficiency is improved.

Owner:CHINA PING AN PROPERTY INSURANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com