Production method of combiner box and production line of combiner box implementing method

A production method and combiner box technology, applied in other manufacturing equipment/tools, metal processing, metal processing equipment, etc., can solve the problems of heavy labor and low efficiency of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

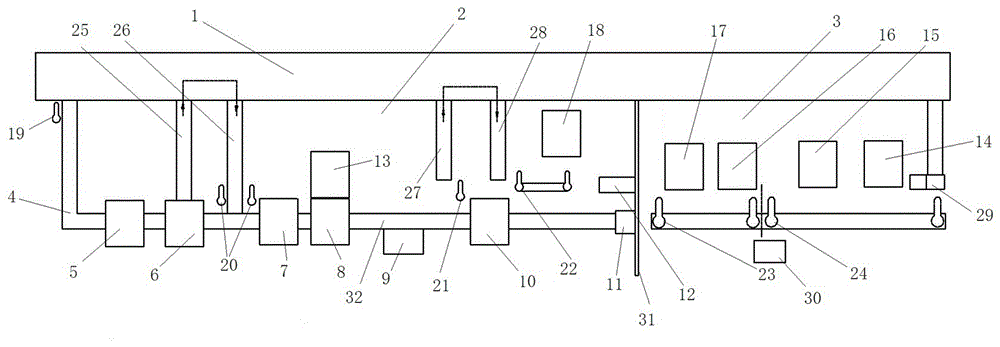

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. A specific embodiment of a combiner box production line of the present invention, such as figure 1 As shown, it includes a material warehouse 1 whose length extends along the front-to-back direction, a conveyor line arranged on the left side of the material warehouse, a material preparation unit 2 and a welding assembly unit 3 arranged in sequence along the conveyor line, the material warehouse 1 is a three-dimensional material warehouse, and the material preparation unit 2 and the welding assembly unit 3 is provided with a partition 31. The material preparation unit 2 includes punching equipment 5, turning equipment 7, primary bending machine 13 and secondary bending machine 18 arranged in sequence, and the welding assembly unit 3 includes plate seam welding equipment 17 and screwing equipment 16 arranged in sequence. , bulk welding equipment 15, grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com