Organic bovine colostrum powder and preparation method thereof

A bovine colostrum powder, organic technology, applied in dairy products, other dairy products, milk preparations and other directions, can solve the problems of low immunoglobulin content, inactivation of immunoglobulin, low nutritional value, etc. The effect of protein inactivation, easy storage and convenient consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

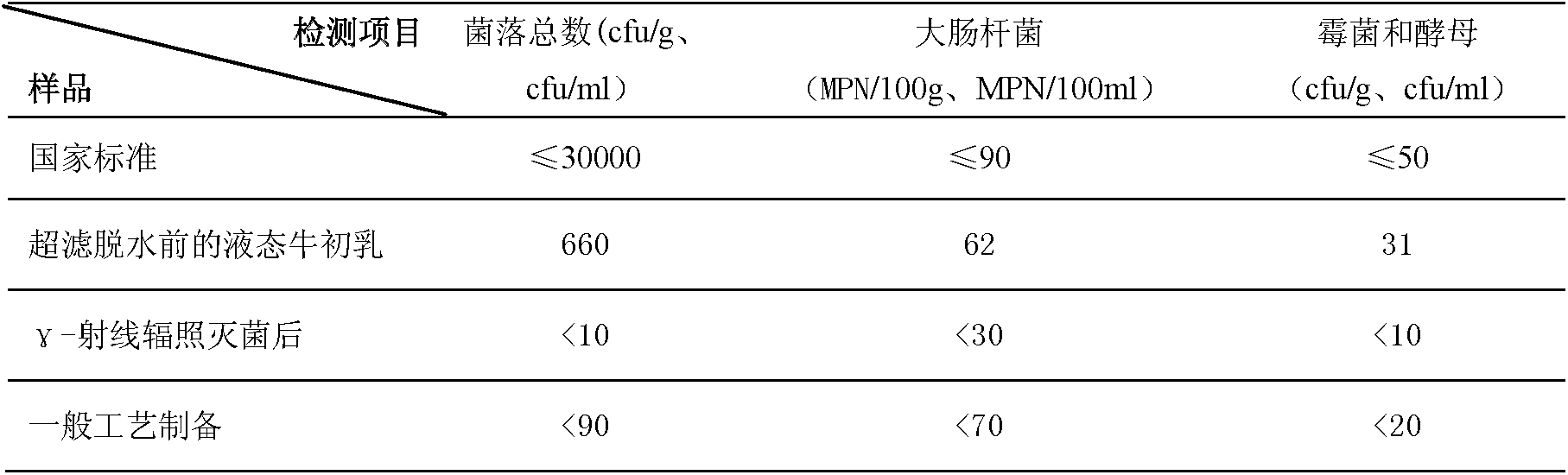

[0025] Experimental Example 1 Contrast experiment of various microbial indexes

[0026] (1) Specific experimental methods and operations

[0027] The liquid bovine colostrum before ultrafiltration and dehydration in Example 1 of the present invention, the bovine colostrum powder after gamma-ray irradiation sterilization in Example 1 of the present invention, and the bovine colostrum powder sprayed at high temperature by the general process were carried out according to RHB602-2005. Detection, the specific operation steps are:

[0028] 1. Determination of the total number of bacterial colonies

[0029] 1. Dilution of samples

[0030] 1.1 Bovine colostrum capsule powder: Weigh 25g of powdered sample and place it in a sterile homogenizing cup filled with 225mL of normal saline, homogenize at 8000r / min-10000r / min for 1min-2min, and make a 1:10 homogeneous sample solution. Raw milk sample before ultrafiltration concentration and dehydration: Take 25mL sample with a sterile pipe...

experiment example 2

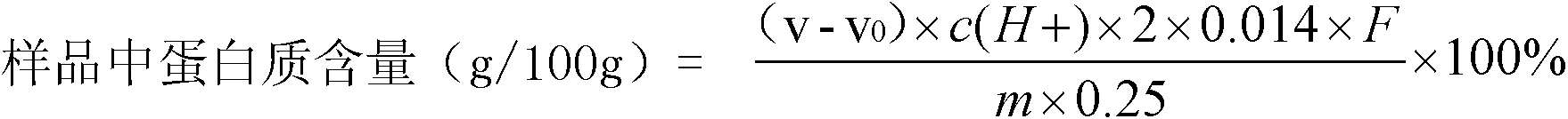

[0100] Experimental example 2 Contrast experiment of each physical and chemical index

[0101] (1) Specific experimental methods and operations

[0102] The liquid bovine colostrum before ultrafiltration and dehydration in Example 1 of the present invention, the bovine colostrum powder after gamma-ray irradiation sterilization in Example 1 of the present invention, and the bovine colostrum powder sprayed at high temperature by the general process were subjected to various physical and chemical indicators according to RHB602-2005 detection, the specific steps are:

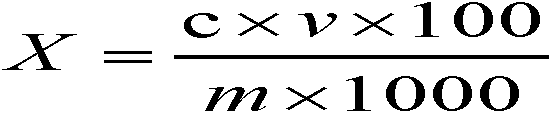

[0103] 1. Determination of IgG

[0104] 1. Principle

[0105] According to the principle of high-efficiency affinity chromatography, the immunoglobulin IgG is connected to the ligand under the condition of phosphate buffer, and the immunoglobulin IgG is eluted under the condition of pH 2.5 glycine hydrochloride,

[0106] 2. Reagents

[0107] 2.1 Mobile phase A: pH6.5, 0.05mol / L phosphate buffer.

[0108] 2.2 M...

Embodiment 1

[0221] Embodiment 1 capsule

[0222] Step 1: Prepare raw materials, select colostrum secreted by healthy dairy cows three days after calving, colostrum, light yellow in color, clean and free of impurities, pH value 6.2, relative density 1.030, solid content 12%; and Store the collected bovine colostrum immediately at 0°C for later use;

[0223] Step 2: High-speed centrifugal degreasing and impurity removal, the collected bovine colostrum raw material is subjected to centrifugal degreasing and impurity removal in a high-speed temperature-controlled centrifuge; the centrifugation parameters are set to 6000r / min, the temperature is 4°C, and the centrifugation time is 15 minutes;

[0224] Step 3: Concentrated and dehydrated by ultrafiltration, the bovine colostrum after high-speed centrifugal degreasing and decontamination is subjected to ultrafiltration, concentration and dehydration; the ultrafiltration machine adopts a German Sartorius tangential flow ultrafiltration machine, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com