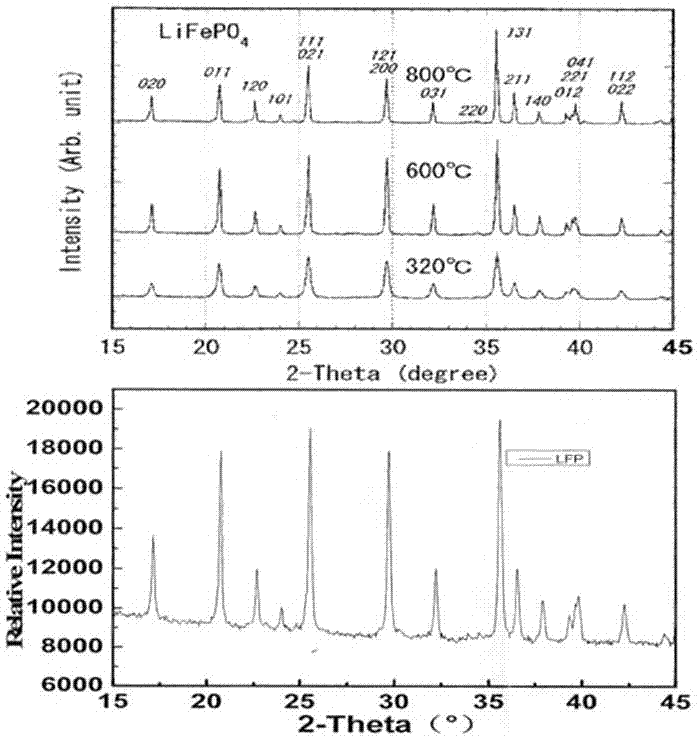

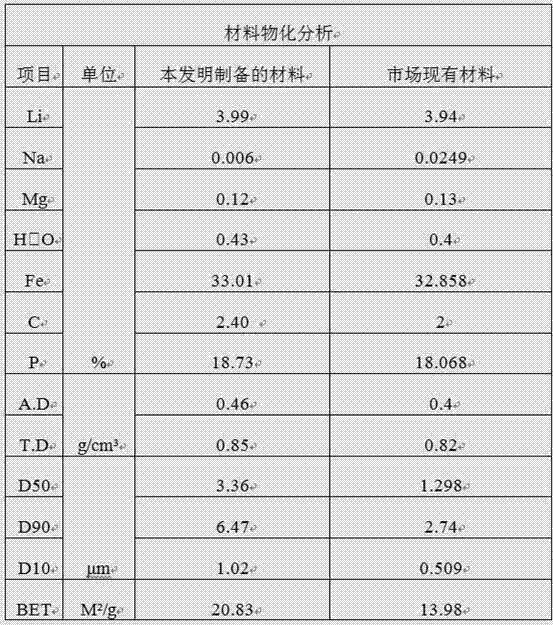

Preparation method of lithium iron phosphate cathode material

A positive electrode material, lithium iron phosphate technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems that affect the domestic industrialization of materials, high manufacturing technology threshold, and low market acceptance, achieving good consistency and low production costs , Improve the effect of mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The method of the present invention will be described in more detail below through specific examples.

[0016] The preparation method of lithium iron phosphate cathode material of the present invention, comprises the following steps:

[0017] The first step, the preparation of raw materials

[0018] Accurately weigh the four raw materials of lithium carbonate, ferrous oxalate, ammonium dihydrogen phosphate and glucose according to the weight percentage of 8%:54%:30%:8%, and put them into the powder mixer with the least amount of doping method Mix for 4 hours, so that the four powders are completely mixed into one;

[0019] The second step, suppression

[0020] Put the fully mixed powder into a 5T~10T press for pressing. The volume of the powder cake formed after pressing is 1 / 5~2 / 5 of the original volume. In actual production, it can be pressed to a diameter of 30cm , A round cake with a thickness of 20~25cm, of course, it can also be pressed into a square or polygon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com