Magnetic fluid sliding bearing

A sliding bearing, magnetic fluid technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve problems such as bearing damage and shortening bearing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

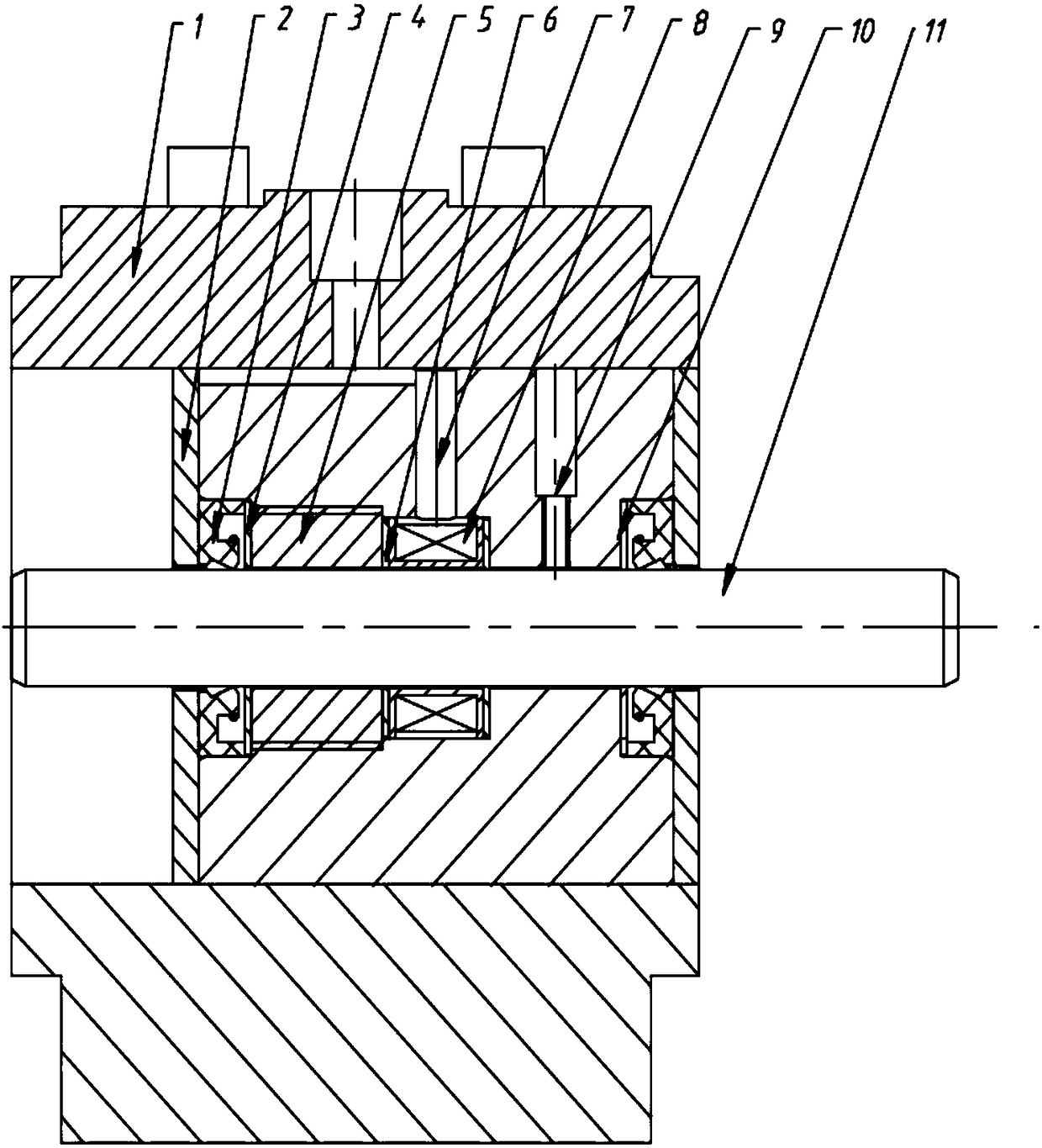

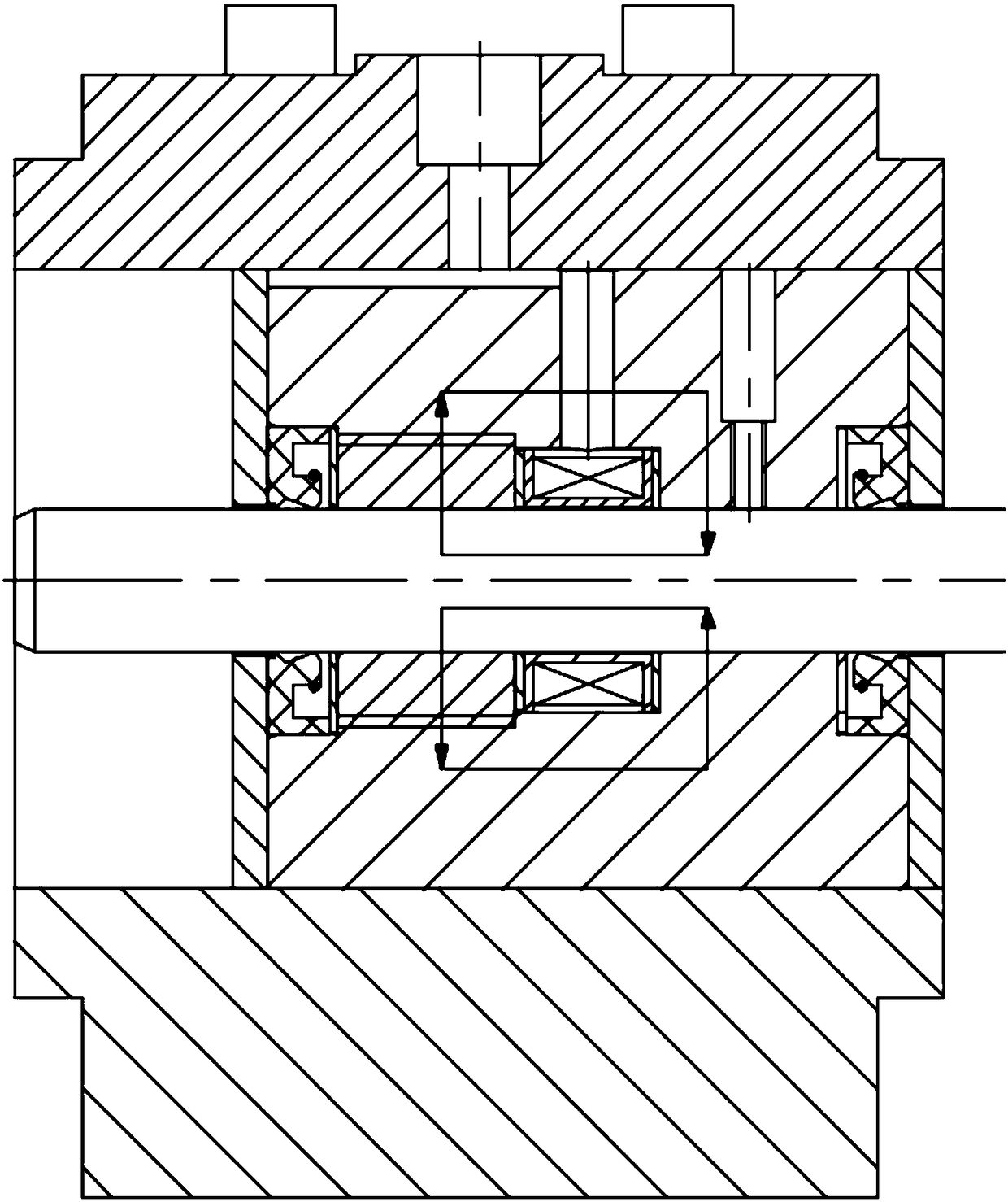

[0022] refer to figure 1 , the present invention provides a magnetic fluid sliding bearing, comprising a bearing end cover 2 and a sealed housing, the sealed housing contains a magneto-rheological fluid guide hole 9, a coil cylinder, a coil skeleton 8, a wire hole 7, and a FB-shaped lip Type sealing ring 3, sealing ring gasket 4, magnetic shaft 11, short magnetic sleeve 5, excitation coil, long magnetic cylinder 10, standard bolts, etc.

[0023] Coil cylinder, which is coaxial with the magnetic conduction shaft 11, and adjacent to the magnetic conduction shaft 11; coil bobbin 8, which is coaxial with the magnetic conduction shaft 11, and the outer ring of the coil bobbin 8 is fixed on Inside the inner wall of the coil cylinder; the coil frame 8 is wound with an excitation coil, so that the excitation coil is arranged around the magnetic conduction shaft 11 once.

[0024] Short magnetically conductive sleeve 5 and long magnetically conductive cylinder 10, the short magneticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com