Oil pressure shaping device for motor coil, and method for shaping motor coil

A coil and front motor technology, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., to achieve the effect of simplifying the coil oil pressure shaping device, high safety, and high reference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

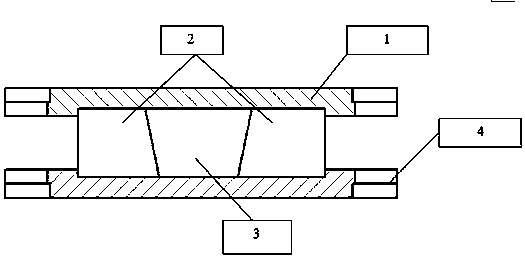

[0028] Such as figure 1 As shown, the motor coil hydraulic shaping device according to the present invention includes an upper pressing plate 1, a lower pressing plate 4, two side molds 2, and a mold core 3.

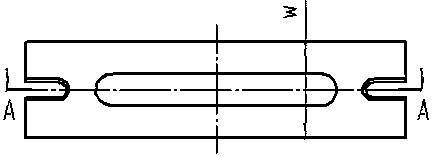

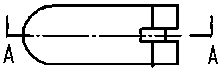

[0029] The structures of the upper pressing plate 1 and the lower pressing plate 4 may be the same or different. But the opposite surface of upper pressing plate 1, lower pressing plate 4 is all provided with groove, and groove length direction and profile are identical, as figure 2 shown. Preferably, the upper pressing plate 1 and the lower pressing plate 4 can be designed to be the same according to the working platform of the hydraulic press, so as to facilitate borrowing and making.

[0030] The two side molds 2 are used to be placed on both sides of the groove of the lower platen 4, and the shape matches the shape on both sides of the groove; the mold core 3 is used to be placed in the middle of the two side molds 2, and the mold core 3 and the two side molds 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com