A high-efficiency stamping device for motor back shell processing and its application method

A technology of punching device and rear shell, applied in the field of punching device, can solve the problems of troublesome maintenance and high use cost of the mechanical arm, and achieve the effects of reducing power equipment, improving punching efficiency and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

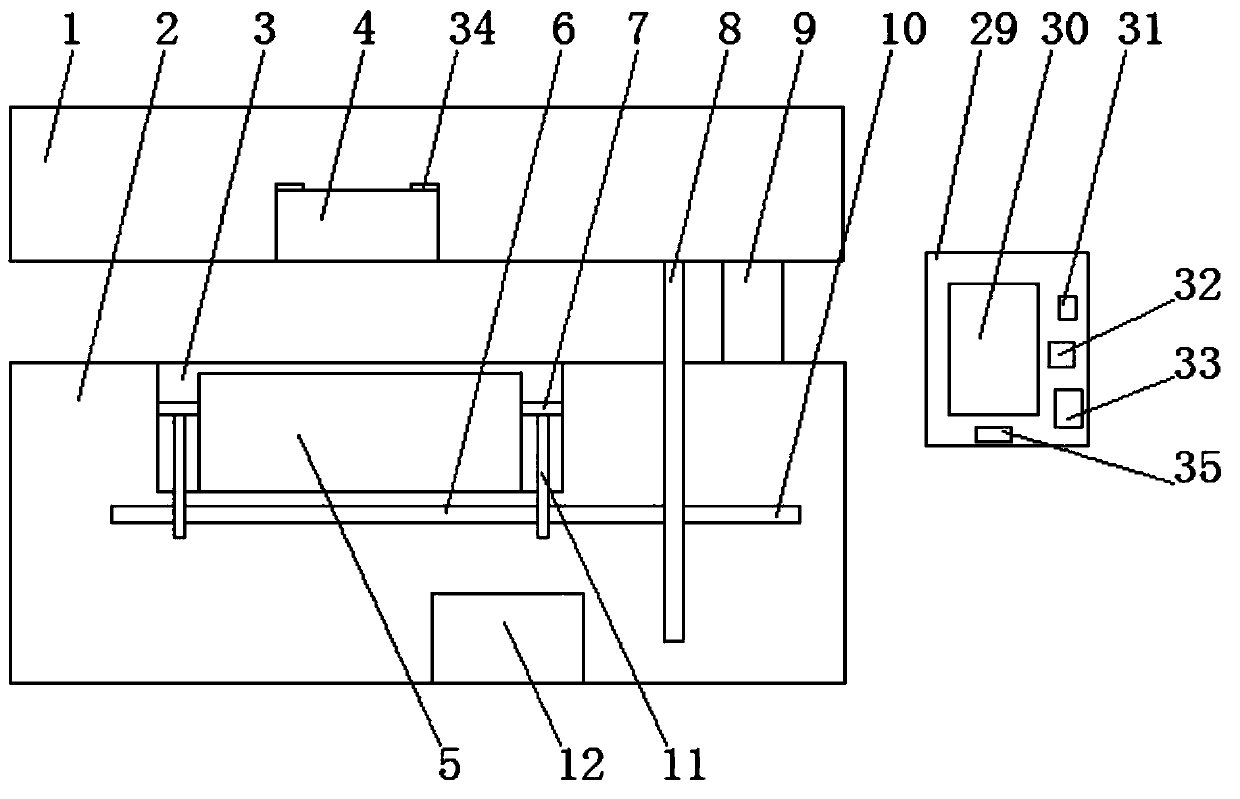

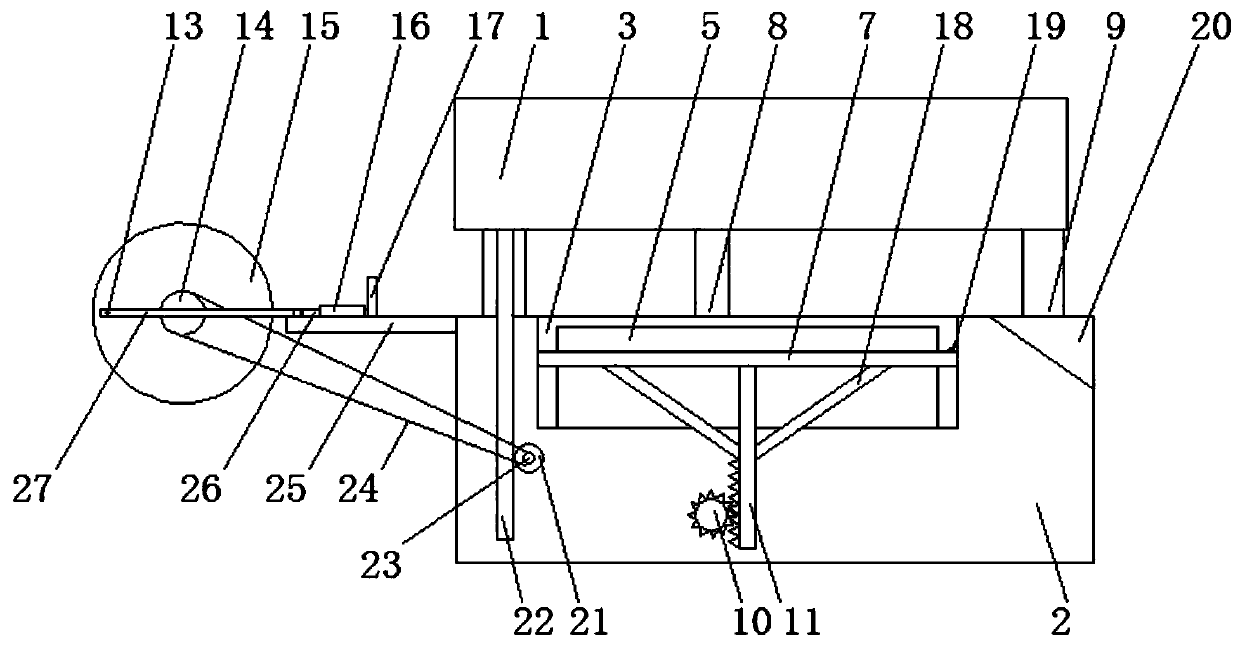

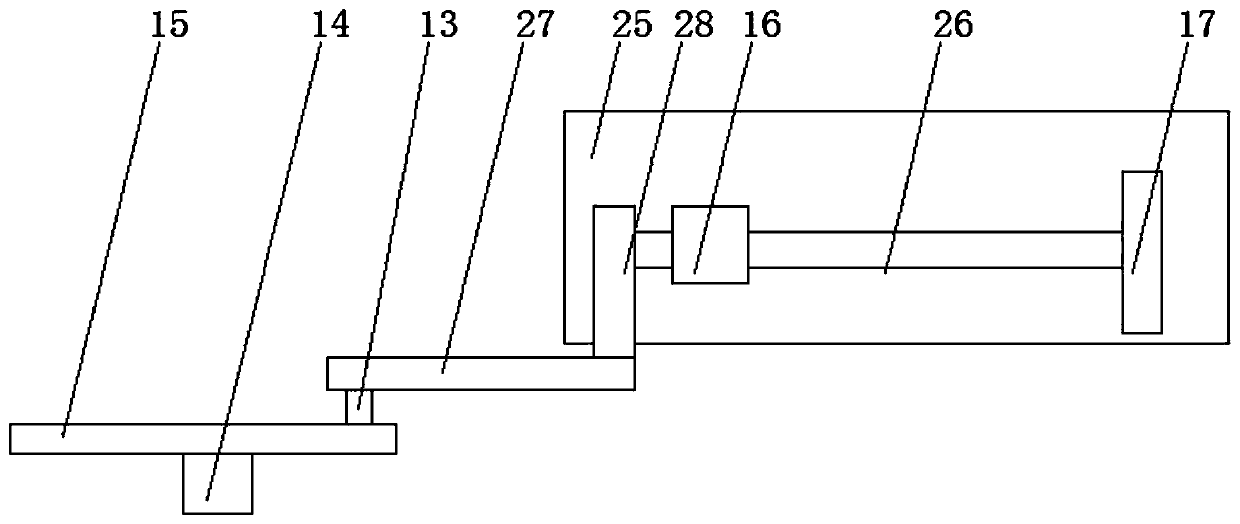

[0027] Embodiment 1, a stamping device for a high-efficiency motor shell equipped with a pressure induction tester, including a stamping base 2, a stamping groove 3 is provided in the middle of the stamping base 2, and a stamping die 5 is provided in the stamping groove 3, so that A top plate 7 is provided between both sides of the stamping die 5 and the stamping groove 3, and the bottom of the top plate 7 is provided with a first fixed rod 11, and the bottom of the first fixed rod 11 is connected to the first rotating shaft 10 through gear engagement. , the upper end of the stamping base 2 is connected to the stamping cover plate 1 through a number of evenly distributed hydraulic rods 9, the middle part of the bottom of the stamping cover plate 1 is provided with a punching machine 4 matching the stamping die 5, and the stamping cover plate 1 One side of the bottom is provided with a fixedly connected first gear bar 8, the bottom of the first gear bar 8 is connected to the fir...

Embodiment 2

[0032]Embodiment 2, a stamping device for a high-efficiency motor shell equipped with a pressure induction tester, including a stamping base 2, a stamping groove 3 is provided in the middle of the stamping base 2, and a stamping die 5 is provided in the stamping groove 3, so that A top plate 7 is provided between both sides of the stamping die 5 and the stamping groove 3, and the bottom of the top plate 7 is provided with a first fixed rod 11, and the bottom of the first fixed rod 11 is connected to the first rotating shaft 10 through gear engagement. , the upper end of the stamping base 2 is connected to the stamping cover plate 1 through a number of evenly distributed hydraulic rods 9, the middle part of the bottom of the stamping cover plate 1 is provided with a punching machine 4 matching the stamping die 5, and the stamping cover plate 1 One side of the bottom is provided with a fixedly connected first gear bar 8, the bottom of the first gear bar 8 is connected to the firs...

Embodiment 3

[0037] Embodiment 3, a stamping device for a high-efficiency motor shell equipped with a pressure induction tester, including a stamping base 2, a stamping groove 3 is provided in the middle of the stamping base 2, and a stamping die 5 is provided in the stamping groove 3, so that A top plate 7 is provided between both sides of the stamping die 5 and the stamping groove 3, and the bottom of the top plate 7 is provided with a first fixed rod 11, and the bottom of the first fixed rod 11 is connected to the first rotating shaft 10 through gear engagement. , the upper end of the stamping base 2 is connected to the stamping cover plate 1 through a number of evenly distributed hydraulic rods 9, the middle part of the bottom of the stamping cover plate 1 is provided with a punching machine 4 matching the stamping die 5, and the stamping cover plate 1 One side of the bottom is provided with a fixedly connected first gear bar 8, the bottom of the first gear bar 8 is connected to the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com