A laser micro-propulsion device and method based on nanofluid micro-droplet working medium

A nano-fluid and micro-droplet technology, applied in the direction of aerospace vehicle propulsion system devices, aerospace vehicle guidance devices, tools, etc., can solve problems such as small specific impulse, achieve the goal of improving the impulse coupling coefficient and comprehensively improving the propulsion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a further understanding and understanding of the features, purposes and functions of the present invention, the design concept of the present invention will be described below in conjunction with specific embodiments, so as to understand the characteristics of the present invention, the detailed description is as follows:

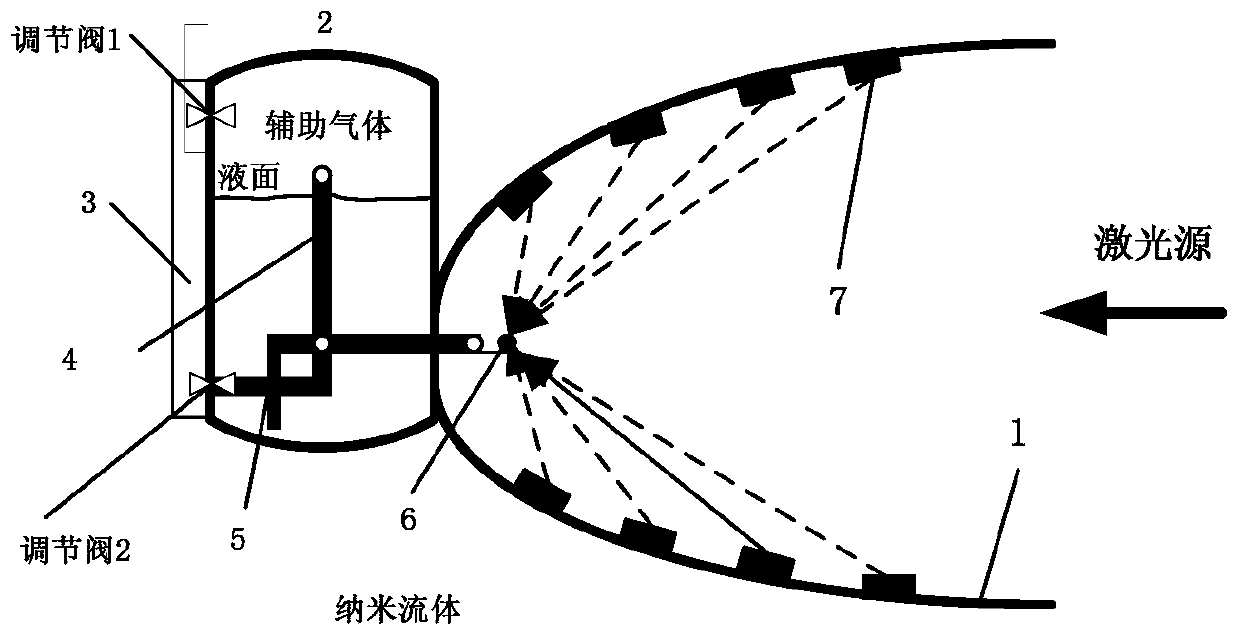

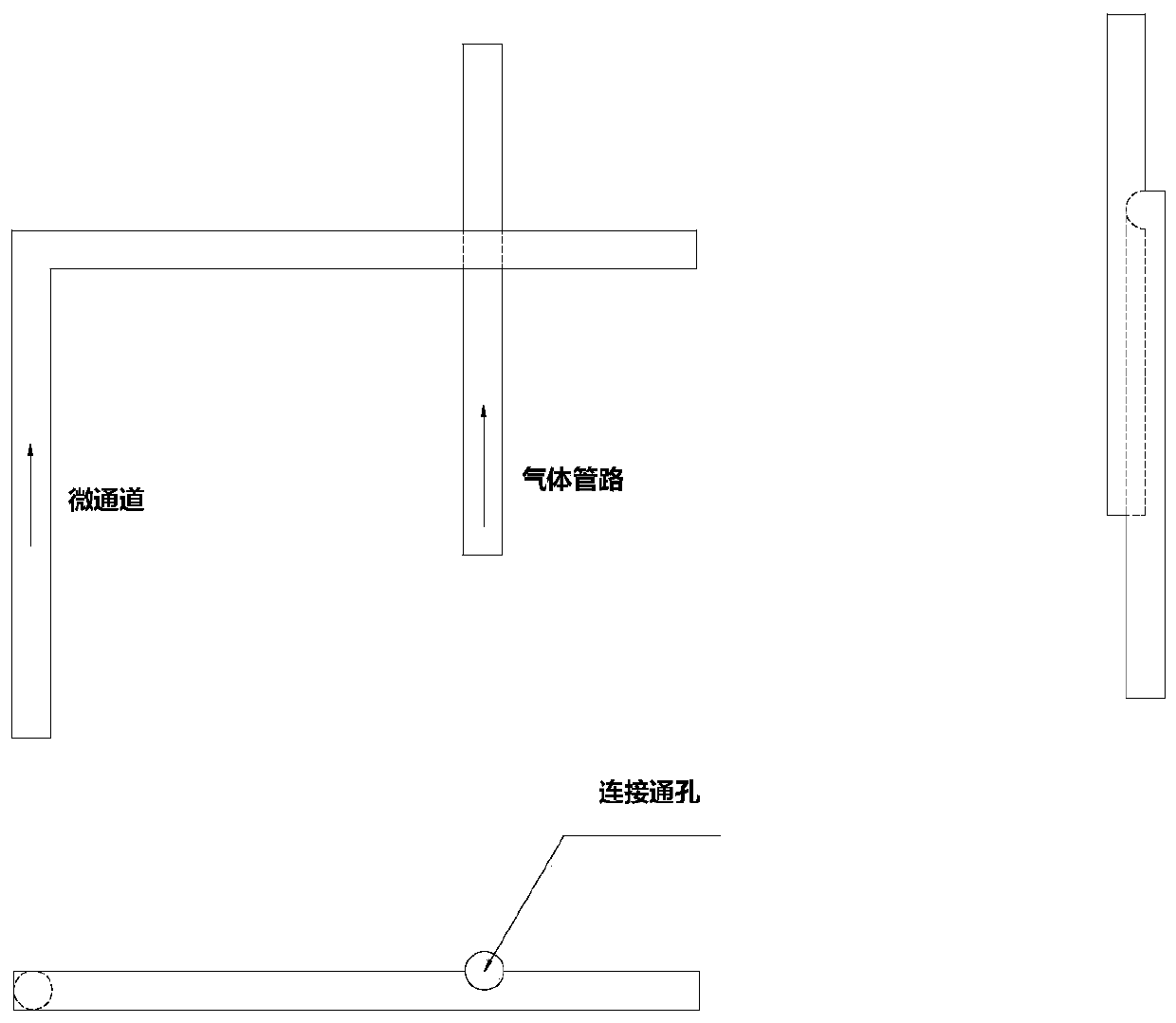

[0022] The laser micro-propulsion device based on nanofluid micro-droplet working medium mainly includes a thruster housing, a working medium cabin, an auxiliary gas storage tank, microfluidic components and nanofluid working medium.

[0023] The thruster shell adopts a low aerodynamic resistance shape design of a rotating parabola. The inner surface of the shell is arranged with high-reflectivity mirrors at intervals. The mirror surface is coated with a super-hydrophobic coating to prevent the jet fluid from adhering to the mirror surface and causing a decrease in mirror reflectivity. The micro-thrust is generated by the reaction for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com