Synthetic leather winding equipment

A synthetic leather and equipment technology, which is applied in the direction of winding strips, textiles and papermaking, sending objects, etc., can solve the problems of offset, complicated operation, loose release paper and synthetic leather, etc., and achieves small errors and good results. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the drawings.

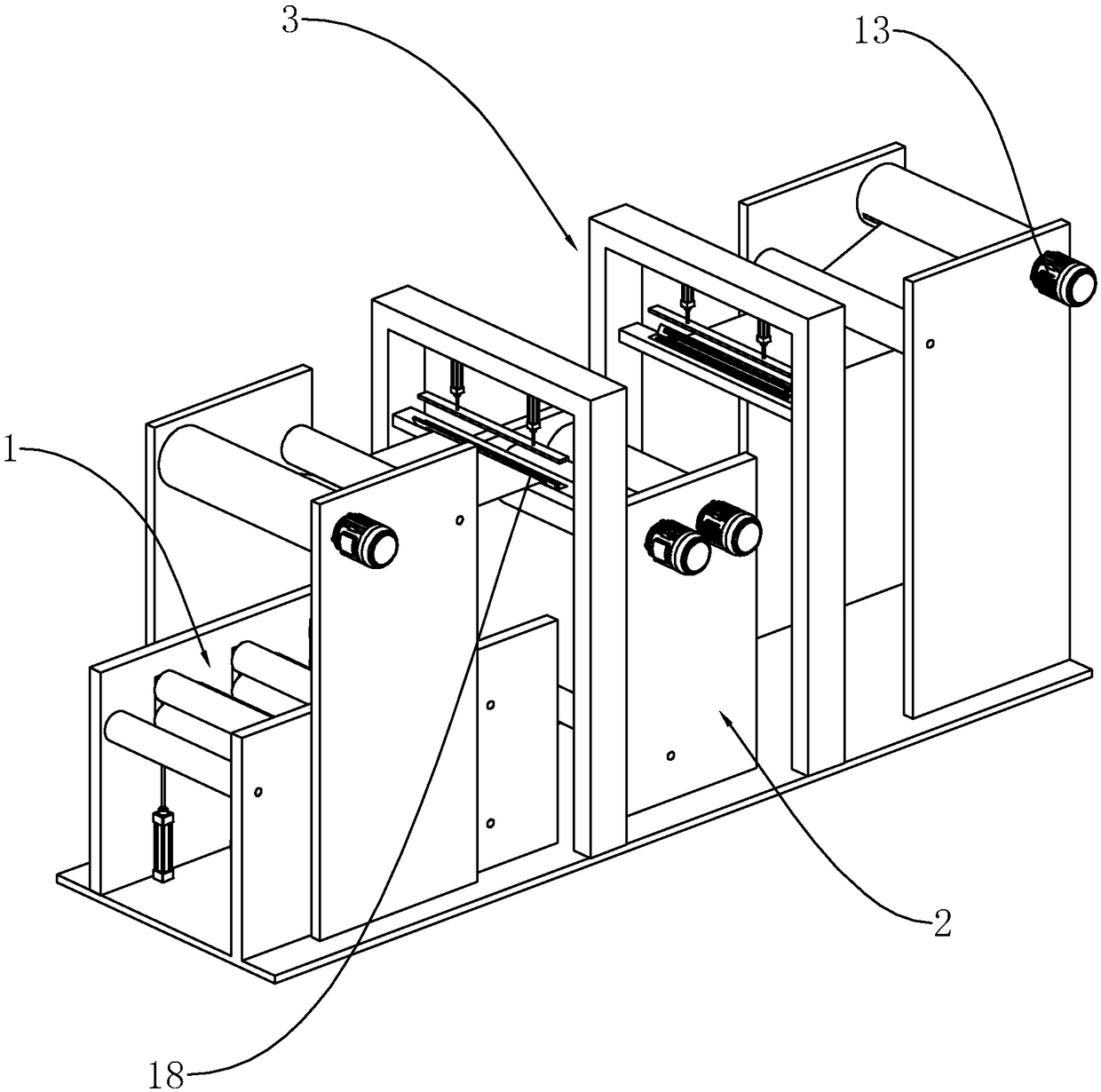

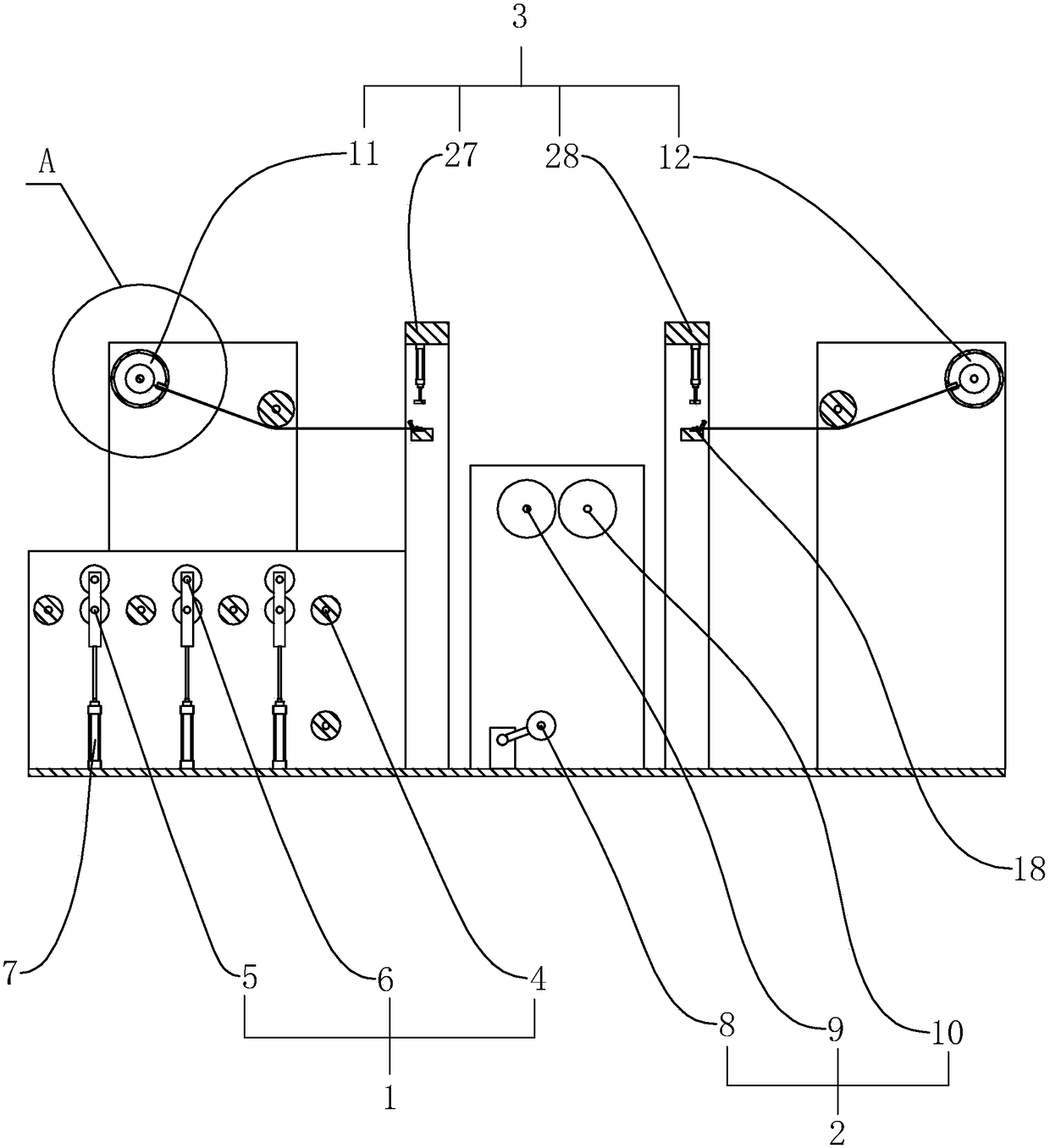

[0033] This embodiment discloses a synthetic leather winding device, such as figure 1 As shown, it includes a feeding module 1, a separation module 2 and a winding module 3. The semi-finished synthetic leather enters from the feeding module 1, and is separated into synthetic leather and release paper after passing through the separation module 2, and then separated by the winding module 3. Winding.

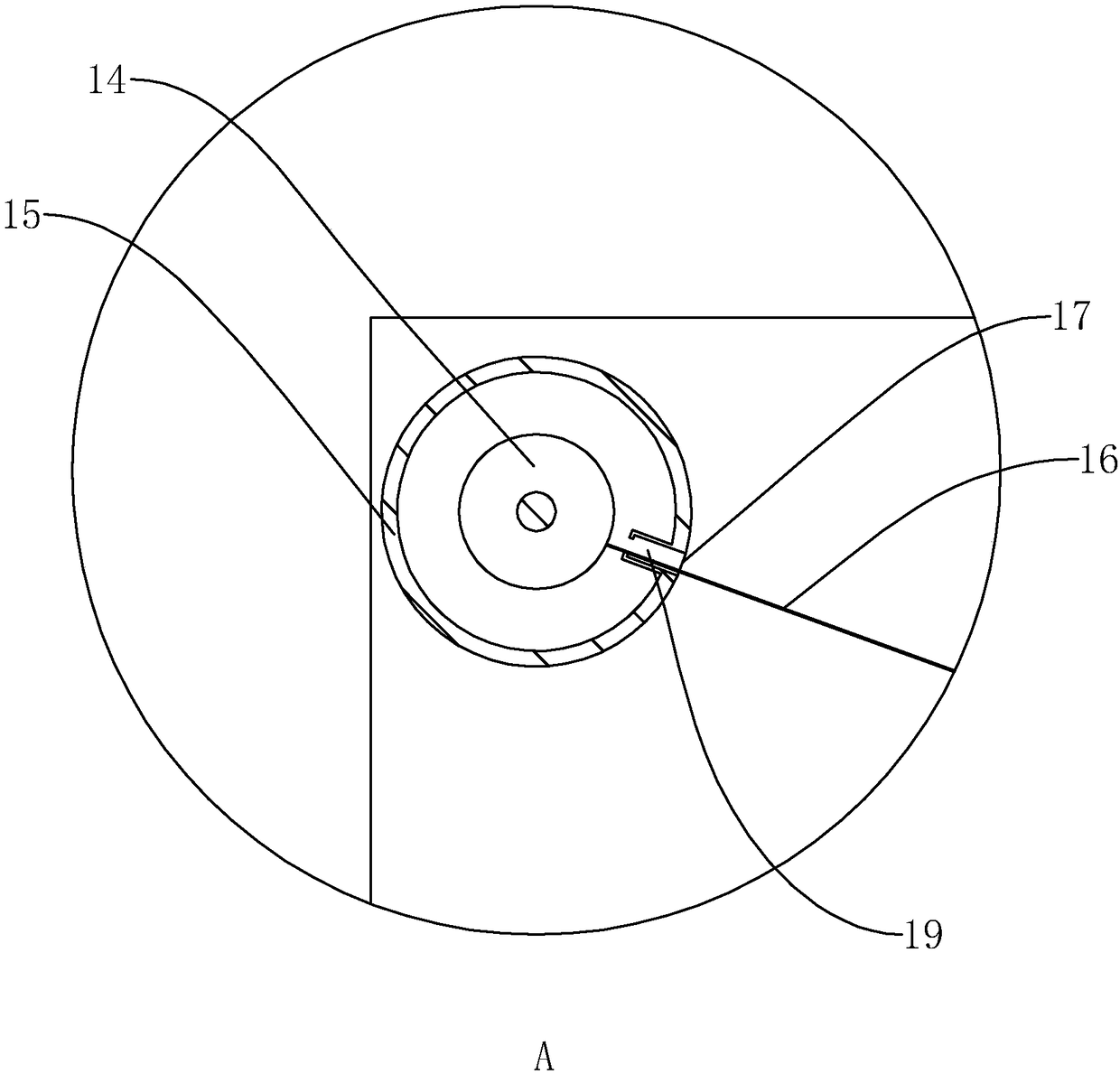

[0034] Such as figure 2 As shown, the feeding module 1 includes several conveying rollers 4 arranged equidistantly in the horizontal direction, several auxiliary rollers 5 installed between any two adjacent conveying rollers 4, and a buffer roller installed directly above the auxiliary rollers 5. 6. The auxiliary roller 5 is flush with the conveying roller 4, and there is a gap between the buffer roller 6 and the auxiliary roller 5. Both ends of the auxiliary roller 5 and the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com