Vehicle main transmission and control method thereof

A main drive, vehicle technology, applied in the direction of transmission, control device, vehicle components, etc., can solve the problems of easy misoperation, no differential function, inconvenient operation, etc., and achieve good driving performance and overall structure. Compact, easy-to-operate mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

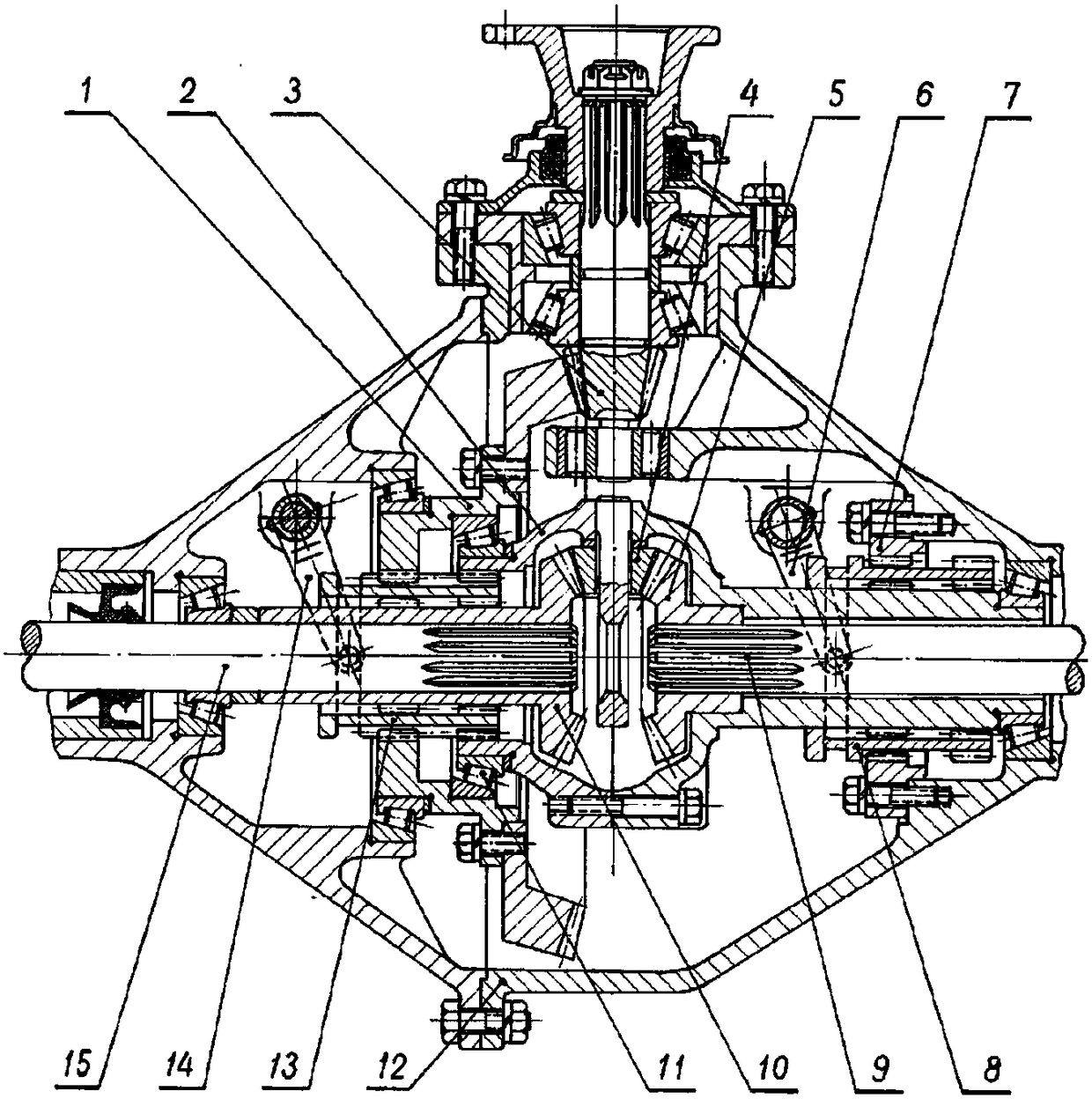

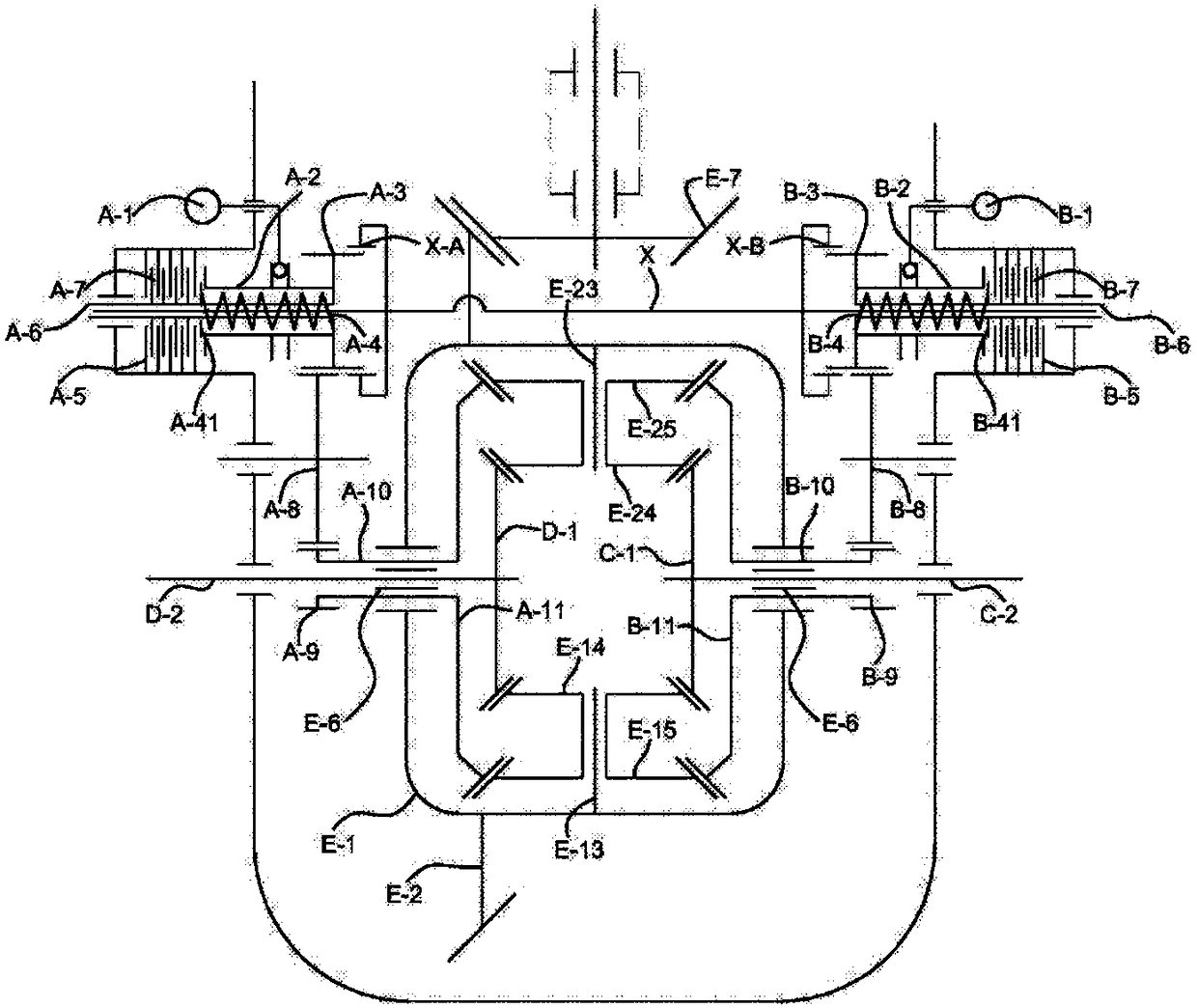

[0051] In this embodiment, the driven bevel gear 102 is fixedly connected to the housing 105 of the first differential, and the gear shaft of the driven bevel gear is coaxially arranged with the left half shaft and the right half shaft of the first differential; Two planetary gears 104 / 108 are arranged on the planetary shaft 103 of a differential, and the first differential drives the side gears located on both sides of the planetary shaft to rotate through the two planetary gears. The number of planetary gears can also be arranged into 4 according to transmission requirements, which is prior art.

[0052] In the first differential and the second differential, the side gears 109 / 106 / 210 / 209 / 309 / 310 are in driving connection with the corresponding side shaft ends through involute splines.

[0053] The right half shaft of the second differential in the left commutator assembly 2 is the same shaft 110 as the left half shaft of the first differential; The right half shaft of a di...

Embodiment 2

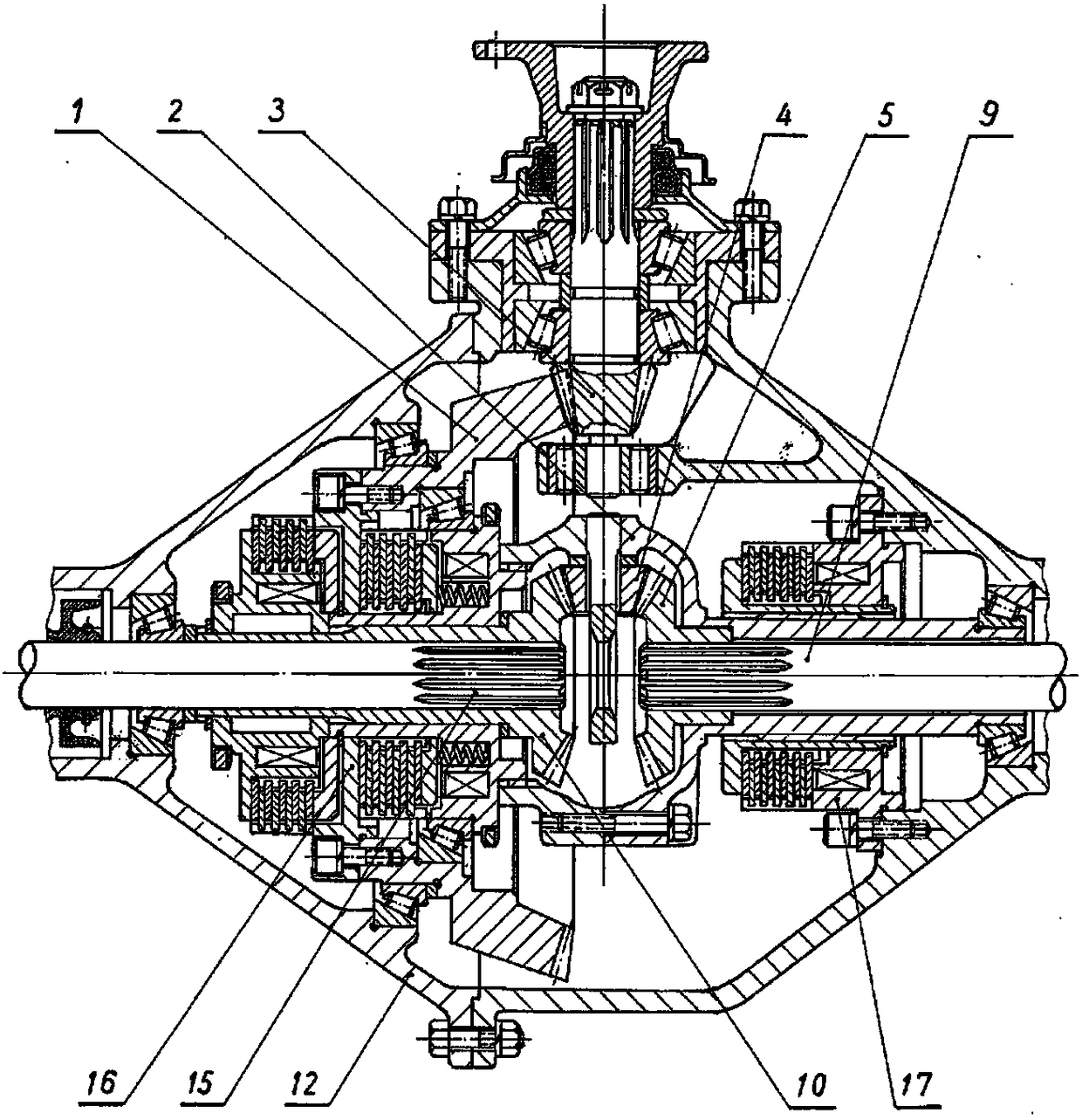

[0069] refer to Figure 4 In the illustrated embodiment, in this embodiment, the main reducer assembly 1 is a conventional final reducer structure, the driven bevel gear 102 is fixedly connected with the first differential case 105; the planetary gears 104 and 108 are arranged on the planetary On the shaft 103, meshed with the side gears 106 and 109, the planetary gears of the first differential can be arranged in two according to transmission requirements (such as Figure 4 middle 104 and 108) or four; both ends of the left half shaft 110 and the right half shaft 107 are arranged with involute splines, and the opposite ends of the two are matched with the involute splines on the side gears 109 and 106 respectively .

[0070] The rotation of the driven bevel gear 102 prompts the planetary shaft 103 fixedly connected to the first differential housing 105 to drive the planetary gears 104 and 108 to rotate, and when there is no differential speed, the left half shaft 110 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com