Green tea drying treatment method

A drying treatment and green tea technology, applied in the directions of tea drying, tea treatment before extraction, drying of solid materials, etc., can solve the problems of uneven heating, time-consuming and labor-intensive green tea, achieve uniform stirring speed, reduce workload, and distribute tea leaves. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

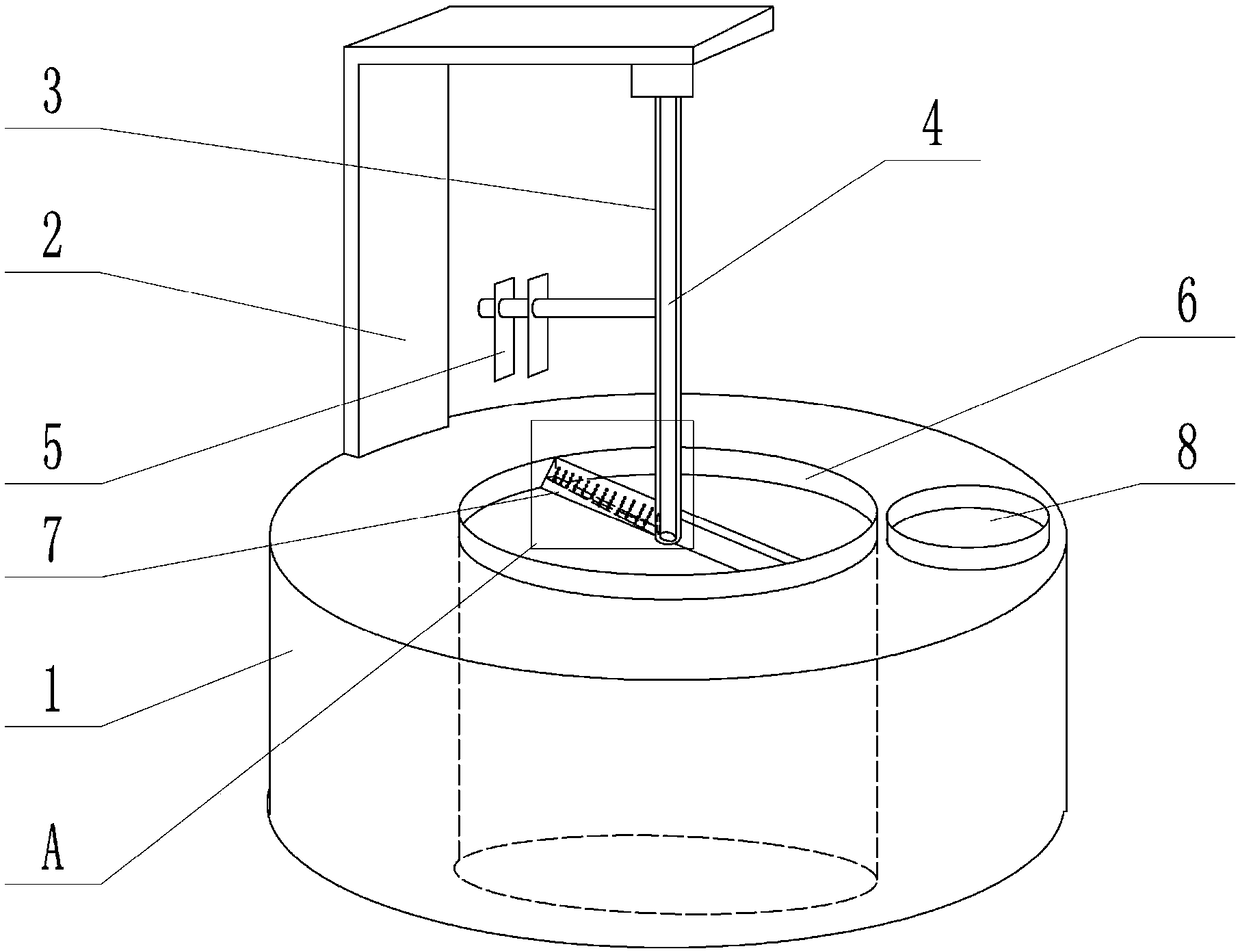

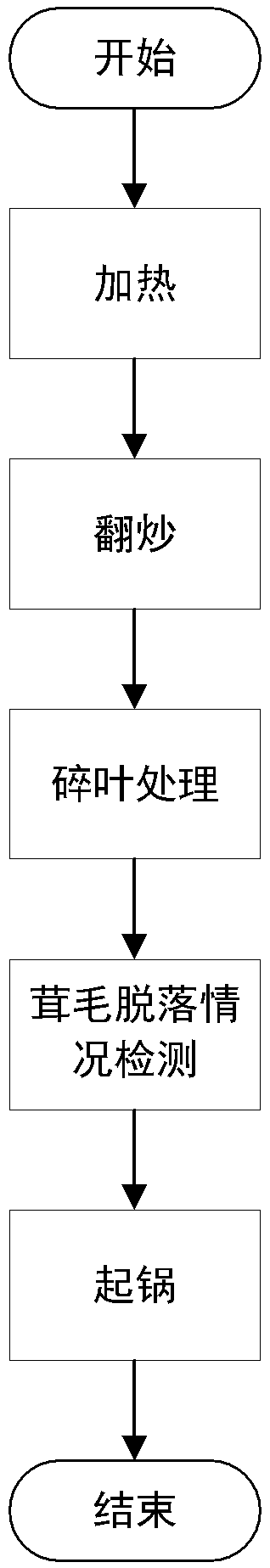

[0036] as attached image 3 Shown, a kind of green tea drying processing method comprises the steps:

[0037] Heating: Pour the tea leaves into the flat-bottomed pot body 6 and lay them flat, then press the button on the installation platform, the button sends an electrical signal to the microcontroller electrically connected to it, and the microcontroller controls the cylinder after receiving the electrical signal The deflation valve of the cylinder is opened, and the upper mounting frame 2 of the mounting frame 2 fixedly connected to the cylinder piston moves downward under the action of gravity, and the bottom end of the hollow rotating shaft 3 and the center position of the pot body 6 abut against; then the microcontroller controls the motor to rotate , at the same time, the microcontroller first controls the electric heater in the heating table 1 to start working;

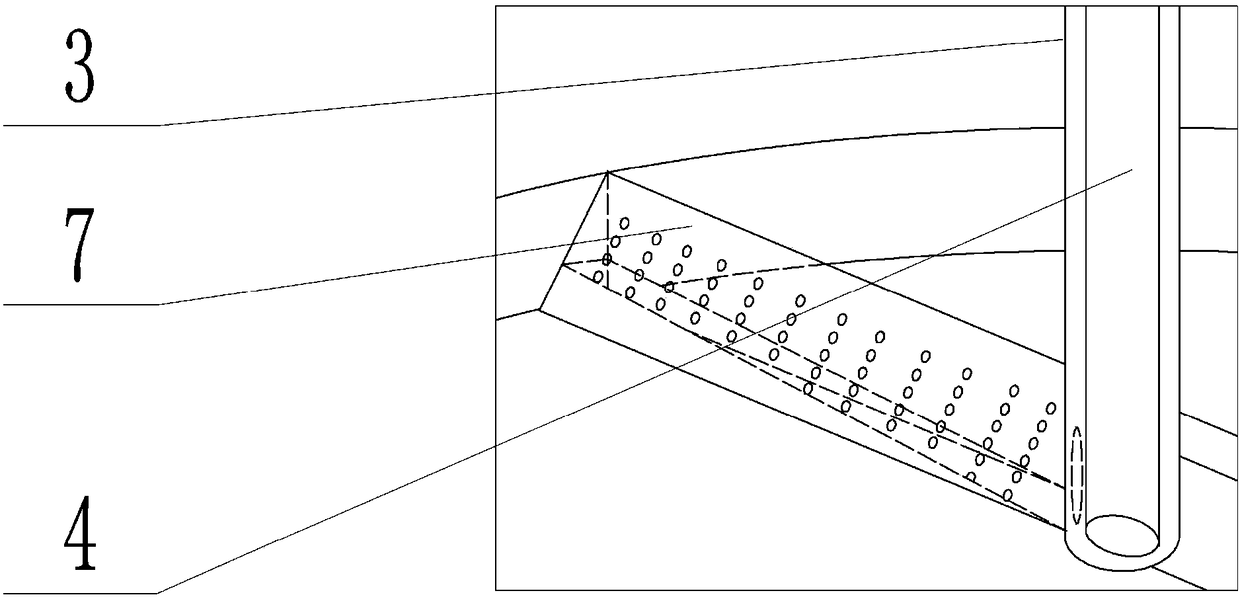

[0038]Stir frying: the rotation of the motor drives the rolling shaft 4 fixedly connected on the output sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com