Weight analysis method for noise source of engine

A technology of weight analysis and engine, applied in computer-aided design, measurement of ultrasonic/sonic/infrasonic, special data processing applications, etc., can solve the lack of consistency inspection standards, the small role of noise source identification, and the difficulty of ensuring the consistency of the coordination judgment matrix and other issues to achieve a more scientific effect in calculating the contribution weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

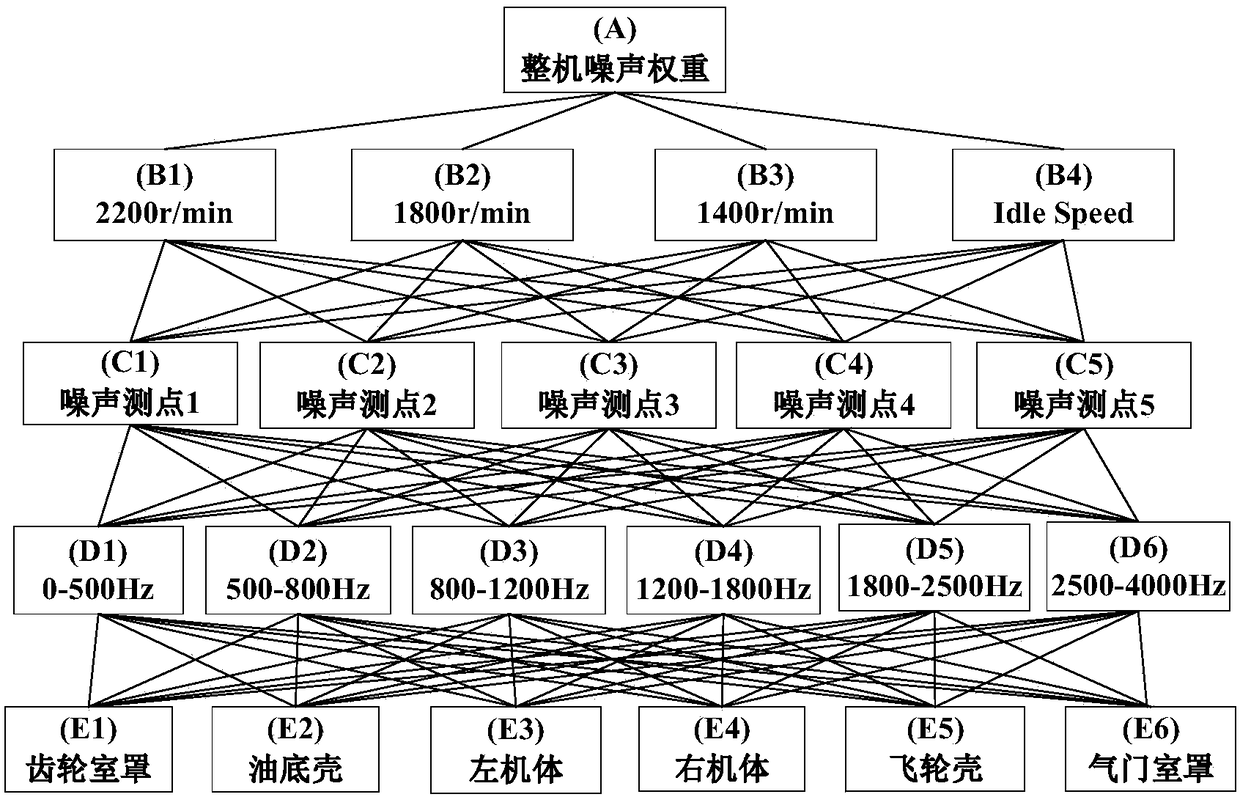

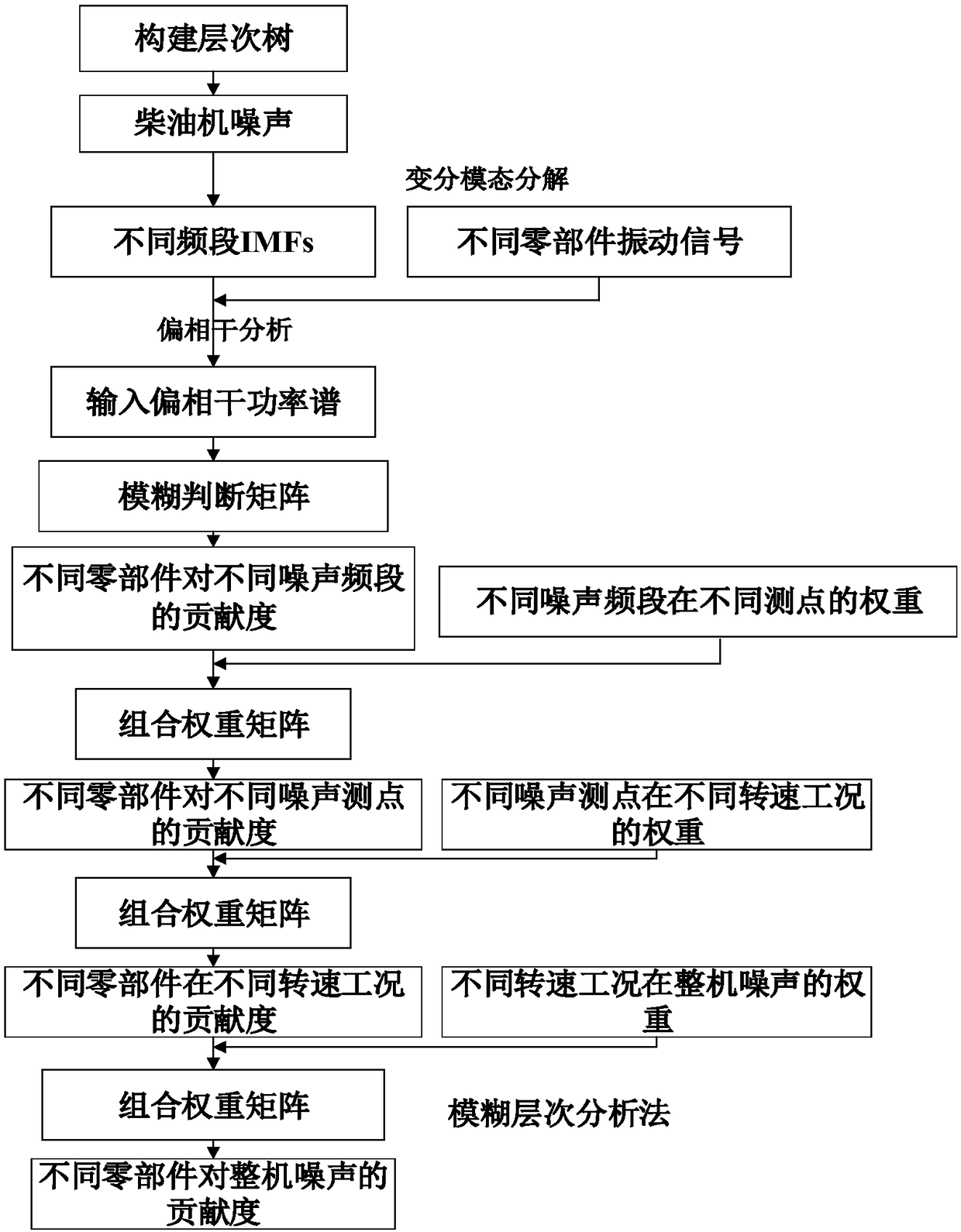

[0026] The invention protects an engine noise source weight analysis method, comprising the following steps:

[0027] (1) Acquisition of vibration and noise signals: refer to GB / T 1859-2000 Engineering Method and Simple Method for Measuring Radiated Air Noise of Reciprocating Internal Combustion Engines. Test the vibration and noise signals of diesel engines under different working conditions.

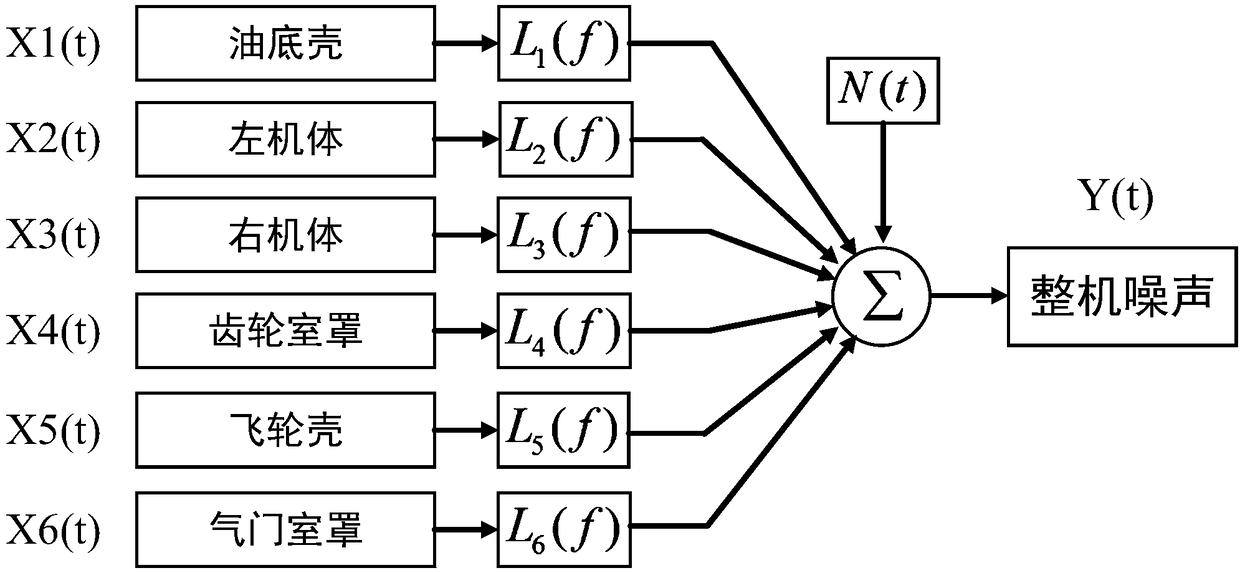

[0028] (2) VMD decomposition of the noise signal: VMD decomposition is performed on the noise signal to obtain IMFs of different frequency bands. And the decomposed IMF is subjected to wavelet transformation to obtain decomposed signals of different frequency band noises. VMD is a decomposition mode that transforms the signal to be decomposed into non-recursive and variational modes, which solves the mode mixing and mode splitting problems of EEMD to a certain extent. The IM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com