Hot pot ingredient barrel and automatic food material separation hot pot device with same

A technology of hot pot ingredients and barrels, applied in kitchen utensils, home utensils, plug-ins, etc., can solve the problems of turbid soup, loss of nutritional value of ingredients, toxic substances, etc., and achieve good separation, avoid nutrient loss, and avoid the production of harmful substances. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

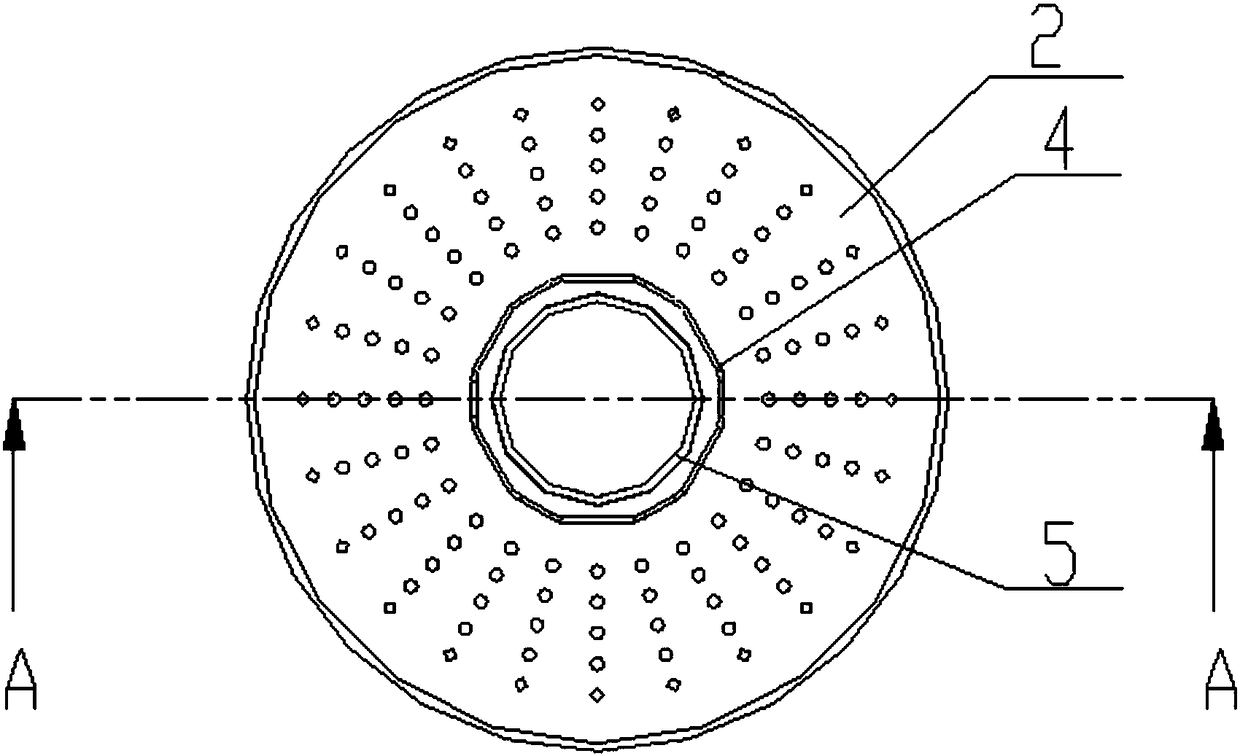

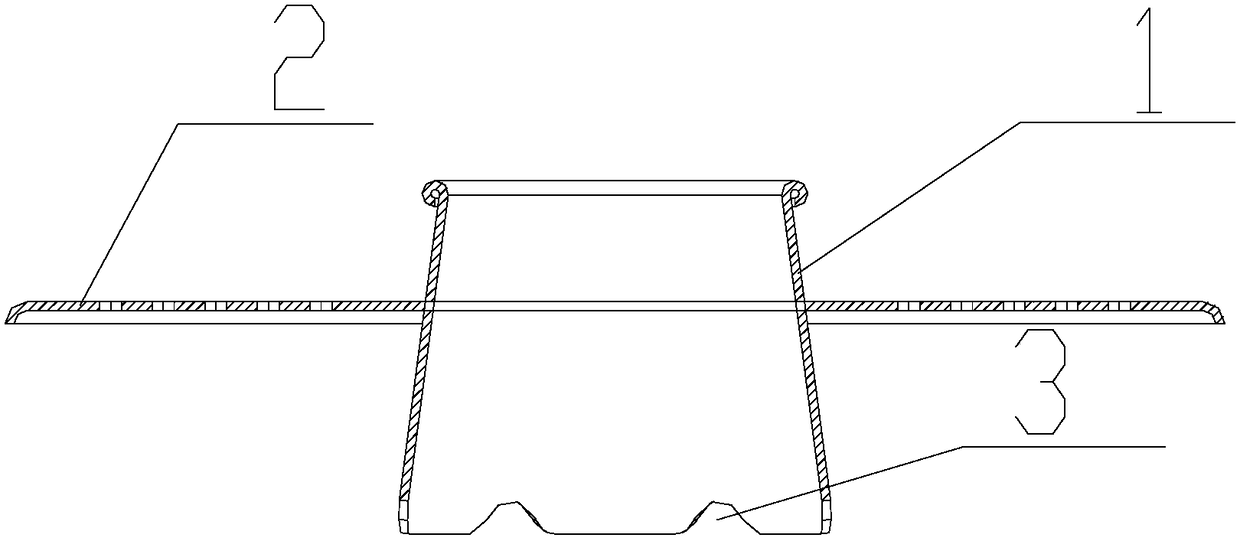

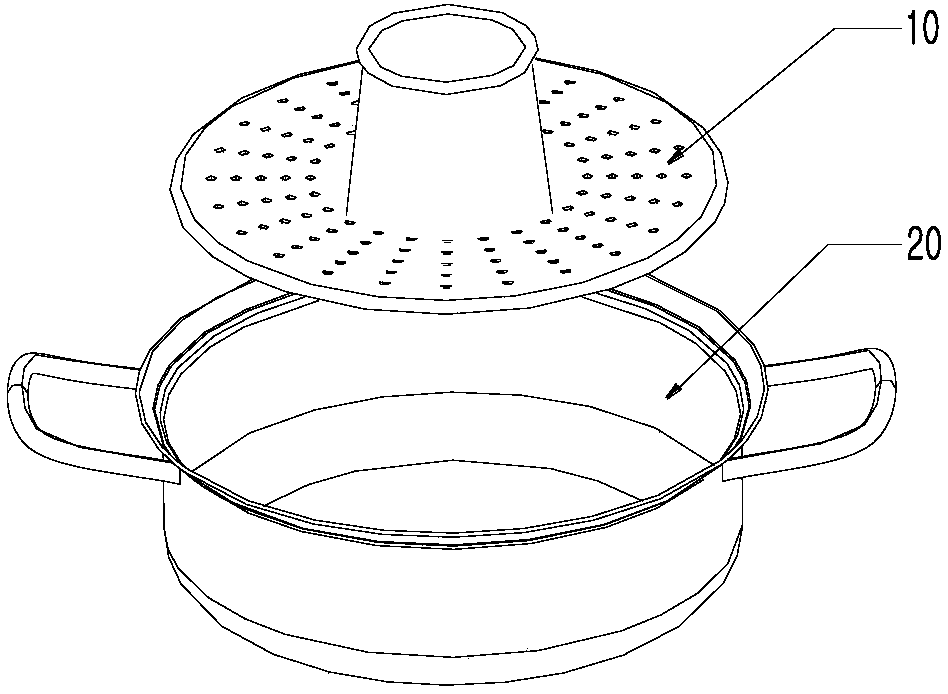

[0043] Carry out the experimental test of the ejection effect of the automatic food separation hot pot device of the present invention, the barrel body 1 is a cylinder, and the notch 3 in the lower part of the barrel body 1 is provided with the same area, and the barrels with different diameters of the upper opening 4 and the lower opening 5 are placed separately. In a pot with the same volume, structure, material, etc., add water with a volume of V (so that the water level line 7 is at 2 / 3 of the height of the tray 2) and a temperature of T1. After the water boils and stabilizes, the upper end of the soup pot barrel is opened for 4 soup. The amount of juice ejection, record the diameter of the opening 4 at the upper end of the cylinder body 1 as D1, the unit of D1 is mm, the diameter of the opening 5 at the lower end of the recording body is D2, the unit of D2 is mm, and the ejection amount is Q (that is, The amount of soup ejected per minute when heated to a steady boil (kg)....

Embodiment 2

[0048] According to the experimental results of Example 1, the cylinder body 1 is a cylinder, and the diameter D1 of the opening 5 at the lower end of the cylinder body 1 is selected to be 100 mm, and the diameter D2 of the upper end opening 4 is 80 mm, and the area of the notch 3 at the bottom of the cylinder body 1 is sprayed. To test the impact of volume, put the barrels with different areas of the lower notch 3 into the same pot with the same volume, structure, and material, add water with a volume of V and a temperature of T1, and check that the boiling of the water is stable. For the amount of soup ejected, record the area of the notch 3 at the bottom of the barrel 1 as S1, and the unit of S1 is mm 2 , the ratio of the area of the notch 3 at the bottom of the barrel body 1 to the open area of the lower end of the barrel body 1 is A, and the amount of ejection is Q (the amount kg of soup ejected per minute when the heating is stable and boiling). The results are s...

Embodiment 3

[0053] According to the experimental results of embodiment 1 and embodiment 2, the cylinder body 1 is a cylinder, the diameter D1 of the lower end opening 5 of the cylinder body 1 is selected to be 100mm, the diameter D2 of the upper end opening 4 is 80mm, and the area of the notch 3 occupies the cylinder body 1 The proportion of the mouth area is 9%, and the experimental test is carried out on the influence of the distance d between the material tray 2 and the top of the barrel on the coverage area of the sprayed soup. Put the barrels with different distances d in the same pot with the same volume, structure, and material, and add For water with a volume of V and a temperature of T1, detect the coverage area of the soup pot 2 sprayed from the upper mouth of the soup pot barrel after the water boils stably (calculate the coverage area S of the soup by measuring the distance diameter of the soup sprayed and sputtered) , record the distance between all the trays 2 and the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com