Precision surgical energy control system

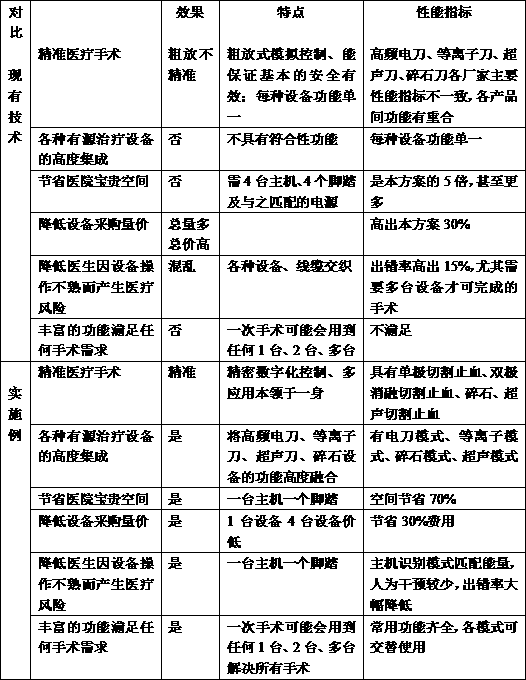

An energy control and precise technology, applied in the field of precise surgical energy control system, can solve the problems of backward technology, rough functional parameters, lack of identification and matching between the main engine and accessories, so as to reduce medical risks, save valuable space, and reduce procurement volume. price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

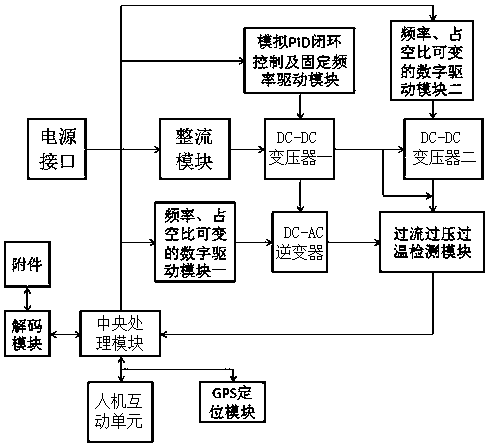

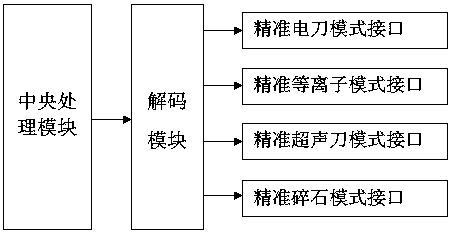

[0017] A precise surgical energy control system, such as figure 1 , Including central processing module, power interface, rectifier module, DC-DC transformer one, DC-DC transformer two, analog PID closed-loop control and fixed frequency drive module, digital drive module with variable frequency and duty cycle 1. Frequency and duty cycle Variable air-ratio digital drive module II. DC-AC inverter, over-current, over-voltage and over-temperature detection module and decoding module. The rectifier module is connected to the power supply through the power interface, and the rectifier module is connected to the DC-DC transformer through a DC-DC transformer. Two, DC-DC transformer one, DC-DC transformer two, and DC-AC inverter are respectively connected to the central processing module through the over-current, over-voltage and over-temperature detection module, and the central processing module is connected through the digital drive module with variable duty cycle. For DC-AC inverters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com