Manual low-cost casting method of large aluminum alloy shell

An aluminum alloy, low-cost technology, used in casting mold components, casting molding equipment, metal processing equipment, etc., can solve the problems of difficulty in adapting to short, fast, easy to form shrinkage holes, and high tooling costs, achieving simple tooling and casting methods, eliminating the need for Cracks and pores, the effect of simplifying production tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

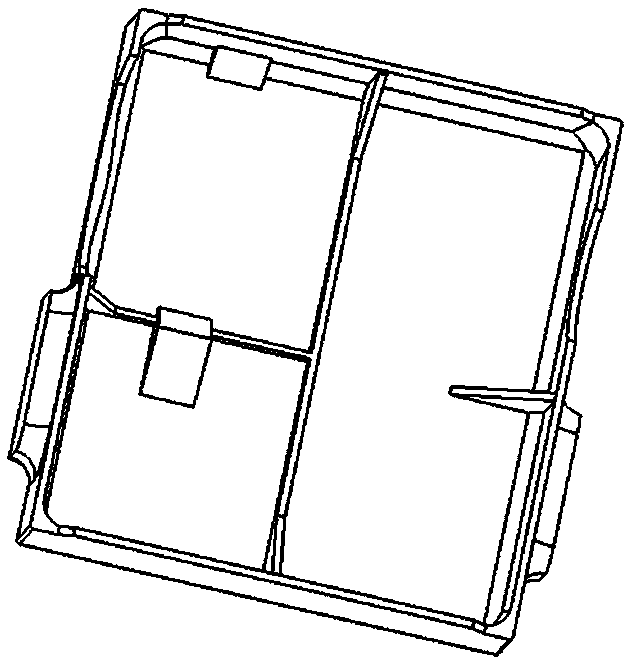

[0036] The bottom of the cavity of the cast aluminum alloy shell is provided with a plane, the shell length: 1000mm × width: 850mm × height: 400mm, the wall thickness is 10-50mm, and the material is aluminum-copper alloy.

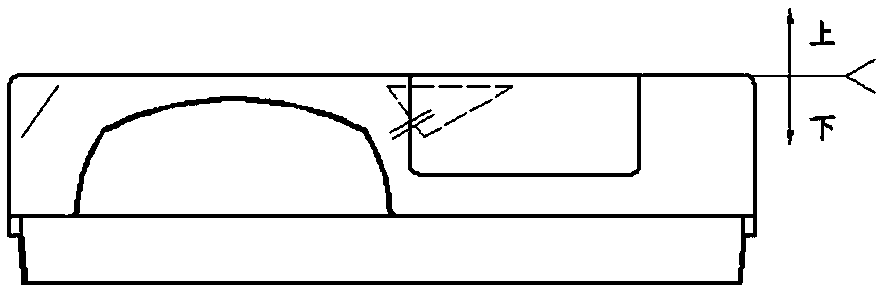

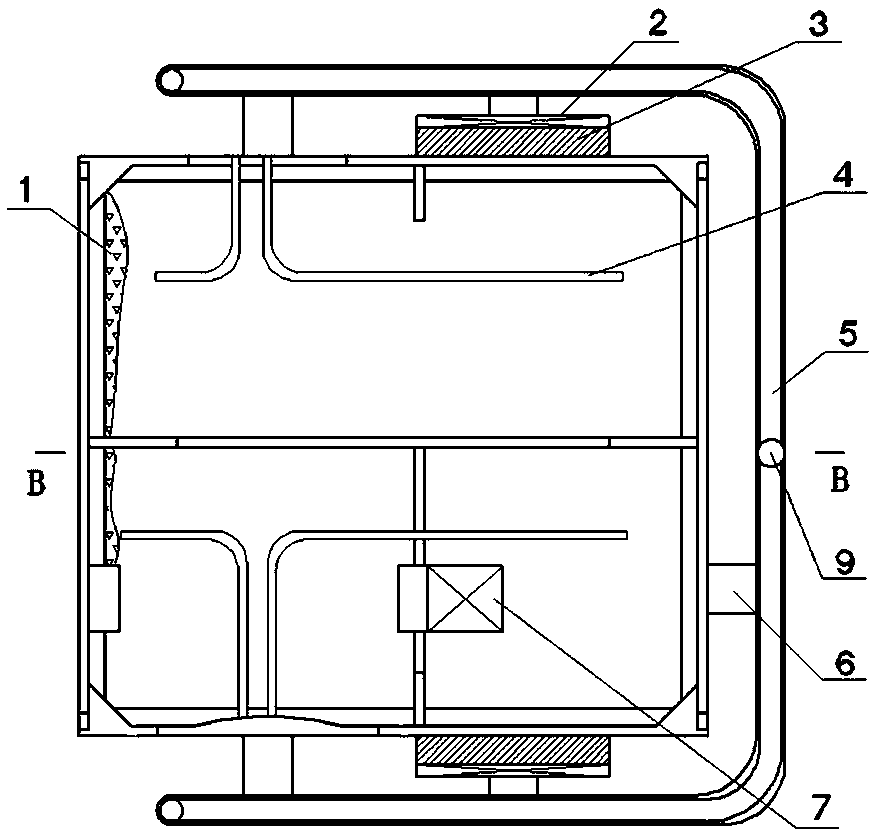

[0037] 1. Process the wooden mold of the shape of the part according to the casting drawing of the shell, place the wooden mold with the plane up and the inner cavity down in the iron frame made in advance, mix 40 meshes of 350kg chrome magnesia, 7kg epoxy resin, 3.5 Kg phosphoric acid was mixed on a bowl sand mixer for 40s to obtain furan resin sand; press Figures 2 to 4 As shown in the figure, place cold iron I2 in the thick part of the mold and place chilled sand 1 at the chamfer, and fill the mold with the aforementioned mixed furan resin sand to make the lower sand mold; set the top-casting gating system on the upper sand mold, and the riser 3 is located in the upper part of the mold. In the thick and large part of the upper sand mold, 15 air outlet h...

Embodiment 2

[0042] The cast aluminum alloy casing is the same as in Example 1.

[0043] 1. Process the wooden mold of the shape of the part according to the casting drawing of the shell, and then paint 2mm of epoxy resin with 60wt% 815B curing agent on the surface of the wooden mold, and place the wooden mold with the plane on the top and the inner cavity downward In the iron frame, mix 380kg carbon sand with 60 meshes, 7.6kg epoxy resin and 3.8kg phosphoric acid on a bowl sand mixer for 60s to obtain furan resin sand; Figures 2 to 4 As shown, place cold iron Ⅰ 2 on the local thick part of the mold and place chilled sand 1 on the chamfer, and fill the mold with the aforementioned mixed furan resin sand to make the lower sand mold; For the thick part of the upper sand mold, 25 air outlet holes 10 are evenly drilled on the top of the upper sand mold; the mold is solidified for 14 hours and removed from the iron frame to obtain the mold.

[0044] 2. Put cold iron Ⅱ7 in the core box as show...

Embodiment 3

[0048] The cast aluminum alloy casing is the same as in Example 1.

[0049] 1. Process the wooden mold of the shape of the part according to the casting drawing of the shell, place the wooden mold plane on the top and the inner cavity downward in the pre-made iron frame, mix 360kg chrome sand of 50 mesh with 6.8kg epoxy resin, 3.3 Mix 50 kg of phosphoric acid on a bowl-type sand mixer for 50 seconds to obtain furan resin sand; place cold iron and chamfering chilled sand on the local thick parts of the mold as shown in 2 to 4, and fill the mold with the aforementioned mixed furan resin sand. The lower sand mold; set the top pouring pouring system on the upper sand mold, the riser 3 is located at the thick part of the upper sand mold, and 20 air outlet holes 10 are evenly drilled on the top of the upper sand mold; the mold is solidified for 13 hours and the iron frame is removed to obtain the mold.

[0050] 2. Put cold iron II 7 in the core box as shown in 2 to 4, mix 180kg chro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com