Method for rapidly preparing copper nanowires at low cost

A copper nanowire, low-cost technology, applied in the field of metal nanowires, can solve problems such as cumbersome processes and costs, and achieve the effects of cost reduction, reaction rate improvement, and simple and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The method for rapidly preparing copper nanowires at low cost in this embodiment comprises the following steps:

[0029] (1) Weigh 18.9 mg of copper chloride powder, 3 mg of copper nitrate powder, 160 mg of hexadecylamine, and 50 mg of glucose powder, place them in a strain bottle, add deionized water and magnets, and make 10 ml The mixture A;

[0030] (2) Stir the mixed solution A at a speed of 300r / min for 10h at room temperature to obtain a uniformly dispersed copper ion complex, turn off the stirring, and heat at 100°C for 6h to obtain the mixed solution B;

[0031] (3) After taking out the mixed solution B from the strain bottle, it was centrifuged and washed with 80°C deionized water at 8000r / min.

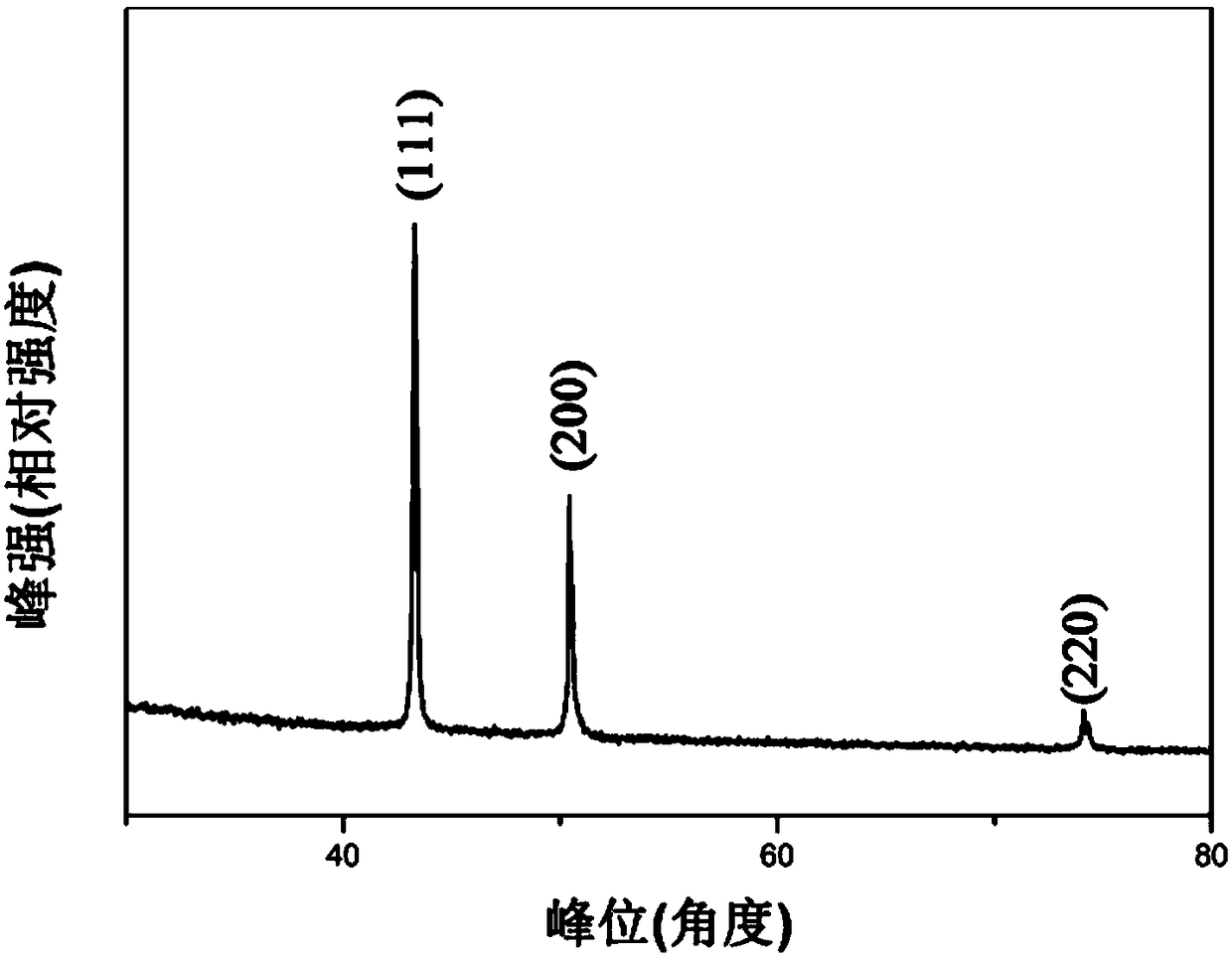

[0032] figure 1 It is the X-ray diffraction spectrogram of the copper nanowire prepared in embodiment 1, by figure 1 It can be seen that the prepared product is a pure face-centered cubic metal copper nanowire. figure 2 It is the scanning electron micrograph of th...

Embodiment 2

[0034] The method for rapidly preparing copper nanowires at low cost in this embodiment comprises the following steps:

[0035] (1) Weigh 16.8mg of copper chloride powder, 6mg of copper nitrate powder, 170mg of hexadecylamine, and 50mg of glucose powder, place them in a strain bottle, add deionized water and magnets, and make 10ml The mixture A;

[0036] (2) Stir the mixed solution A at a speed of 300r / min for 11 hours at room temperature to obtain a uniformly dispersed copper ion complex, turn off the stirring, and heat at 100°C for 6 hours to obtain the mixed solution B;

[0037] (3) After taking out the mixed solution B from the strain bottle, it was centrifuged and washed with 80°C deionized water at 9000r / min.

[0038] image 3 It is the scanning electron micrograph of the copper nanowire prepared in embodiment 2, by image 3 It can be seen that the prepared product is a pure copper nanowire with an average diameter of 30nm.

Embodiment 3

[0040] The method for rapidly preparing copper nanowires at low cost in this embodiment comprises the following steps:

[0041] (1) Weigh 14.7mg of copper chloride powder, 9mg of copper nitrate powder, 160mg of hexadecylamine, and 50mg of glucose powder, place them in a strain bottle, add deionized water and magnets, and make 10ml The mixture A;

[0042] (2) Stir the mixed solution A at a speed of 300 r / min for 9 hours at room temperature to obtain a uniformly dispersed copper ion complex, turn off the stirring, and heat at 100° C. for 6 hours to obtain the mixed solution B;

[0043] (3) After taking out the mixed solution B from the strain bottle, it was centrifuged and washed with 80°C deionized water at 8000r / min.

[0044] Figure 4 and Figure 5 All are scanning electron microscope images of the copper nanowires prepared in Example 3, and the prepared product is pure copper nanowires with an average diameter of 40nm.

[0045] In summary, above-mentioned three embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap