Automatic control method for tailstock of numerical control lathe

一种数控车床尾座、数控车床的技术,应用在数控车床领域,能够解决数控机床的尾座不能自动进给、钻孔深度尺寸难以保证、加工效率低等问题,达到提高灵活性、控制钻孔深度、提高自动化程度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

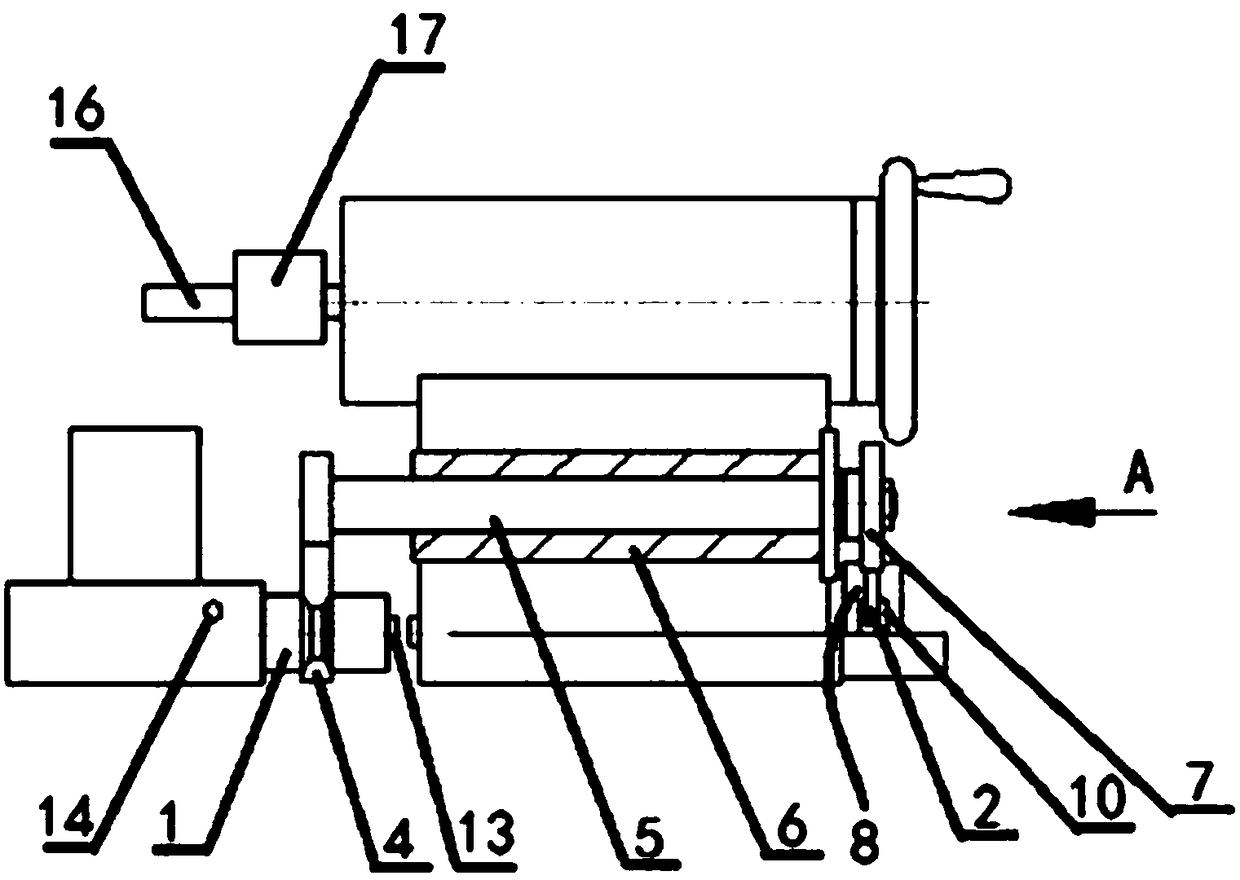

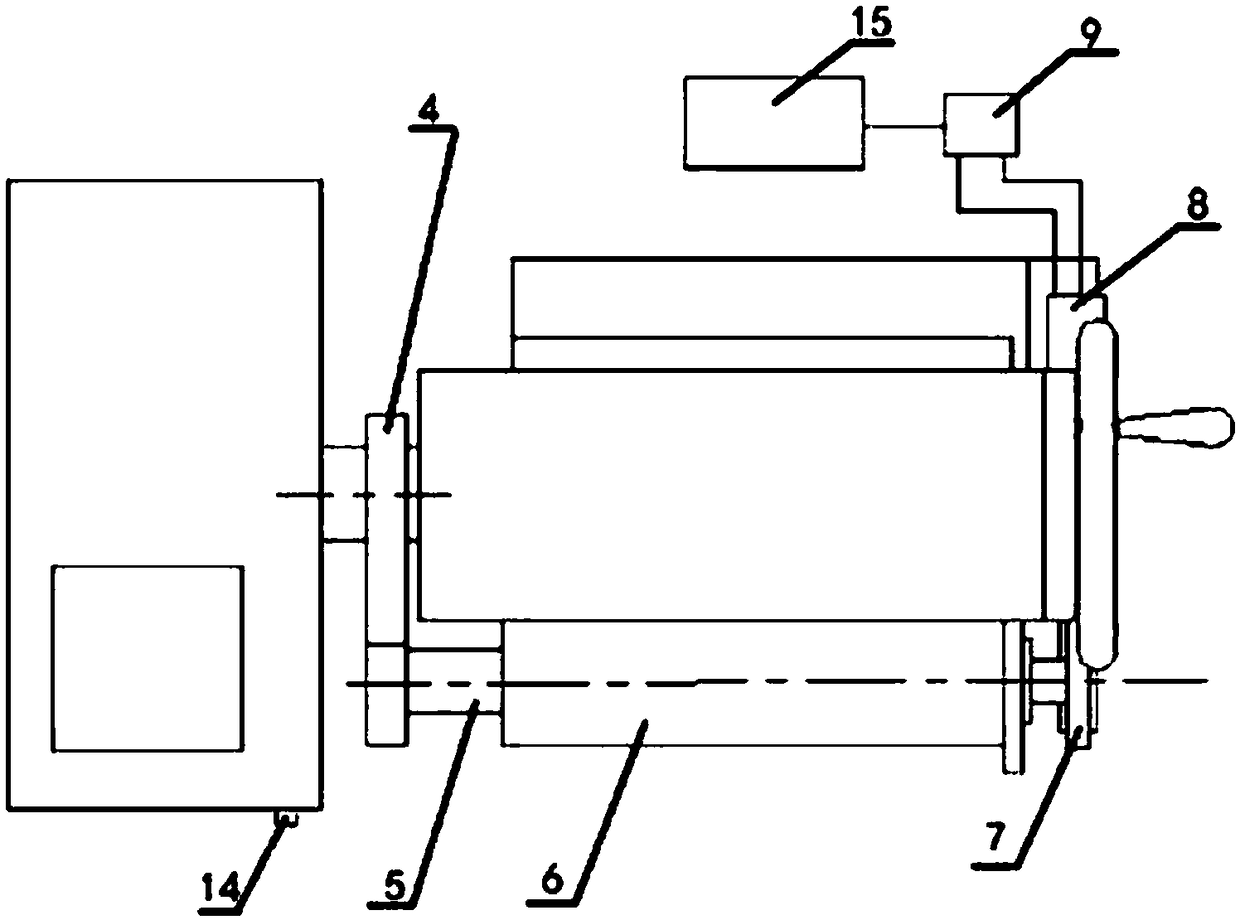

[0021] An automatic control method for a tailstock of a CNC lathe, which uses a cylinder to realize the automatic engagement and disengagement of a saddle and a tailstock of a CNC lathe, and includes a connecting column 1, a rotating arm assembly, a driving assembly and a drill assembly. The middle part of the connecting column 1 is provided with a ring groove 3, the connecting column 1 is fixedly connected with the saddle of the CNC lathe, and a pair of sensors 13 are arranged on the shaft end of the connecting column 1 and the side of the tailstock, and the sensors can be magnetic effect sensors or Hall effect sensors. The sensor can also be a photoelectric sensor.

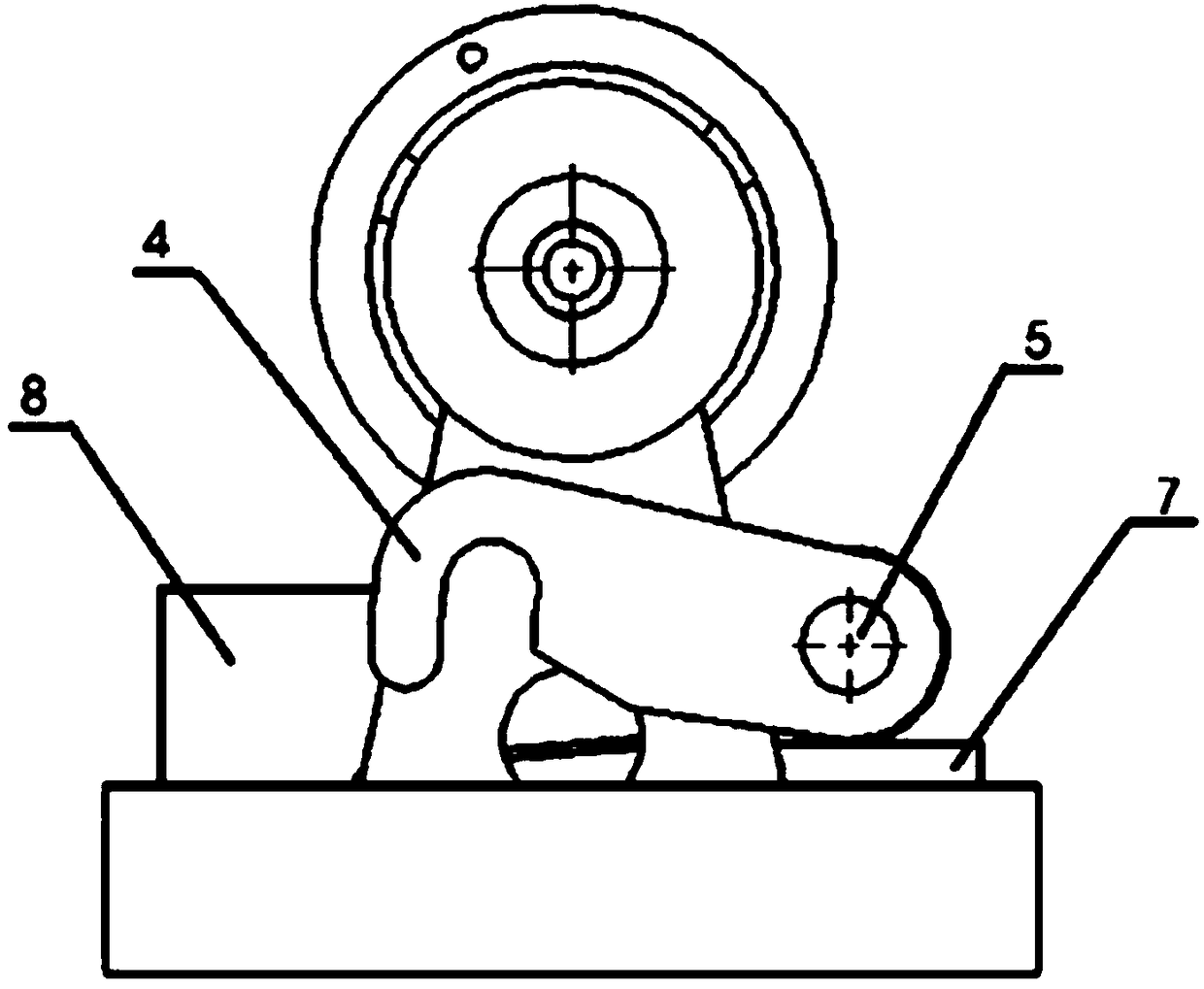

[0022] Described rotating arm assembly comprises rotating arm 4, rotating shaft 5, axle sleeve 6 and bull gear 7, and described axle sleeve 6 is fixed on the front side of CNC lathe tailstock, and described rotating shaft 5 passes through axle sleeve 6, and rotates The front end of the shaft 5 is fixedly connect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap