Lead frame structure

A lead frame and junction box technology, which is used in the installation of busbars, auxiliary devices, electrical components, etc., can solve the problems of damage, high welding temperature, and cables are susceptible to high temperature, and achieve good protection function, simple structure and design. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

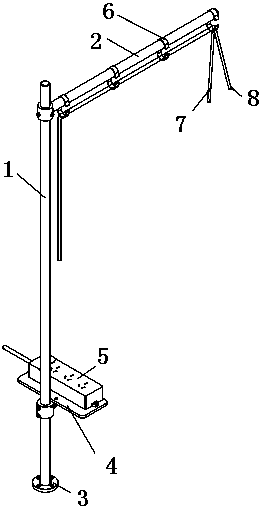

[0011] Depend on figure 1 It can be seen that a lead frame structure includes a cross bar 2 and a vertical bar 1, the cross bar 2 is sleeved on the upper end of the vertical bar 1, the bottom of the vertical bar 1 is fixed by a fixed base 3, and the vertical bar 1 The bottom of the bar 1 is provided with a wire box supporting plate 4, and the described wire box supporting plate 4 is provided with a three-phase three-seat junction box 5; Soldering iron cable 7 and PT temperature measuring resistance wire 8. The electric soldering iron cable 7 and the PT temperature measuring resistance line 8 go along the vertical bar 1 to the three-phase three-seat junction box 5, and the electric soldering iron cable 7 and the PT temperature measuring resistance line can be connected by buckles along the vertical bar 1 8 is fixed on the vertical bar 1.

[0012] The hooks 6 are equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com