Intelligent torque wrench

A torque wrench, intelligent technology, applied in the direction of wrenches, wrenches, screwdrivers, etc., can solve the problems of low torque control accuracy, no communication function, limited torque range, etc., to improve response speed and stability, improve work efficiency and Quality, the effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to better illustrate the technical solutions and innovative features of the present invention, the present invention will be further described below with reference to the accompanying drawings and embodiments.

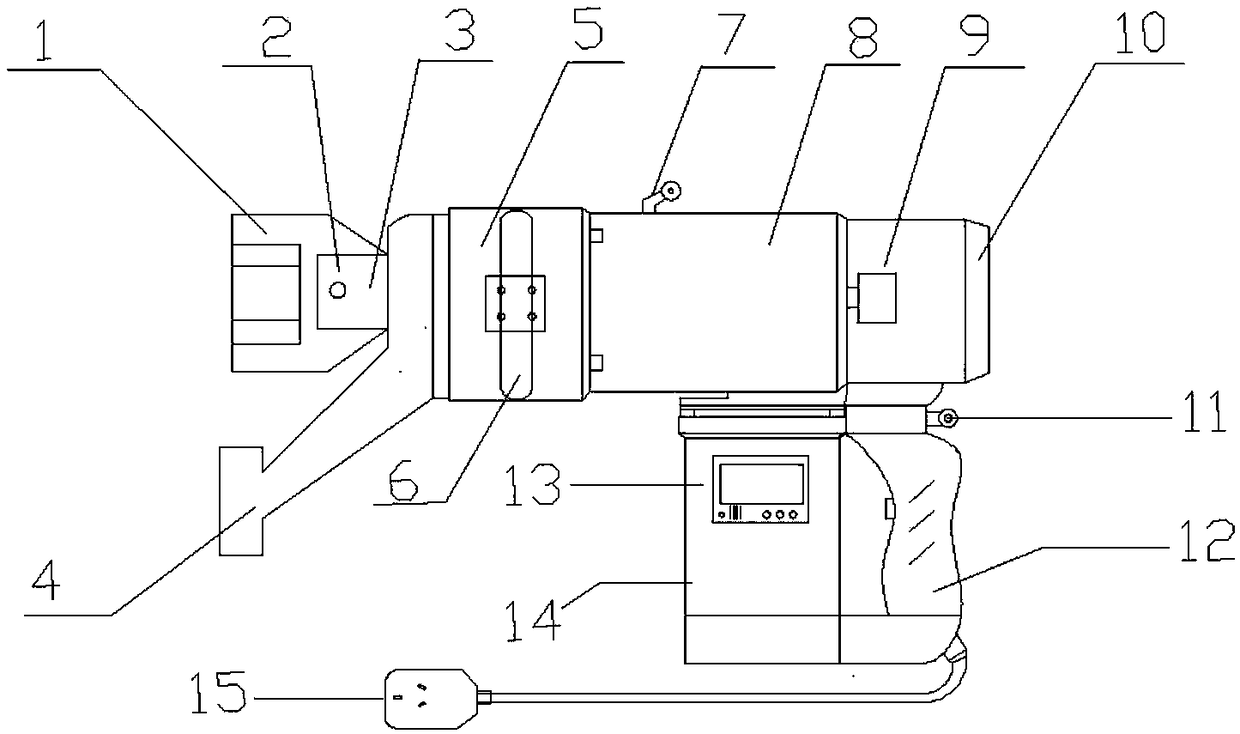

[0043] like figure 1 As shown, an intelligent AC electric wrench includes a sleeve 1, a wrench body 2, a safety pin 3, a reaction arm 4, a reduction gear box 5, an auxiliary handle 6, a first strap ring 7, a second strap ring 11, and synchronously AC motor 8, speed measuring module 9, fan 10, handle 12, control panel 13, control system shell 14, plug (with leakage protection function) 15. The sleeve 1 is connected to the main body of the wrench 2 through the safety pin 3, the reaction arm 4 is connected to the front end of the reduction gear box 5, and plays a role of balancing torque when the motor outputs a large torque, and the auxiliary handle 6 is connected to the reduction gear box 5, The rear end of the reduction gear box 5 is connected to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com