Paperboard rotary die cutting machine and die cutting process

A technology of circular pressing and die-cutting machine, applied in the field of cardboard circular pressing circular die-cutting machine and its die-cutting process, can solve the problems of reducing the cardboard forming efficiency, affecting the quality of the carton, increasing the production cost, etc., and avoiding the indentation and bending. The effect of deformation, avoidance of offset, and improved molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

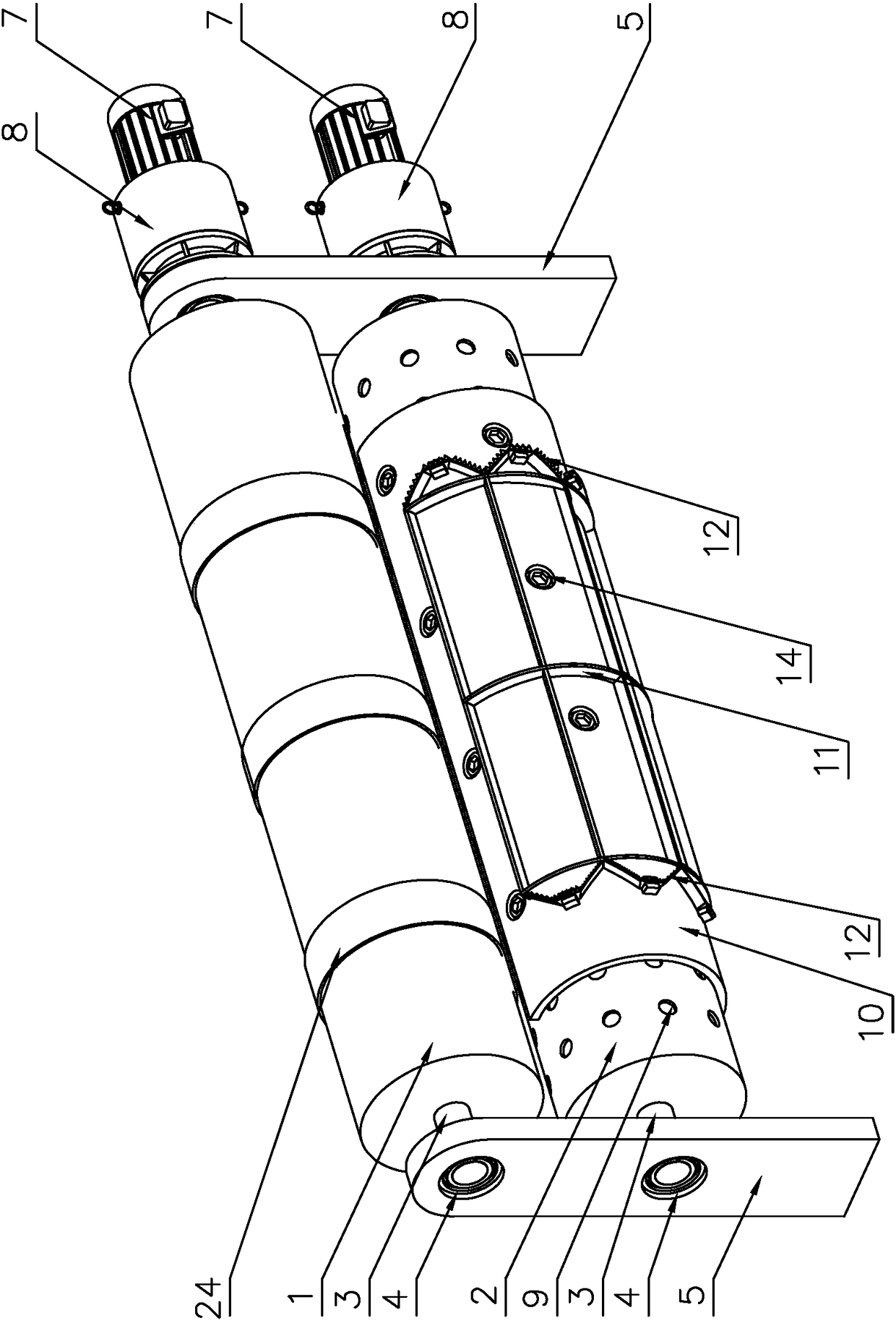

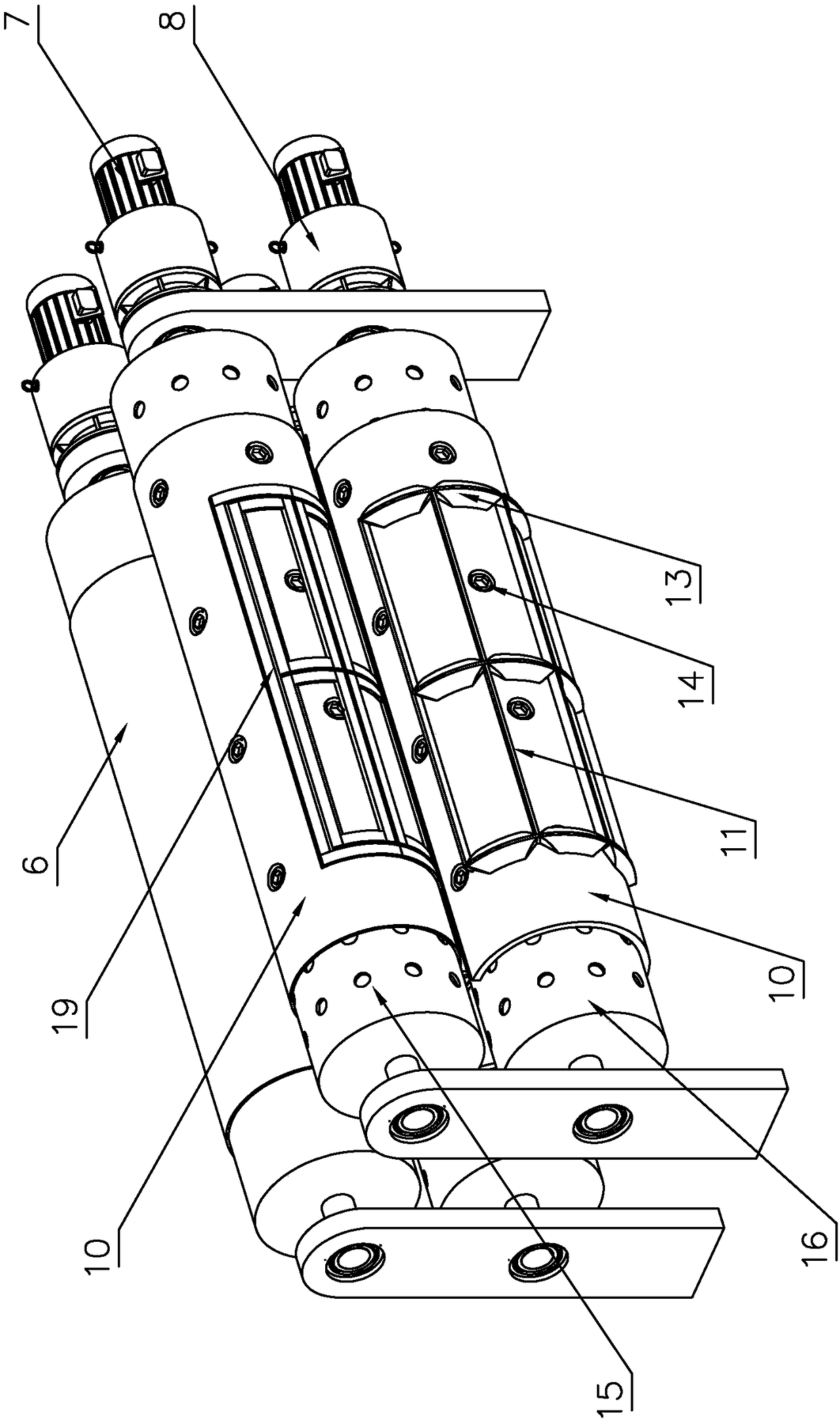

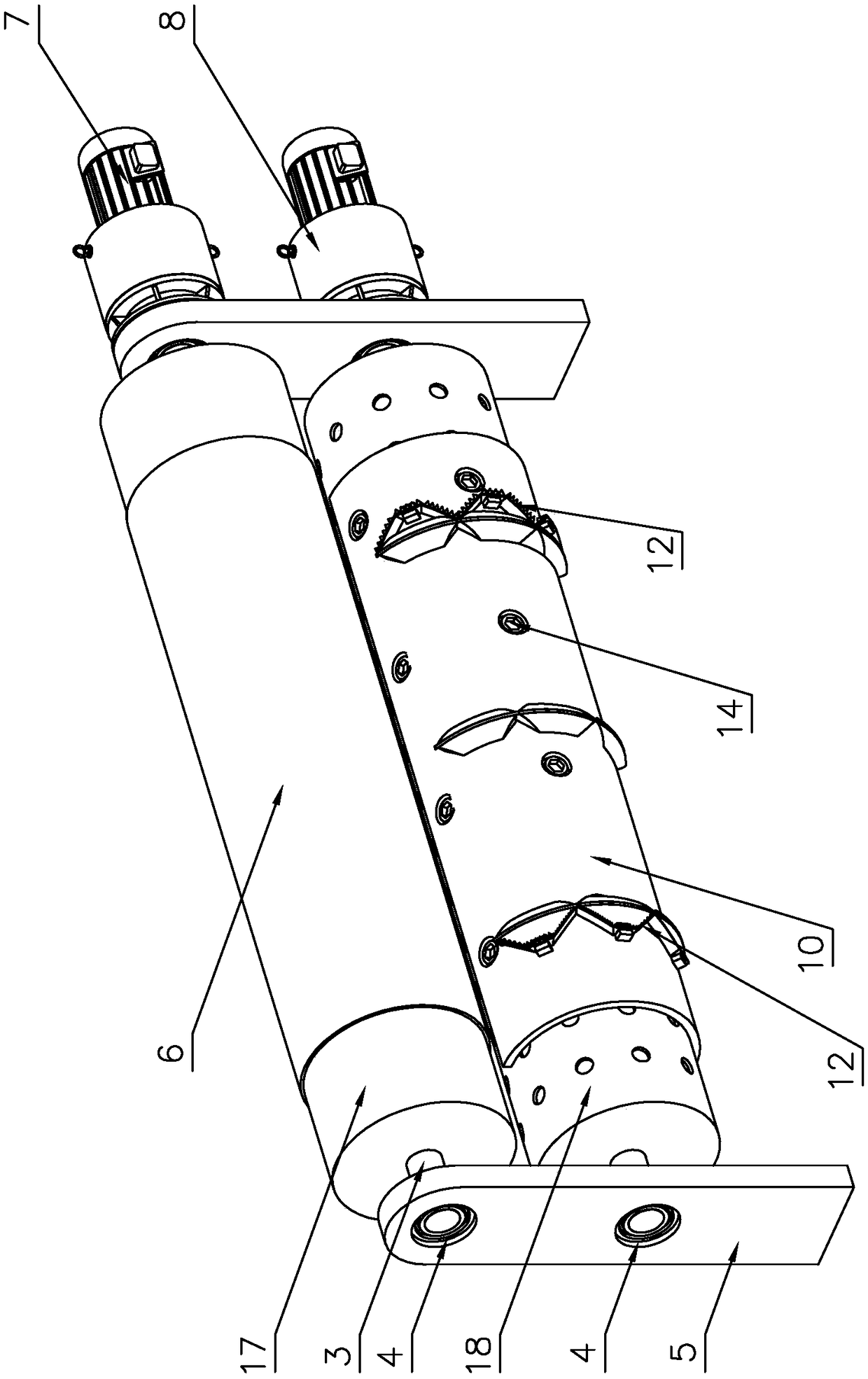

[0032] A cardboard rotary die-cutting machine, including rubber sleeve 6, creasing roller I15, creasing roller II16, die-cutting roller I17, die-cutting roller II18, column 5, motor 7, reducer 8, template 10, creasing Knife 11, die cutter 12, creasing die 19, both ends of the creasing roller I15 are provided with a rotating shaft 3, the rotating shaft 3 is installed on the column 5 through the bearing 4, and the creasing roller I15 is provided with a mounting hole 9 , the mounting hole 9 is a threaded hole; a template 10 is provided on one side of the creasing roller I15, and the template 10 is connected to the mounting hole 9 on the creasing roller I15 through a bolt 14, thereby fixing the template 10 on the creasing roller I15, One side of the template 10 is provided with an indentation die 19, and the indentation die 19 is fixed on the template 10 by superglue, and an indentation groove is arranged between the indentation dies 19, and the depth of the indentation groove is e...

Embodiment 2

[0042] A cardboard rotary die-cutting machine, the die-cutting roller I and the die-cutting roller II are located in front of the creasing roller I and the creasing roller II, and the die-cutting process is as follows:

[0043] 1) Positioning, first fix the creasing knife and die-cutting knife on the creasing roller Ⅱ and die-cutting roller Ⅱ respectively according to the die-cutting position of the cardboard, and then buckle the opening of the positioning plastic strip on the side of the creasing die to the creasing Then apply superglue on the bottom of the creasing mold, start the motors on the side of creasing roller I and creasing roller II, and the motor drives creasing roller I and creasing roller II to rotate through the reducer, so that the creasing mold Fix and glue the corresponding position on the creasing roller Ⅰ to complete the positioning of the creasing die;

[0044] 2) Die-cutting, the creased cardboard is transported between the die-cutting roller Ⅰ and the d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap