Cyclic heating fermentation tank

A technology of cycle heating and fermenter, which is applied in the direction of heating/cooling of chemical fertilizer treatment, application, organic fertilizer, etc. It can solve the problems of affecting fermentation and heating effect, uneven heating of fermenter, organic fertilizer sticking, etc., and achieves good stirring effect , Heating is uniform and sufficient, and the fermentation effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

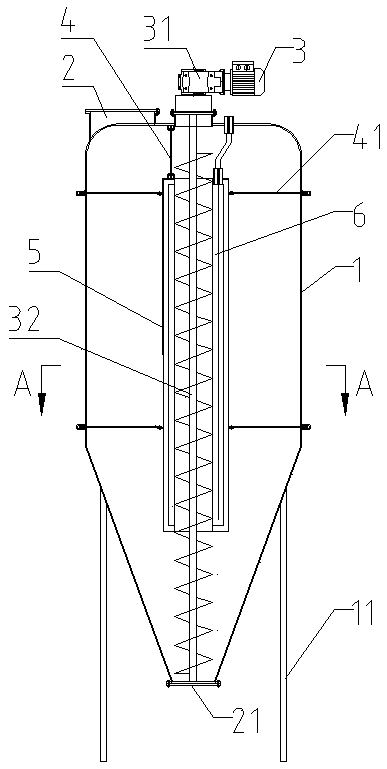

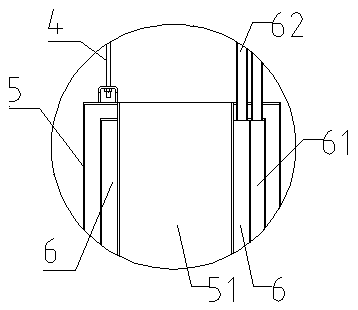

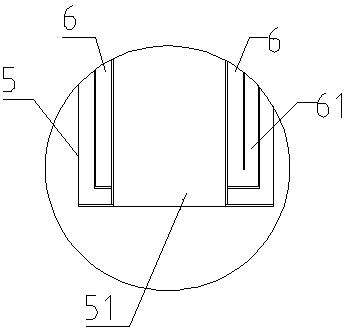

[0022] Such as Figure 1 to Figure 4 As shown, a circulating heating fermenter includes a tank body 1 and a circulation auger 32 vertically arranged in the tank body 1 , the reducer 31 and the motor 3 of the circulation auger 32 are arranged on the upper end surface of the tank body 1 The upper end of the tank body 1 is cylindrical, and the lower end is conical with a large upper end and a smaller lower end. The upper end of the tank body 1 is provided with a feed port 2, and the center of the lower end is provided with a discharge port 21. The feed port 2 and the discharge port 21 are provided with a cover, the central axis of the tank body 1 is provided with a circulation tube 5 fixed by a plurality of fixed rods, the fixed rods include a vertical fixed rod 4 and a horizontal fixed rod 41, and the circulating auger 32 penetrates In the inner cavity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com