The preparation method of 2-chloro-3-methylbenzoic acid and its intermediate

A technology of toluic acid and dimethyl chloroformic acid, which is applied to the preparation of phosgene or haloformate, carboxylate, and organic compounds, and can solve the problems of difficult implementation of industrial production, strict equipment requirements, and reaction problems. Poor selectivity and other problems, to achieve the effect of easy industrial production, high industrial value, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

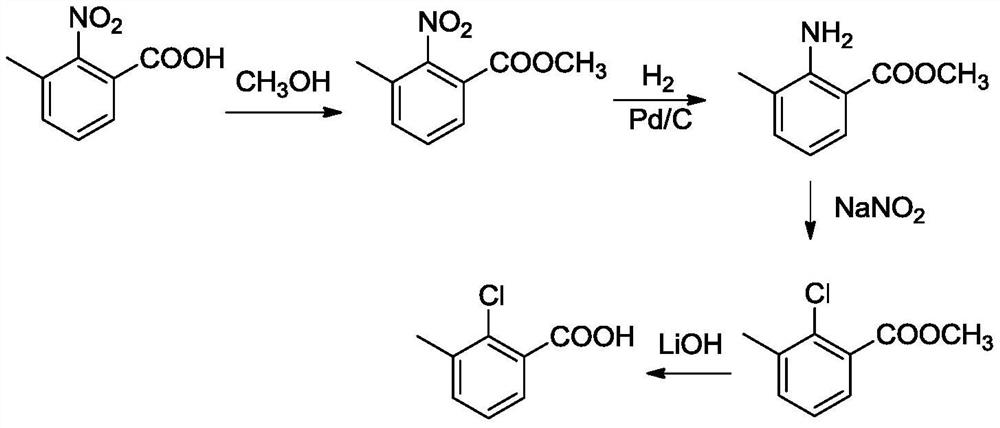

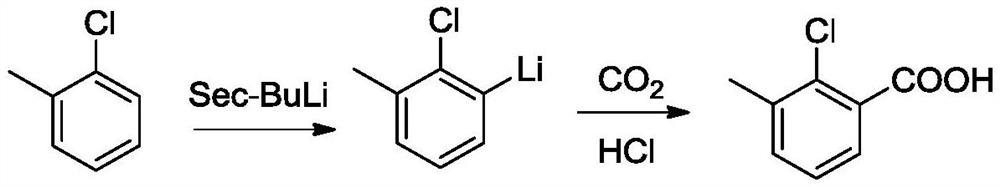

Method used

Image

Examples

Embodiment 1

[0080] Preparation of 2-amino-3-methylbenzoic acid

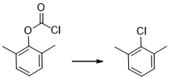

[0081] Step 1 2, the preparation of 6-dimethyl phenyl chloroformate

[0082] Add 122g (1.0mol) of 2,6-dimethylphenol, 18.3g of DMF, and 488g of toluene to a 1L four-necked flask. During the aerobic process, keep the temperature of the reaction system between 50 and 60°C, react for 2 hours, and detect that the raw material is less than 0.5%, and the reaction is complete; cool down the reaction kettle to room temperature, let it stand for 30 minutes, filter out the supernatant liquid, and keep the solid in the bottle Apply to the next batch of reactions. The supernatant was decompressed to remove toluene, and the toluene was directly applied to the next batch of reactions; the supernatant obtained after decompression toluene was removed from the concentrated solution was sampled, the mass content of the test was 98.5%, the concentrated solution weighed 184g, and the calculated yield was 98.2% . The crude product was directl...

Embodiment 2

[0089] In the L four-necked bottle, add 122g (1.0mol) 2,6-dimethylphenol, 18.3g pyridine or the solid after pyridine catalytic reaction, and 488g toluene. (2.0mol) phosgene, during the process of passing phosgene, keep the temperature of the reaction system between 50-60°C, react for 2 hours, and detect the raw material <0.5%, the reaction is complete; cool the reaction kettle to room temperature, let it stand for 30min, and filter out The supernatant and the solid were left in the bottle and applied to the next batch of reactions. The toluene was removed from the supernatant under reduced pressure, and the toluene was directly applied to the next batch of reactions; the crude concentrate was sampled, and the mass content of the concentrate was 62.7%. The concentrate weighed 180g, and the calculated yield was 61.2%.

Embodiment 3

[0091] In a 1L four-necked flask, add 122g (1.0mol) 2,6-dimethylphenol, 18.3g pyridine or the solid after pyridine catalytic reaction, and 488g toluene. (2.0mol) phosgene, during the process of passing phosgene, keep the temperature of the reaction system between 50-60°C, react for 2 hours, and detect the raw material <0.5%, the reaction is complete; cool the reaction kettle to room temperature, let it stand for 30min, and filter out The supernatant and the solid were left in the bottle and applied to the next batch of reactions. The toluene was removed from the supernatant under reduced pressure, and the toluene was directly applied to the next batch of reactions; the crude concentrate was sampled, and the mass content of the concentrate was 62.7%. The concentrate weighed 180g, and the calculated yield was 61.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com