Fragrant sesame oil production method

A technology of sesame sesame oil and sesame seeds, which is applied in the direction of fat oil/fat refining, edible oil/fat, fat oil/fat production, etc., can solve the problems of environmental pollution, deterioration of nutrients, endanger the health of consumers, etc., and increase the steam circulation space. , the effect of meeting health needs and increasing the number of feeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

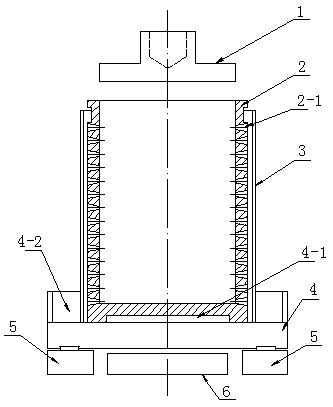

[0057] Taking the daily processing of 1270 kg of sesame as an example, combined with Figure 5 , further describe the present invention as follows:

[0058] 1. Raw material preparation

[0059] (1) 1,270 kilograms of sesame seeds were produced in the same year, which met the requirements of the national standard GB11761;

[0060] (2) Cake cloth: choose 3027# food-grade non-woven fabric, cut into 1 meter * 1 meter size, sterilize in boiling water, dry in the sun for use, 40 sheets are needed on duty, and can be reused.

[0061] 2. Mechanical equipment preparation

[0062] (1) Electric temperature-controlled frying pan;

[0063] (2) Electric stone mill;

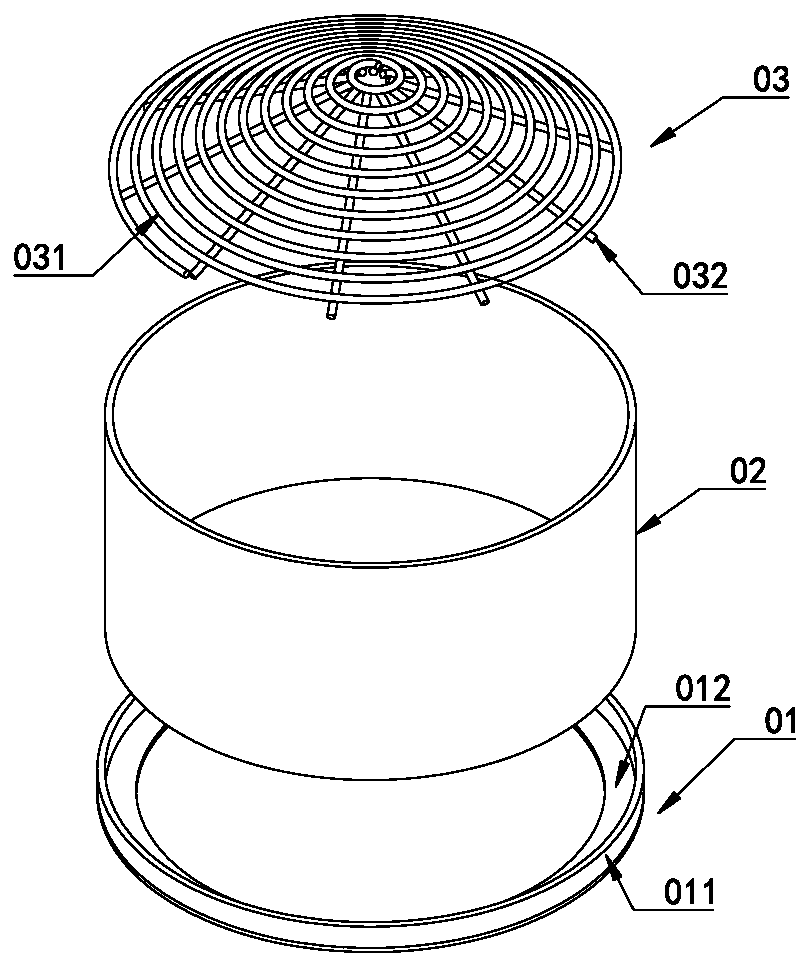

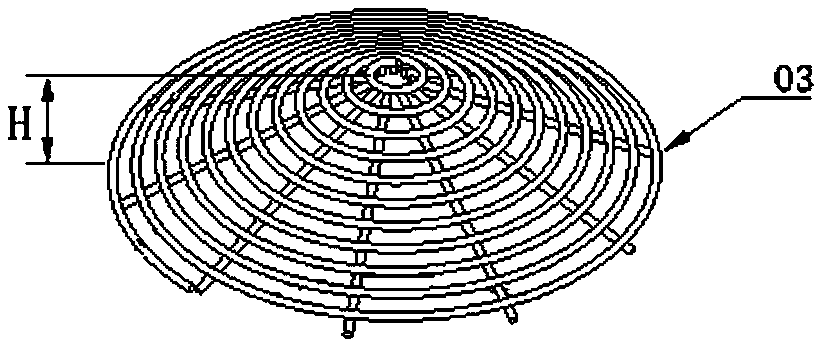

[0064] (3) Steaming pot: the diameter of the pot is 1.2 meters, and the spherical steaming rack ( figure 1 The spherical steaming rack shown) adopts a separate type, the diameter is the same as the pot body, the arch height is 0.25 meters, and the steaming time and steaming temperature are controlled;

[0065] (4) Cake pr...

Embodiment 2

[0084] In embodiment 1, described steaming process comprises:

[0085] ①Wash the material steamer, and put the designed amount of drinking water in the pot. The ideal amount of water is calculated at room temperature of 25°C. When the water temperature is lower than 25°C, the amount of water decreases. When the water temperature is higher than 25°C, the amount of water Increase;

[0086] ②A spherical steaming rack is placed on the steamer and a cotton sackcloth with good air permeability is placed on it, wherein the spherical steaming rack device has a hemispherical surface, and the diameter of the device is matched with the diameter of the steamer;

[0087] ③ After the water in the steamer reaches the design capacity, open the steam supply valve;

[0088] ④Put the set amount of materials according to the process design to lay the materials on the hemispherical surface of the spherical steaming rack device;

[0089] ⑤ Carry out numerical control of steaming time and temperat...

Embodiment 3

[0098] Taking 1270 kilograms of processed sesame daily as an example, the present invention is further described:

[0099] 1. Raw material preparation

[0100]Select sesame seeds and meet the GB22165 food hygiene standards, and use color sorters to control the acceptance of raw materials.

[0101] 2. Mechanical equipment preparation

[0102] The steaming pot, the diameter of the pot body is 1.2 meters, the spherical steaming material rack is separated, the arch height is 0.25 meters, and the diameter is the same as the pot body.

[0103] 3. Process flow

[0104] Start-up conditions, with 380V power supply, drinking water source, qualified measuring instruments, accurate digital control device. Clean and disinfect the production workshop and the facilities and equipment and pipelines used, and scrub them clean to ensure that the clean production oil products are not contaminated. The process includes:

[0105] (1) Wash the material steamer, the water is clean and the oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Perimeter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap