A preparation method of large diameter x80 longitudinal submerged arc welded pipe

A technology of straight seam submerged arc welding and large diameter, which is applied in the field of pipeline steel production, can solve problems such as the performance difference between plate and tube, and achieve the effect of small performance difference, reducing internal stress and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

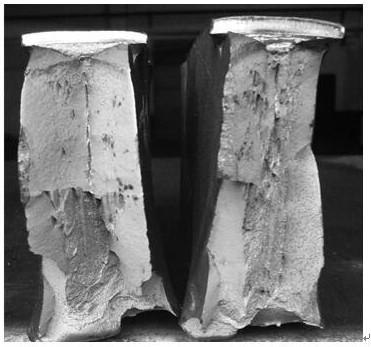

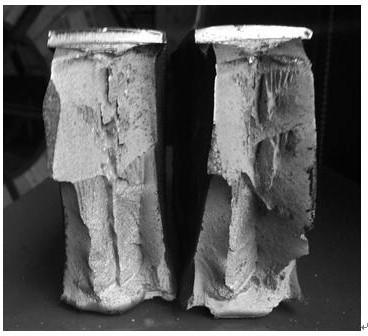

Image

Examples

Embodiment 1

[0016] Example 1: The thickness of the steel plate is 25.7 mm, and the diameter of the steel pipe is φ 1422mm.

[0017] The chemical composition mass percentage of steel is: C=0.04, Si=0.19, Mn=1.69, P=0.011, S=0.0014, Als=0.027, Nb=0.056, Ti=0.018, V=0.003, Cr=0.17, Mo= 0.20, Ni=0.19, Cu=0.13, B=0.0003, N=0.0036, the balance is Fe and inevitable impurities, of which Ti / N=5.86.

[0018] The key process steps of the preparation method include:

[0019] (1) Steel plate rolling: Two-stage controlled rolling is adopted, the end temperature of rough rolling is 1092 °C, the starting temperature of finishing rolling is 910 °C, and the final rolling temperature is 800 °C; relaxation after rolling is 60s; cooling rate is 14~ 16℃ / s, the temperature of returning to red is 430~480℃;

[0020] (2) Tempering of steel plate: the tempering temperature is 450℃;

[0021] (3) Steel pipe forming, diameter expansion, hydrostatic pressure: the number of JCOE forming steps is 25; the diameter exp...

Embodiment 2

[0031] Example 2: The thickness of the steel plate is 30.8 mm, and the diameter of the steel pipe is φ The chemical composition mass percentage of 1422mm steel is: C=0.03, Si=0.22, Mn=1.70, P=0.009, S=0.0015, Als=0.031, Nb=0.062, Ti=0.017, V=0.020, Cr=0.18, Mo = 0.20, Ni = 0.28, Cu = 0.15, B = 0.0003, N = 0.0029, the balance is Fe and inevitable impurities, where Ti / N = 5.0.

[0032] The key process steps of the preparation method include:

[0033] (1) Steel plate rolling: Two-stage controlled rolling is adopted, the end temperature of rough rolling is 1080°C, the starting temperature of finishing rolling is 890°C, and the final rolling temperature is 808°C; relaxation after rolling is 50s; cooling rate is 12~ 14℃ / s, the temperature of returning to red is 420~460℃;

[0034] (2) Tempering of steel plate: the tempering temperature is 425℃;

[0035] (3) Steel pipe forming, diameter expansion, hydrostatic pressure: the number of JCOE forming steps is 28; the diameter expansion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com