Aluminum alloy plate node shear connecting structure and connecting method thereof

A technology of aluminum alloy plate and connection structure, which is applied in the direction of building structure and construction, can solve the problems of large size of hexagonal prism, high precision requirements, increase of node quality, etc., to achieve increased consumables, accurate positioning, and improved shear resistance The effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

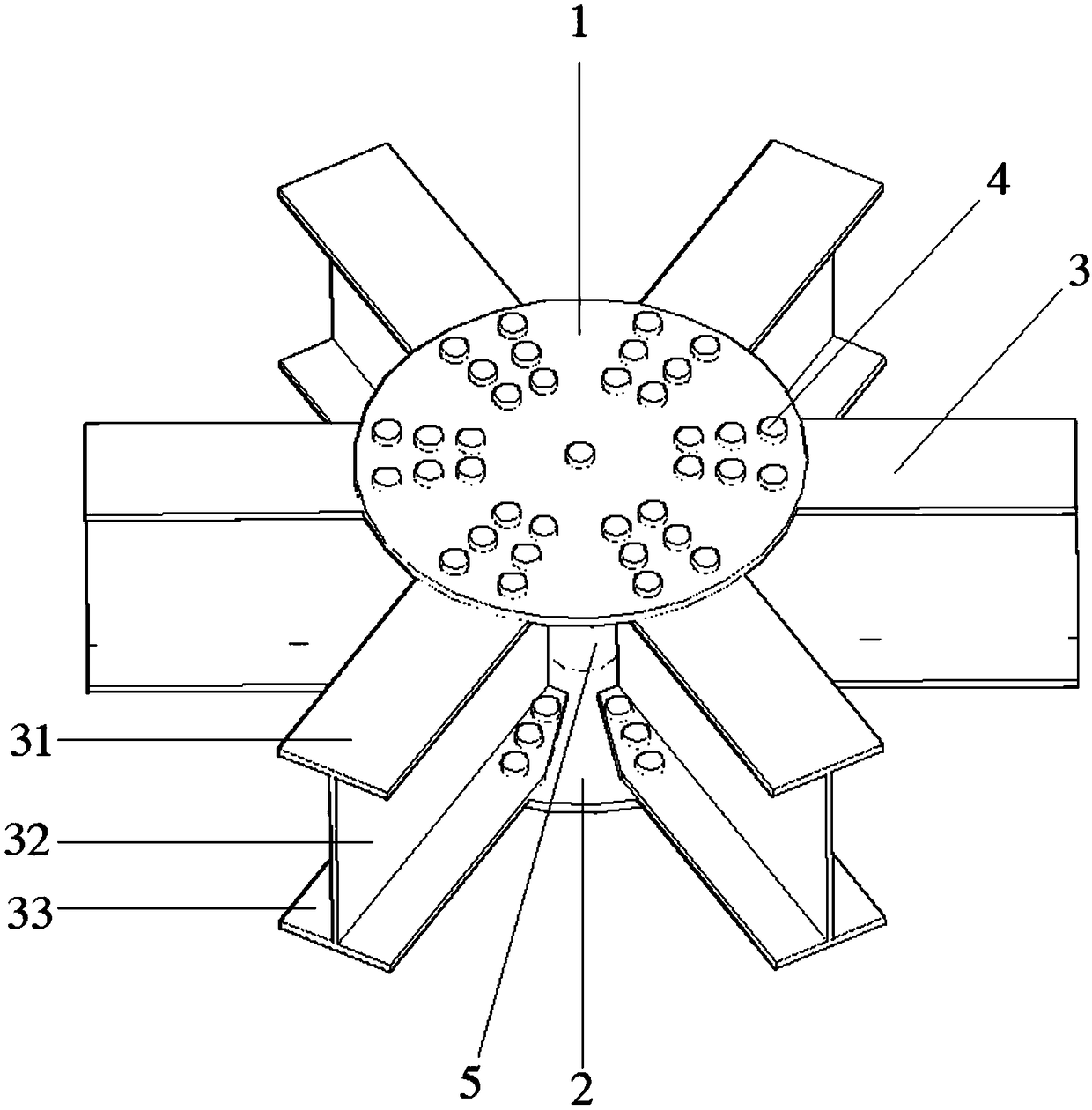

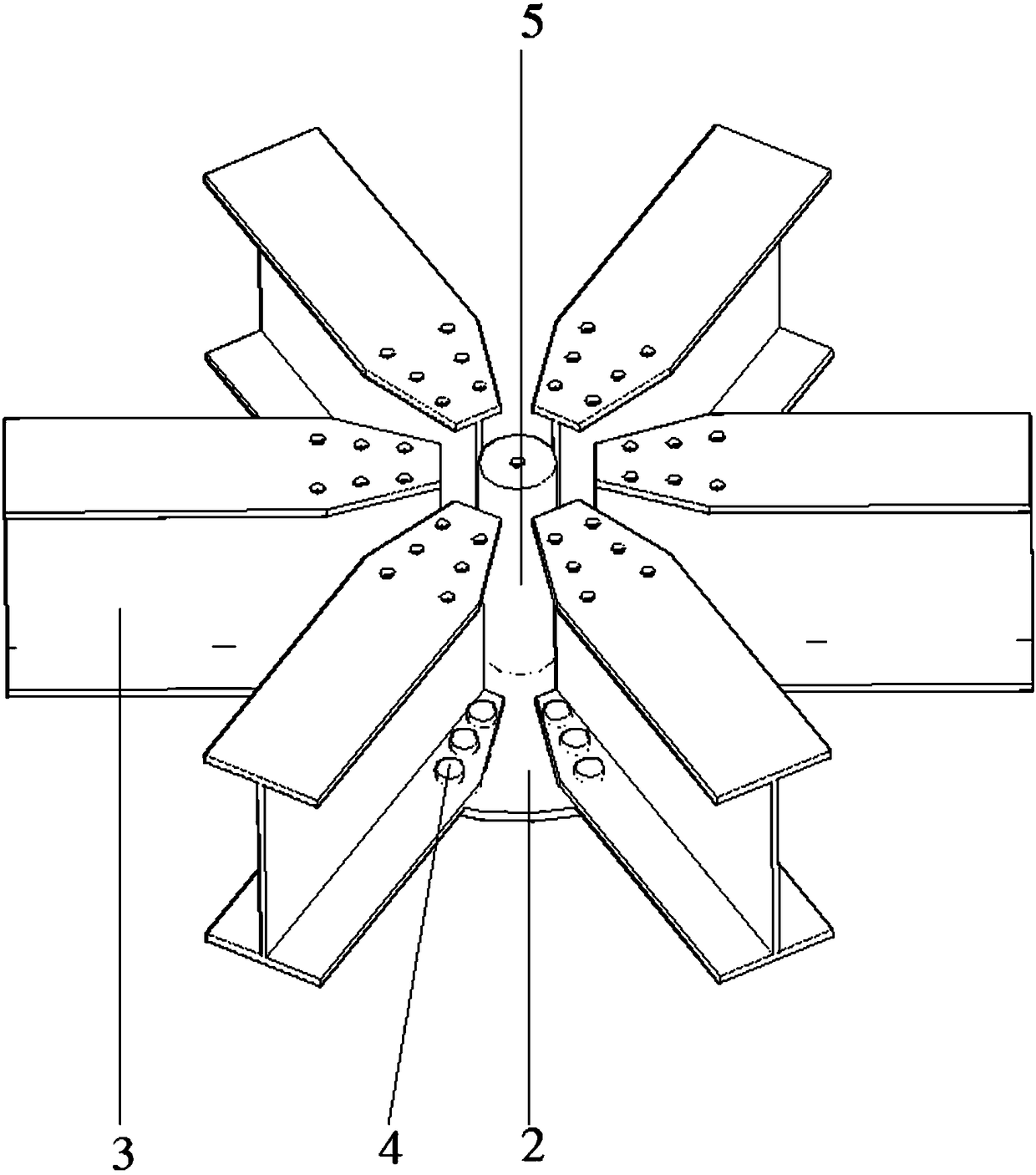

[0029] An aluminum alloy plate node shear connection structure, such as figure 1 , 2 As shown, it includes an upper cover 1, a lower cover 2, six connecting rods 3 and a plurality of fasteners 4, the fasteners 4 are stainless steel bolts, the upper cover 1, the lower cover 2 and the connecting rods 3 The diameter of the bolts on the top is 1.5mm larger than the diameter of the stainless steel bolts. After the stainless steel bolts are tightened, an anti-loosening device is installed, such as double nuts or other anti-loosening measures. A stiffening rod 5 is vertically arranged between the upper cover 1 and the lower cover 2, the upper cover 1 is horizontally arranged on the top of the stiffening rod 5, the lower cover 2 is horizontally arranged at the lower end of the stiffening rod 5, and the stiffening rod 5 The center lines along the length direction coincide with the center lines of the upper cover plate 1 and the lower cover plate 2 respectively, and the centers of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com