Robot plastering bucket device for building wall construction

A robot and construction technology, applied in construction, building construction, etc., can solve problems such as poor stability, swaying of plastering boards, and uneven thickness of mortar painting, so as to achieve the effect of ensuring stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

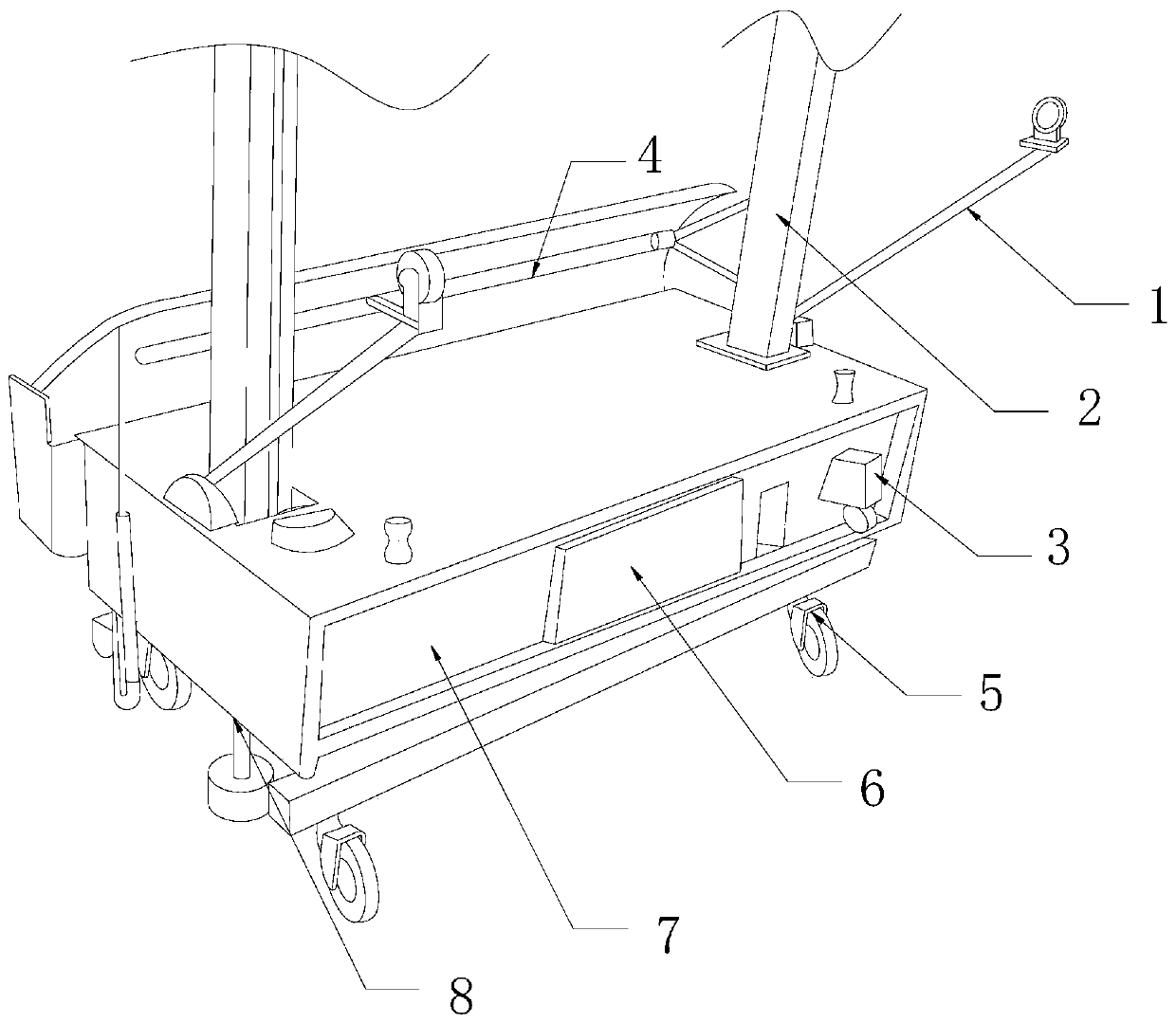

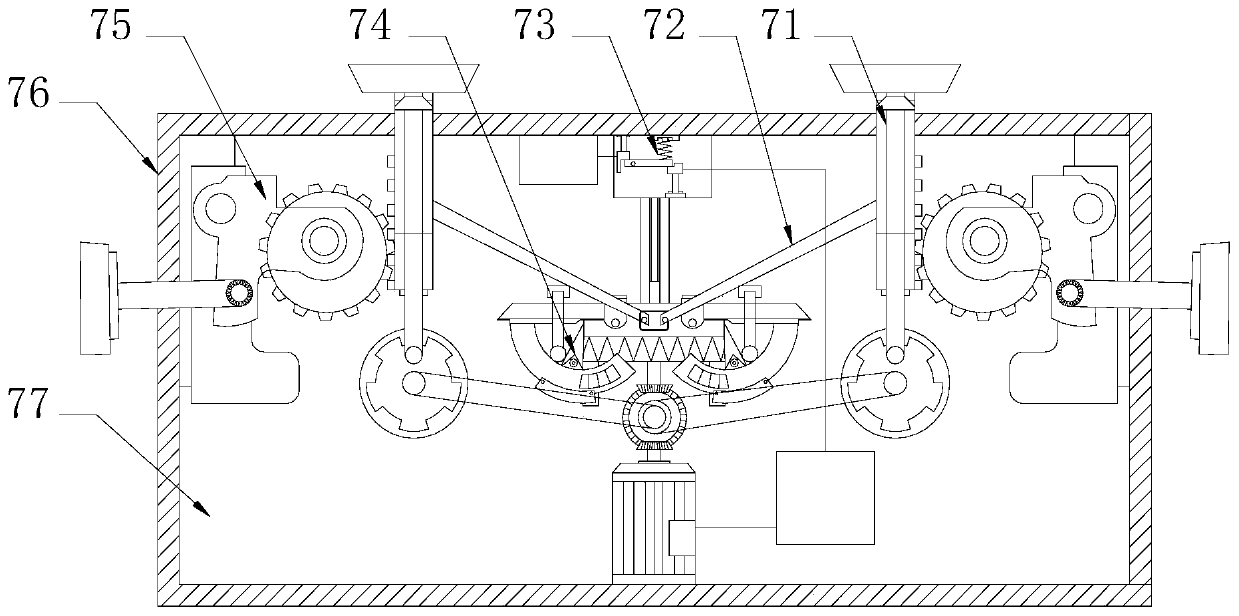

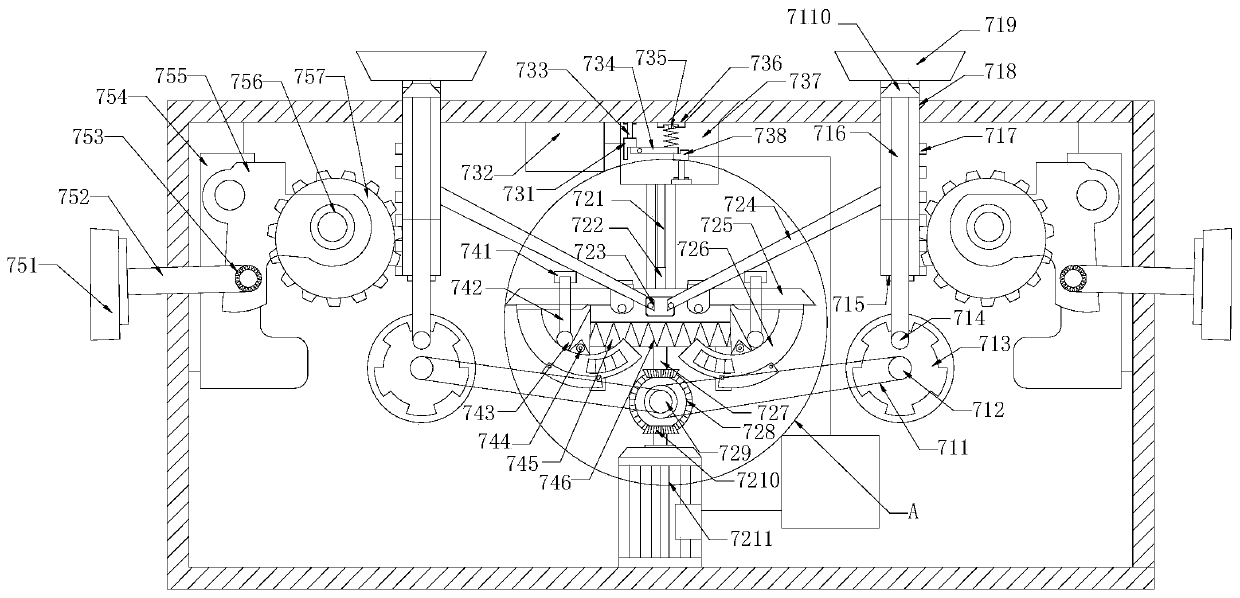

[0022] see Figure 1-Figure 4, the present invention provides a robot plastering bucket device for building wall construction, the structure of which includes a waist rod 1, a vertical rod 2, a tensioning wheel 3, a wiper plate 4, a moving wheel 5, a control panel 6, an automatic adsorption structure 7, and a main body 8, The automatic adsorption structure 7 is installed inside the main body 8, a control panel 6 and a tension wheel 3 are installed on the side of the main body 8, and a wiping plate 4 is installed on the other side of the main body 8 opposite to the control panel 6, and the main body 8 Two or more moving wheels 5 are installed on the bottom surface, a vertical rod 2 is installed on the top of the main body 8, and the vertical rod 2 is mechanically connected with the waist rod 1, and the automatic adsorption structure 7 is provided with a negative pressure adsorption structure 71 and a synchronous drive structure 72 , a power-off structure 73, an automatic adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com