Shape memory alloy energy consumption combined column with resetting function and mounting method thereof

A memory alloy and combined column technology, applied in building types, buildings, building components, etc., can solve the problems of inability to consume energy, low assembly degree of combined special-shaped columns, etc., to save space, save building space and construction costs, and protect safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

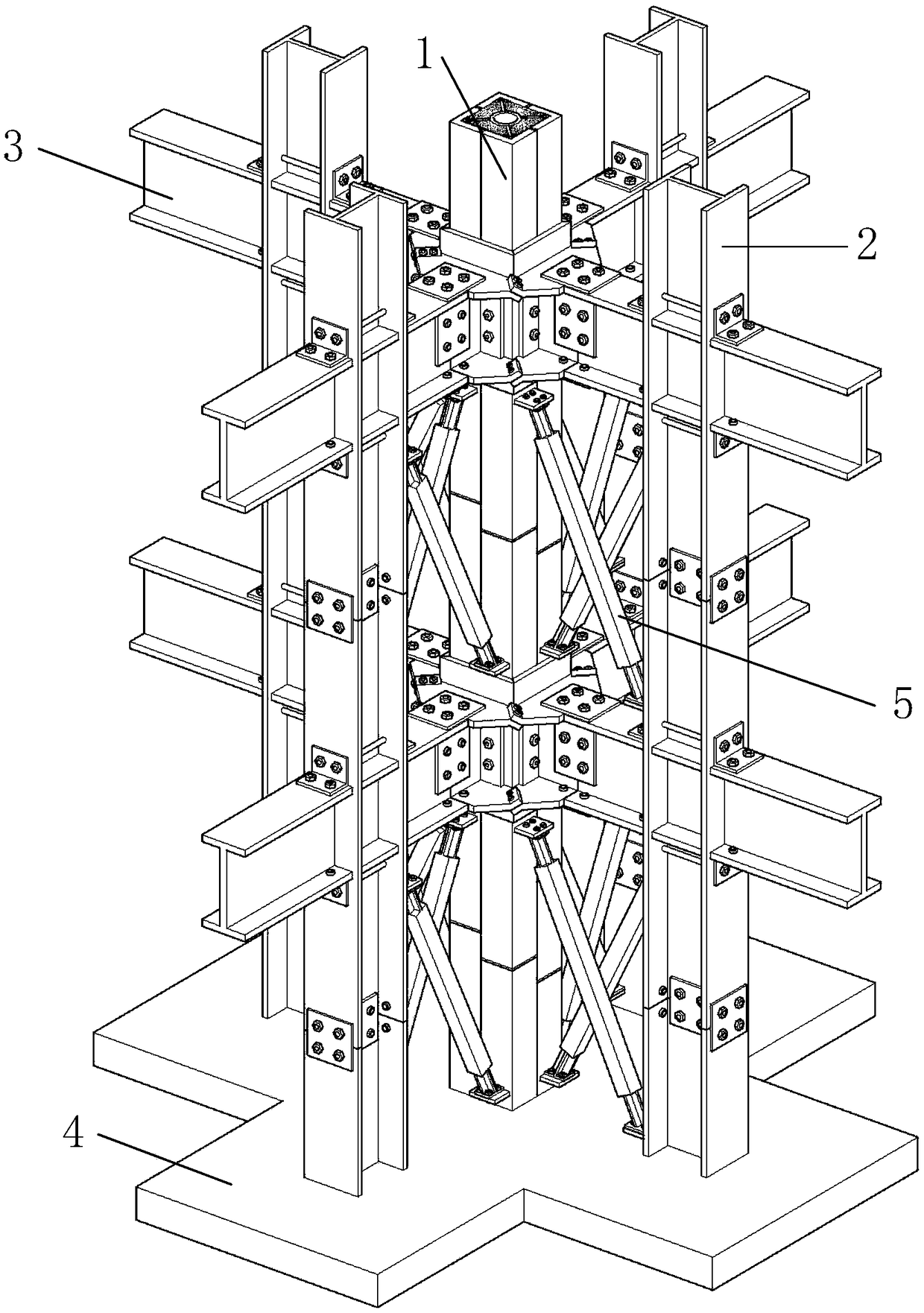

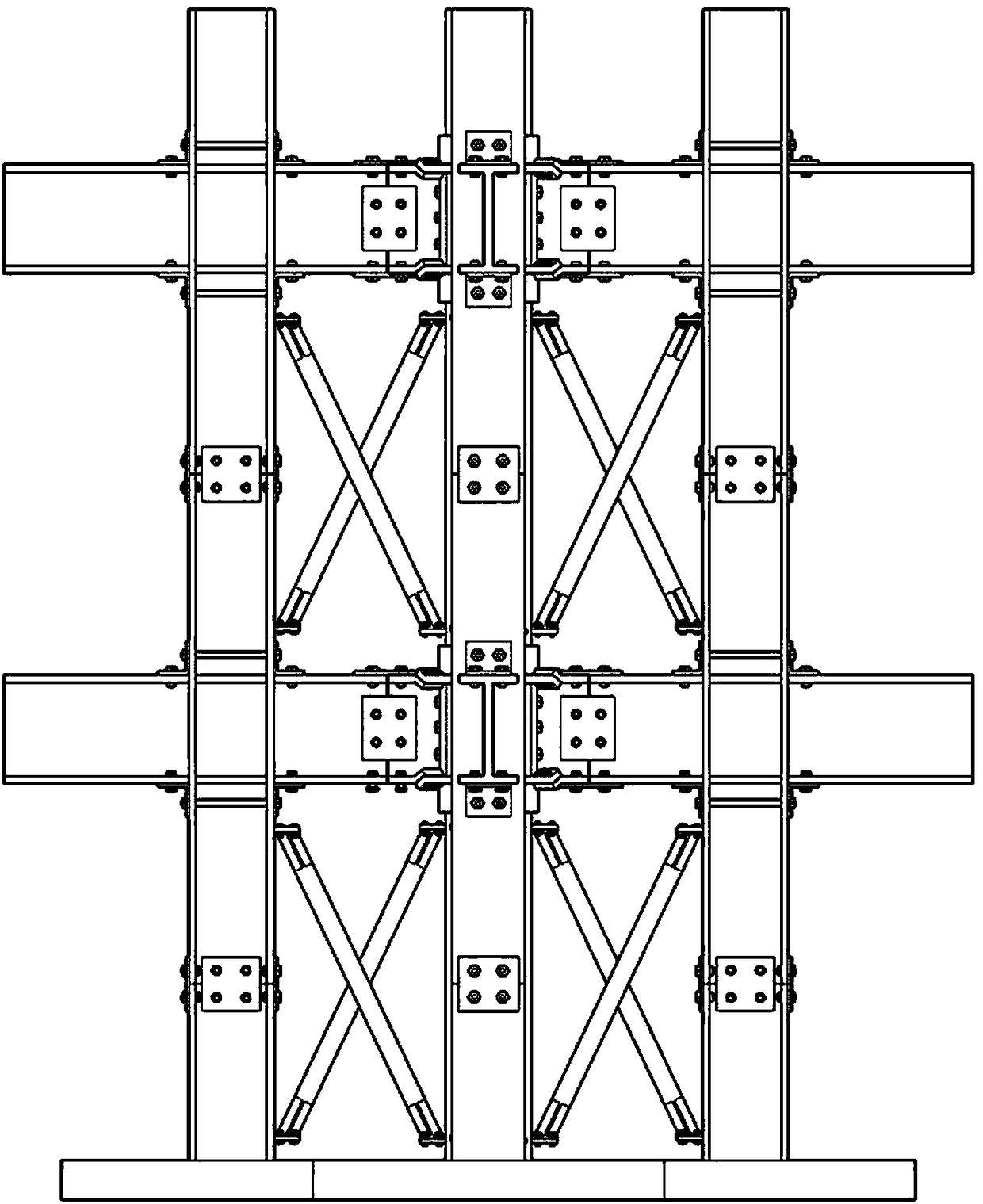

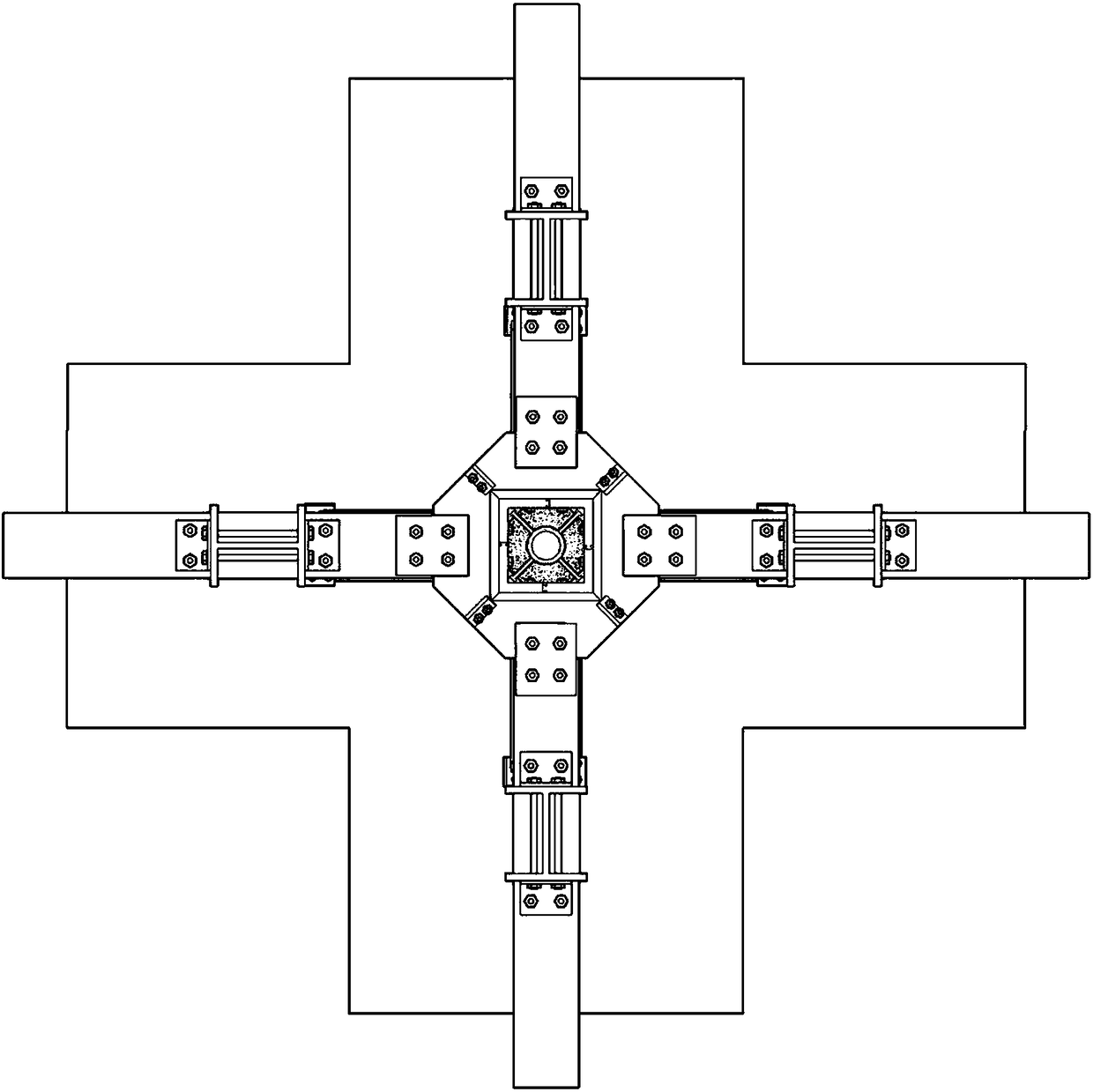

[0045] Such as Figure 1 to Figure 3As shown, the resettable shape memory alloy energy-dissipating composite column of the present invention includes an assembled square steel tube column 1, an I-shaped column 2, an H-shaped steel beam 3, a foundation 4, a buckling-resistant support 5, and a connecting short beam 14 , fixedly installed on the foundation 4 at the bottom are assembled square steel pipe column 1 and I-shaped column 2; the node domain part of assembled square steel pipe column 1 is fixed with T-shaped assembled plate 9, and the upper and lower sides of T-shaped assembled plate 9 are provided with grooves , the T-shaped assembly plate 9 is connected with the assembled square steel pipe column 1 by self-locking bolts 10; Through bolt connection, shape memory alloy long bolts 16 are provided between the upper and lower flanges of the I-shaped column 2, and one end of the L-shaped connecting plate 15 is fixedly connected to the connecting short beam 14, and the other ...

Embodiment 2

[0058] What needs to be explained in this embodiment is that, if Figure 11 to Figure 14 As shown, in the resettable shape memory alloy energy-dissipating composite column described in the present invention, the combination of the assembled square steel column 1 and the I-shaped column 2 structures is changeable, and the structure is not unique.

[0059] For example, if Figure 1 to Figure 3 As shown, an assembled square steel pipe column 1 is connected with four I-shaped columns 2 to form a "ten"-shaped composite column structure.

[0060] Such as Figure 11 to Figure 12 As shown, an assembled square steel pipe column 1 is connected with three I-shaped columns 2 to form a "T"-shaped side column composite column structure.

[0061] Such as Figure 13 to Figure 14 As shown, an assembled square steel pipe column 1 is connected with two I-shaped columns 2 to form an "L"-shaped corner column composite column structure.

Embodiment 3

[0063] The installation method of the resettable shape memory alloy energy dissipation combined column of the present invention comprises the following steps:

[0064] The first step: assemble the assembled square steel pipe column 1 from the assembled column standard part 13;

[0065] Step 2: Slide the inner cylinder set 6 into the column through the slideway at the corner of the assembled column standard part 13 from top to bottom;

[0066] Step 3: Fix the T-shaped assembly plate 9 on the outer wall of the assembled square steel pipe column 1 through self-locking bolts 10;

[0067] Step 4: Pouring concrete 7 between the inner cylinder kit 6 and the inner wall of the assembled square steel pipe column 1;

[0068] Step 5: Assemble four standard parts of the divided plate 8 into a complete ring plate. The positions of the assembled plates 802 are corresponding and then connected and fixed by high-strength bolts 11. Each node domain needs to assemble two sets of ring plates;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com