Adjusting mechanism for inlet guide blades of centrifugal blower

A centrifugal blower and regulating mechanism technology, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve problems such as noise pollution, reduce the aerodynamic performance of the whole machine, weaken the flow separation at the inlet guide vane, and achieve weakened flow separation , Reduce aerodynamic loss and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

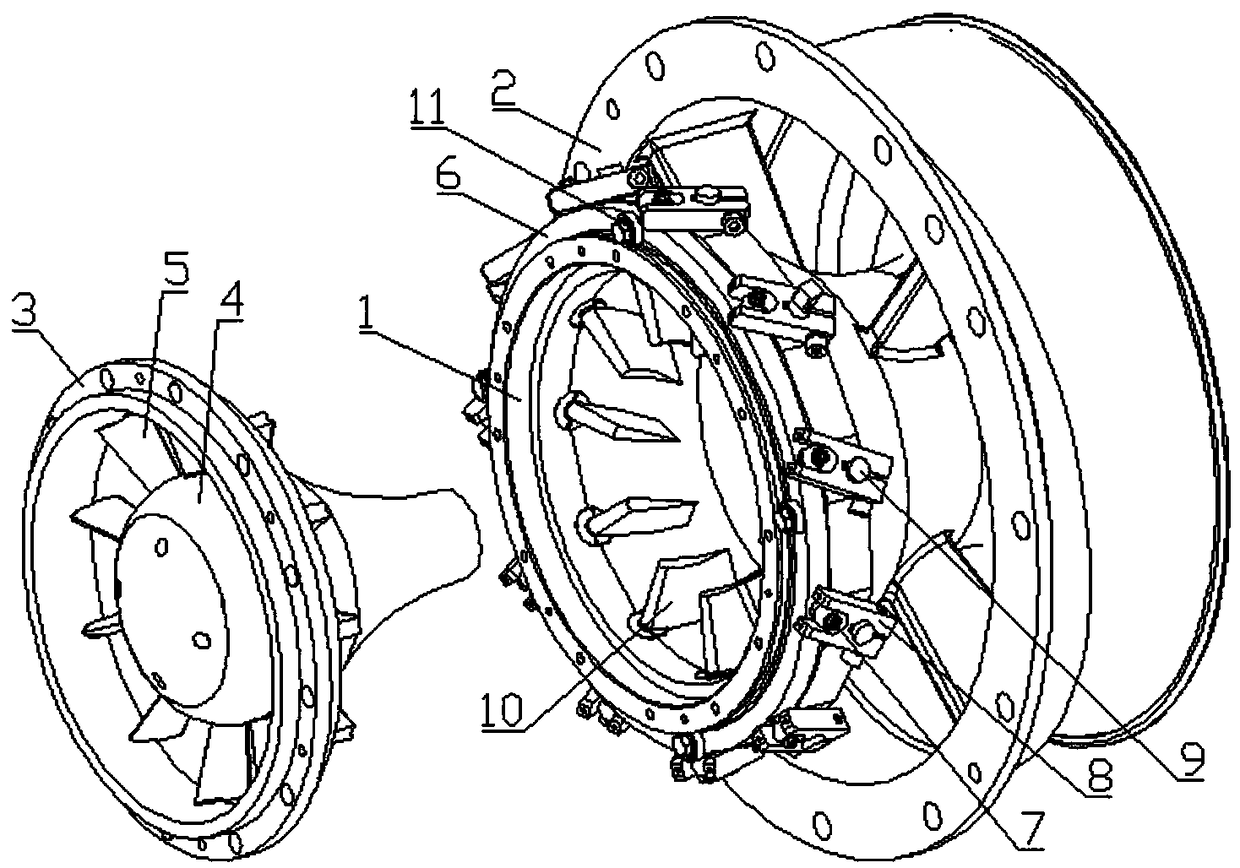

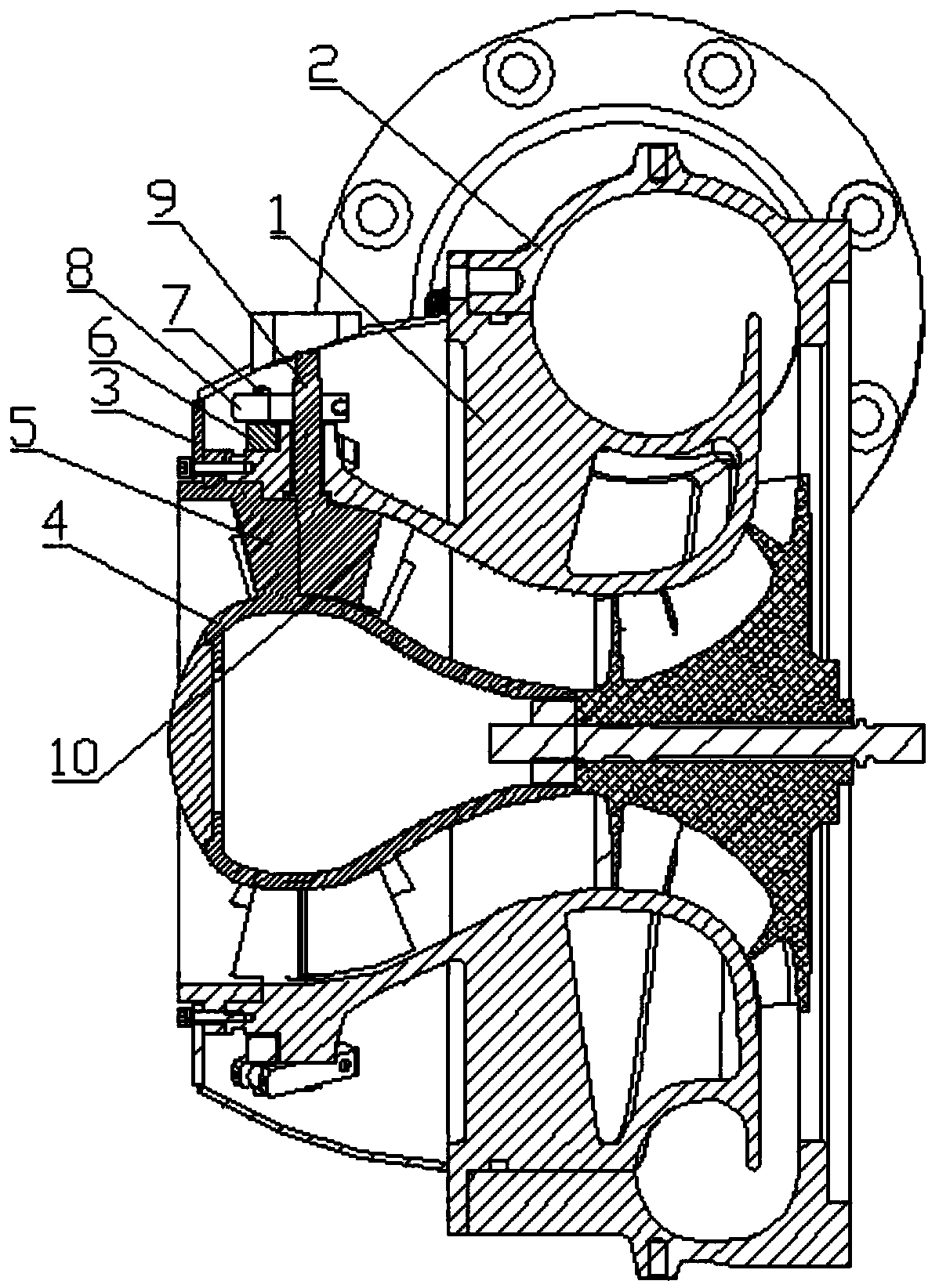

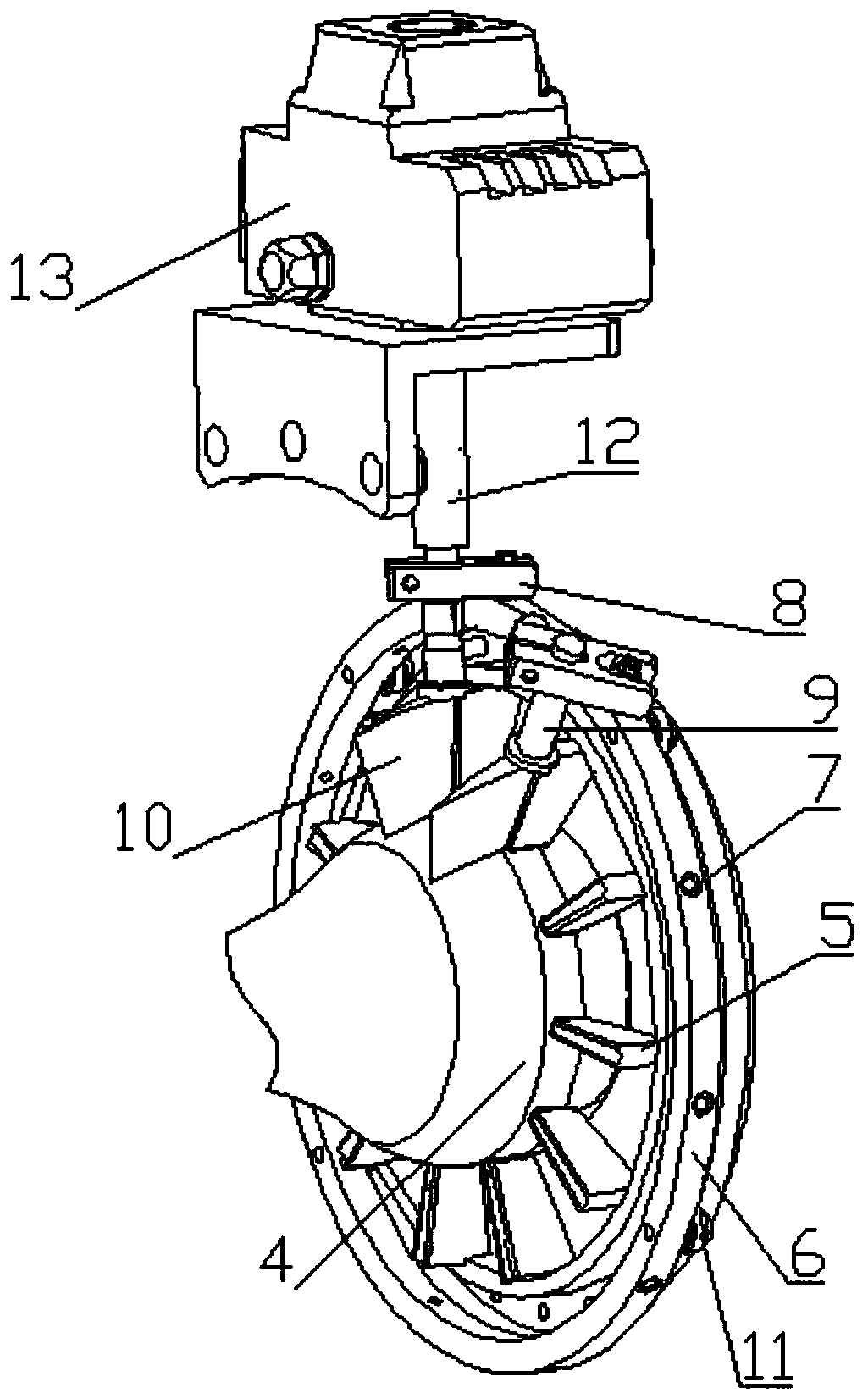

[0017] Below in conjunction with accompanying drawing, the present invention will be further described in detail, so that those skilled in the art can understand more clearly, as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention includes:

[0018] Inner volute 1, outer volute 2, cover cap 3, front guide vane assembly and rear guide vane assembly,

[0019] The front-section guide vane assembly includes a flow guide 4, a number of front-section guide vanes 5 are evenly and fixedly connected to the outer peripheral wall of the flow guide 4 along the circumferential direction, and the upper end of the front-section guide vanes 5 is fixedly connected to the peripheral wall of the inner volute 1 ;

[0020] The rear guide vane assembly includes a centrally rotatable drive ring 6 set on the outer peripheral surface of the inner volute 1, and the drive ring pins 7 having the same number as the front guide vanes are evenly distributed on the outer periphera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com