Heavy hammer material level detection system and detection method based on image analysis

A material level detection and image analysis technology, applied in the field of machine vision, can solve the problems of increasing the burden of on-site manual maintenance, the heavy hammer being buried by the billet, and the complex mechanical structure, so as to achieve easy use and maintenance, self-maintenance, and wide application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0029] Below in conjunction with accompanying drawing and embodiment the invention patent is further described.

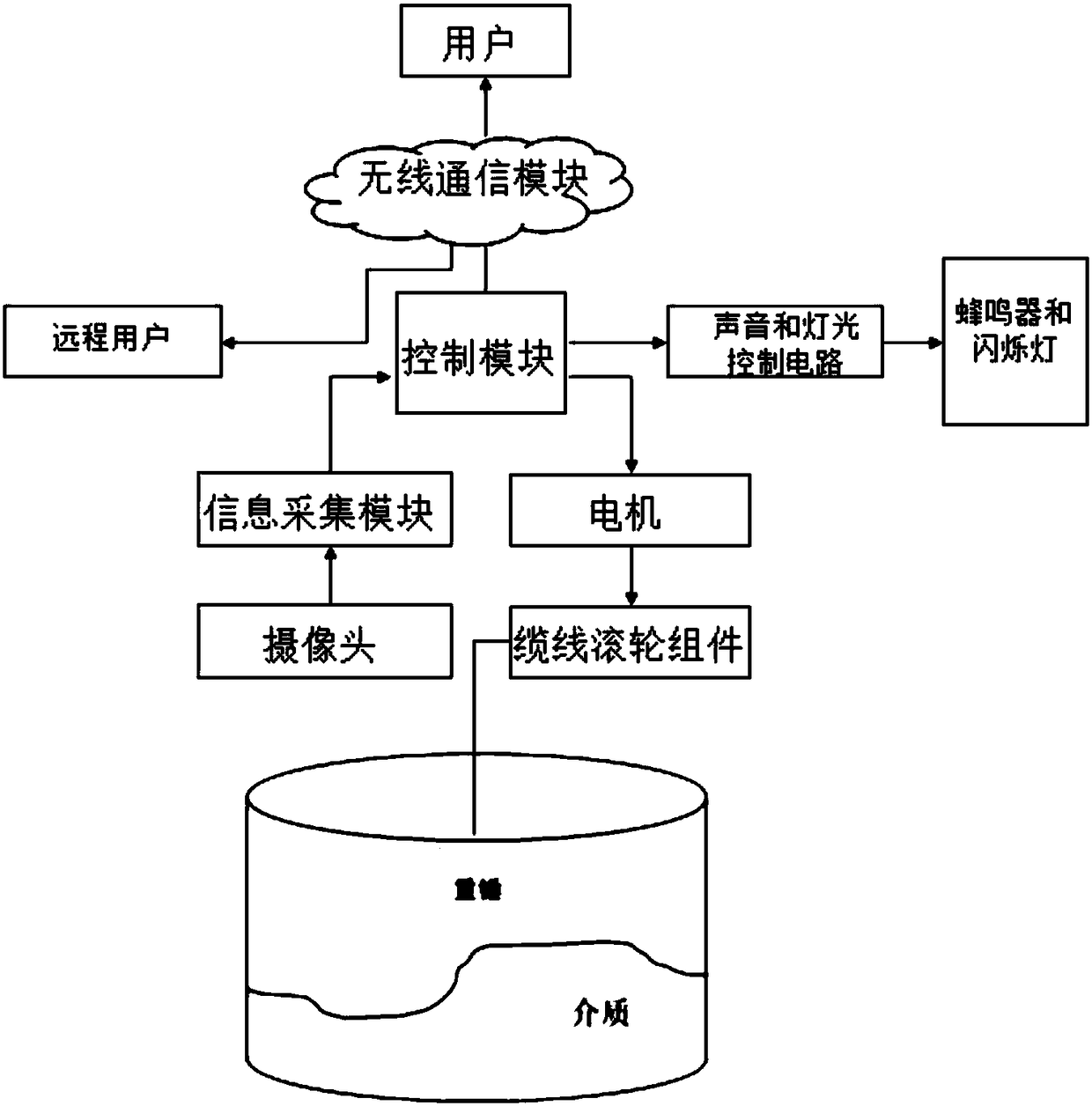

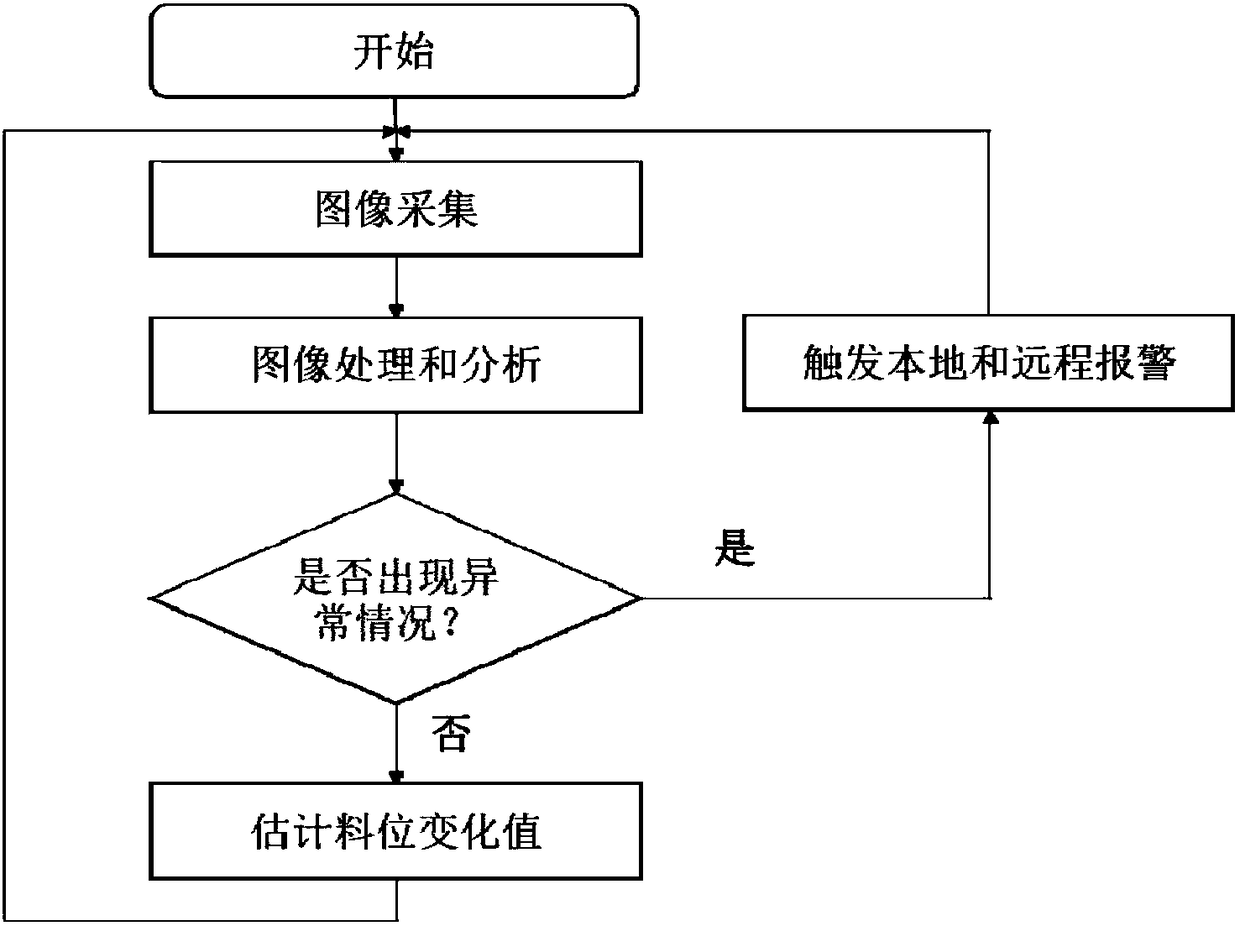

[0030] like figure 1 As shown, the present invention provides a heavy hammer material level detection system based on image analysis, including a control module, a camera, an information collection module, a wireless communication module, a user, a heavy hammer and a cable roller assembly; the heavy hammer is placed in the The camera is placed above the wall of the silo to take images of the movement of the weight in the silo, and the images are sent to the control module via the information collection module, and the control module The received image frame is calculated and processed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com