High-temperature environment high-speed train wheel axle wearing simulation box

A technology for high-speed trains and simulated boxes, which is used in mechanical bearing testing, railway vehicle testing, etc., can solve problems such as inability to determine whether normal operation can be performed, and achieve the effects of simple structure, uniform temperature, and improved operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

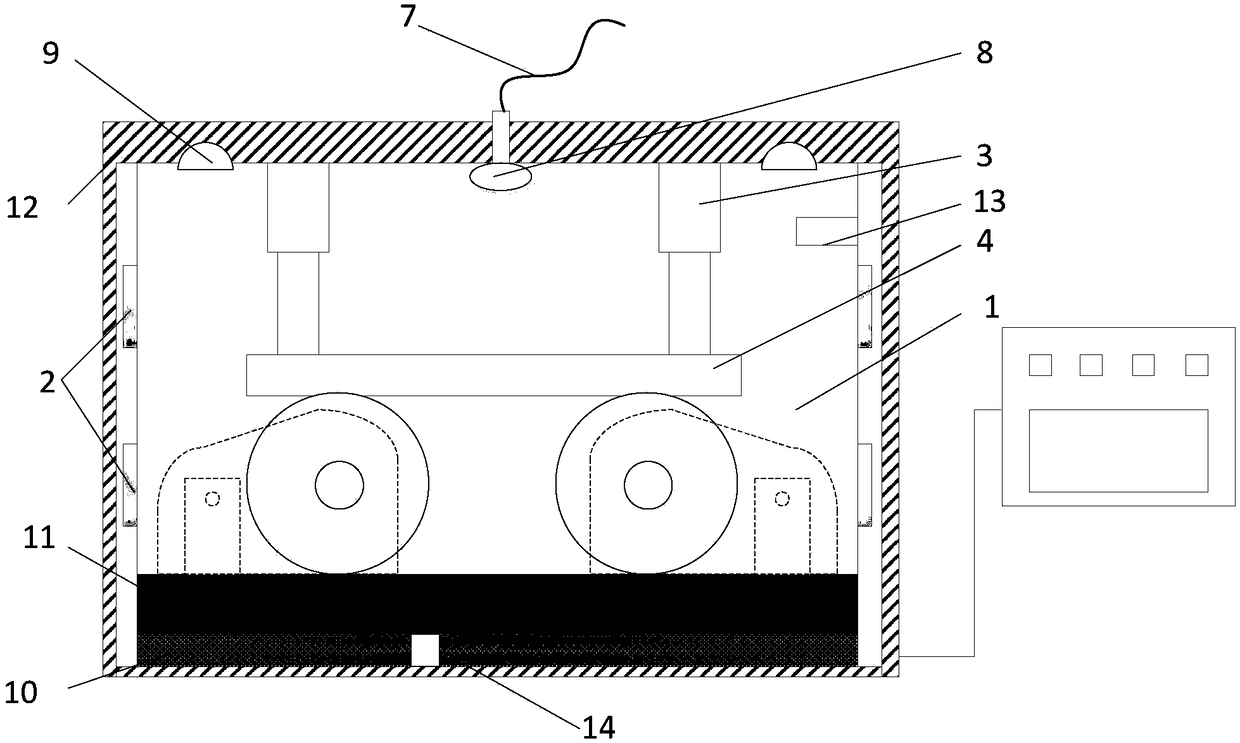

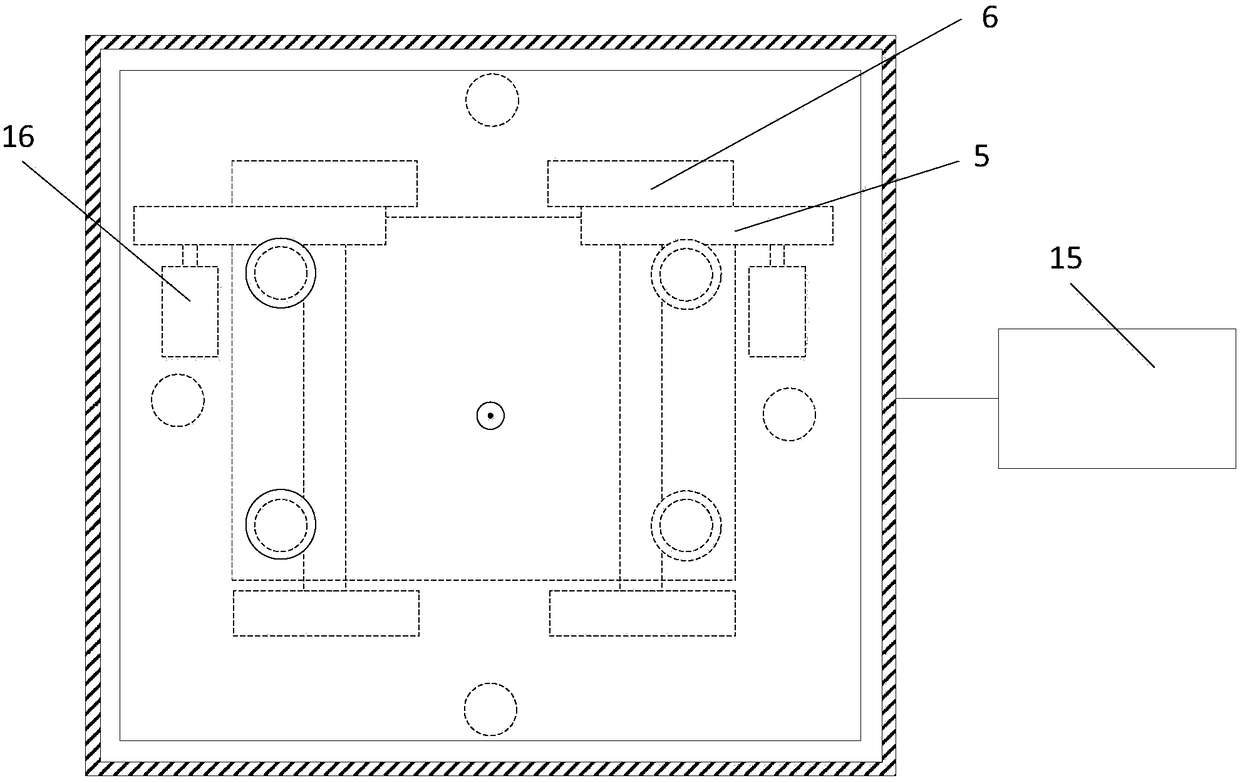

[0015] Please refer to figure 1 , 2 , the embodiment of the present invention provides a high-speed train axle wear simulation box in a high-heat environment, including a box body 1, a fan 2, a pressure shaft 3, a pressure plate 4, and a gear box 5. The fan 2, the pressure shaft 3, the pressure plate 4, The gear box 5 is located inside the box body 1; the fan 2 is located on both sides of the box body 2 to ensure the drying inside the box body 1; Heating, wind heat can ensure uniform heating in the box body 1; the pressure plate 4 is connected to the pressure shaft 3 and is located above the gear box 5; the pressure shaft 3 is connected to an external force applying device; The gear box 5 drives the wheel shaft 6 to be tested to rotate, and the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com