Dangerous material location fire monitoring method and system

A dangerous goods and cargo location technology, applied in the field of warehouse cargo location management, can solve the problems of easy dust interference, hysteresis, cumbersome monitoring point network design and other problems, achieve good economic and social benefits, and ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

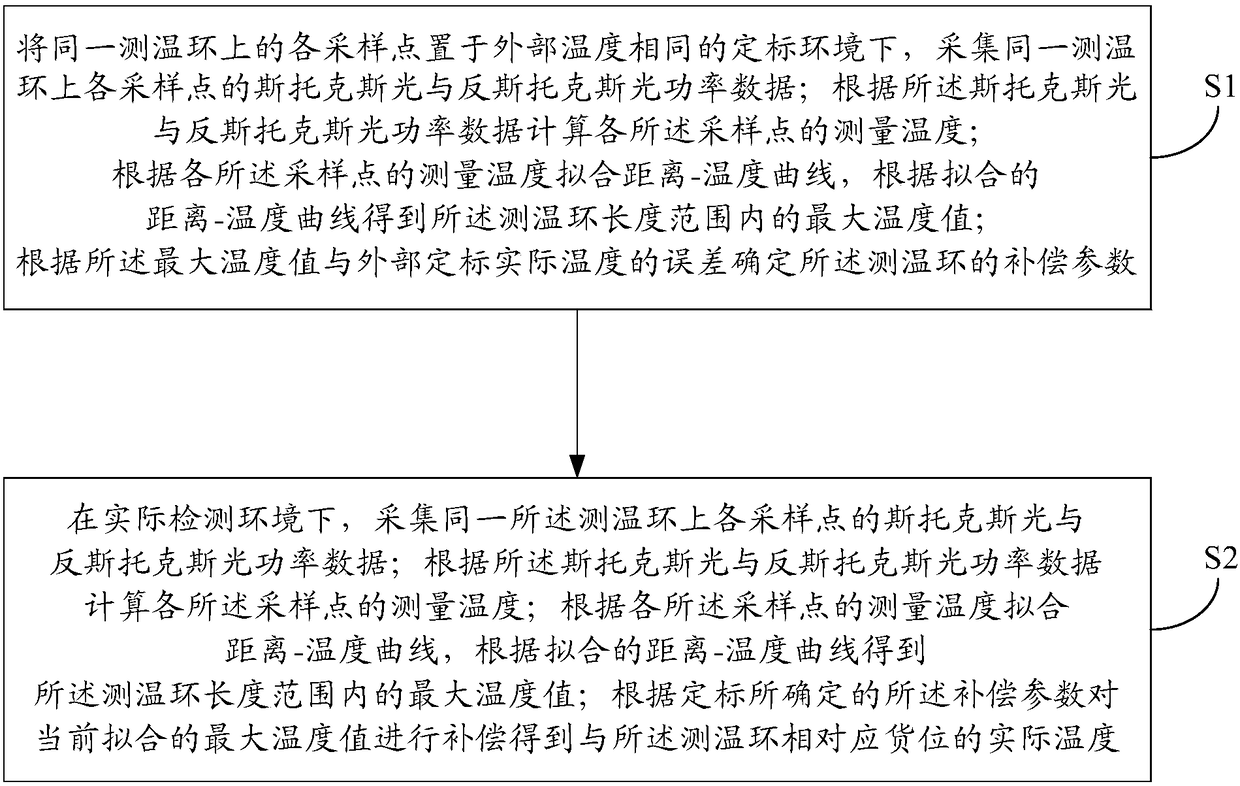

[0019] This embodiment discloses a fire monitoring method for a dangerous cargo space, such as figure 1 shown, including:

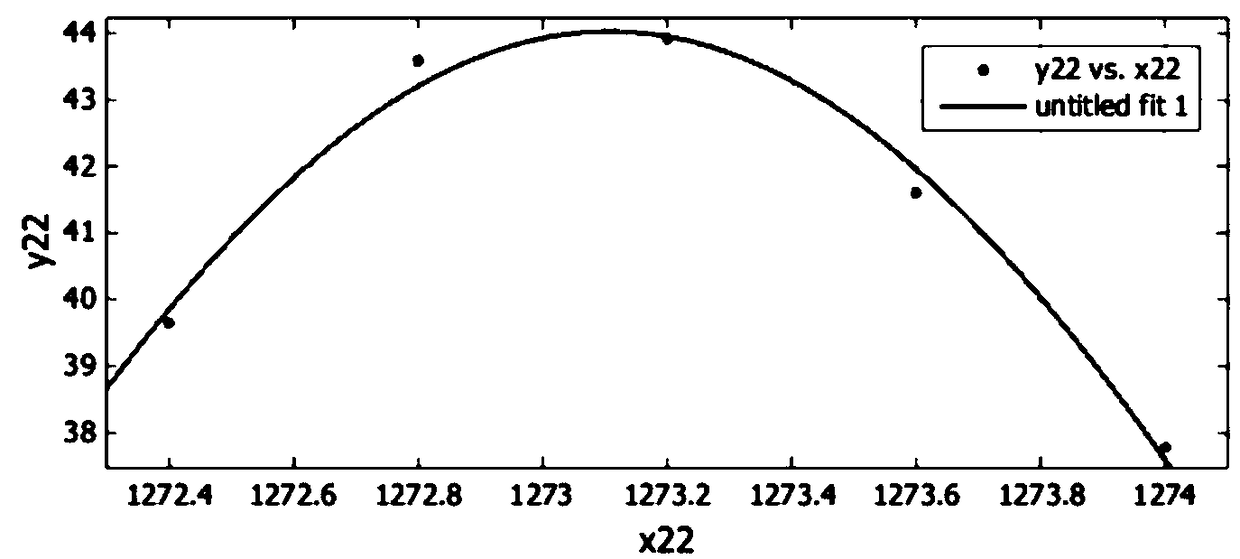

[0020] Step S1, place each sampling point on the same temperature measuring ring in a calibration environment with the same external temperature, and collect the Stokes light and anti-Stokes light power data of each sampling point on the same temperature measuring ring; The Stokes light and anti-Stokes light power data are used to calculate the measured temperature of each of the sampling points; the distance-temperature curve is fitted according to the measured temperature of each of the sampling points, and the distance-temperature curve is fitted according to the fitted distance-temperature curve Obtaining the maximum temperature value within the length range of the temperature measuring loop; determining the compensation parameters of the temperature measuring loop according to the error between the maximum temperature value and the actual temperature...

Embodiment 2

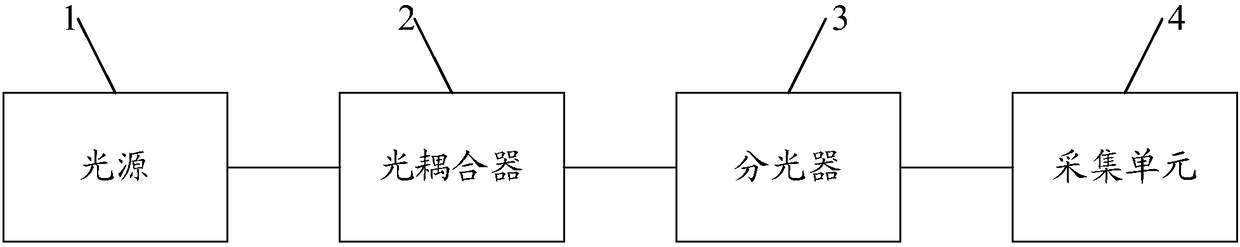

[0045] Corresponding to the above method embodiments, this embodiment discloses a fire monitoring system for dangerous cargo locations, including:

[0046] The first subsystem is used to place each sampling point on the same temperature measuring ring in a calibration environment with the same external temperature, and collect the Stokes light and anti-Stokes light of each sampling point on the same temperature measuring ring power data; calculate the measured temperature of each of the sampling points according to the Stokes light and anti-Stokes light power data; fit the distance-temperature curve according to the measured temperature of each of the sampling points, and The distance-temperature curve obtains the maximum temperature value within the length range of the temperature measuring ring; determines the compensation parameter of the temperature measuring ring according to the error between the maximum temperature value and the actual temperature of the external calibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com