OLED product and production method thereof

A production method and product technology, applied in the production of OLED products, in the field of OLED products, can solve problems such as poor compatibility, and achieve the effects of improving product quality and production efficiency, smooth surface, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

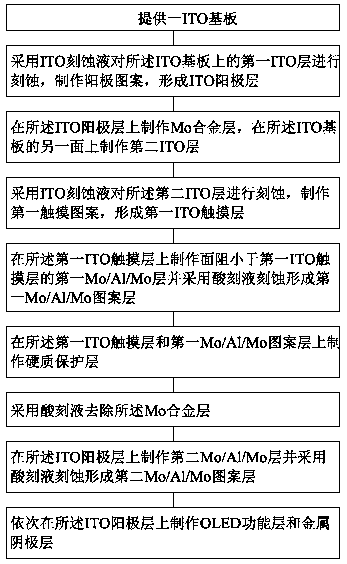

[0028] Such as figure 1 As shown, it represents a manufacturing method of an OLED product provided by the present invention. The manufacturing method of the OLED product specifically includes the following steps:

[0029] Step 1, providing an ITO substrate; specifically, the step 1 may include: step 1.1, providing a transparent substrate; step 1.2, making a SiO2 layer on the transparent substrate; step 1.2, plating the second SiO2 layer on the SiO2 layer One ITO layer. Wherein, the transparent substrate is preferably a glass substrate, and its surface is polished before making the SiO2 layer, and the thickness of the SiO2 layer is 200 to 300 Å; the manufacturing method of the first ITO layer is magnetron sputtering, The deposition temperature is between 200-280°C, and the thickness can be 800-2200Å. After the first ITO layer is manufactured, the surface needs to be soft-polished to control its surface roughness Ra<10Å.

[0030] Step 2, using ITO etchant to etch the first IT...

Embodiment 2

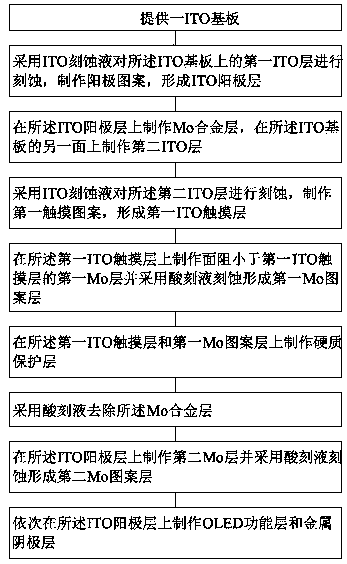

[0041] The principle of this embodiment is the same as that of the previous embodiment, and the structure is similar. The only difference is that, as figure 2 As shown, the first Mo / Al / Mo layer is replaced by the first Mo layer, and the first Mo / Al / Mo pattern layer is replaced by the first Mo pattern layer;

[0042] Specifically, a method for manufacturing an OLED product provided in this embodiment specifically includes the following steps:

[0043] Step 1, providing an ITO substrate;

[0044] Step 2, using an ITO etchant to etch the first ITO layer on the ITO substrate to make an anode pattern to form an ITO anode layer;

[0045] Step 3, making a Mo alloy layer on the ITO anode layer, and making a second ITO layer on the other side of the ITO substrate;

[0046] Step 4, using ITO etchant to etch the second ITO layer to make a first touch pattern to form a first ITO touch layer;

[0047] Step 5. On the first ITO touch layer, make a first Mo layer with an area resistance l...

Embodiment 3

[0054] This embodiment provides an OLED product, which is obtained by using the method for manufacturing an OLED product described in any of the above embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com