Production process of metal gear shifting ball head

A manufacturing process and ball head technology, which is applied in metal material coating process, superimposed layer plating, coating, etc., can solve problems such as damage, surface scratches, deformation, etc., and achieve the goal of improving wear resistance and strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to easily understand the technical means, creation features, objectives and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

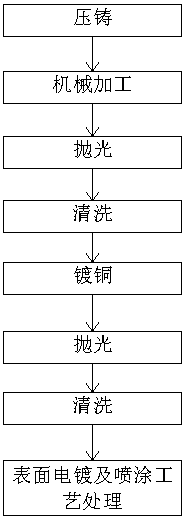

[0024] Such as figure 1 As shown, a manufacturing process of a metal shift ball head includes the following steps:

[0025] (1) Die-casting: the aluminum alloy ingot is melted to form the base material of the part by die-casting;

[0026] (2) Machining: The base material of the part is machined through the CNC process, and the CNC equipment processes the base material of the part and forms a specific shape;

[0027] (3) Polishing: Mirror polishing is performed on the surface of the part to ensure the smoothness of the surface;

[0028] (4) Cleaning: Clean the polished parts;

[0029] (5) Copper plating: Copper plating is performed on the surface of the part to fill the air holes generated when the surface of the part is polished;

[0030] (6) Polishin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com