Feeding device in Chinese art paper production

A technology of feeding device and rice paper, applied in bark, wood processing utensils, manufacturing tools, etc., can solve the problems of personal injury of operators, low efficiency and unsafety of raw material preparation and feeding, etc. Improve efficiency and avoid the effect of stress extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

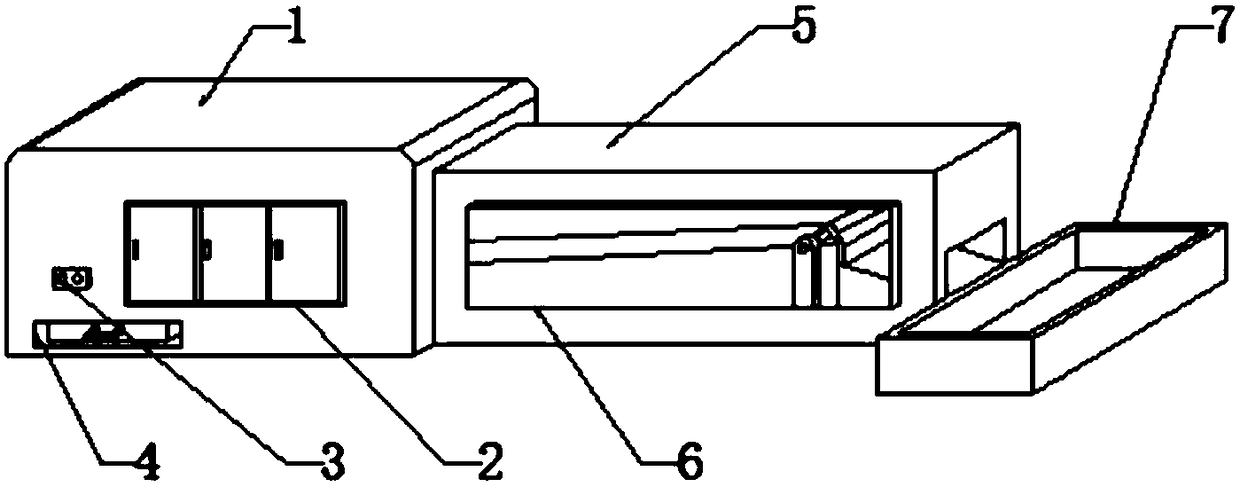

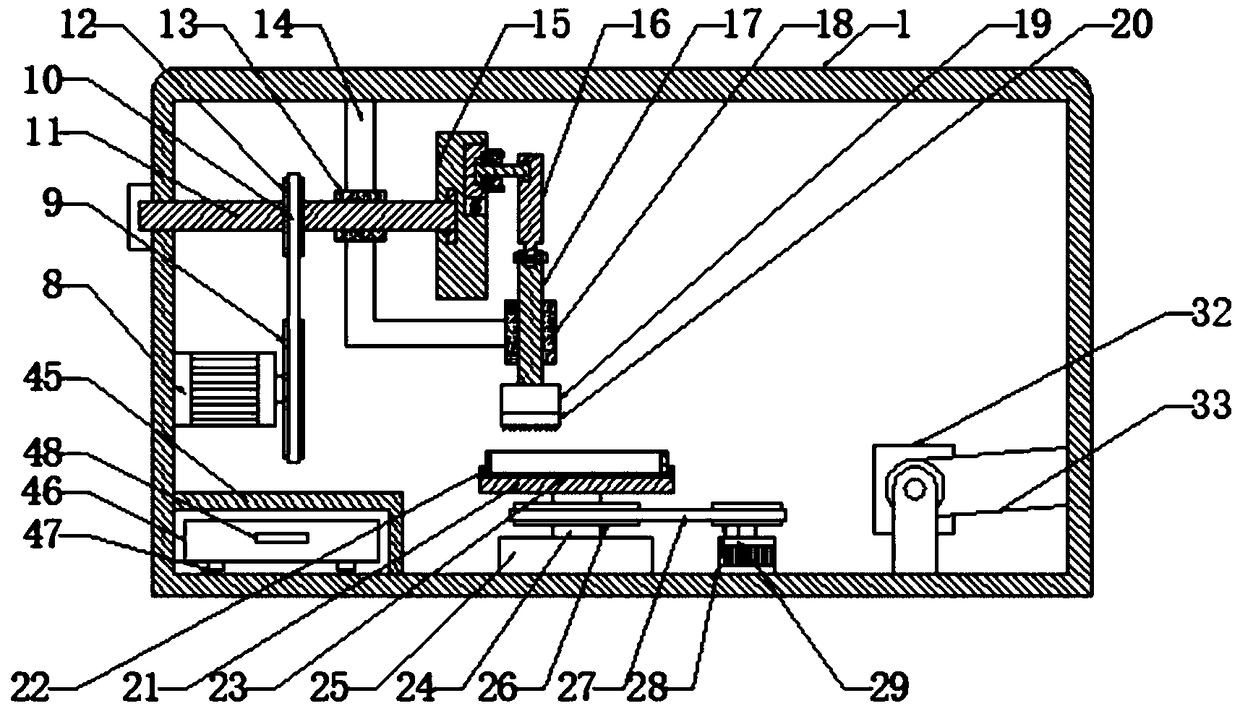

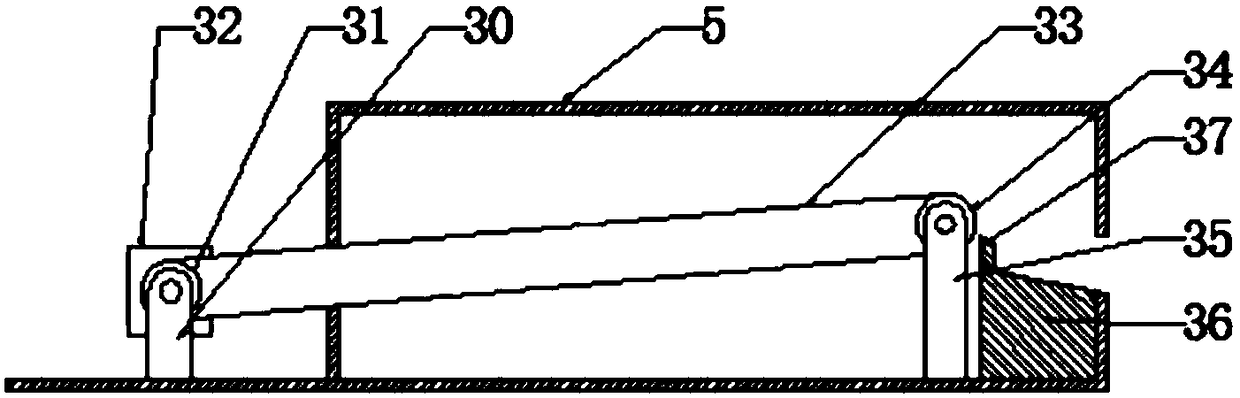

[0024] see Figure 1-5 , the present invention provides a technical solution: a feeding device in the production of rice paper, including a processing mechanism for peeling raw materials, the processing mechanism includes a first shell 1, the middle of one side of the first shell 1 is provided with a moving Door 2, the side of the first shell 1 side is provided with a control switch 3, the bottom of the first shell 1 side is provided with a through hole 4, the inside of the first shell 1 is provided with a transmission mechanism, and the transmission mechanism is connected with the peeling piece. Connection, the bottom of the peeling piece is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com