Sound insulation mortar and preparation method thereof

A mortar and elastic damping technology, which is applied in the field of sound-proof mortar and its preparation, can solve problems such as difficult to meet floor noise, and achieve good sound-proof effect, easy purchase of raw materials, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The soundproof mortar of this embodiment includes the following components in parts by weight: 30 parts of sand, 10 parts of cement, 5 parts of elastic damping particles, 2 parts of polyester fiber, and 1 part of cement foaming agent, wherein the elastic damping particles are rubber Particles, the raw material of the rubber particles is from waste tires, the particle size of the sand is 1 mm, the particle size of the elastic damping particles is 1 mm, and the particle size of the polyester fiber is 1 mm.

[0017] The preparation method of the soundproof mortar of the present embodiment may further comprise the steps:

[0018] (1) mixing and stirring the above-mentioned nano-zinc, nano-scale titanium dioxide, resin, nano-silver and water;

[0019] (2) Heat the above slurry at 40-80°C and continue to stir evenly, and control the pH value of the slurry to 1-2 during the heating and stirring process;

[0020] (3) Testing and packaging.

[0021] According to JGJ / T 70-2009 ...

Embodiment 2

[0027] The soundproof mortar of this embodiment includes the following components in parts by weight: 35 parts of sand, 12 parts of cement, 6 parts of elastic damping particles, 3 parts of polyester fiber, and 1.2 parts of cement foaming agent, wherein the elastic damping particles are rubber Particles, the raw material of the rubber particles comes from waste tires, the particle size of the sand is 2 mm, the particle size of the elastic damping particles is 3 mm, and the particle size of the polyester fiber is 5 mm. .

[0028] The preparation method and usage method of the soundproof mortar of this embodiment are the same as the first embodiment.

Embodiment 3

[0030] The soundproof mortar of this embodiment includes the following components in parts by weight: 32 parts of sand, 11 parts of cement, 5 parts of elastic damping particles, 3 parts of polyester fiber, and 1 part of cement foaming agent, wherein the elastic damping particles are rubber Particles, the raw material of the rubber particles comes from waste tires, the particle size of the sand is 1.5 mm, the particle size of the elastic damping particles is 2 mm, and the particle size of the polyester fiber is 3 mm.

[0031] The preparation method and usage method of the soundproof mortar of this embodiment are the same as the first embodiment.

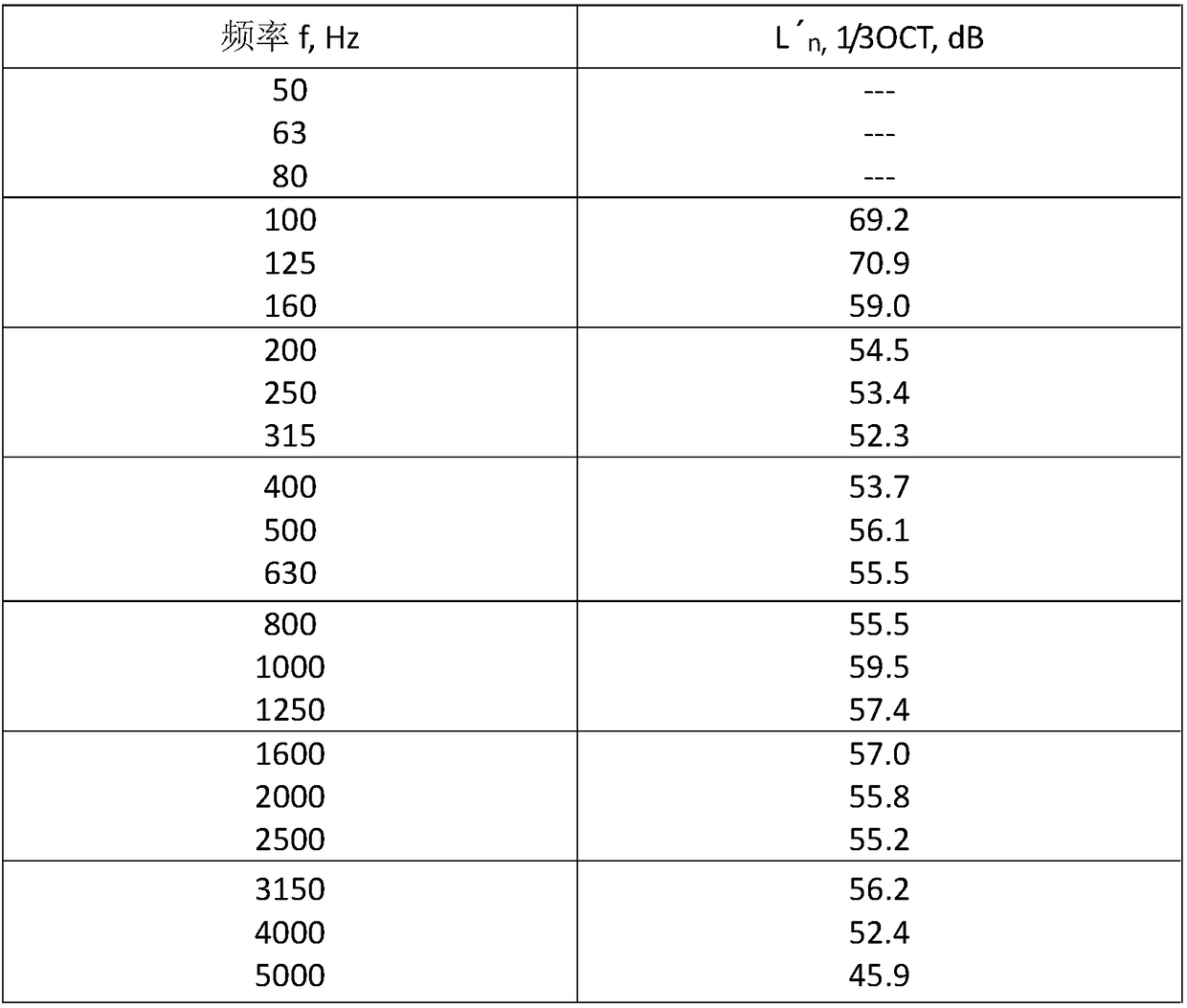

[0032] The sound insulation mortar of the present invention is used for building floors, and the effect of sound insulation is better achieved. According to GB / T19889.7-2005 "Acoustic Building and Building Components Sound Insulation Measurement Part 7: On-site Measurement of Floor Impact Sound Insulation" , after testing, through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com