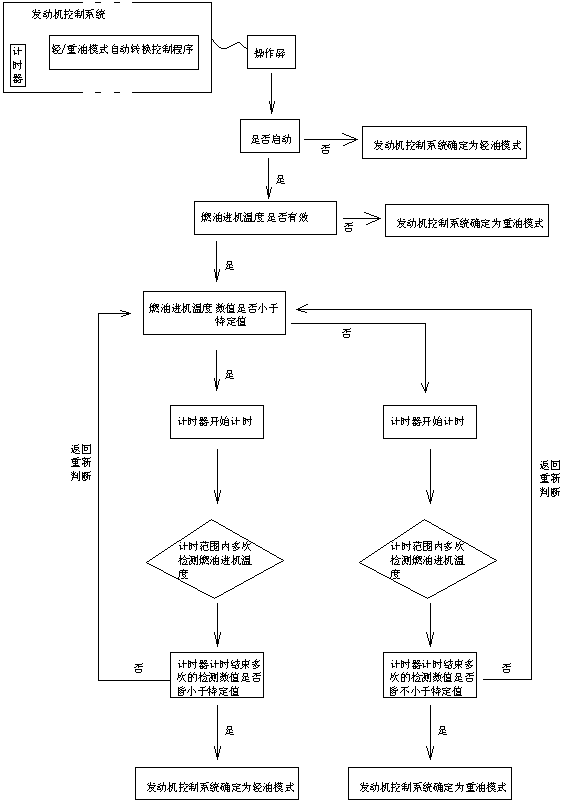

Automatic light oil mode and heavy oil mode switching control method

A technology of automatic conversion and control methods, applied in the direction of engine control, machine/engine, combustion engine, etc., which can solve the problems of cumbersome operation, increased production cost, and increased wiring layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1

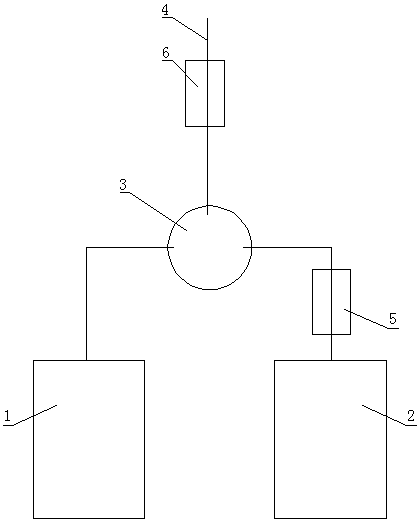

[0028] The existing ship A adopts X-type marine engine, which is equipped with relevant hardware such as engine control system, operation panel, fuel temperature sensor, etc., and its mutual connection relationship will not be described in detail, and the engine control system The light / heavy fuel mode automatic conversion control program is implanted in the engine;

[0029] When the ship is driving in the offshore waters, the above-mentioned light / heavy fuel mode automatic conversion control program is not started, the engine control system of the X-type marine engine directly uses the light fuel mode, and the engine runs normally for 20 nautical miles.

[0030] After the ship sails into the deep sea area, the above-mentioned light / heavy fuel mode automatic conversion control program is started, the engine control system extracts the temperature value collected from the fuel temperature sensor, and no fuel inlet temperature is detected, that is, the fuel in...

Embodiment 2

[0032] Existing ship B adopts X-type marine engine, which is equipped with related hardware such as engine control system, operation panel, fuel temperature sensor, etc., and its mutual connection relationship will not be described in detail, and the engine control system The light / heavy fuel mode automatic conversion control program is implanted in the engine;

[0033] When the ship is driving in the offshore waters, the above-mentioned light / heavy fuel mode automatic conversion control program is not started, the engine control system of the X-type marine engine directly uses the light fuel mode, and the engine runs normally for 30 nautical miles.

[0034]After the ship sails into the deep sea area, start the above-mentioned light / heavy fuel mode automatic conversion control program, the engine control system extracts the temperature value collected from the fuel temperature sensor, the value of the fuel oil inlet temperature is 85°C, if it is greater than the specified value...

Embodiment 3

[0036] The existing ship C adopts X-type marine engine, which is equipped with related hardware such as engine control system, operation panel, fuel temperature sensor, etc., and its mutual connection relationship will not be described in detail, and the engine control system The light / heavy fuel mode automatic conversion control program is implanted in the engine;

[0037] When the ship is running in the sea, start the above-mentioned light / heavy fuel mode automatic conversion control program, the engine control system extracts the temperature value collected from the fuel temperature sensor, the value of the fuel oil inlet temperature is 41 ℃, if it is less than a specific value of 80 ℃, start the timer , through multiple judgments by the engine control system within 5s that the fuel inlet temperature values are all less than 80°C, the light / heavy fuel mode automatic switching control program sends a signal to the engine control system to ensure that the engine control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com