Order-oriented flexible production dynamic scheduling system based on multi-agent

A flexible production and dynamic scheduling technology, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve the problems of low resource utilization, reduced flexibility, shortage of raw materials, etc. The effect of adaptability and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

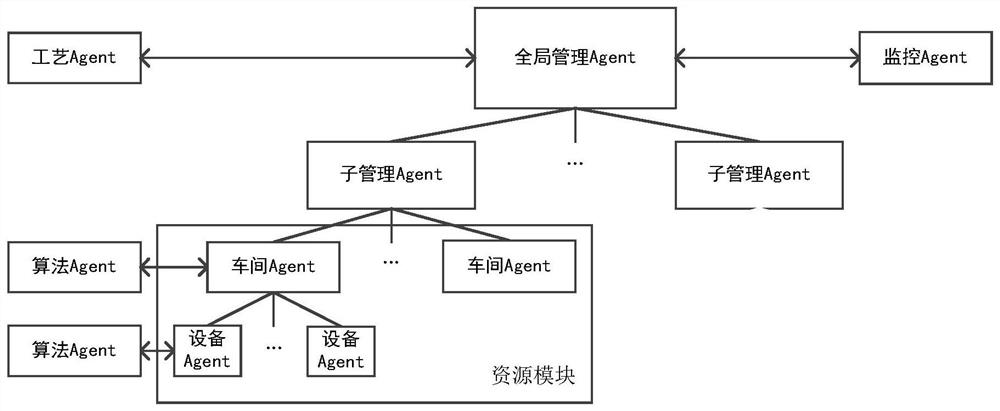

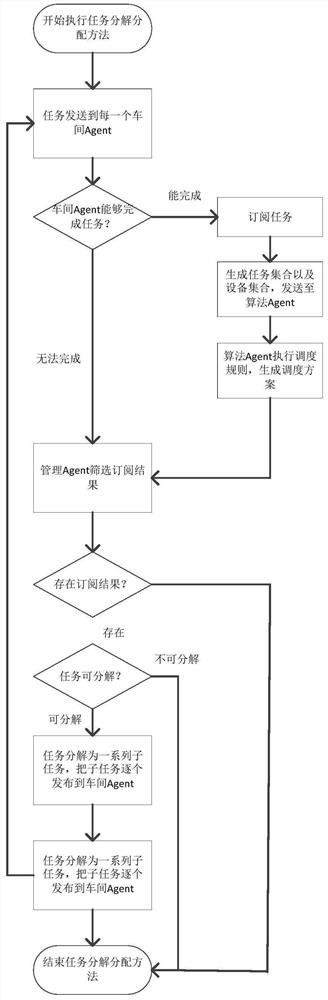

[0092] Embodiment 1: When the dynamic scheduling system is started, the following operations are performed:

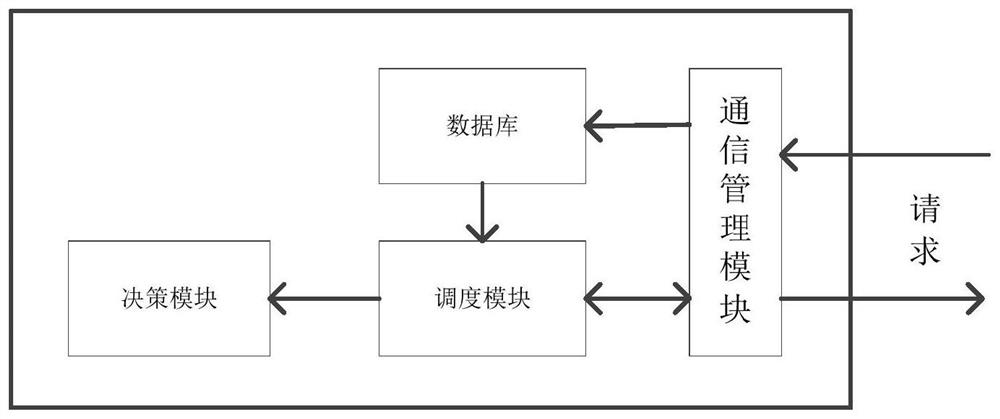

[0093] S1. Start the global management agent. The management agent runs in the center of the whole scheduling system, which is equivalent to the central server. After the management agent is started, the communication management module and the scheduling execution module are initialized, and the registration from other agents is monitored. Display the work progress of workshops and equipment in each factory to the system administrator through the interface.

[0094] S2, start the process Agent. The process agent provides data query service for other agents, so the startup sequence is second only to the global management agent. The system administrator can view the process confidence managed by the process agent through the interface, and can perform operations such as adding, deleting, checking, and modifying the process information.

[0095] S3. Start the algorith...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com