Adjustable type longitudinal beam balance shaft set hole drilling template

A balancing shaft and adjustable technology, applied in the direction of drilling molds for workpieces, etc., can solve the problems of drilling template shaking, easy hole deviation, uncontrollable gap between drilling template and L plate, etc., to ensure the drilling quality and prevent The effect of partial hole problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

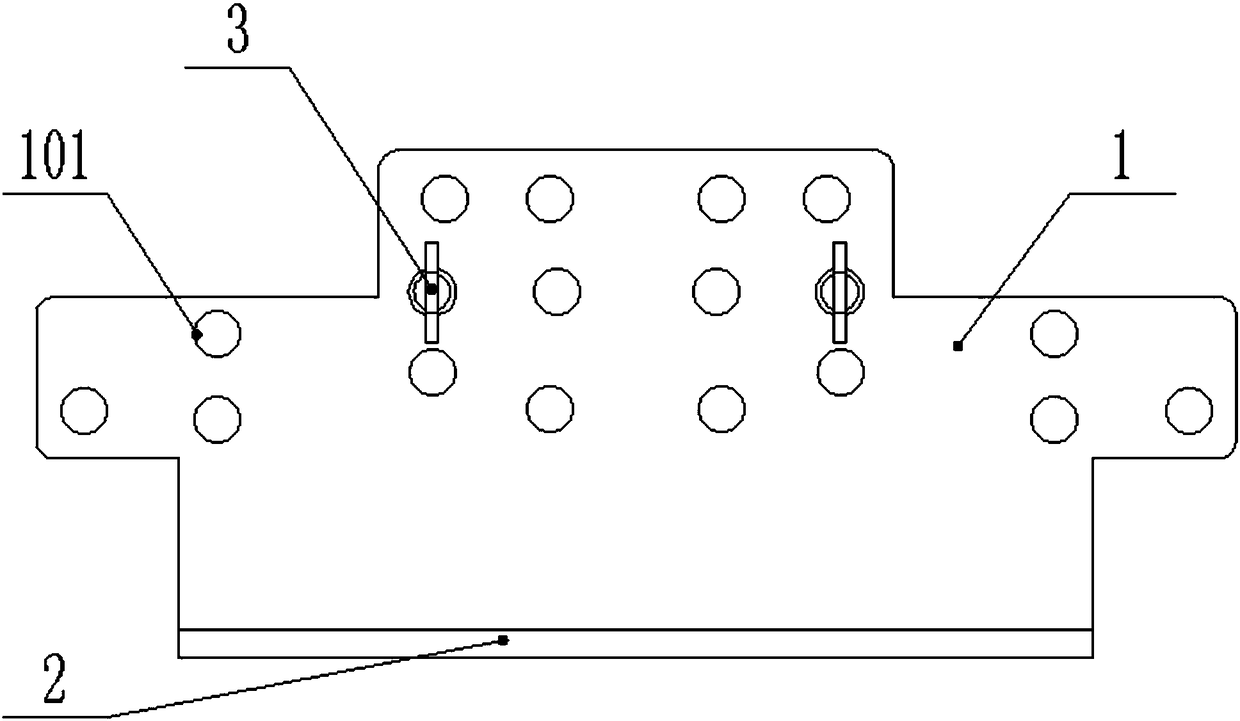

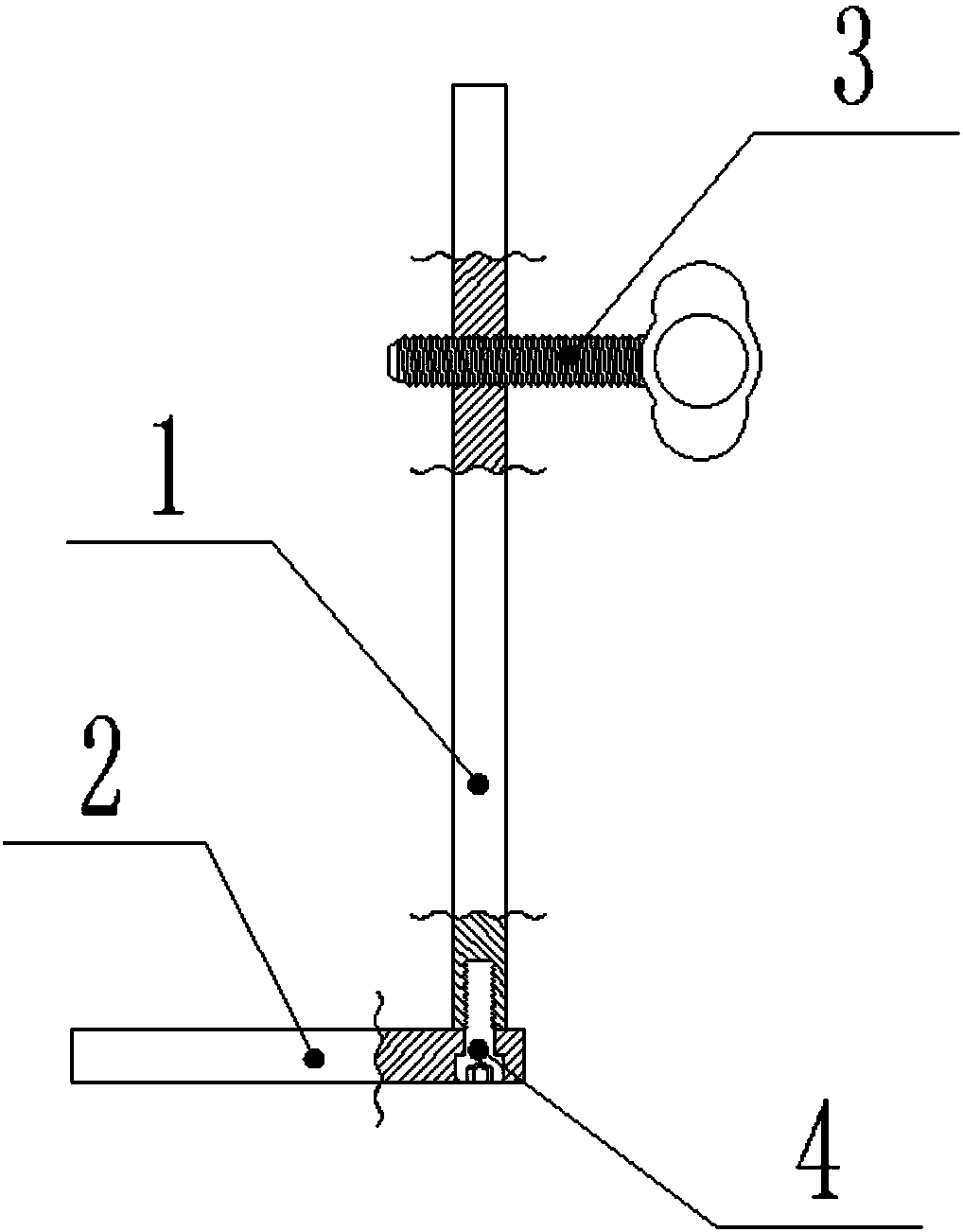

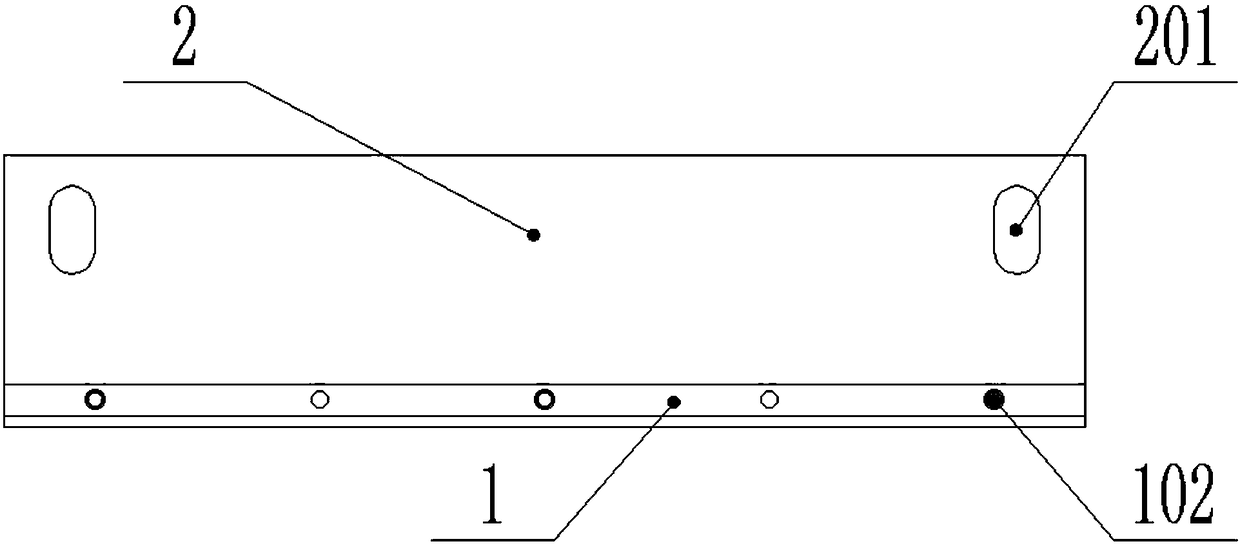

[0024] as attached figure 1 to attach image 3 Shown:

[0025] The present invention provides an adjustable longitudinal beam balance shaft group hole drilling template, including an airfoil drill positioning template 1, screw adjustment holes 101, through holes 102, ventral positioning 2, positioning holes 201, M15 screws 3 and countersunk head hexagonal bolts 4; The diameter of the screw adjustment hole 101 provided inside the airfoil drill positioning template 1 is 18 mm, and the top end surface of the airfoil drill positioning template 1 is provided with five through holes 102; the ventral positioning 2 is a rectangular plate structure, and the ventral surface There are two positioning holes 201 at the front end of the positioning 2; the M15 screw 3 is installed on the airfoil drill positioning template 1, and the top of the countersunk head hex bolt 4 is installed in the bottom of the airfoil drilling positioning template 1.

[0026] Wherein, the airfoil drill positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com