CNC machining center

A machining center and machine tool technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of not designing a classification and receiving cutting chip system, inconvenient cutting chip recycling, affecting production efficiency, etc., to achieve resource improvement. Utilization rate, efficiency improvement, effect of easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

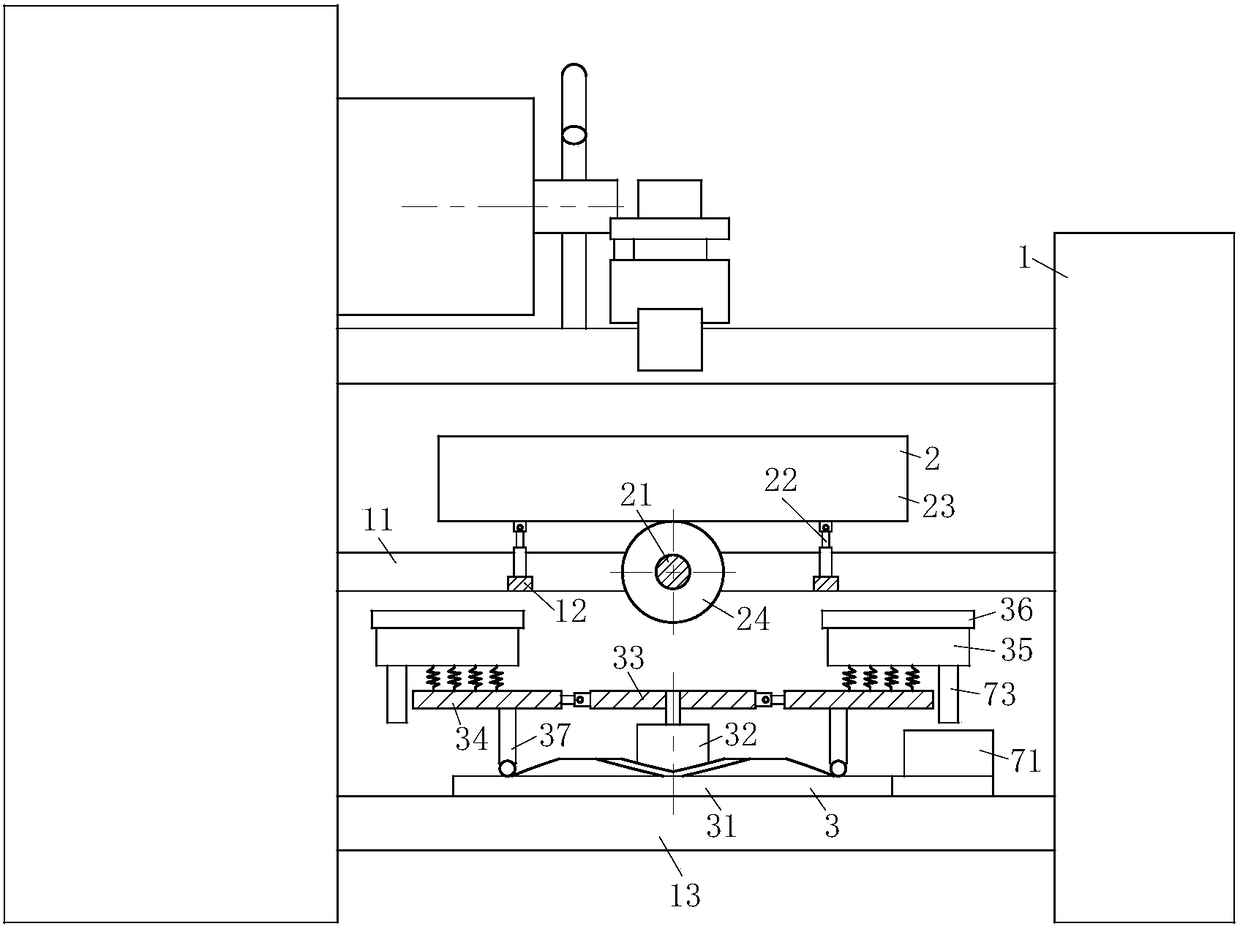

[0036] As an embodiment of the present invention, the classification module 3 includes a chassis 31, a rotary motor 32, a turntable 33, a vibration plate 34, a classification box 35, a screen frame 36, a support rod 37 and a projection 38; the chassis 31 passes through The second beam 13 is fixedly installed at the bottom of the machine tool 1; the middle of the chassis 31 is fixedly installed with a rotary motor 32; the upper end of the rotating shaft of the rotary motor 32 is fixedly connected to a turntable 33; The classification box 35 is installed on the upper surface of the vibration plate 34 through a set of springs; the classification box 35 is provided with a screen frame 36, and the screen frame 36 is used to separate the liquid in the cutting chips; one end of the support rod 37 is fixedly connected On the lower surface of the vibration plate 34; the other end of the support rod 37 is rotatably mounted with a rolling ball; the rolling ball contacts the upper surface ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap