White bar aramid fiber paper honeycomb core stretching and unfolding method

A honeycomb core and aramid paper technology, applied in household components, household appliances, other household appliances, etc., can solve the problems of high maintenance cost, high cost and high equipment price, and achieve wide adaptability, low cost and convenient implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

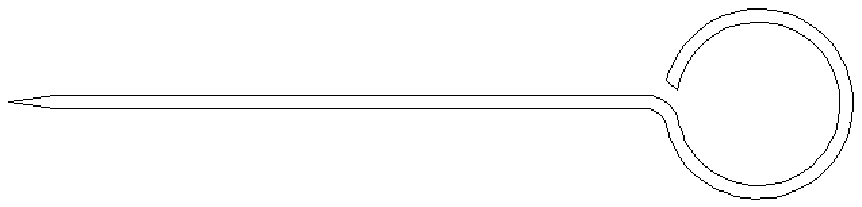

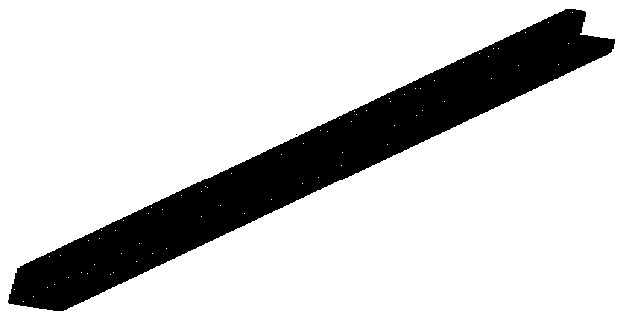

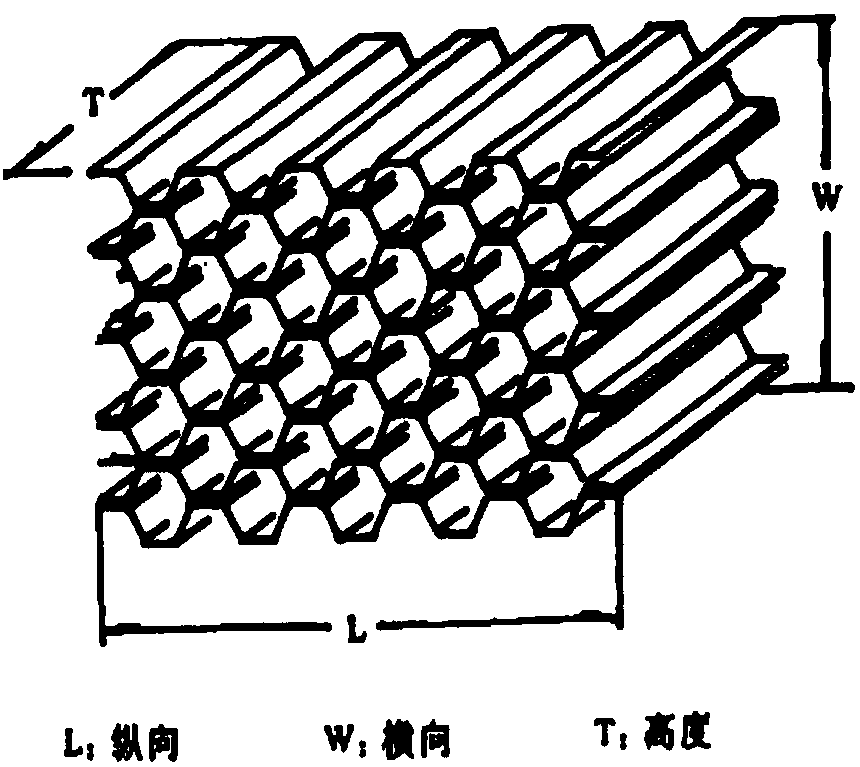

[0015] Such as Figure 1-3 As shown, a method for solving the stretching and unfolding of the white-striped aramid paper honeycomb core includes the following steps: using 4 L-shaped materials and multiple pins to fix the white-striped aramid paper honeycomb core horizontally; Stretch and unfold.

[0016] In the above steps, the 4 L profiles are placed in pairs back to back, and the two sets of L profiles are placed in parallel at both ends of the white striped aramid paper honeycomb core. The core is fixed, and each group of L-shaped profiles is manually clamped. The four people retreat evenly in pairs, and horizontally unfold the white aramid paper honeycomb core along the W direction. The height of the insertion pin is determined according to the height T of the honeycomb core. After the honeycomb cell is unfolded, it should be approximate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com