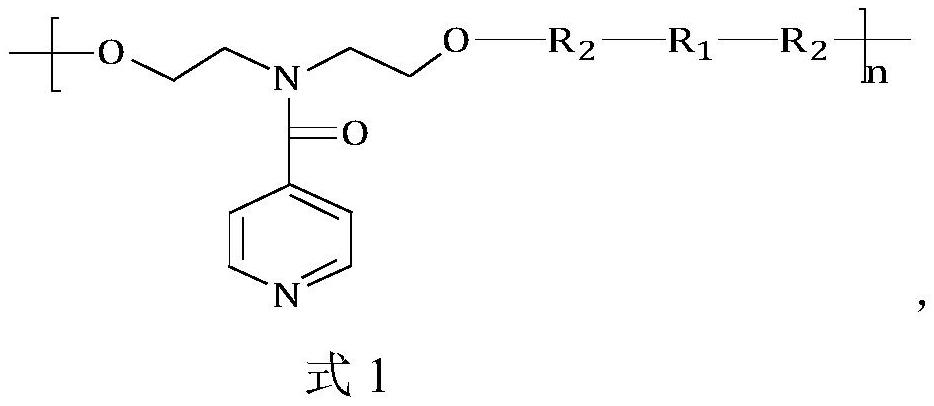

A kind of pH sensitive biodegradable polyurethane urea material and preparation method thereof

A technology of biodegradation and polyurethane urea, applied in the field of polymer chemistry, can solve the problems of cumbersome preparation process and long time-consuming, and achieve the effects of simple process, improved mechanical properties, and avoidance of acidic inflammation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

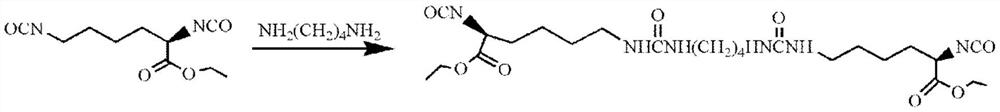

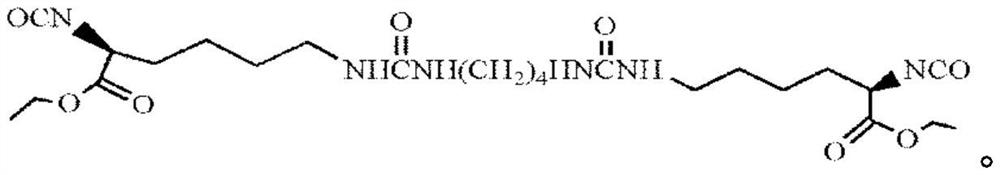

Method used

Image

Examples

Embodiment 1

[0057] Under the protection of dry nitrogen, 10.0g (5mmol) PLA-PEG-PLA (M n =2000, the mass content of PEG is 22.0%) mixed with 6.30g (30mmol) N,N-di(2-hydroxyethyl)isonicotinamide, added N,N-dimethylformamide (DMF) to dissolve (0.5 g / mL), the temperature of the reaction system was raised to 80°C, and the DMF solution (1.0g / mL) of LBL (35.7mmol) was added dropwise. About 10% solution, 8 times the volume of glacial ether is settled, and the obtained solid is vacuum-dried at 35°C to obtain pH-sensitive biodegradable polyurethane urea;

[0058] Dissolve the solid in the organic solvent chloroform to make a solution with a concentration of 6.0% (g / mL), volatilize it with a polytetrafluoroethylene film at 25°C under normal pressure for 80 hours, remove the film from the film, and then warm it at ordinary times. Vacuum-dried to obtain pH-sensitive biodegradable polyurethane urea film material I, and the drug-loaded film material was prepared in the same way.

Embodiment 2

[0060] Under dry nitrogen protection, 20.0g (10mmol) PCL-PEG-PCL (M n =2000, the mass content of PEG is 26.4%) mixed with 14.70g (70mmol) N,N-bis(2-hydroxyethyl)isonicotinamide, added N,N-dimethylformamide (DMF) to dissolve (0.5 g / mL), the temperature of the reaction system was raised to 85°C, and a DMF solution (1.0 g / mL) of LBL (82.1 mmol) was added dropwise. About 10% solution, 8 times the volume of glacial ether is settled, and the obtained solid is vacuum-dried at 35°C to obtain pH-sensitive biodegradable polyurethane urea;

[0061] Dissolve the solid in the organic solvent chloroform to make a concentration of 5.0% (g / mL), use a polytetrafluoroethylene film to volatilize at 28°C under normal pressure for 90 hours, remove the film from the film, and dry it in vacuum at room temperature , to obtain the pH-sensitive biodegradable polyurethane urea membrane material II, and prepare the drug-loaded membrane material by the same method.

Embodiment 3

[0063] Under the protection of dry nitrogen, 15.0g (5mmol) PLA-PEG-PLA (M n =3000, the mass content of PEG is 43.3%) mixed with 8.40g (40mmol) N,N-di(2-hydroxyethyl)isonicotinamide, adding N,N-dimethylformamide (DMF) to dissolve (0.6 g / mL), the temperature of the reaction system was raised to 90°C, and a DMF solution (1.0 g / mL) of LBL (45.7 mmol) was added dropwise. About 10% solution, 8 times the volume of glacial ether is settled, and the obtained solid is vacuum-dried at 35°C to obtain pH-sensitive biodegradable polyurethane urea;

[0064] Dissolve the solid in the organic solvent chloroform to make a concentration of 6.0% (g / mL), use a polytetrafluoroethylene film to volatilize at 22°C under normal pressure for 75 hours, remove the film from the film, and dry it in vacuum at normal temperature , to obtain the pH-sensitive biodegradable polyurethane urea membrane material III, and prepare the drug-loaded membrane material by the same method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com