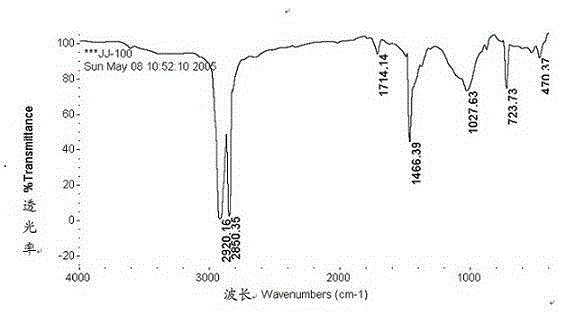

Patents

Literature

33results about How to "Slow degradation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

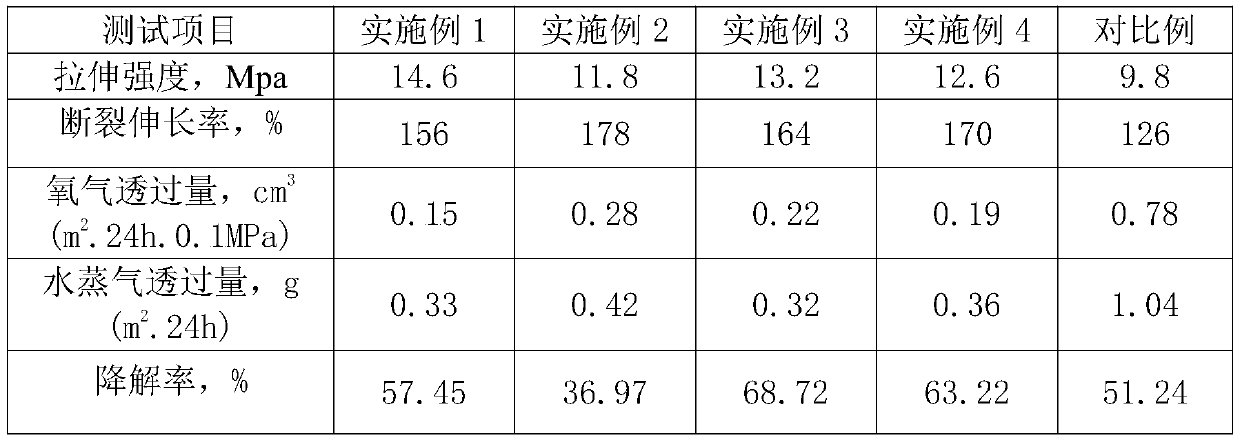

Fully-degradable high-barrier composite material for flexible package as well as preparation method and application thereof

ActiveCN110791069AImprove barrier propertiesGood flexibilityFlexible coversWrappersNanostructured carbonPowder talc

The invention relates to a fully-degradable high-barrier composite material for flexible package, which is mainly prepared by blending the following components in parts by weight: 100 parts of a biodegradable matrix resin, 0-30 parts of an inorganic filler, and 0.1-15 parts of auxiliary agent; preferably, the composite material is formed by double-layer co-extrusion compounding of an inner layer biodegradable matrix resin and an outer layer biodegradable matrix resin; the inner layer biodegradable matrix resin is prepared from the following components in parts by weight: 10 to 90 parts of PBAT, 10 to 90 parts of PCL and 0.1 to 5 parts of an auxiliary agent, and the total weight part of PBAT and PCL is 100 parts; the outer layer biodegradable matrix resin is prepared from the following components in parts by weight: 10 to 90 parts of PBAT, 10 to 90 parts of PLA, 1 to 20 parts of an inorganic filler and 0.1 to 8 parts of an auxiliary agent, and the total weight part of PBAT and PLA is 100 parts, and the inorganic filler is nano calcium carbonate or talcum powder.

Owner:佰信(福建)新材料科技有限公司

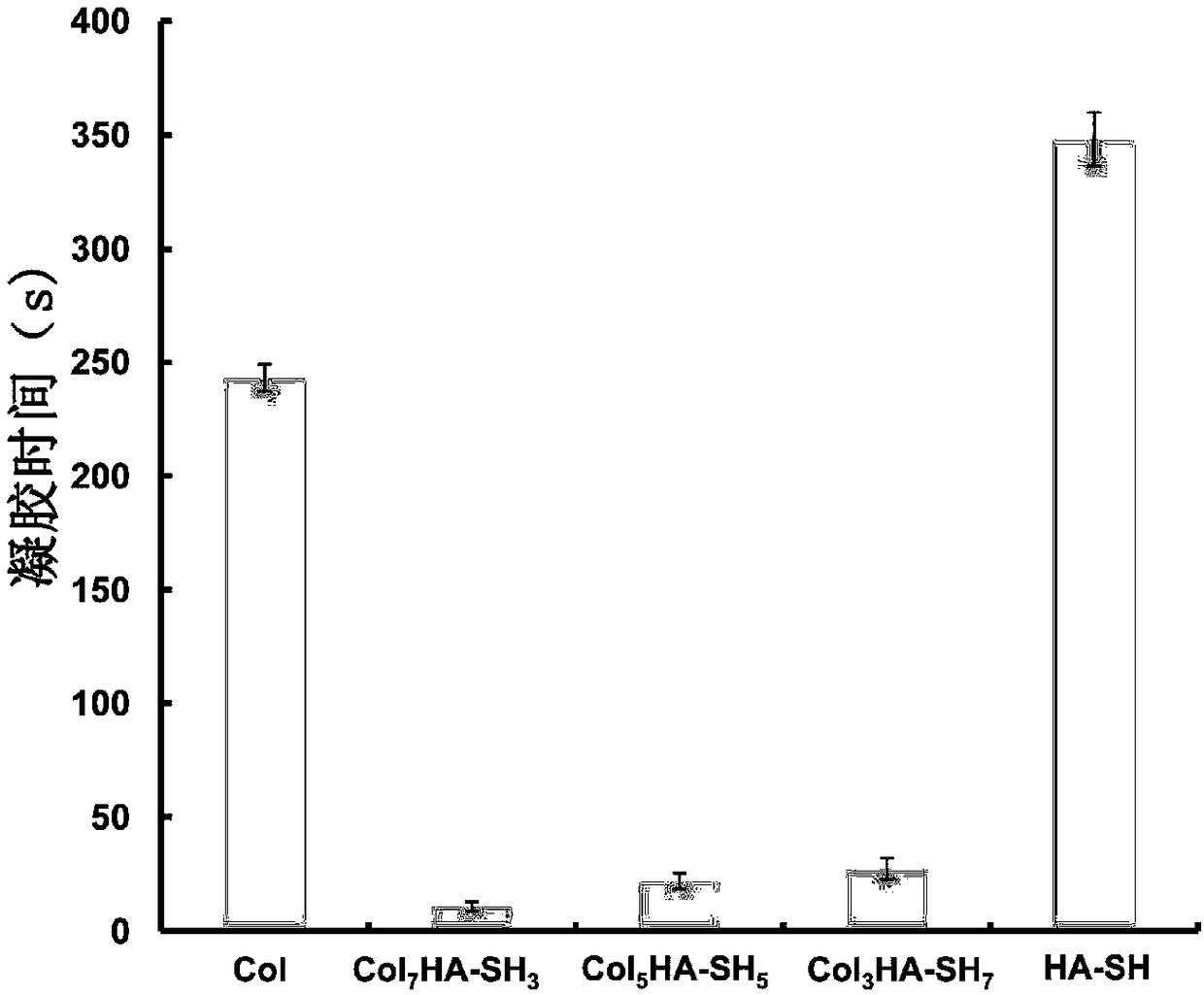

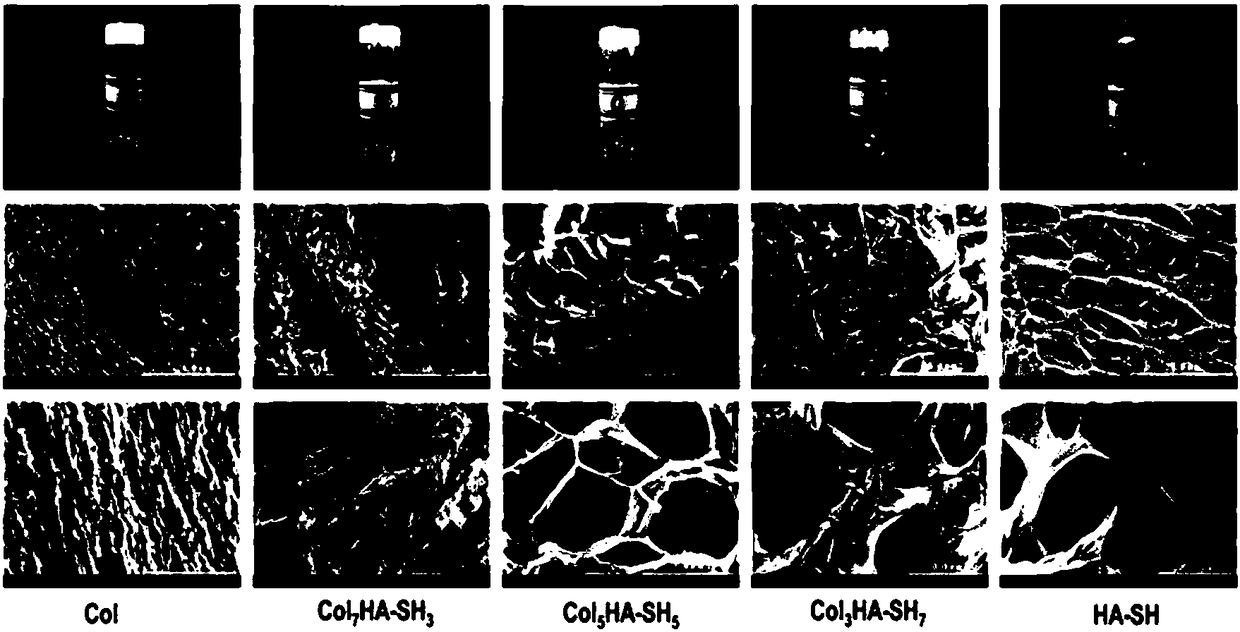

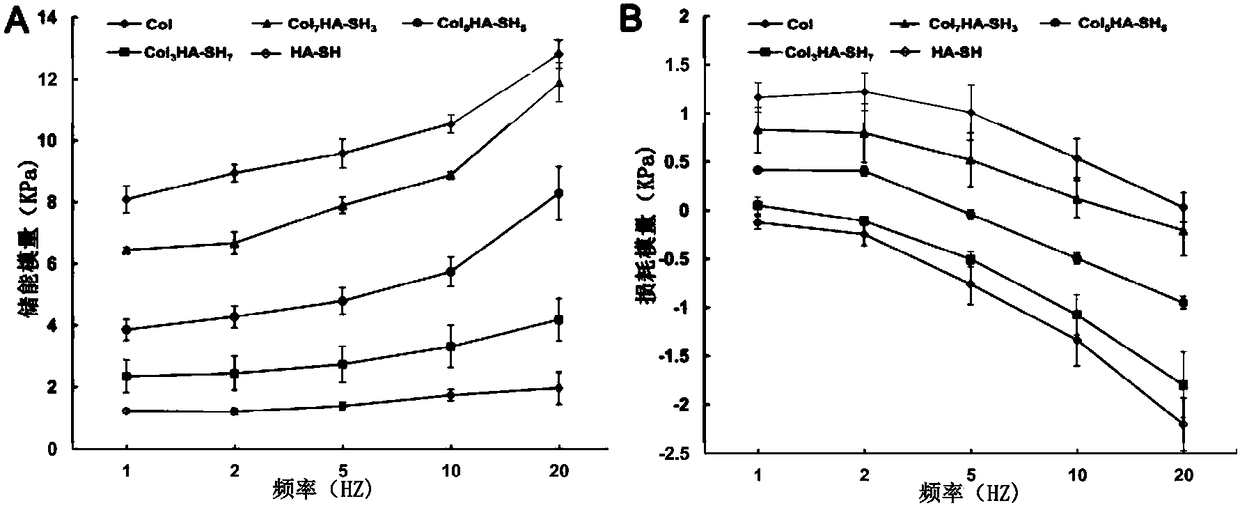

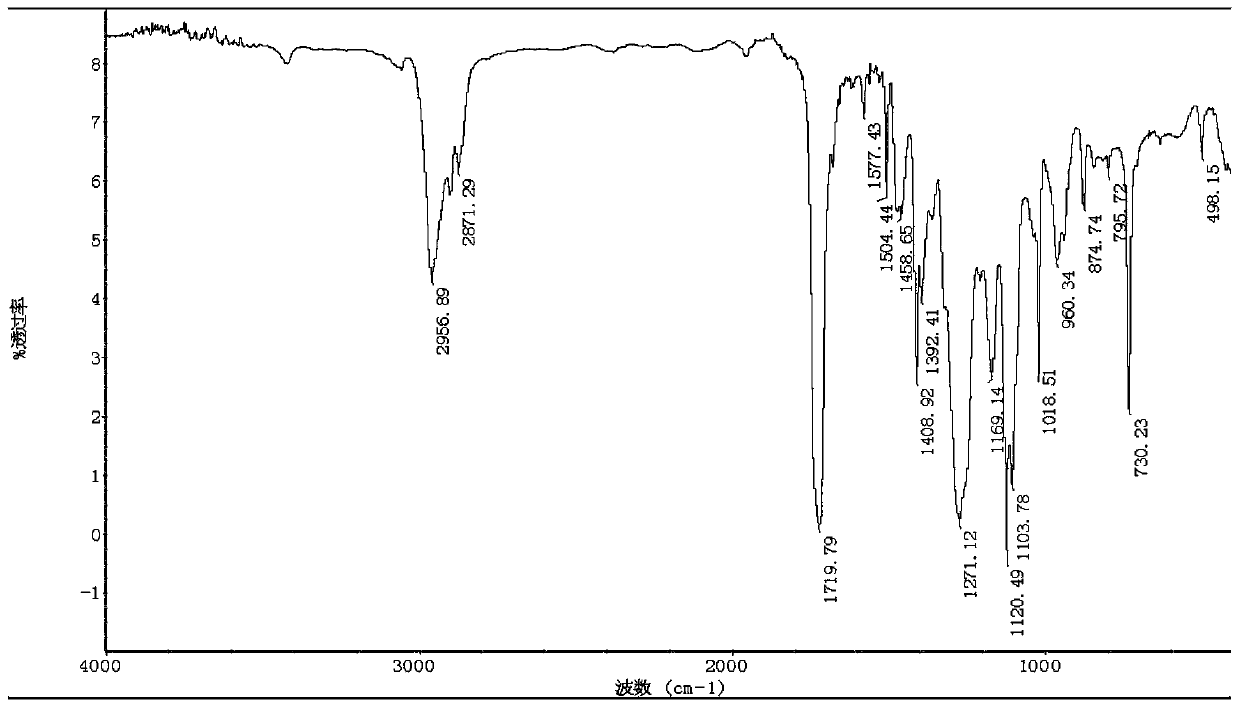

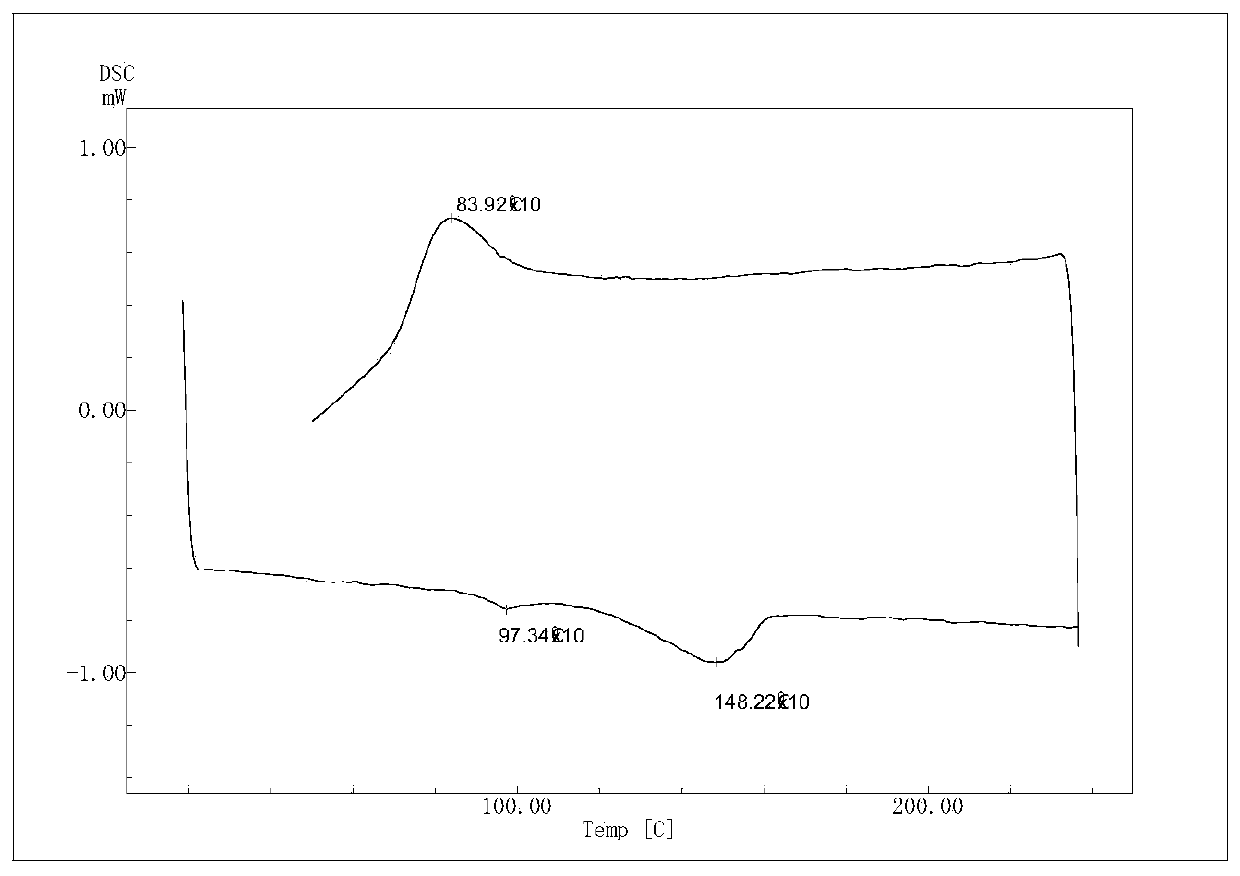

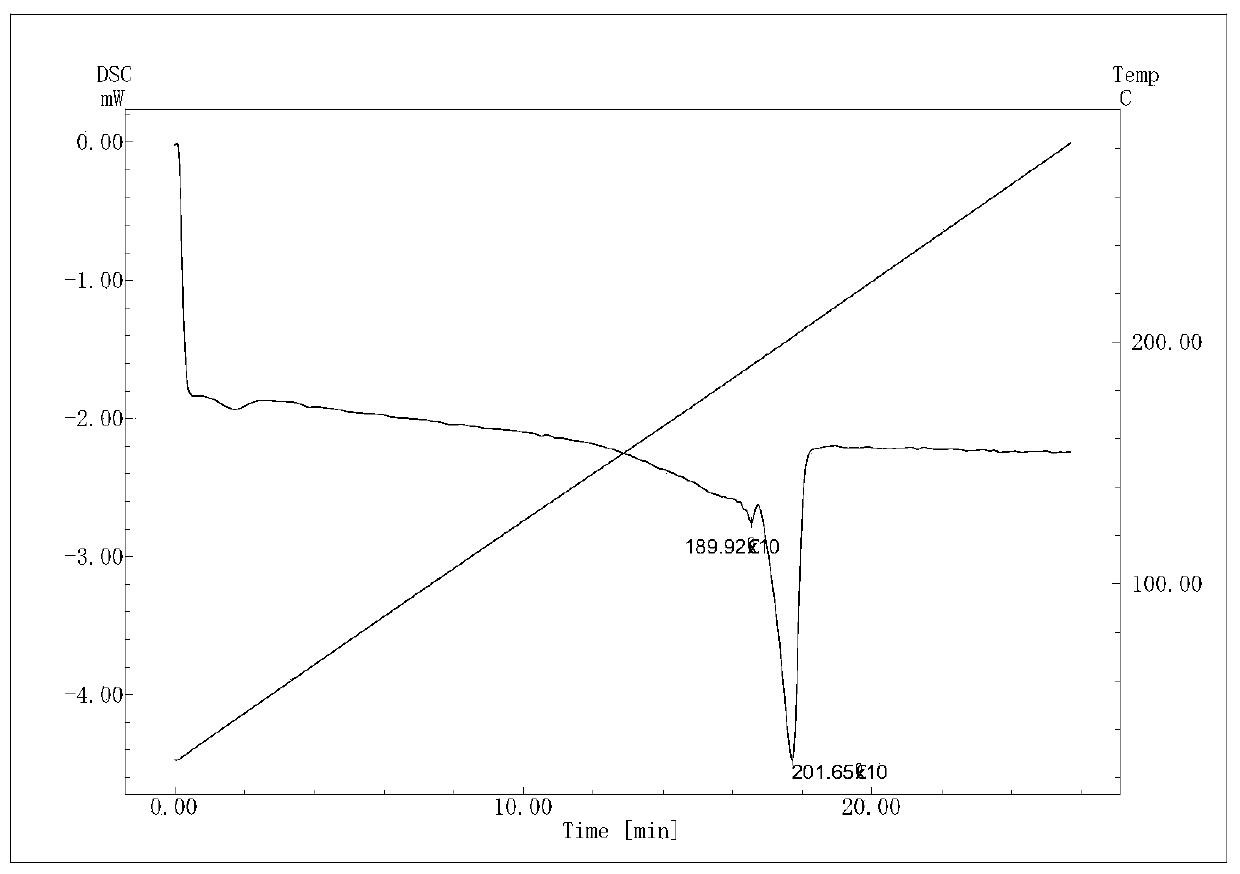

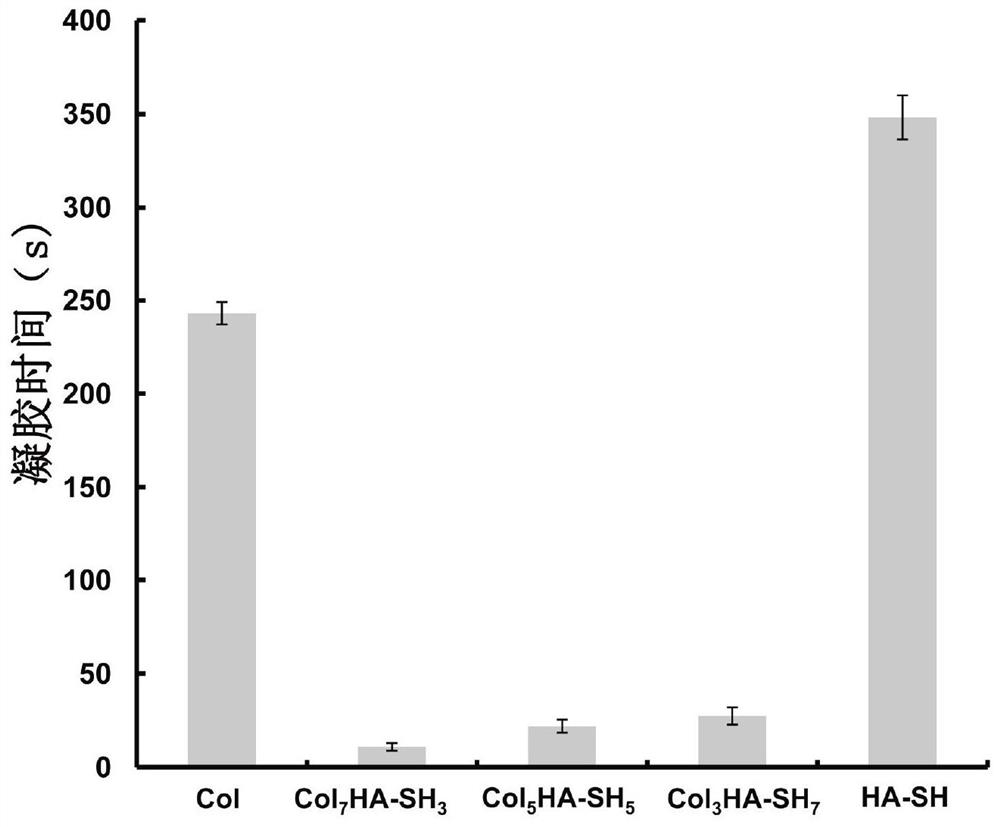

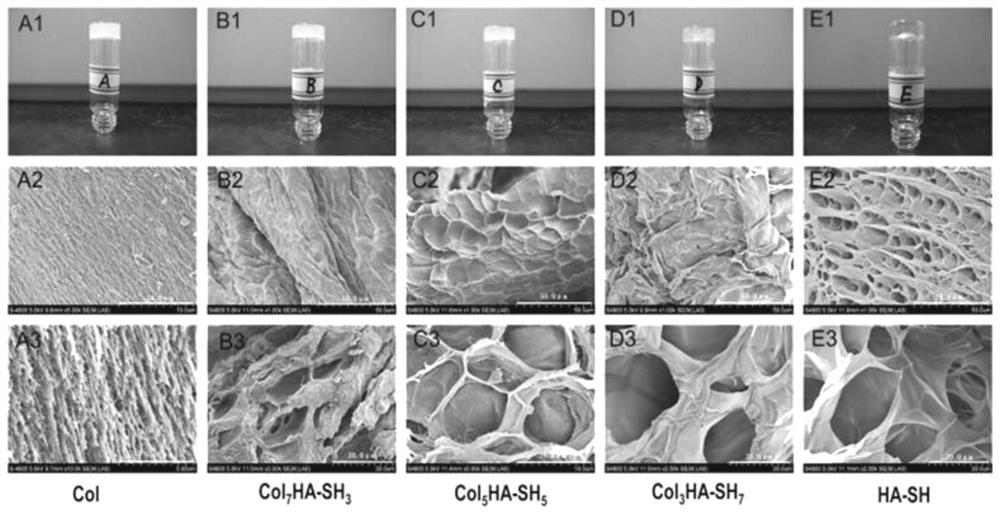

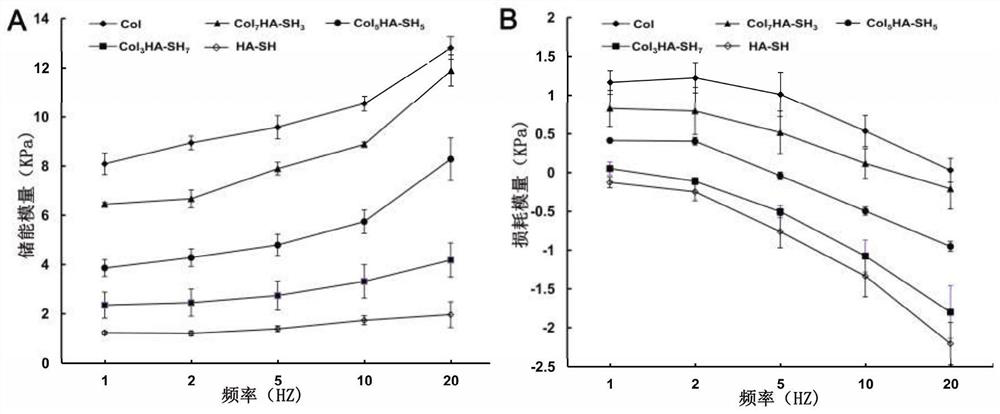

Controllable self-crosslinking sulfhydrylated hyaluronic acid-collagen composite hydrogel as well as preparation method and application thereof

ActiveCN108084461AGood biocompatibilityGood biodegradabilityPharmaceutical delivery mechanismTissue regenerationCell adhesionChemistry

The invention provides controllable self-crosslinking sulfhydrylated hyaluronic acid-collagen composite hydrogel as well as a preparation method therefore. The composite hydrogel is prepared from hyaluronic acid hydrogel and I-type collagen or II-type collagen; the I-type collagen or II-type collagen is distributed in a three-dimensional crosslinking network structure. The composite hydrogel has rigidity and elasticity, is high in mechanical property, can promote spreading growth of cartilage cells, is favorable for phenotype maintaining for cells, can relieve the shortcomings that an existinggel material for cartilage reparation is easy to shrink and low in cell adhesion, and has an important application value in the field of cartilage injury reparation.

Owner:SICHUAN UNIV

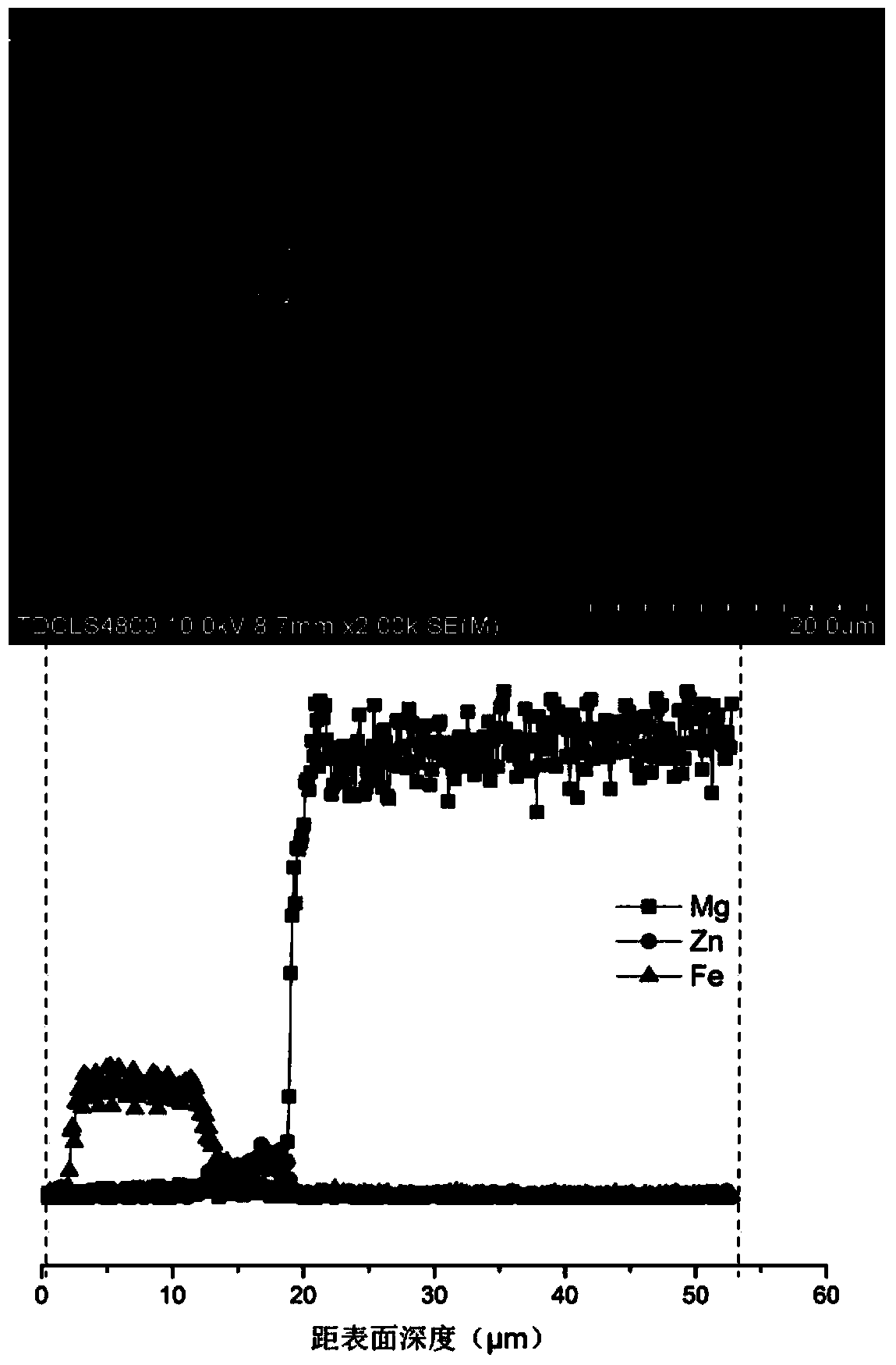

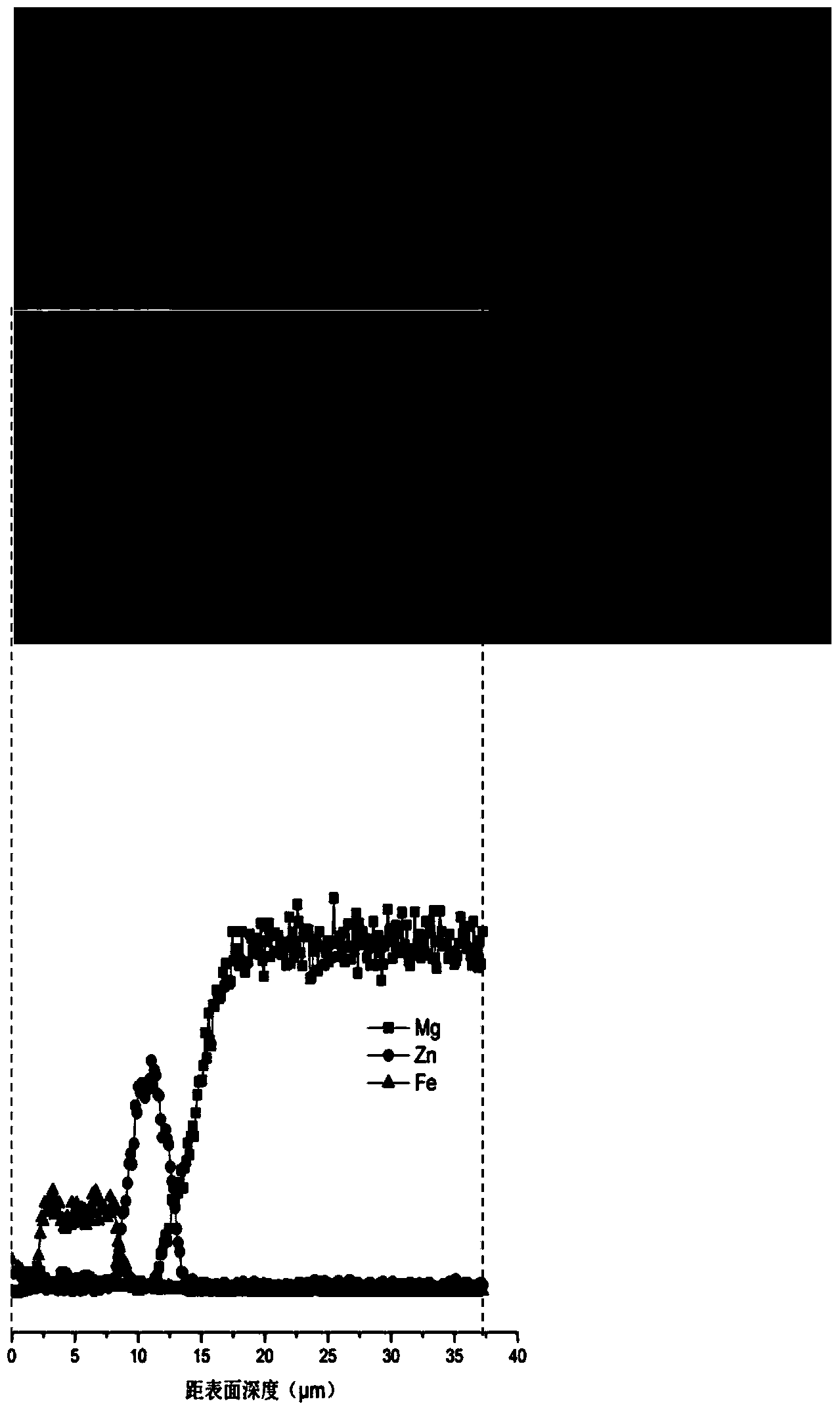

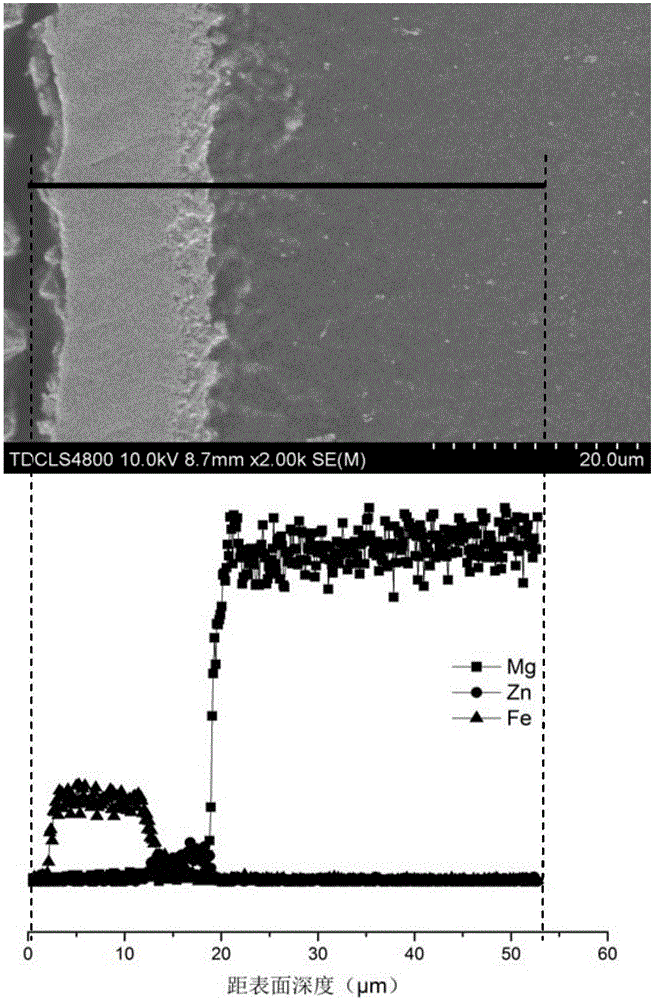

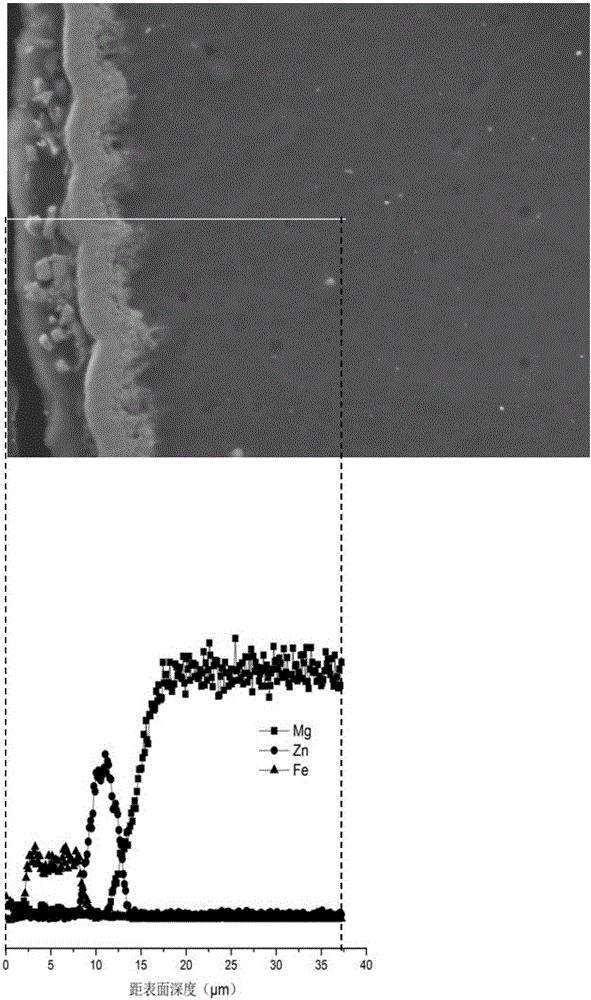

Degradable iron, zinc and magnesium-based gradient composite material based on biological bone healing and preparation thereof

InactiveCN103465542AAvoid secondary surgeryTight and reliableProsthesisMetal layered productsIntermediate stageBone cell

The invention discloses a degradable iron, zinc and magnesium-based gradient composite material based on biological bone healing. A zinc layer and an iron layer are sequentially arranged on the surface of a magnesium matrix, and the thickness or the diameter of the magnesium matrix is 30-90% of bone dimension in the repaired part. The thicknesses of the zinc and iron layers are respectively determined according to the corrosion rates of zinc and iron in an in vitro simulated body fluid. According to the composite material, rigid fixation in early stage is realized to promote bone healing, the composite material is gradually degraded, use of the material with lower rigidity is transited to dynamic fixation, and finally, the material is fully absorbed in vivo to prevent from being taken out in the second operation. Rapid degradation in the non-mechanical bearing later stage is realized, and growth by differentiation of bone cells and ingrowth of blood vessels on the surface of material are induced by hoping to combine the advantages that iron in higher rigidity in the early stage realizes rigid fixation and zinc in lower rigidity in the middle stage realizes dynamic fixation by means of quicker corrosion rate of magnesium. Finally, the composite material is fully absorbed, so as to realize the bone repairing purpose. The composite material disclosed by the invention is applicable to gradient structure designs of internal fixing materials after fracture with change demands on mechanical property with the passage of time.

Owner:TIANJIN UNIV

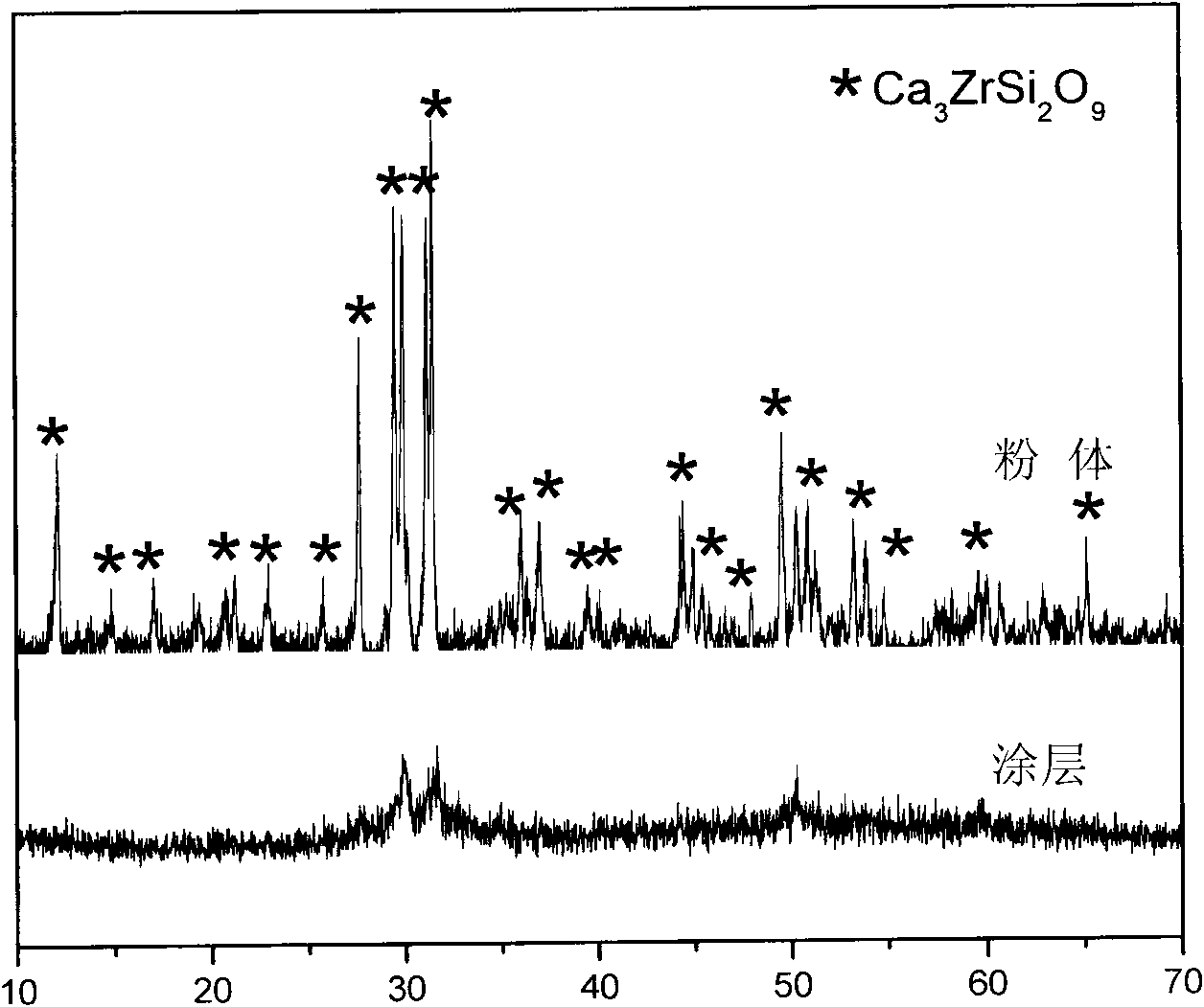

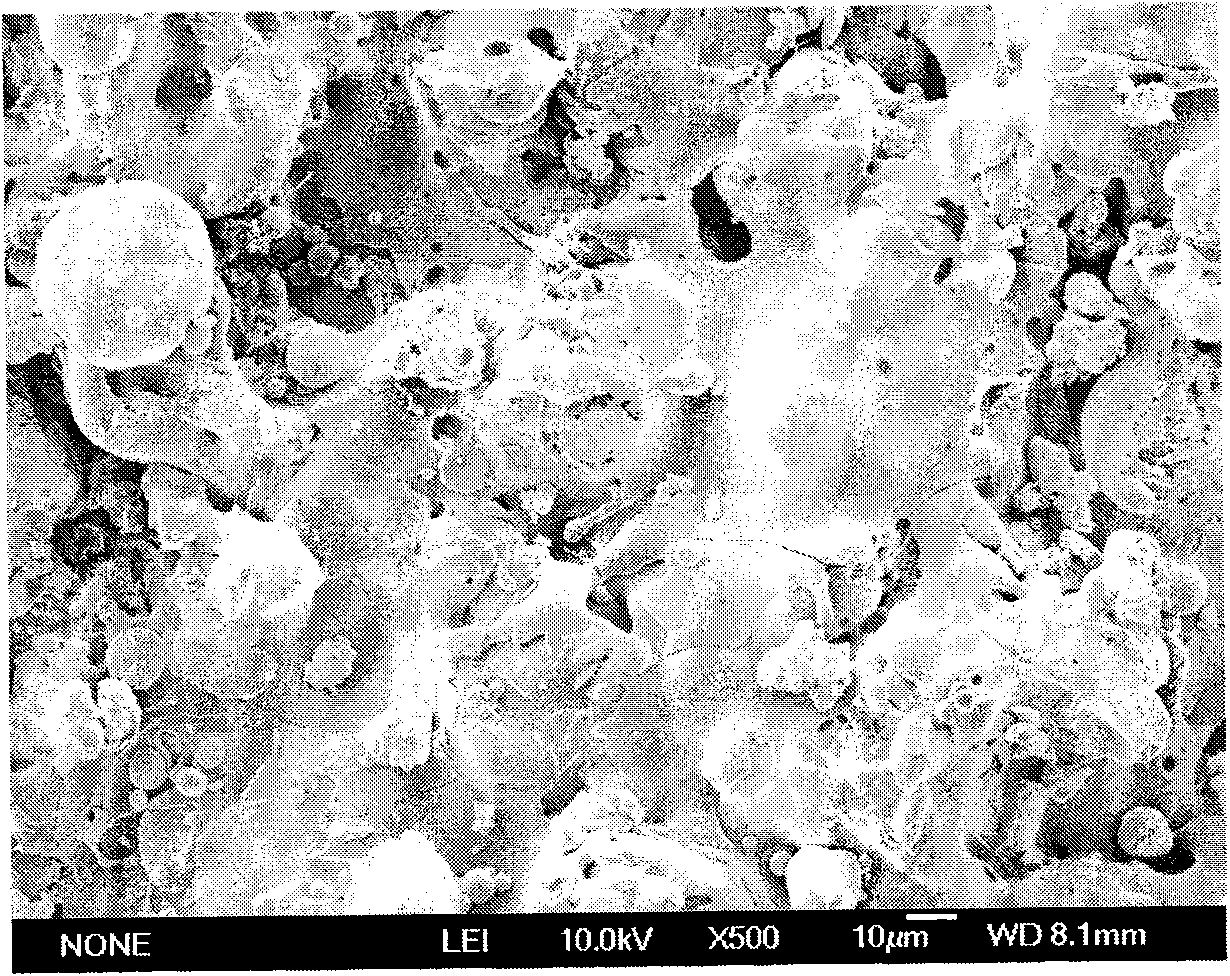

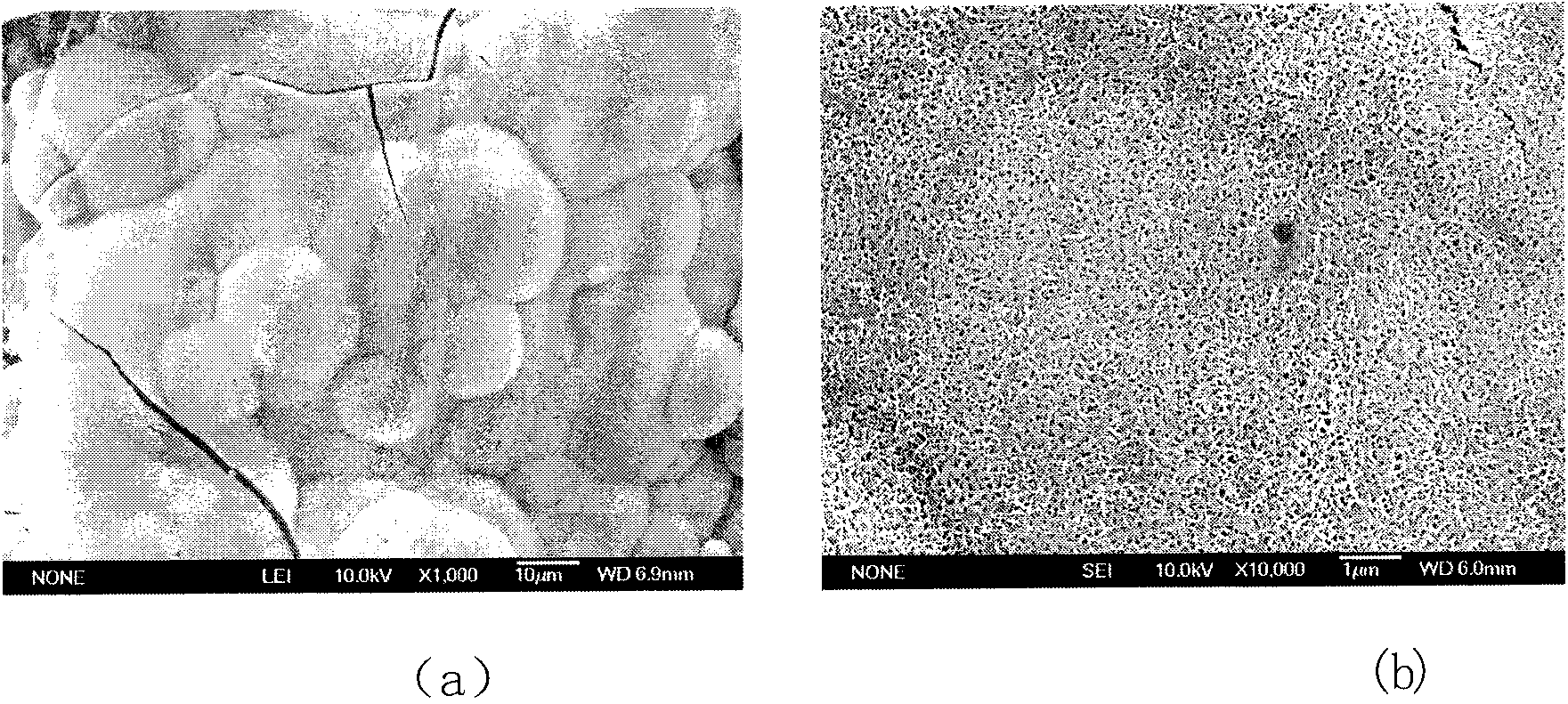

Bone substitute material for Ca3ZrSi2O9 coating-titanium alloy and preparation method of bone substitute material

InactiveCN102049065AGuaranteed service lifeHigh bonding strengthMolten spray coatingProsthesisTi 6al 4vTitanium

The invention relates to a bone substitute material for a Ca3ZrSi2O9 coating-titanium alloy and a preparation method of the bone substitute material. The bone substitute material is characterized in that medical titanium and titanium alloy (Ti-6Al-4V and the like) are taken as substrates, a Ca3ZrSi2O9 coating is deposited on the surfaces of the substrates and consists of Ca3ZrSi2O9 in a monoclinic system and a glass phase, the depth of the coating is 50-420 mu m. The preparation method comprises the following steps: synthesizing Ca3ZrSi2O9 powder; and then depositing the Ca3ZrSi2O9 coating on the titanium alloy substrate by using a plasma spraying technology, wherein the bond strength of the coating and the titanium alloy is 25-35 MPa. The provided coating can induce the formation of bone-like apatite in simulation body fluid, and has good bioactivity; and the bone substitute material can be degraded slowly in Tris-HCL buffer solution and has excellent long-term stability.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

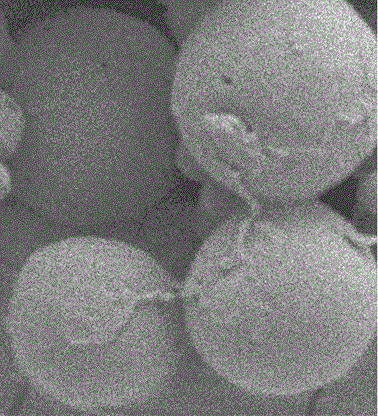

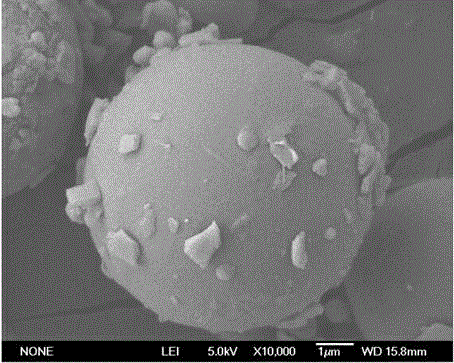

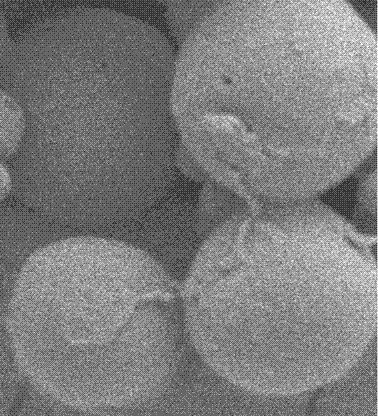

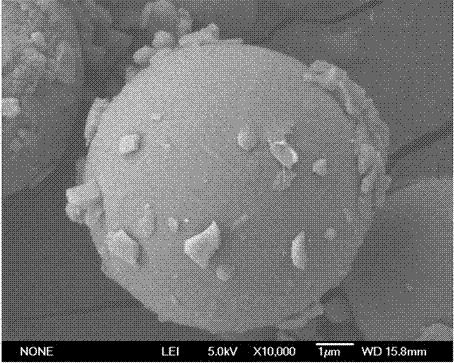

Biodegradable emamectin benzoate microsphere

The invention discloses a biodegradable emamectin benzoate microsphere and a preparation method thereof. Emamectin benzoate serves as an active substance namely a core material, and a biodegradable material serves as a balling material namely a wall material. The biodegradable emamectin benzoate microsphere has the advantages of safety, low toxicity, high efficiency, long lasting period, high stability and the like. Compared with a conventional common high-polymer wall material microsphere, the biodegradable emamectin benzoate microsphere has the advantages of high environment compatibility and good material mechanics property; meanwhile, by changing a ratio of polylactic acid to polypropylene carbonate in the wall material, the slow release performance and the particle size of the microsphere can be regulated and controlled, the drug release performance is improved, the environmental friendliness is improved, the production cost is reduced, and requirements on pollution-free agricultural production are met.

Owner:FUJIAN AGRI & FORESTRY UNIV

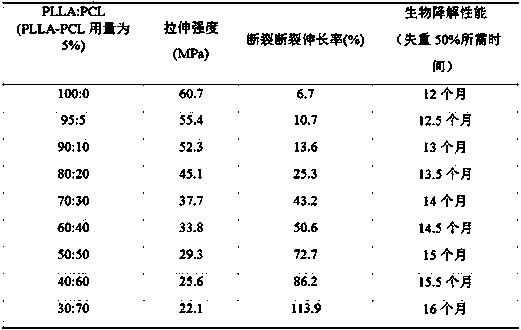

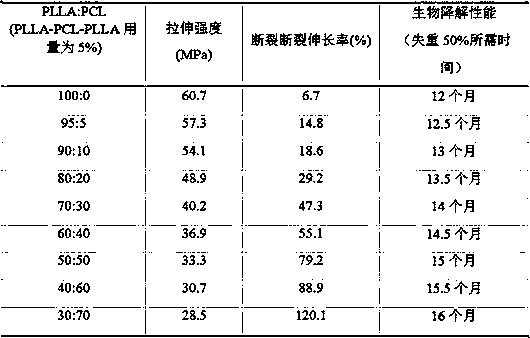

3D printing medical PLA (polylactic acid)/PCL (polycaprolactone) blend resin and preparation method thereof

The invention relates to 3D printing medical PLA (polylactic acid) / PCL (polycaprolactone) blend resin and a preparation method thereof. The preparation method comprises steps as follows: PLA and PCL are mixed in the mass ratio being (100:5)-(5:100), a PLA / PCL copolymer solubilizer accounting for 5% of the total mass of PLA and PCL is added, and the mixture is mixed uniformly and granulated in an extruder; granules are prepared into linear materials through a 3D printing consumable extruder, and the 3D printing medical PLA / PCL blend resin is obtained. The 3D printing medical PLA / PCL blend resincan be further printed into a high-precision medical intervention material through a fused deposition molding 3D printing technology. The 3D printing medical PLA / PCL blend resin has whole-resin biodegradability, control of mechanical performance, biocompatibility, biodegradability and drug coating property of medical resin is realized by changing the proportion of PLA and PCL, and individualizedand accurate medical treatment is really realized.

Owner:MINJIANG UNIV

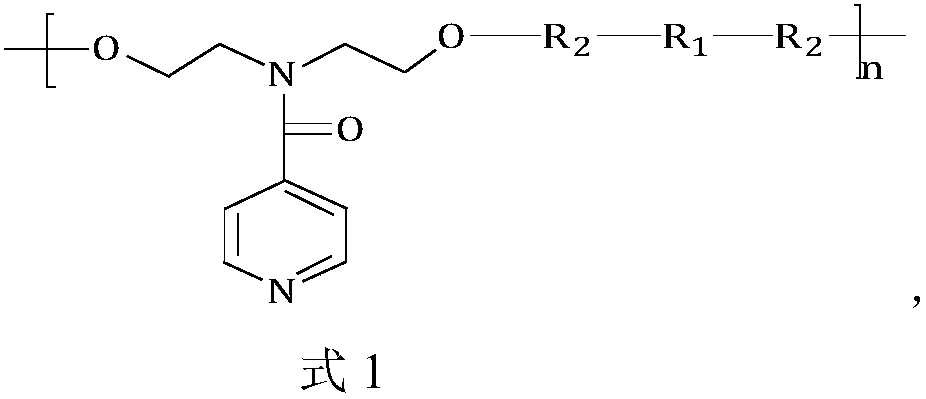

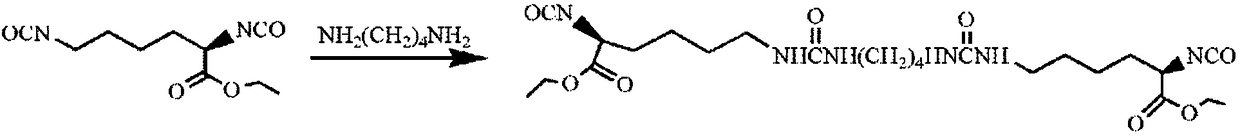

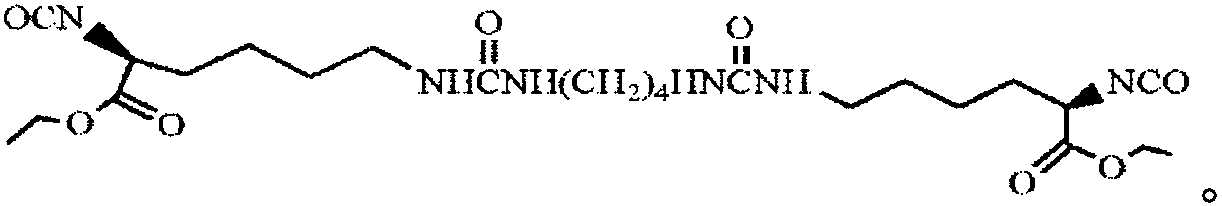

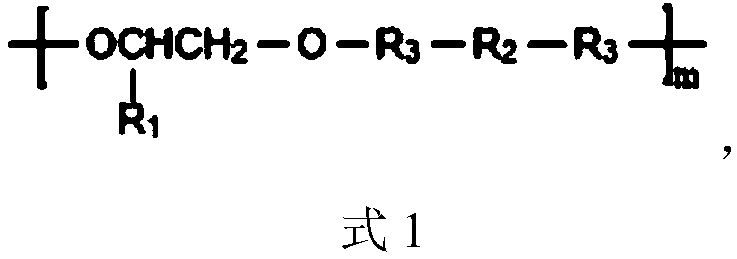

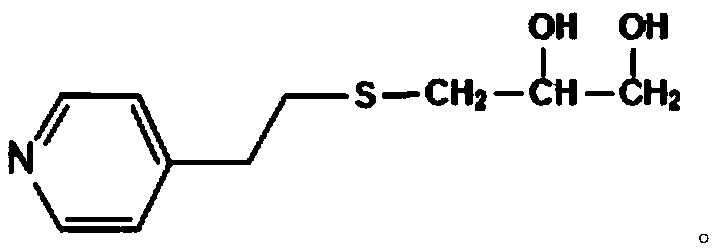

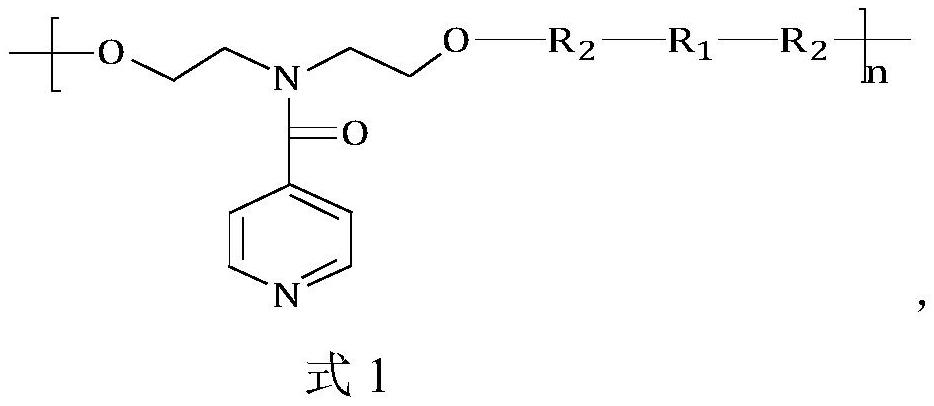

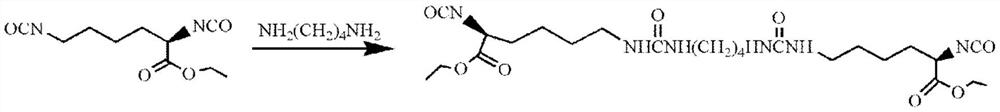

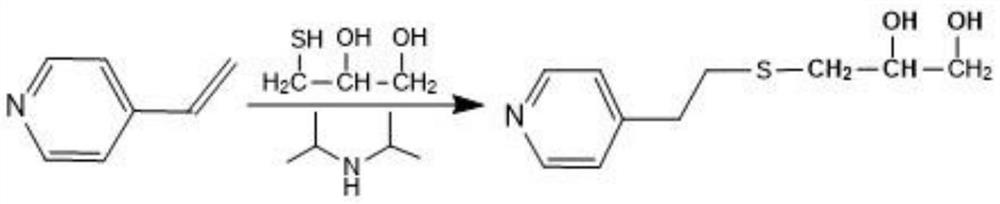

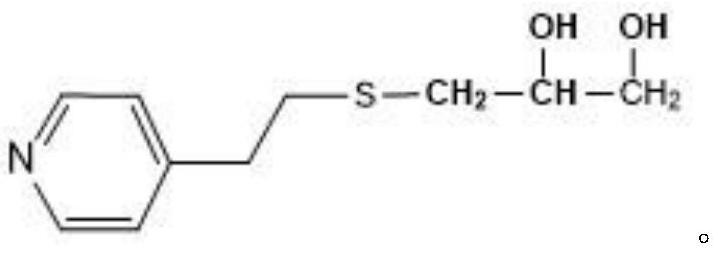

PH-sensitive biodegradable polyurethane-urea material and preparation method thereof

ActiveCN108559048APH sensitivity hasPH sensitive biodegradable withPharmaceutical non-active ingredientsSheet deliveryDrug release rateSide chain

The invention discloses a pH-sensitive biodegradable polyurethane-urea material and a preparation method thereof. The polyurethane-urea is pH-sensitive biodegradable polyurethane-urea prepared by mixing dihydroxy-terminal polyether ester with N,N-bis(2-ethoxy) 4-pyridinccarbox amide, carrying out chain expansion by using carbamido-containing diisocyanate and purifying; the polyether ester is usedas a main soft segment, a chain segment containing carbamido and urethane group is used as a hard segment and a pyridine ring is positioned on a side chain. The polyurethane-urea has the characteristics of biodegradability, absorbability of a degradation product, pH sensitivity, high expanding and degrading rate in acidic mediums, as well as basically no expansion and low degrading rate in neutraland alkaline mediums; in addition, the pH sensitivity is not basically affected by temperature and can be applied to the field of controlled release as a drug carrier, and further the drug release rate is controlled according to pH values of different parts of an organism. The hard segment formed by carbamido-containing structure diisocyanate contains dense hydrogen bonds, so that the mechanicalproperty of the material is improved.

Owner:烟台研创聚氨酯科技有限责任公司

High efficiency chlopyrifos degradating strain capable of generating magic spots

InactiveCN102399705ASlow degradation rateParticipate in the regulation of biodegradation processBacteriaMicroorganism based processesChlorpyrifosMicrobiology

The invention relates to a high efficiency chlopyrifos degradating strain Klebsiella sp. CPK capable of generating magic spots, and the accession number of the strain is CGMCC No.4167. The invention relates a preparation method and application of the strain. The strain provided in the invention can be widely used for removal of residual pollution of chlopyrifos and for bioremediation and has the advantages of powerful degradation capability, stable degradability, in-depth metabolic studies, etc.

Owner:中国农业科学院研究生院

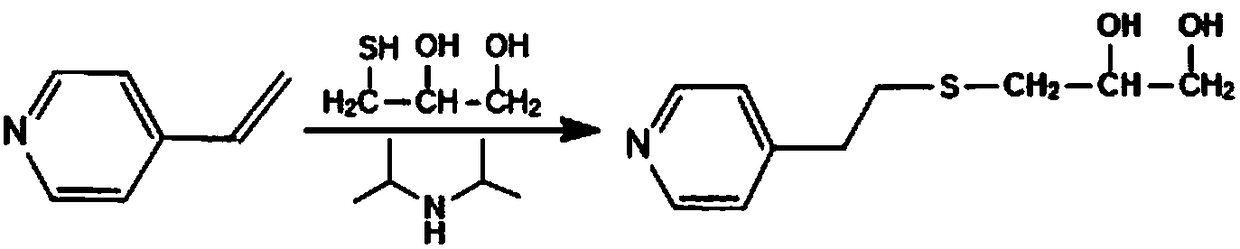

PH sensitive medical polyurethane urea material and preparation method thereof

ActiveCN108530606AGood pH sensitivityFast degradation ratePharmaceutical non-active ingredientsLysine diisocyanateCarbamate

The invention discloses a pH sensitive medical polyurethane urea material and a preparation method thereof. The preparation method comprises the following steps: mixing a terminal dihydroxypyridine compound and a double-end hydroxyl polyethylene glycol to obtain polyurethane urea, and dissolving by adding N,N-dimethylformamide, carrying out chain extension in the presence of urea-containing diisocyanate, and purifying to obtain pH-sensitive polyurethane urea, wherein diisocyanate is L-lysine diisocyanate-1,4-butylenediamine-L-lysine diisocyanate. The pyridine group on a side chain of polyurethane urea is Lewis base, which is able to decompose hydrogen bonds in a polyurethane urea network under acidic conditions, resulting in discontinuous volume expansion of material. According to the invention, H<+> is removed under neutral or alkaline conditions, and N on a pyridine ring and NH on carbamate or ureido form a hydrogen bond, approximating a network structure, so that the polyurethane urea molecular chain shrinks and the swelling degree decreases remarkably. Therefore, by controlling the change of the pH of a medium, the degree of swelling of polyurethane urea can be effectively controlled.

Owner:科莱新材料技术(广州)有限公司

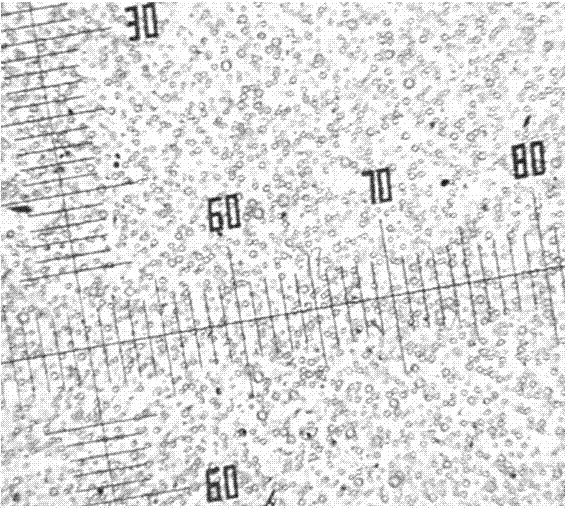

Modification method used for surface of magnesium alloy stent

InactiveCN101632842BControl degradation rateSlow degradation rateAnodisationStentsPorosityMicro arc oxidation

The invention discloses a modification method used for the surface of a magnesium alloy stent and contains controlledly degradable magnesium alloy stent surface micro-arc oxidation modification treatment and drug molecule biomimetic deposition; the magnesium alloy stent surface micro-arc oxidation modification treatment is first performed on the surface of magnesium alloy stent substrate to form controlledly degradable microporous ceramic oxide film with high porosity, the thickness of the film is 80-120mu m, the porosity is 20-40%; then drug molecule biomimetic deposition capable of promoting endothelial growth or dissolving thrombus and anticoagulating is performed on the microporous ceramic oxide film and the width of the settled layer is 5-10mu m. The modification of the surface of the magnesium alloy stent of the invention can effectively improve the in vivo biodegradation rate of the stent and the corresponding consistency of the mechanical property thereof, increase the compatibility between the stent and vascular walls, reduce the restenosis rate of blood vessels, lower the incidence of complications of patients and improve the survival rate and the life quality.

Owner:SOUTH CHINA UNIV OF TECH

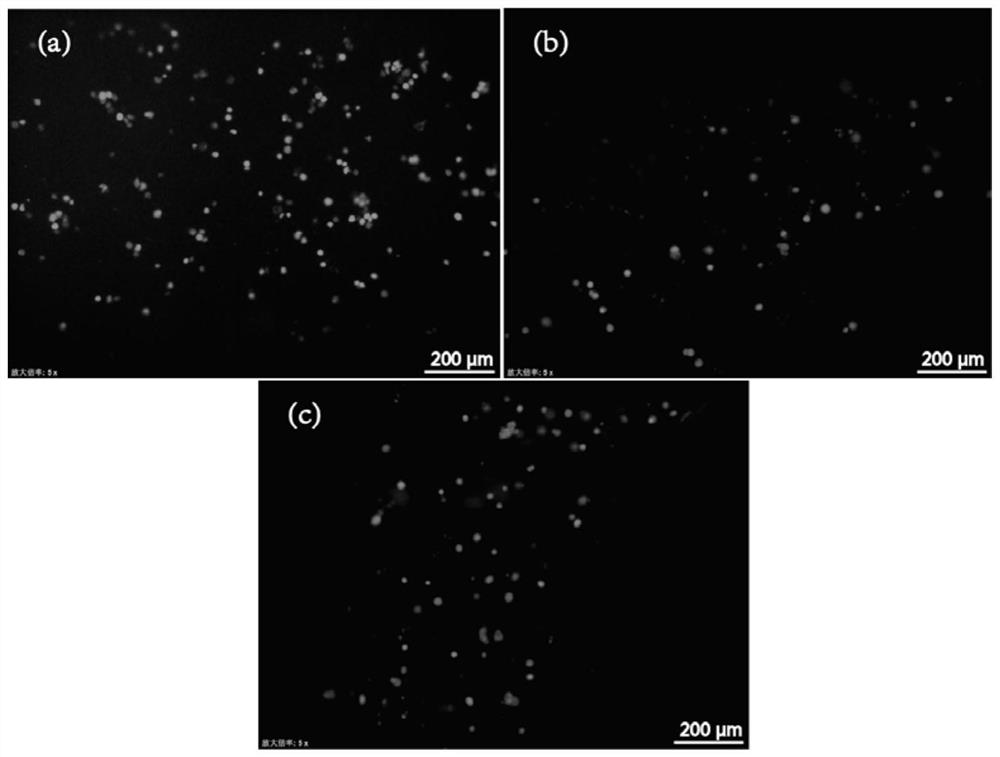

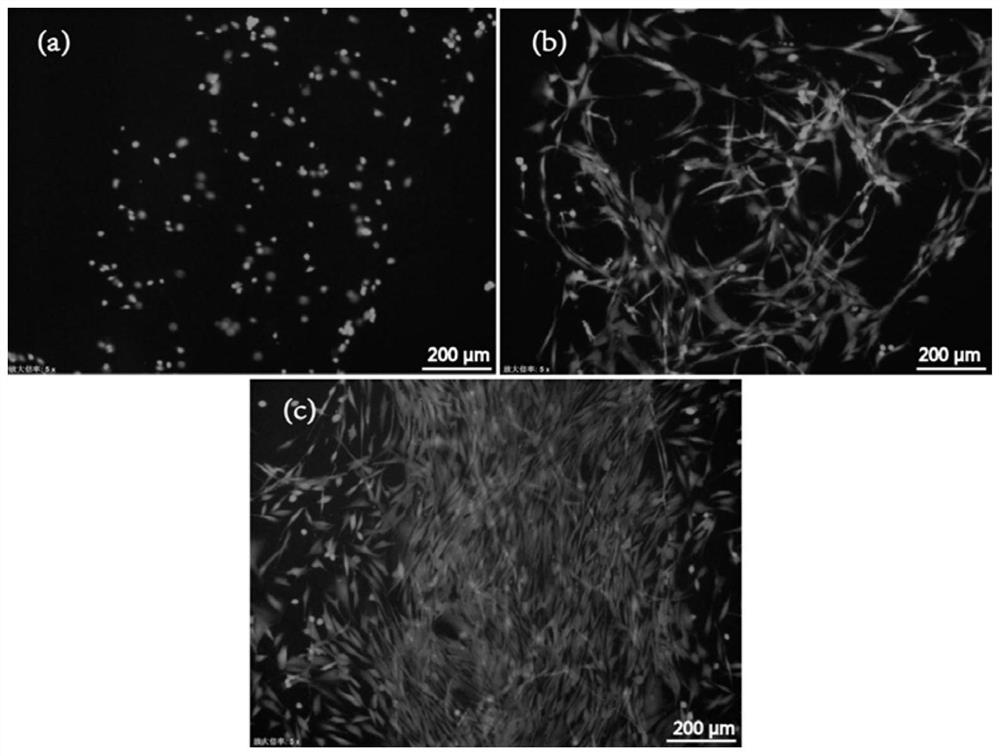

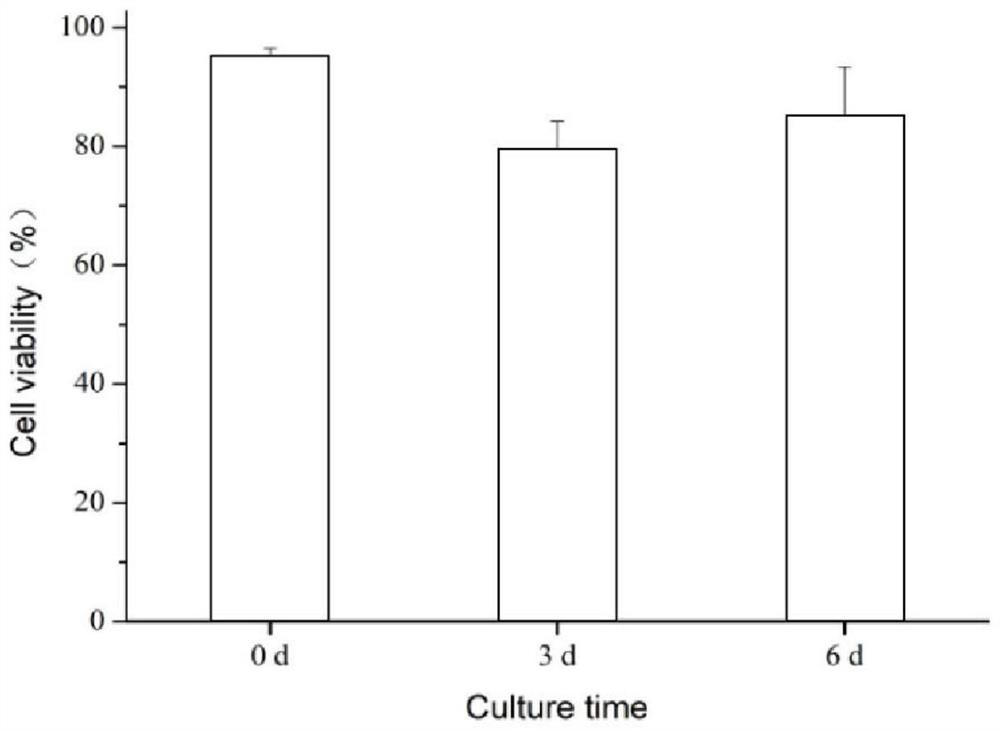

A composite scaffold of 3D printed degradable polymer scaffold and photocrosslinked hydrogel

ActiveCN111166933BIncrease the degree of cross-linkingImprove mechanical propertiesTissue regenerationProsthesis3d printPolymer science

The invention relates to a 3D-printed degradable macromolecular scaffold and photo-crosslinked hydrogel composite scaffold. The 3D-printed degradable macromolecular scaffold and photo-crosslinked hydrogel composite scaffold comprises a 3D-printed degradable macromolecular scaffold, wherein the interior of the 3D-printed degradable macromolecular scaffold comprises photo-crosslinked hydrogel with high substitution degree and photo-crosslinked hydrogel with low substitution degree, the photo-crosslinked hydrogel with high substitution degree is crosslinked with the photo-crosslinked hydrogel with low substitution degree, and preferably, a polycaprolactone (PCL) scaffold and methacrylic anhydride gelatin (GelMA) with different substitution degrees are crosslinked and compounded. In the composite scaffold, the 3D-printed degradable macromolecular scaffold has good mechanical properties; the photo-crosslinked hydrogel with high substitution degree has high crosslinking degree, can form a fiber network and micropores, and well supports cells; and the photo-crosslinked hydrogel with low substitution degree has multiple active sites, is beneficial to cell adhesion growth, and can adsorb alarge amount of nutrient solution. Through cooperation of the 3D-printed degradable macromolecular scaffold, the photo-crosslinked hydrogel with high substitution degree and the photo-crosslinked hydrogel with low substitution degree, the composite scaffold is suitable for cell growth and vascularization from an inner layer to an outer layer, and when the composite scaffold is used for medical human body repair, scaffold integration is realized to promote regeneration of new tissues.

Owner:NOVAPRINT THERAPEUTICS SUZHOU CO LTD

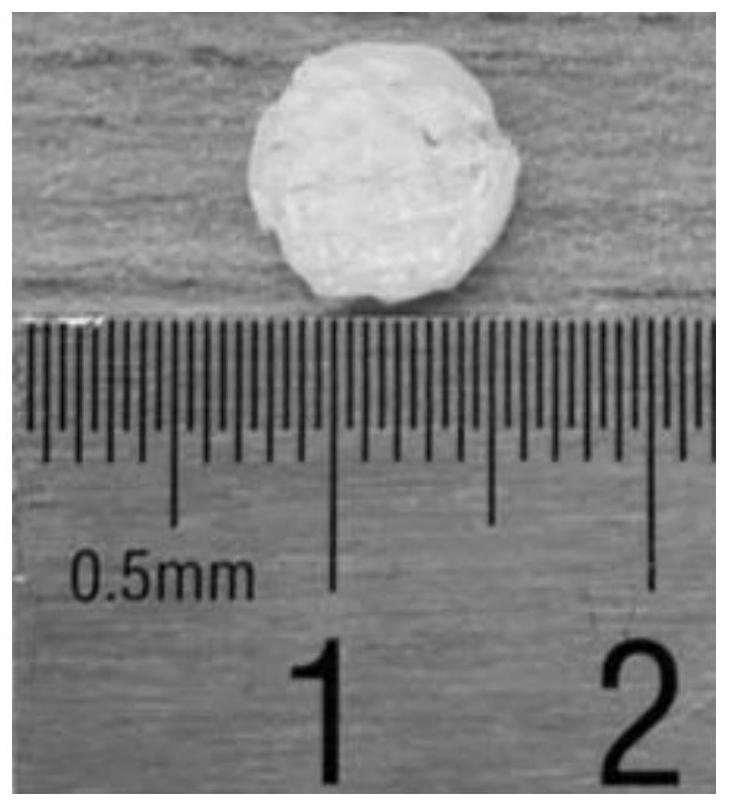

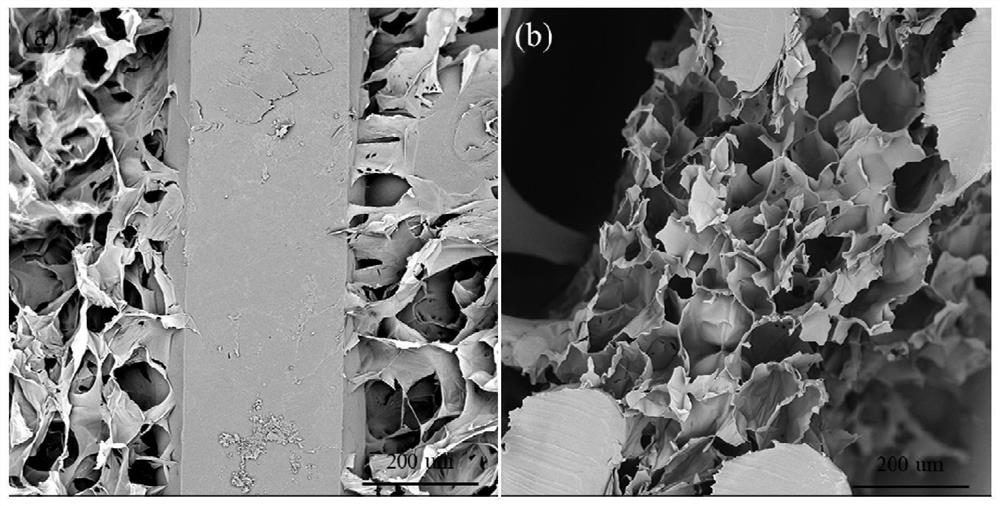

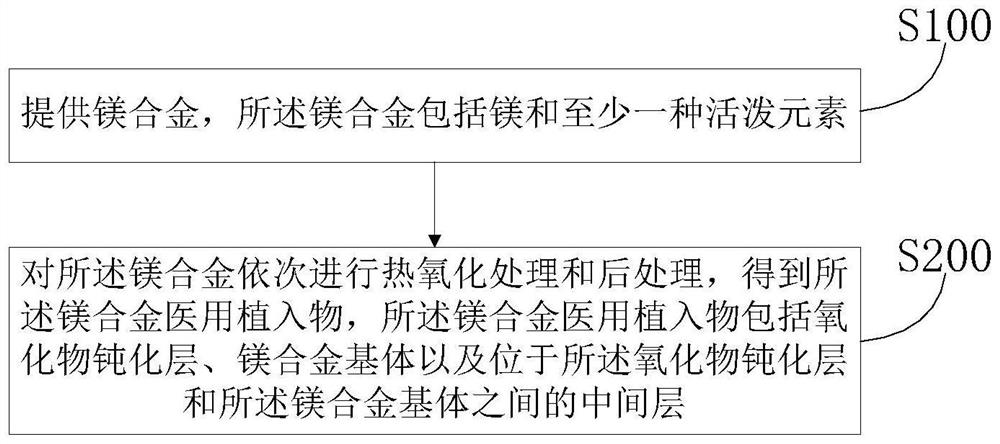

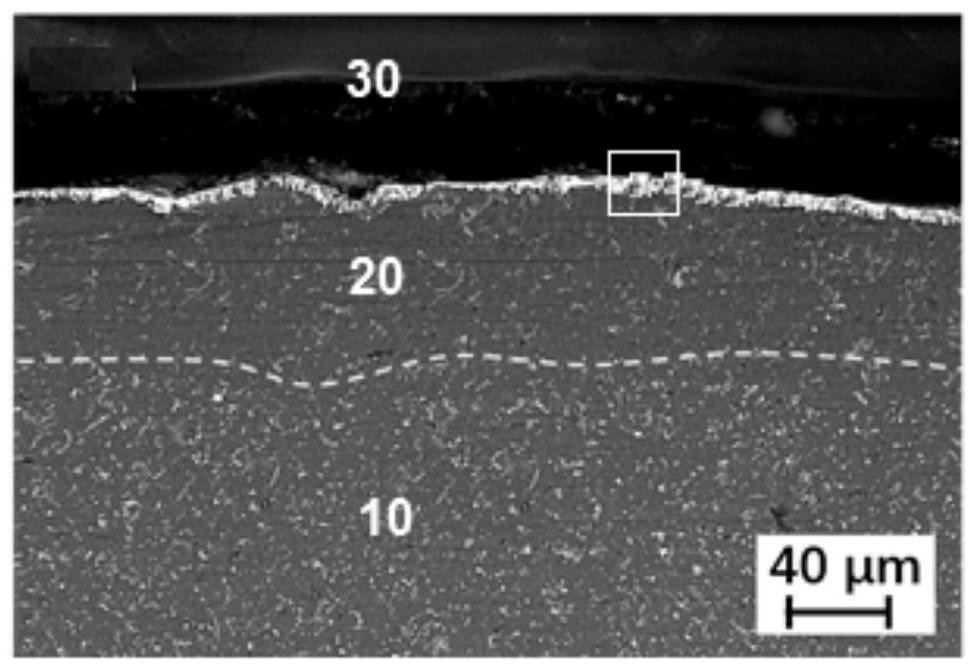

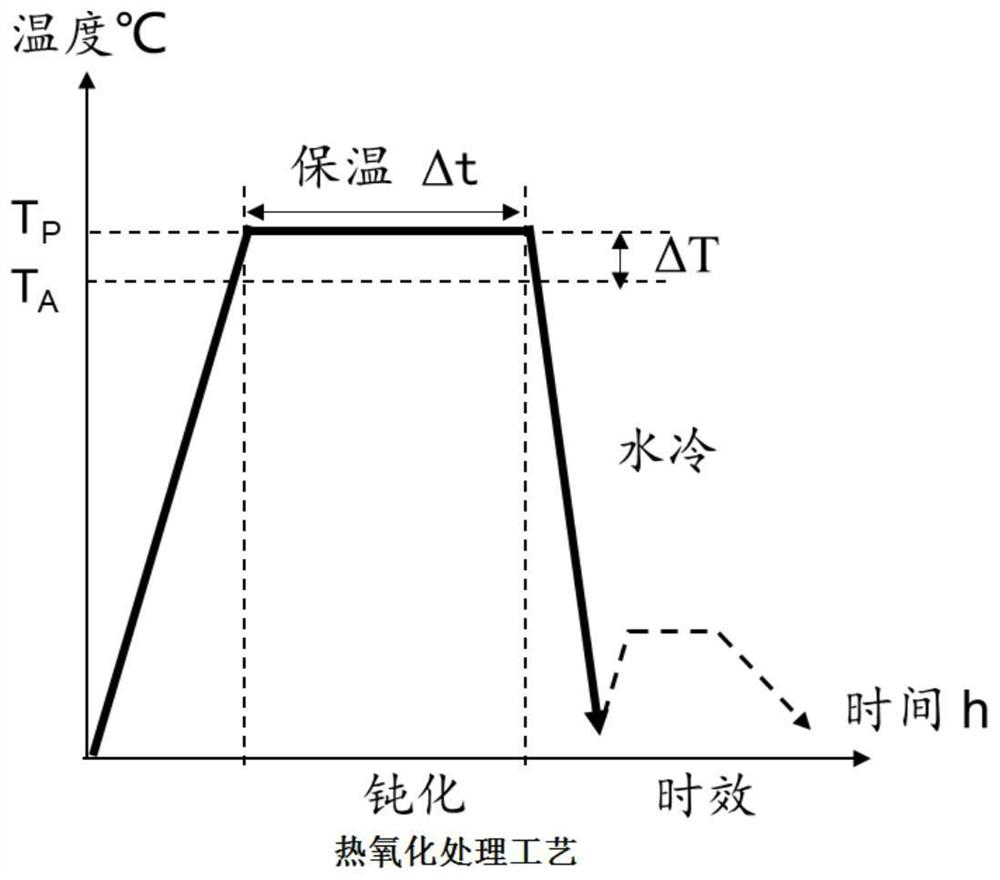

Magnesium alloy medical implant and preparation method thereof

PendingCN114288471AReduce the rate of degradationDoes not affect biocompatibilityAdditive manufacturing apparatusSuperimposed coating processMg alloysSkeletal tissue

The invention provides a magnesium alloy medical implant and a preparation method thereof, and the preparation method comprises the following steps: providing a magnesium alloy which comprises magnesium and at least one active element; the magnesium alloy is sequentially subjected to thermal oxidation treatment and post-treatment, the magnesium alloy medical implant is obtained, and the magnesium alloy medical implant comprises an oxide passivation layer, a middle layer and a magnesium alloy base body. The magnesium alloy medical implant has a customized appearance matched with bone defects and a composite structure comprising the oxide passivation layer on the surface, the middle layer and the magnesium alloy base body, the oxide passivation layer and the middle layer are degraded slowly in body fluid, the magnesium alloy base body is separated from the body fluid, the degradation rate of the magnesium alloy medical implant is decreased, and the service life of the magnesium alloy medical implant is prolonged. The degradation period is matched with bone tissue reconstruction and functional recovery, and the bone defect repair effect is improved. The preparation method is not influenced by geometric structures, no other materials are added, the degradation period is adjustable, the effect is stable, operability is high, and industrial production and clinical application are facilitated.

Owner:TSINGHUA UNIV +1

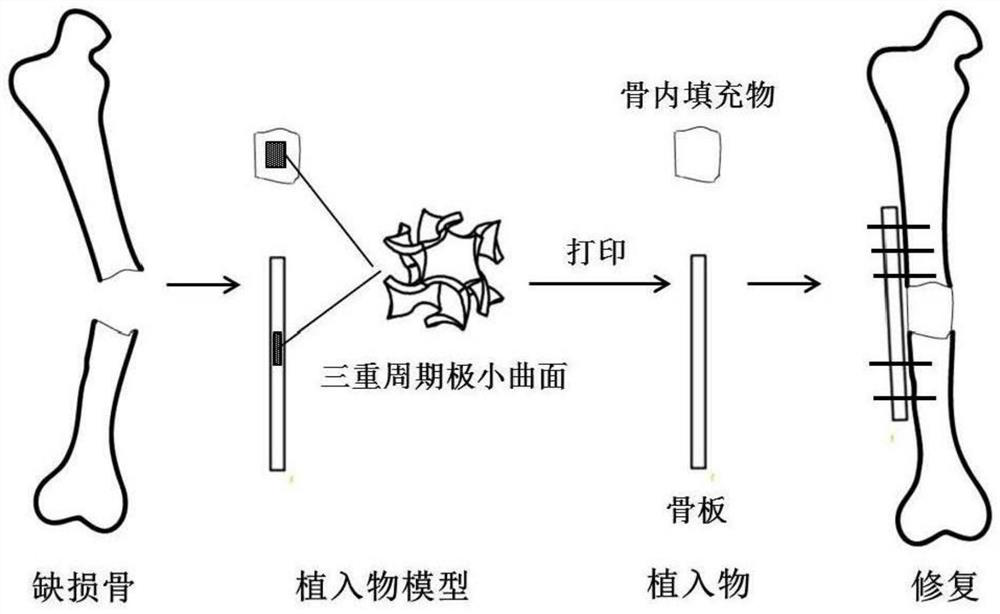

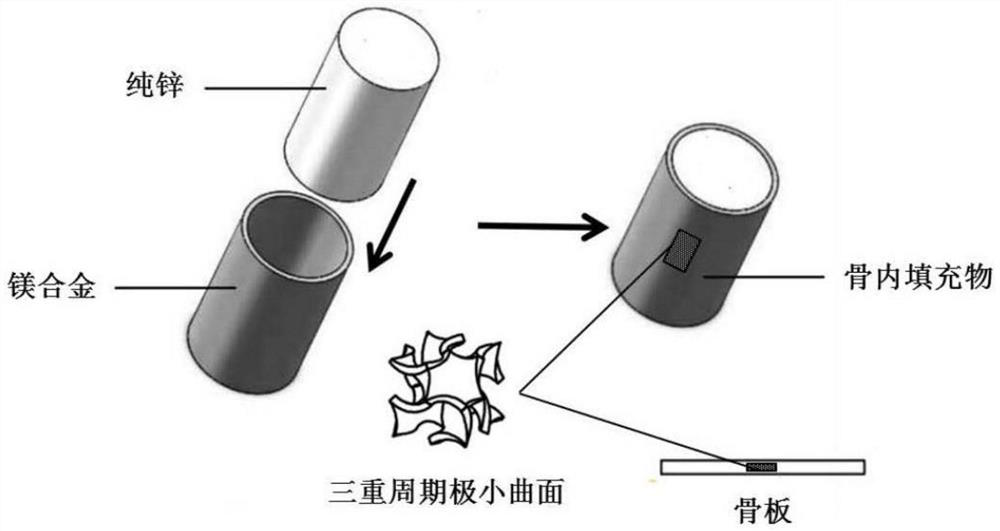

Manufacturing method of composite material metal bone implant with structural function

ActiveCN113427019ASafe bearerSlow degradation rateAdditive manufacturing apparatusIncreasing energy efficiencySurgical operationComputer printing

The invention provides a manufacturing method of a composite material metal bone implant with a structural function. The method comprises the following steps that bone defect image data are imported into a computer and are processed, and a three-dimensional model of a filling bone implant is established; according to the requirements of bone repairing, fixing and resetting, reliable bearing and bone healing promotion, the bone implant is divided into functional areas with different bearing and degradation characteristics, corresponding alloys are adopted for implant material design, pore units with different porosities are adopted for implant internal structure design, and three-dimensional models of parts in the different functional areas are established on the basis of considering assembling and surgical operations; the three-dimensional models of the different functional areas are subdivided, printing parameters are set according to materials and structures, printing data of all section contours are obtained, and the printing data are input into a laser powder bed fusion printer; and parts of the different functional areas are printed on the basis of the printing data, and alloy powder is printed and formed in a layer-by-layer powder feeding and layer-by-layer laser scanning melting and solidifying mode.

Owner:TSINGHUA UNIV +1

Foam board and preparation method thereof

The invention discloses a foam board which comprises the following components in parts by weight: 60-100 parts of polylactic acid, 30-50 parts of polyethylene, 6-17 parts of polyethylene glycol ether,2-8 parts of polyester polyol, 5-16 parts of polyester resin, 6-18 parts of starch, 1-5 parts of a foam stabilizer, 2-6 parts of a seaweed extract, 1-4 parts of silicone oil, 3-5 parts of high bauxite, 8-15 parts of ethylene-vinyl acetate, 0.5-3 parts of expanded graphite, 3-7 parts of bamboo fiber, 1-4 parts of magnesium carbonate and 0.2-0.5 part of a stabilizer. The preparation method comprises the steps of mixing, ultrasonic treatment, pre-foaming, extrusion and the like. The foam board is low in degradation rate and long in service life, generated degradation products are almost harmlessto human bodies and the environment, and the foam board has good structural strength and fireproof performance.

Owner:徐州飞云泡沫制品有限责任公司

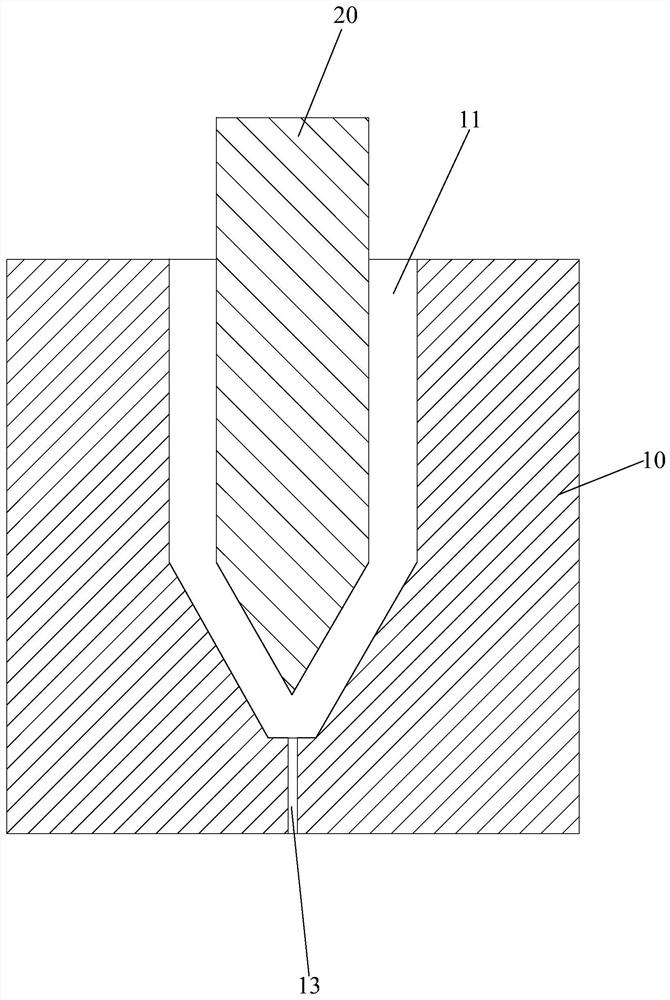

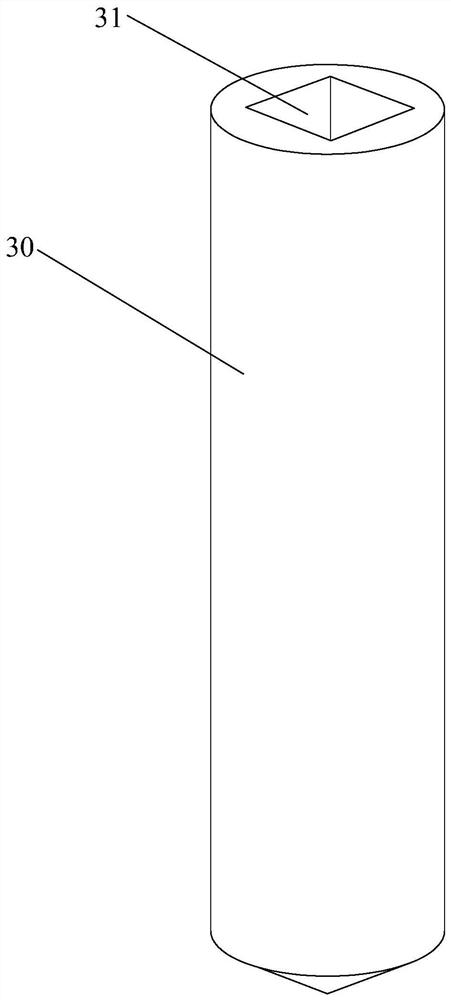

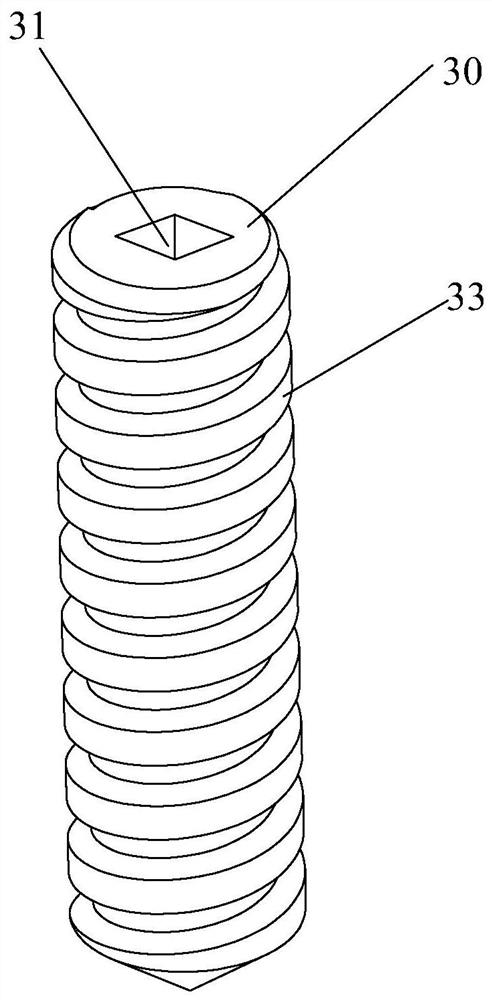

Corrosion-resistant orthopedic degradable screw and manufacturing method thereof

PendingCN112916694ACompact structureGood mechanicsShaping toolsInternal osteosythesisComposite materialCorrosion resistant

The invention discloses a manufacturing method for a corrosion-resistant orthopedic degradable screw. The manufacturing method comprises the following steps that (1) a degradable metal bar, a female die and a stamping male die are provided, an open conical die cavity is formed in the female die, the other side of the die cavity communicates with an overflow hole, and the stamping male die is provided with a tip; (2) the degradable metal bar is placed in the die cavity of the female die, the stamping male die is operated to impact the degradable metal bar, the stamping male die impacts a groove in the degradable metal bar in the impact process, and a part of metal flows outsides from the overflow hole; and (3) the orthopedic screw is obtained in the die cavity through repeated impacting for a certain time for multiple times. According to the manufacturing method, through cooperation of the female die and the stamping male die, the degradable metal bar is hammered and stamped for multiple times to obtain the orthopedic screw which is of a compact structure and good in mechanical properties, so that the corrosion resistance of the orthopedic screw is improved, the degradation rate is low after the orthopedic screw is implanted into a human body, the process is simple, and the cost is low. The invention further provides the corrosion-resistant orthopedic degradable screw manufactured by the method.

Owner:东莞立德生物医疗有限公司

A kind of pH sensitive biodegradable polyurethane urea material and preparation method thereof

ActiveCN108559048BPH sensitivity hasPH sensitive biodegradable withPharmaceutical non-active ingredientsSheet deliveryDrug release ratePolymer science

Owner:烟台研创聚氨酯科技有限责任公司

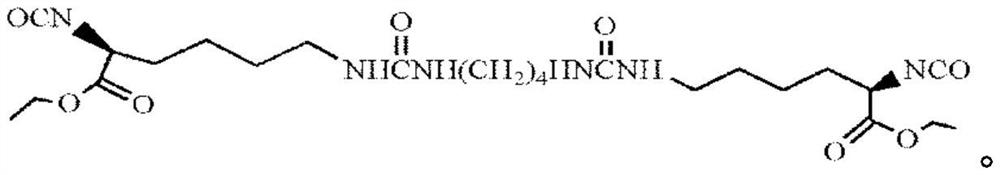

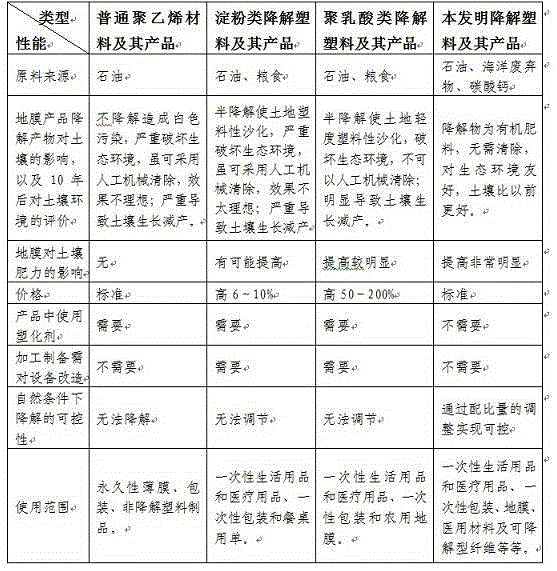

Nano-calcium plastic biodegradation composite resin and preparation and use method thereof

The invention relates to a nano-calcium plastic biodegradation composite resin. The composite resin is prepared from 0.5 to 20% of KV-environment-friendly plastic biodegradation cellulose and 80 to 99.5% of a nano-calcium modified plastic composite material, and under the condition of 100 to 130 DEG C, granulation via plastic extrusion is performed by mixing and stirring at 150 to 200rpm; then 1 to 65% of particles manufactured and 35 to 99% of polyethylene, polyvinyl chloride or polypropylene are mixed, and different degradable plastic products can be prepared. According to the composite resin, biological waste and natural calcium carbonate are taken as main raw materials, the distribution is wide, and the resources are rich; the preparing operation of the composite resin is simple and convenient, an original process does not need to be changed, and a plasticizer is not used; the degradability is controllable, a product only needs simple packaging, and can be stored for 3 years in a dry and lucifugal condition, the storage cost is low, and the production cost is equivalent to that of a common plastic product; compared with the prior art, the product performance is improved obviously and the composite resin has no toxicity, so that the composite resin is suitable for preparation of degradable plastic products which take polyethylene, polyvinyl chloride and polypropylene as raw materials, the quality and flexibility of the products are improved, and the degradable plastics are favorably used widely.

Owner:西安普草瑞珊生物科技有限责任公司

A fully degradable high barrier composite material for flexible packaging

ActiveCN110791069BImprove barrier propertiesGood flexibilityFlexible coversWrappersPolymer scienceNanostructured carbon

Owner:佰信(福建)新材料科技有限公司

Soft tissue repair patch material, soft tissue repair patch and manufacturing method and application of soft tissue repair patch

ActiveCN113663124APromote repairGood biocompatibilityAdditive manufacturing apparatusTissue regenerationTissue repairGraphene

The invention provides a soft tissue repair patch material, a soft tissue repair patch and a manufacturing method and application of the soft tissue repair patch, and relates to the technical field of biological tissue repair. The soft tissue repair patch material comprises sodium alginate / graphene hydrogel and fibrous protein / graphene hydrogel, wherein the sodium alginate / graphene hydrogel has certain mechanical strength and is low in degradation rate, and the defects that the mechanical property of the fibrous protein / graphene hydrogel is insufficient and the degradation rate is too high can be overcome; therefore, enough mechanical support and tissue repair time are provided for a prepared soft tissue repair patch, the fibrous protein / graphene hydrogel is beneficial to mass amplification and propagation of cells, soft tissue repair is promoted, and through cooperative use of the two hydrogel systems, the soft tissue repair patch prepared from the soft tissue repair patch material is endowed with mechanical properties suitable for clinical use, a degradation rate matched with tissue repair and good cell compatibility, and has a wide clinical application prospect.

Owner:NOVAPRINT THERAPEUTICS SUZHOU CO LTD

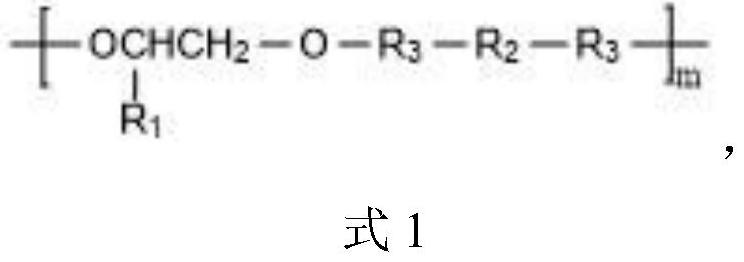

Biodegradable polyester material and preparation method and application thereof, carrier material and preparation method thereof

ActiveCN111548481AHigh elongation at breakFunctionalPharmaceutical non-active ingredientsDimethyl terephthalateTrans esterification

The invention provides a biodegradable polyester material and a preparation method and application thereof, a carrier material and a preparation method thereof, and belongs to the technical field of carrier materials. According to the invention, dimethyl terephthalate and polycaprolactone are used as monomers to synthesize the polyester material; the prepared polyester material contains polycaprolactone and a rigid aromatic ring structure of a polyester structure, the aromatic ring structure can improve the overall strength, impact performance, heat resistance and the like of the material, andthe open-loop polycaprolactone chain structure in the transesterification process is good in flexibility and can be completely degraded under natural conditions; furthermore, the prepared polyester material integrates the performance advantages of two reaction monomers (dimethyl terephthalate and polycaprolactone); the elongation at break of the polyester material is obviously improved, the heatresistance is obviously improved, and meanwhile, the polyester material has certain corrosion resistance and a shape memory function, is low in degradation rate and has a wide application prospect inthe aspect of long-acting drug carriers.

Owner:BEIJING CO FOUND HIGH TECH INCUBATOR

Controllable self-crosslinking thiolated hyaluronic acid-collagen composite hydrogel and its preparation method and application

ActiveCN108084461BSpread growth promotionGood biocompatibilityPharmaceutical delivery mechanismTissue regenerationCartilage cellsCell adhesion

Owner:SICHUAN UNIV

A kind of bio-magnesium alloy of lpso structure with high volume fraction and preparation method thereof

InactiveCN103981417BWeakened corrosion potential differenceIncreased degradation rateProsthesisShielding gasImpurity

The invention relates to high-volume-fraction biological magnesium alloy of an LPSO structure and a preparation method. The biological magnesium alloy comprises the following components by mass percent: 3.6 to 4.9 percent of Gd, 0.6 to 0.9 percent of Zn, 0.3 to 0.6 percent of Zr and the balance of Mg and inevitable impurities. The preparation method comprises the steps: placing the well-prepared raw materials into a crucible with protection gas to be smelted and cast to form cast ingot, placing the cast ingot after being solidified into the water to be rapidly cooled, and then placing the cast ingot into a resistance furnace with a protection atmosphere to be thermally treated, wherein the thermal treatment temperature is 340 to 460 DEG C, and the heat preserving time is 1h to 6h. The magnesium alloy has the LPSO structure with the volume fraction being greater than 30 percent, the alloy of the structure is excellent in degradability, and the problems of the biologically degradable magnesium alloy in a human body environment that the degradation speed is high and the degradation is non-uniform can be effectively solved; moreover, the alloy is toxicity-free to the cells and expected to be applied to the biomedicine field.

Owner:江苏凯晞投资有限公司

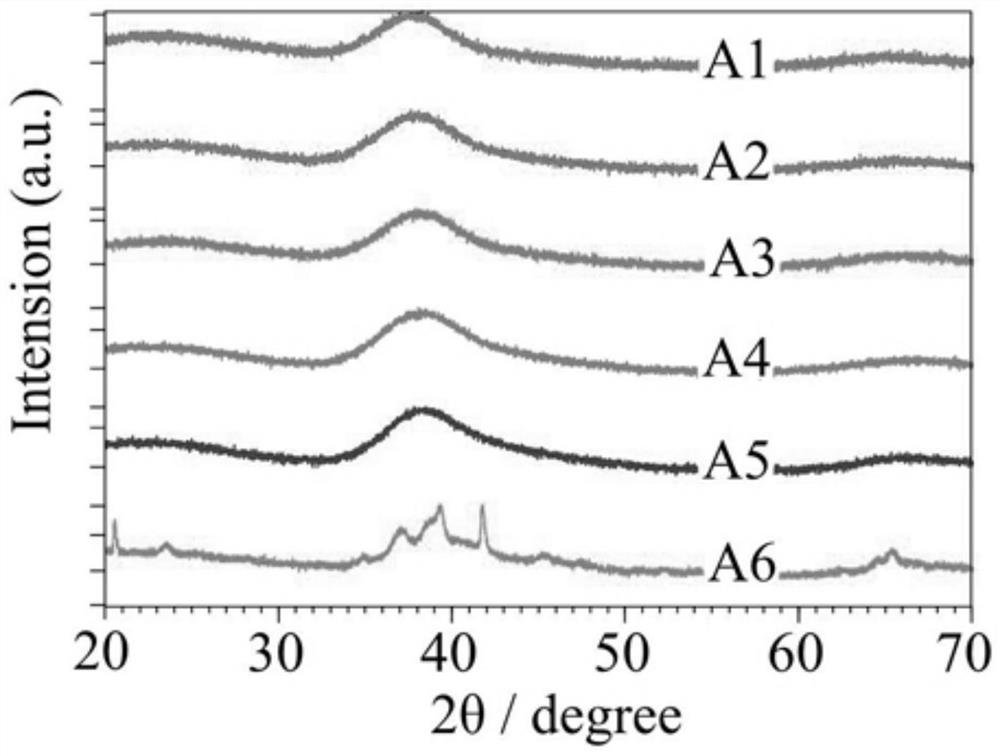

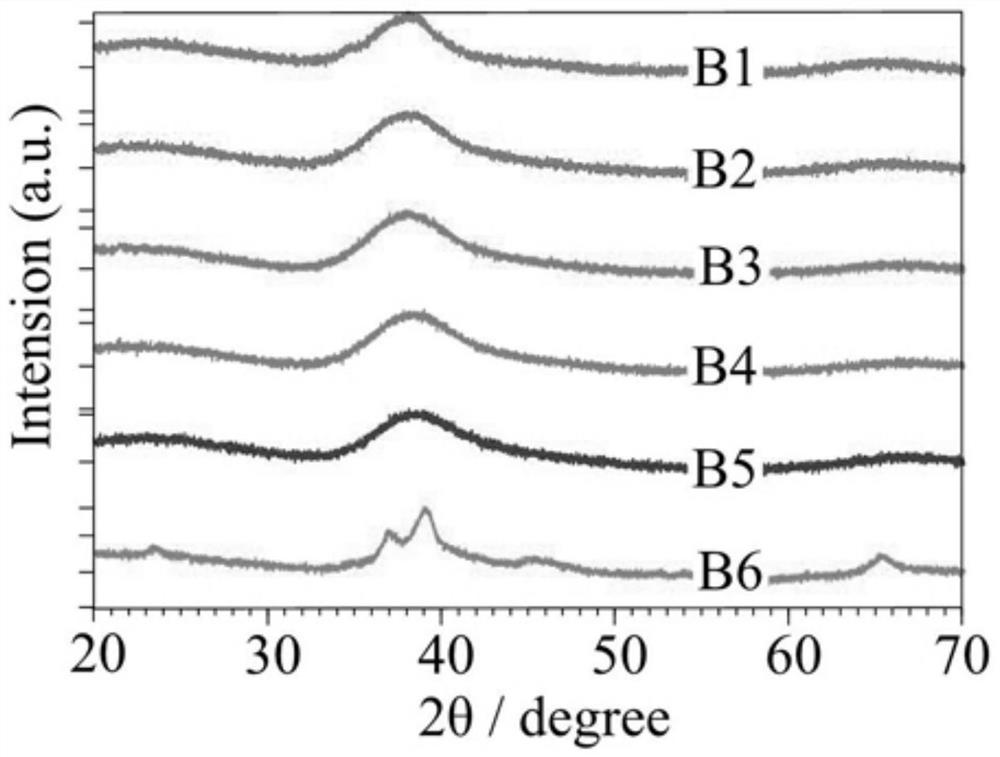

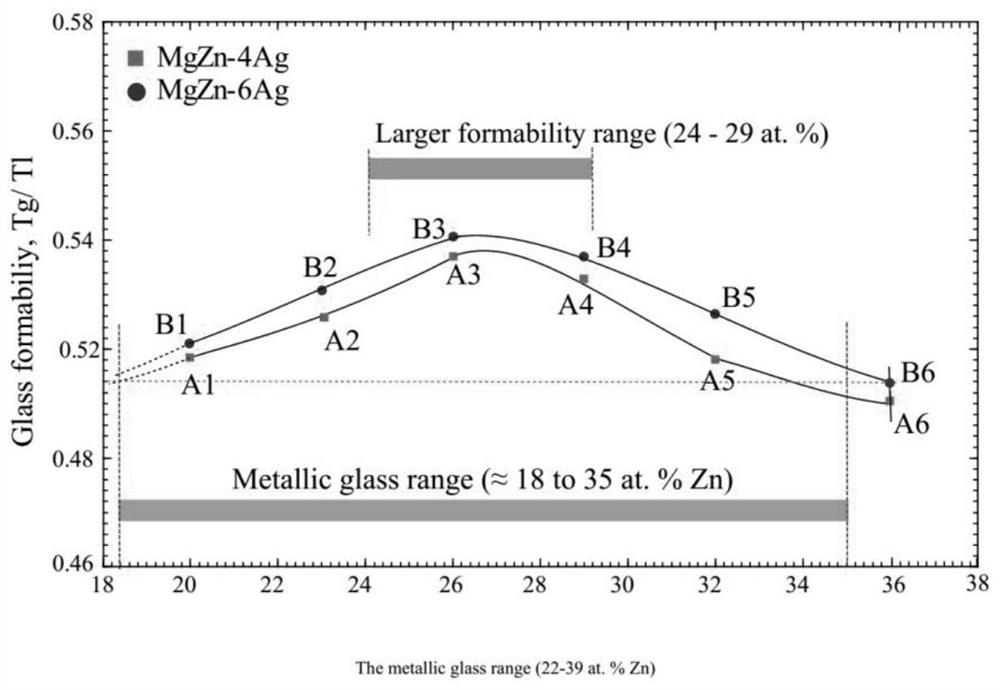

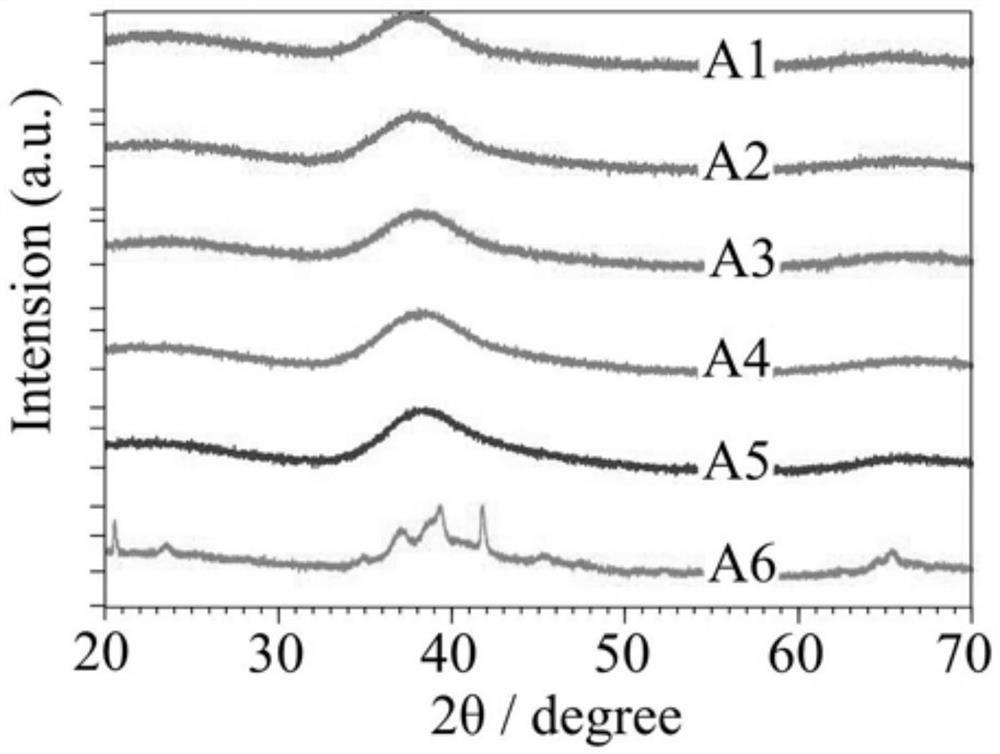

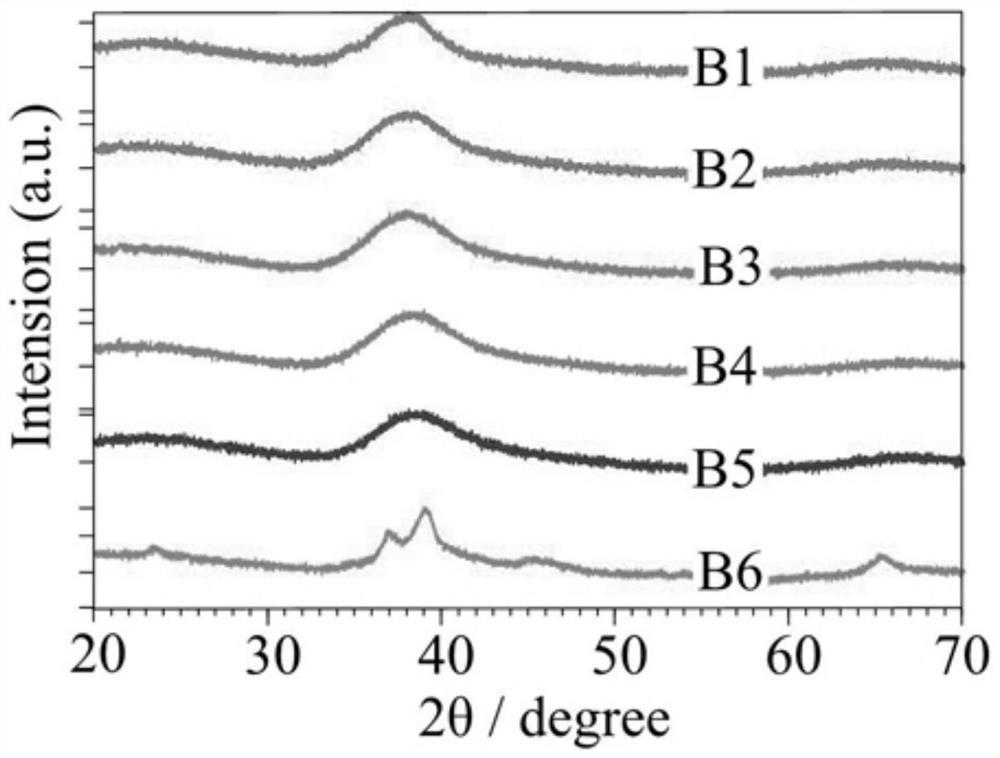

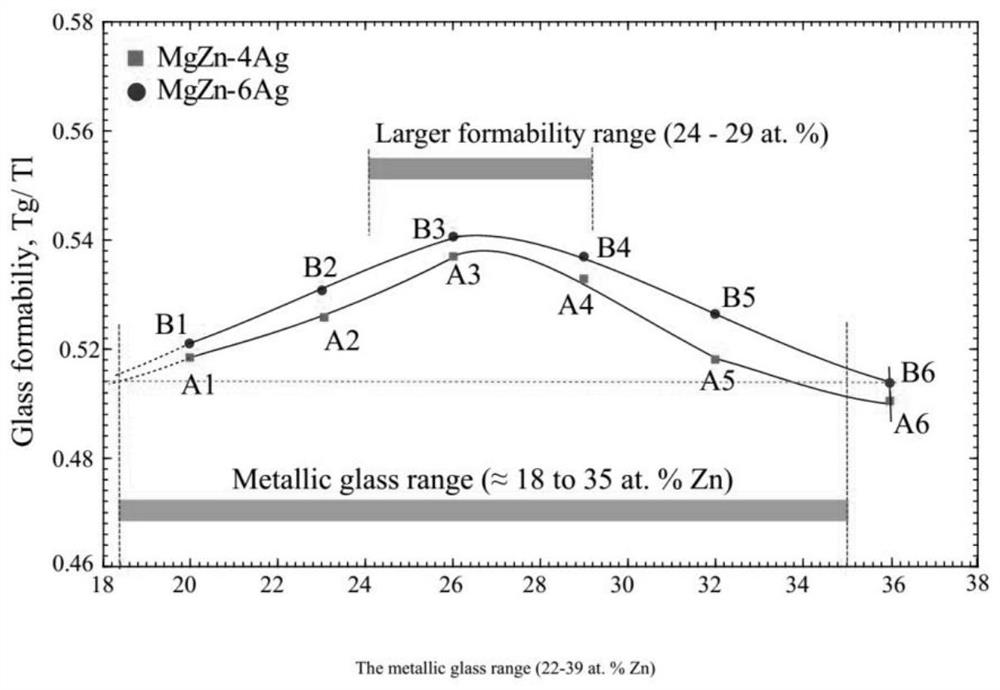

Fully absorbed mg-zn-ag system amorphous medical implant substrate, its preparation method and application

ActiveCN110257732BFulfil requirementsHigh mechanical strengthSurgeryProsthesisHuman bodyBiological body

The invention relates to a fully absorbed Mg-Zn-Ag based amorphous medical implant base material with strong corrosion resistance, high strength and good biocompatibility, and also provides its preparation method and application. The fully absorbed Mg The -Zn-Ag based amorphous medical implant substrate is made of a Mg-Zn-Ag amorphous alloy having the following composition consisting of the following composition in the following atomic percentages Composition: silver 0%-10%, and the silver content is not 0%, zinc 15%-40%, impurity 0%-5%, and the balance is magnesium. The fully absorbed Mg-Zn-Ag based amorphous medical implant substrate of the present invention has excellent mechanical strength and hardness, low gas release during use, and slow degradation rate in the human body, and is suitable as a biodegradable implant in the human body. Implant materials are used to prepare components, components or devices used in the diagnosis, treatment, and repair of living organisms, and are used to prepare artificial tissues and artificial organs that replace damaged tissues and organs of living organisms, etc., and have broad market application prospects .

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

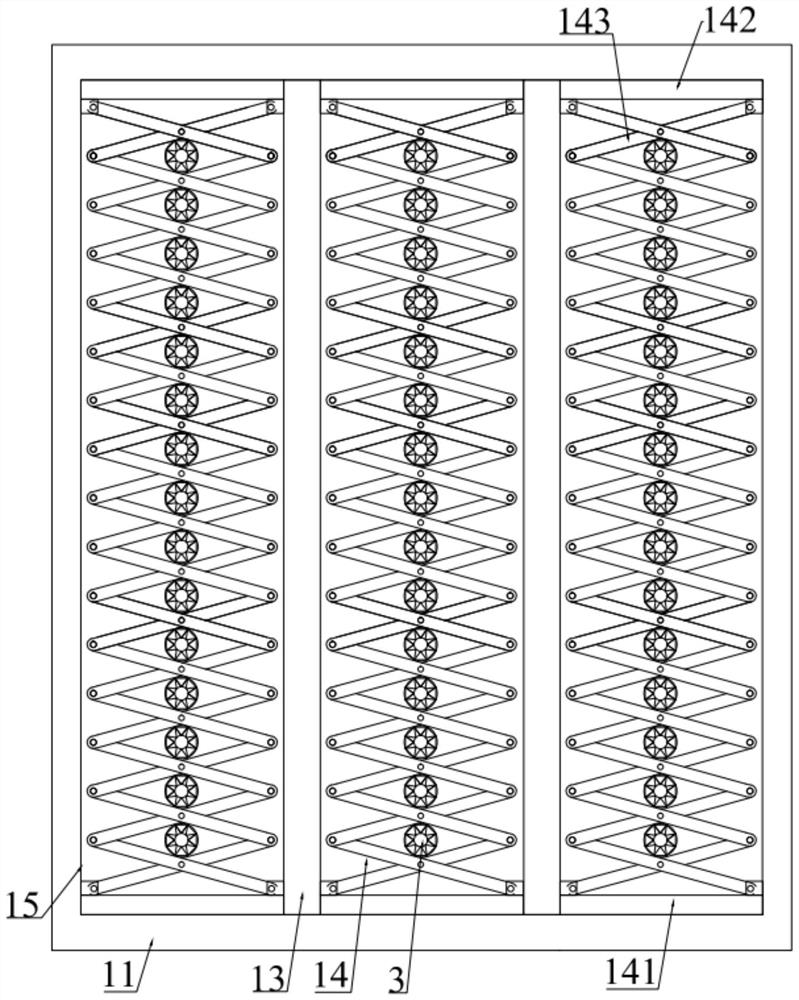

High-strength heat-preserving foam box and forming process thereof

InactiveCN112722510AImprove foaming efficiencyImprove stiffnessDomestic cooling apparatusLighting and heating apparatusNew materialsPolymer

The invention discloses a high-strength heat-preserving foam box and a forming process, and belongs to the technical field of preparation of new polymer packaging materials. The high-strength heat-preserving foam box comprises a foam box bottom plate and four foam box side plates, wherein the foam box bottom plate and the four foam box side plates form a rectangular box body structure with an opening in the upper end; and the foam box bottom plate comprises a lower bottom plate body, an upper pressing plate, a set of partition plates and a set of reinforcing supporting frame assemblies. The high-strength heat-preserving foam box is simple in structure and reasonable in design, the stiffness and strength of the foam box are improved, and the foam box is not prone to bending in the carrying process; the packaging cost is reduced; and moreover, foam has good impact resistance, the environmental protection effect is obvious, and the weight is reduced by about 20%. According to the forming process of the high-strength heat-preserving foam box, the preparation process is is simple, the foaming efficiency is high, foaming is uniform, the sound insulation and heat preservation effects of the foam plates are enhanced, and the structural strength and the surface smoothness of the foam plates are improved.

Owner:太仓大中包装材料有限公司

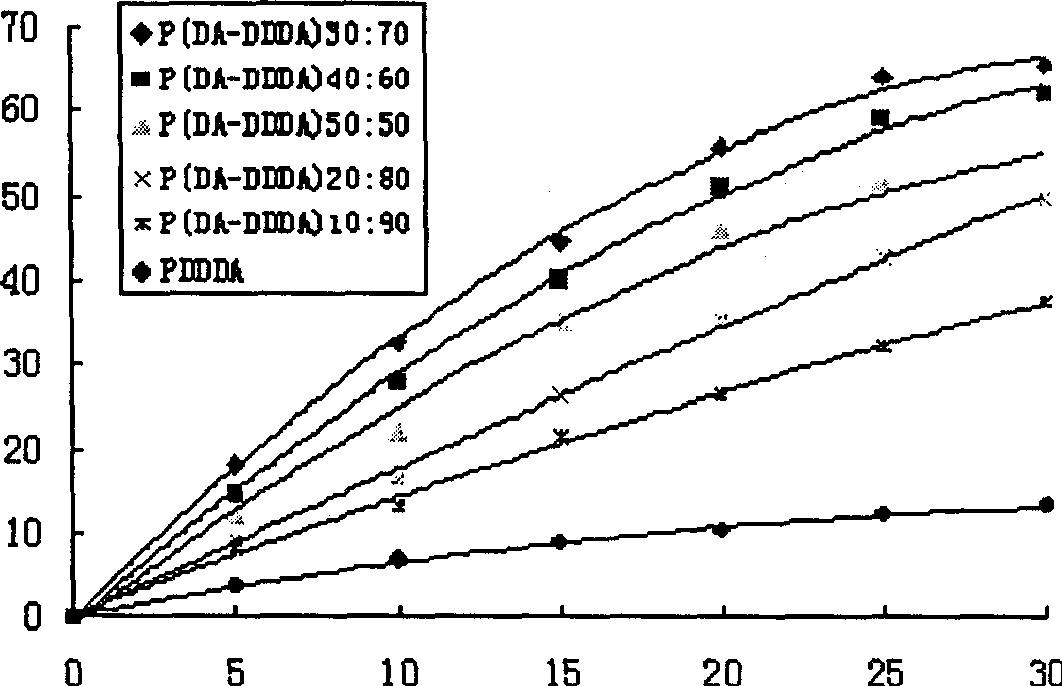

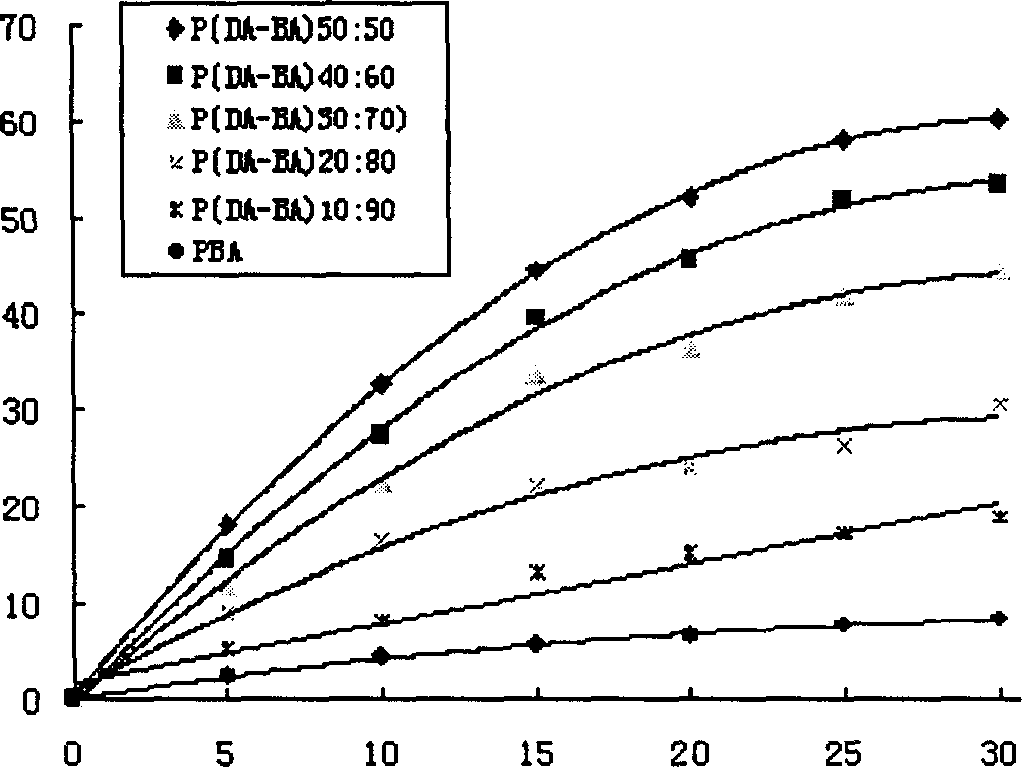

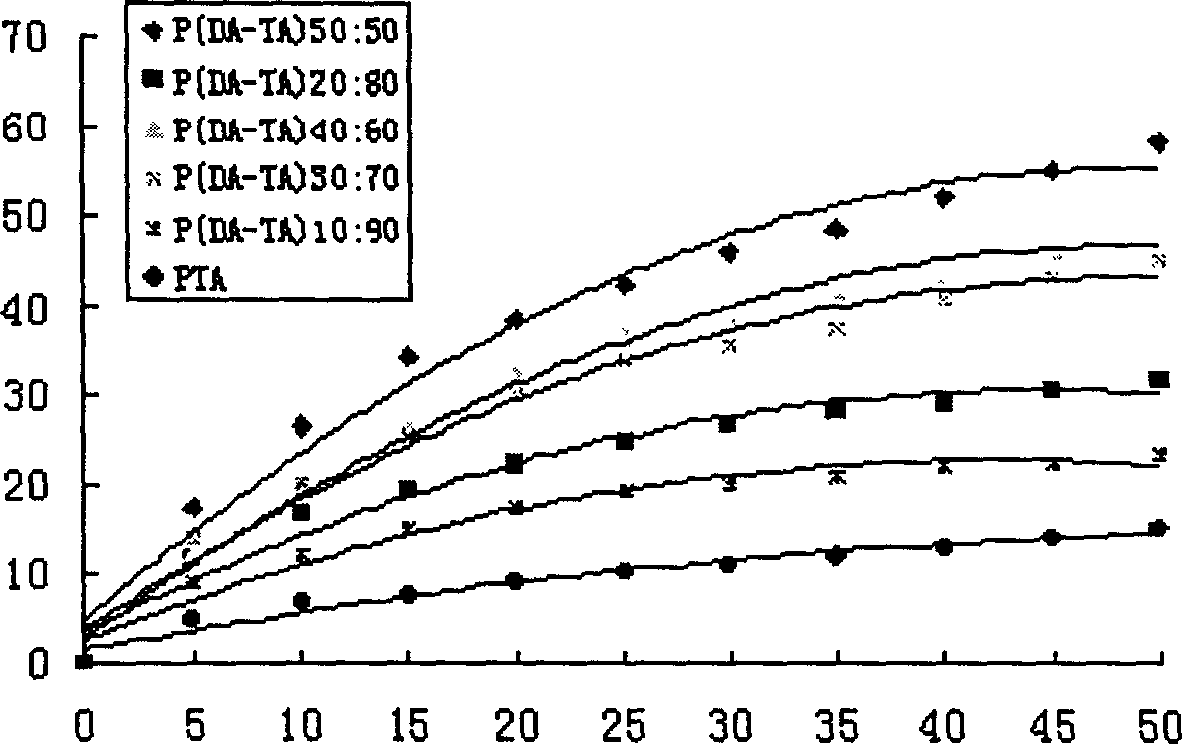

Poly acid anhydride for release-controlled medicine carrier and method for producing the same

InactiveCN1232563CReduce stimulationLong release periodPharmaceutical non-active ingredientsImmunological disordersDiseaseSynthesis methods

The invention adopts the copolymerization of dibasic fatty acid and dimer acid to prepare the carrier of hydrophilic anti-inflammatory drug and antitumor drug: polyanhydride. Because the polyanhydride material uses a diacid with a long carbon chain as a monomer, the degradation rate is slow and the drug release period is long, so it is suitable for the local sustained release drug treatment of osteomyelitis and solid tumor diseases.

Owner:HUAZHONG UNIV OF SCI & TECH

Plant fiber foaming buffer packaging material

The invention discloses a plant fiber foaming buffer packaging material, which is prepared from the following ingredients in parts by weight: polyvinyl alcohol resin, polyvinyl alcohol, modified plantfibber, epoxy propane, ethyl methacrylate, foaming agents, zinc oxide, sodium methyl silicate, slaked lime and polyethylene glycol. The plant fiber foaming buffer packaging material provided by the invention has the advantages that a specific formula is selected, so that the microstructure of the plant fiber is changed from the inside; the hole number and the uniformity of the foaming material ofthe buffer material are obviously improved; meanwhile, the mechanical property of the material is also improved.

Owner:梁概泉

Biodegradable iron-zinc-magnesium-based gradient composites based on biological bone healing and its preparation

InactiveCN103465542BHigh modulusSlow degradation rateProsthesisMetal layered productsDynamic fixationIn vivo

The invention discloses a degradable iron, zinc and magnesium-based gradient composite material based on biological bone healing. A zinc layer and an iron layer are sequentially arranged on the surface of a magnesium matrix, and the thickness or the diameter of the magnesium matrix is 30-90% of bone dimension in the repaired part. The thicknesses of the zinc and iron layers are respectively determined according to the corrosion rates of zinc and iron in an in vitro simulated body fluid. According to the composite material, rigid fixation in early stage is realized to promote bone healing, the composite material is gradually degraded, use of the material with lower rigidity is transited to dynamic fixation, and finally, the material is fully absorbed in vivo to prevent from being taken out in the second operation. Rapid degradation in the non-mechanical bearing later stage is realized, and growth by differentiation of bone cells and ingrowth of blood vessels on the surface of material are induced by hoping to combine the advantages that iron in higher rigidity in the early stage realizes rigid fixation and zinc in lower rigidity in the middle stage realizes dynamic fixation by means of quicker corrosion rate of magnesium. Finally, the composite material is fully absorbed, so as to realize the bone repairing purpose. The composite material disclosed by the invention is applicable to gradient structure designs of internal fixing materials after fracture with change demands on mechanical property with the passage of time.

Owner:TIANJIN UNIV

A kind of biodegradable emamectin benzoate microspheres

InactiveCN104886091BPromote degradationLow costBiocideAnimal repellantsControlled releaseMicrosphere

Owner:FUJIAN AGRI & FORESTRY UNIV

Fully absorbed mg-zn-ag system amorphous alloy and preparation method thereof

The invention relates to a fully-absorbed Mg-Zn-Ag-based amorphous alloy with strong corrosion resistance, high strength and good biocompatibility and a preparation method thereof. The alloy is composed of the following components in the following atomic percentages : Silver 0%‑10%, and the silver content is not 0; zinc 15%‑40%; impurity 0%‑5%; the balance is magnesium. The fully absorbed Mg-Zn-Ag series amorphous alloy of the present invention has excellent mechanical strength and hardness, low gas release, strong corrosion resistance, and can be gradually absorbed by the human body as the damaged tissue heals after being implanted into the human body. It can be absorbed and degraded without secondary surgery, and it is an excellent choice as a degradable implant material in the human body, and has broad application prospects.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com