High-strength heat-preserving foam box and forming process thereof

A foam box, high-strength technology, applied in the molding process of high-strength, heat-insulating foam boxes, and the field of heat-insulating foam boxes, can solve the problems of poor strength, no good impact force, and easy damage of foam boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

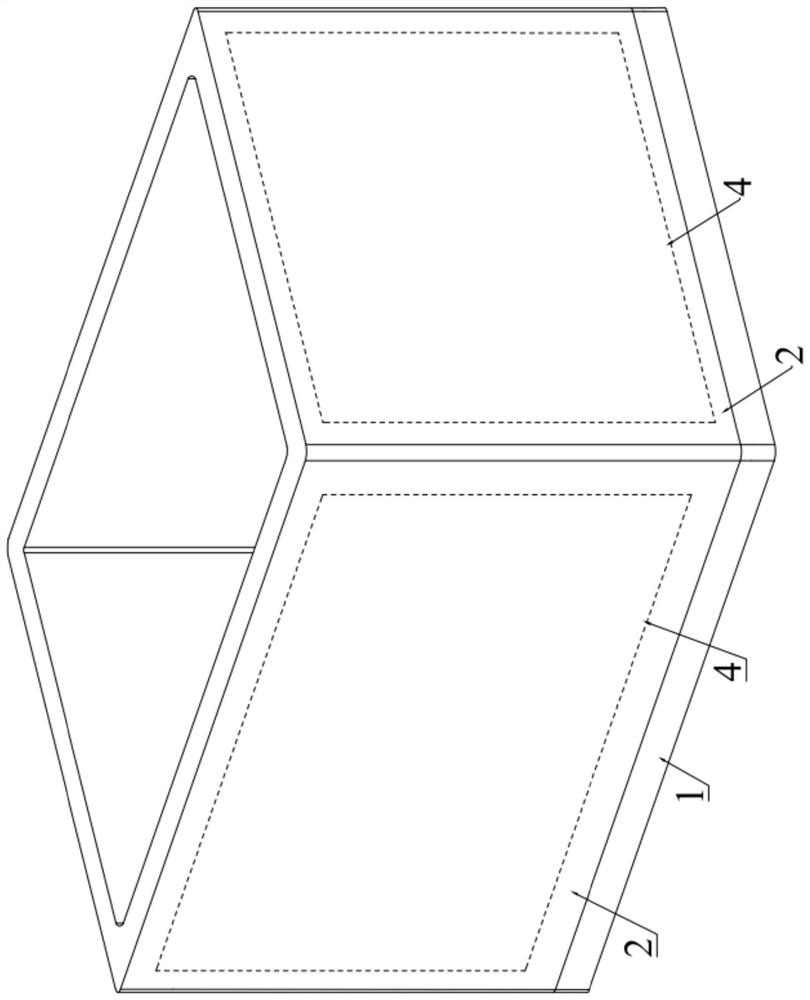

[0040] Such as figure 1 The shown high-strength, thermal insulation foam box includes a foam box bottom plate 1 and four foam box side panels 2, the lower ends of the four foam box side panels 2 are fixedly connected to the foam box bottom plate 1, and the foam box bottom plate 1 and Four foam box side panels 2 form a rectangular box structure with an upper end opening.

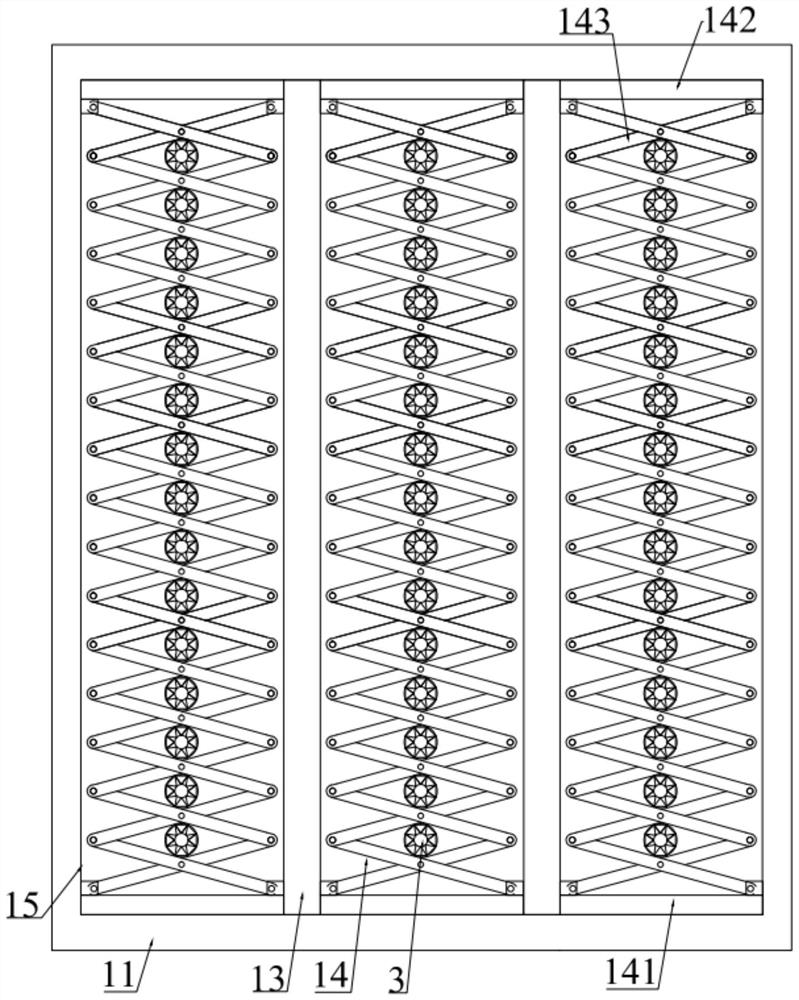

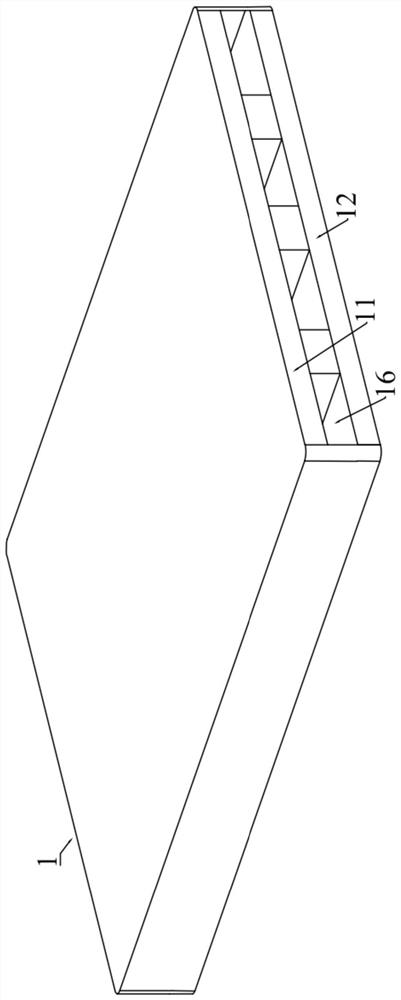

[0041] Among them, such as figure 2 , 3 The shown foam box bottom plate 1 includes a lower bottom plate body 11, an upper platen 12, a set of partition plates 13 and a set of reinforced support frame assemblies 14, the cross sections of the lower plate body 11 and the upper platen 12 are rectangular, and the upper The pressure plate 12 is covered on the upper end of the lower floor body 11, the middle position of the lower floor body 11 is provided with a rectangular cavity 15, and the set of partition plates 13 are arranged in parallel in the rectangular cavity 15, and separate The two ends of the plate ...

Embodiment 2

[0059] Based on the first embodiment, the foam box bottom plate 1 and the foam box side plate 2 include the following components in parts by weight: 60-100 parts of polylactic acid, 30-50 parts of polyethylene, and 6-17 parts of polyethylene glycol ether , 2-8 parts of polyester polyol, 5-16 parts of polyester resin, 6-18 parts of starch, 1-5 parts of foam stabilizer, 2-6 parts of seaweed extract, 1-4 parts of silicone oil, high alumina bauxite 3-5 parts, 8-15 parts of ethylene-vinyl acetate, 0.5-3 parts of expanded graphite, 3-7 parts of bamboo fiber, 1-4 parts of magnesium carbonate, 0.2-0.5 parts of stabilizer.

[0060] The present invention also provides its preparation method of the foam box bottom plate 1 and the foam box side plate 2, comprising the following steps:

[0061] 1. Put polylactic acid, polyethylene, polyethylene glycol ether, polyester polyol, and polyester resin in a mixer for mixing and stirring. The stirring temperature is 105-115°C, the stirring rate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com