Fully-degradable high-barrier composite material for flexible package as well as preparation method and application thereof

A composite material and fully degradable technology, which is applied in the field of fully degradable high-barrier composite materials for flexible packaging and its preparation, can solve the problems of insufficient brittleness of PLA, poor heat resistance, and consumption of petroleum resources, and achieve the goal of enhancing mechanical properties and enhancing flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

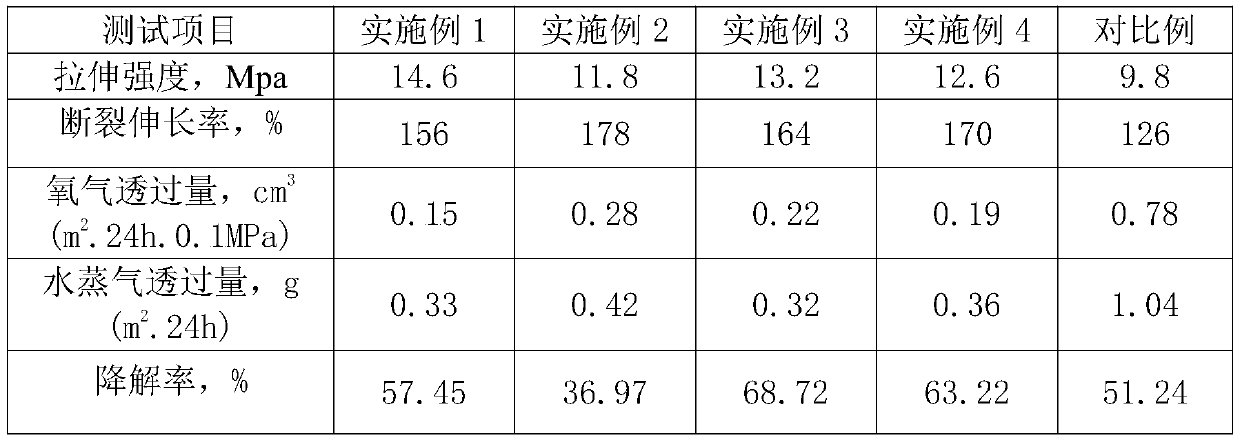

Examples

Embodiment 1

[0050] The fully degradable high-barrier composite material of this embodiment is composed of an inner layer of biodegradable matrix resin and an outer layer of biodegradable matrix resin through double-layer co-extrusion.

[0051] The inner biodegradable matrix resin in this embodiment acts as a barrier, and the mass ratio between the inner biodegradable matrix resin and the outer biodegradable matrix resin is 1.5:1. Each layer is counted in parts by weight, and the biodegradable matrix resin in the inner layer is mainly composed of the following components: 20 parts of PBAT and 80 parts of PCL, wherein the total parts by weight of PBAT and PCL is 100 parts; 0.5 parts, 0.3 parts of chain extender, and 0.3 parts of end-capping agent.

[0052] In parts by weight, the outer biodegradable matrix resin is mainly composed of the following components: 20 parts of PBAT, 80 parts of PLA, wherein the total parts by weight of PBAT and PLA is 100 parts; 5 parts of talcum powder, equivale...

Embodiment 2

[0063] The composite material in this embodiment is composed of an inner layer of biodegradable matrix resin and an outer layer of biodegradable matrix resin through double-layer co-extrusion, wherein the inner layer of biodegradable matrix resin acts as a barrier, and the inner layer of biodegradable matrix resin 1. The mass ratio between the outer biodegradable matrix resins is 0.8:1. Each layer is counted in parts by weight, and the biodegradable matrix resin in the inner layer is mainly composed of the following components: 80 parts of PBAT and 20 parts of PCL, wherein the total parts by weight of PBAT and PCL is 100 parts; compatible 1 part of agent, 0.3 part of chain extender, and 0.3 part of end-capping agent.

[0064] In parts by weight, the outer biodegradable matrix resin is mainly composed of the following components: 80 parts of PBAT, 20 parts of PLA, wherein the total parts by weight of PBAT and PLA is 100 parts; 15 parts of talcum powder, equivalent 1 part of co...

Embodiment 3

[0066] In view of the slow degradation rate of PBAT due to the presence of aromatic PBT segments, in this embodiment, a degradation regulating accelerator is added to both the inner biodegradable matrix resin and the outer biodegradable matrix resin. The degradation regulating accelerator uses biochar with a particle size of 150-200 mesh as a carrier, forms a biochar composition by loading nano-zinc oxide or / and nano-titanium dioxide on the biochar, and acts on the biochar composition Carry out surface coupling coating treatment.

[0067]The inner biodegradable matrix resin in this embodiment acts as a barrier, and the mass ratio between the inner biodegradable matrix resin and the outer biodegradable matrix resin is 1:1. Each layer of the composite material of the present embodiment is composed as follows: in parts by weight, the biodegradable matrix resin of the inner layer is composed of the following parts by weight: 40 parts of PBAT, 60 parts of PCL, 5 parts of degradatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com