Nano-calcium plastic biodegradation composite resin and preparation and use method thereof

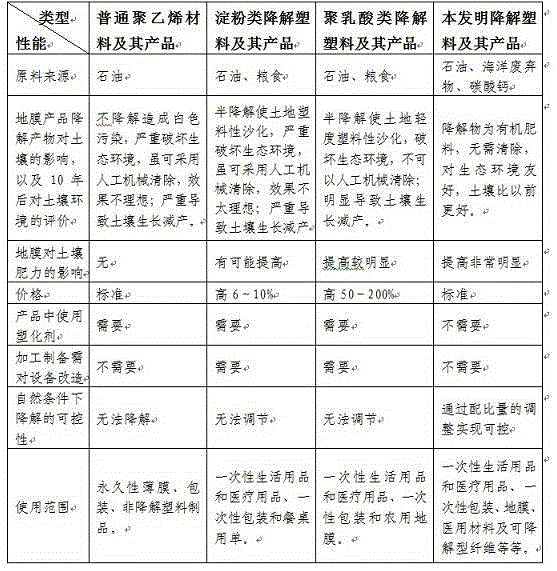

A biodegradable and composite resin technology, applied in the field of composite materials, can solve the problems of large amount of addition, high high-temperature carbonization rate, and low physical performance indicators of degraded plastic products, so as to improve quality and flexibility, improve comprehensive performance, and degradability adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

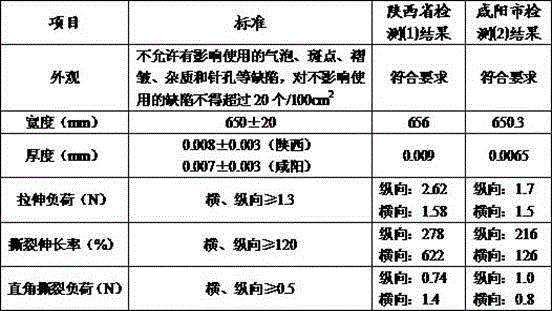

[0023] Take 0.5 kg of KV-environmentally friendly plastic biodegradable element and mix it with 99.5 kg of nano-modified plastic composite material. Under the condition of 100 ° C, mix and stir at 150 rpm for 10 minutes, extrude and granulate, and obtain nano-calcium plastic biological Degradation of composite resin particles; (1) Take 5kg of the particles and 95kg of polyethylene to blow the film; (2) Take the particles of 30kg and 70kg of polyethylene to blow the film; (No: JQ2004-250W) and Xianyang City Product Quality and Technical Supervision Institute (No: Xianjian 2004-B096), the product meets the national GB13735-1992 quality standard. The results are as follows:

[0024]

[0025] The obtained degradable plastic film can be used for covering plastic film, nursery stock conservation bag and water-saving bag. In Tongchuan, Chang'an, Ganxian, Shaanxi, Lanzhou, Urumqi, Harbin and other places, different crop experiments such as nursery seedling cultivation, watermelon ...

Embodiment 2

[0027] Take 5kg of KV-environmentally friendly plastic biodegradable element and mix it with 95kg of nano-modified plastic composite material, and mix and stir at 180 rpm for 6 minutes at 110°C to extrude and granulate to obtain nano-calcium plastic biodegradable composite resin Particles; (1) take 10kg of the particles and 90kg of polyethylene to mix and blow the film, and the obtained degradable plastic film is tested to meet the national quality standard of GB13735-1992; (2) take the particles of 40kg and 60kg of polyethylene to mix and blister, and the prepared degradable plastic Products (disposable daily necessities and medical supplies, disposable food containers, medicine bottles and other packaging containers) have been tested and conform to the national GB18006.1-2009 technical standard and GB15980-1995 hygienic standard.

Embodiment 3

[0029] Mix 15kg of KV-environmentally friendly plastic biodegradable element with 85kg of nano-modified plastic composite material, and mix and stir at 150 rpm for 10 minutes at 130°C to extrude and granulate to obtain nano-calcium plastic biodegradable composite resin Granules, take 15kg of the granules and mix them with 85kg polyethylene to blow the film, and the obtained degradable plastic film is tested to meet the national standards GB13735-1992, GB18006.1-2009, GB / T4456-1996, GB / T10457-1989, GB / T1004 -2008, and YBB00132002.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com