A composite scaffold of 3D printed degradable polymer scaffold and photocrosslinked hydrogel

A composite scaffold and 3D printing technology, applied in prosthesis, tissue regeneration, medical science, etc., can solve problems such as unfavorable cell adhesion and growth, achieve good swelling effect, low swelling rate, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

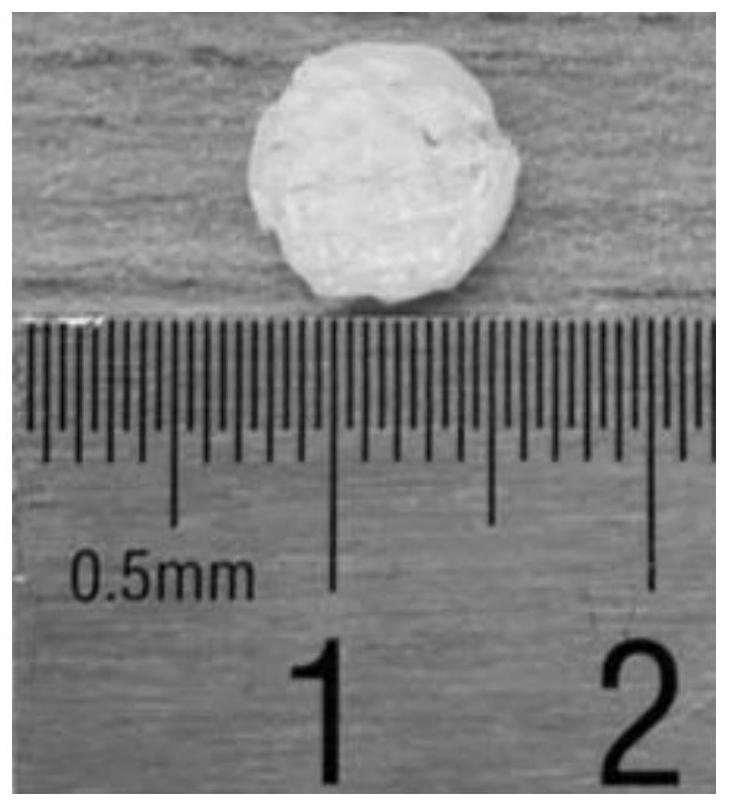

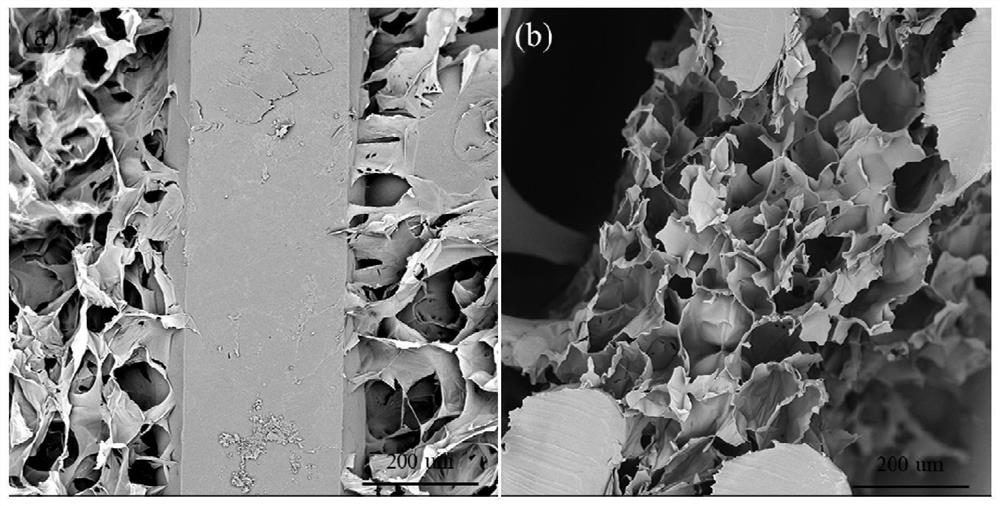

[0050] ①Preparation of PCL stent by 3D printing:

[0051] The printer used for 3D printing is the OPUS seven-channel bioprinting system. The molecular weight of the PCL used is 43,000. The diameter of the 3D printed fibers is 200 μm, and the distance between the fibers is 200 μm. The printing temperature is 90 ° C, 600 Psi, and 250 mm / min. speed. The specific steps of 3D printing are as follows: design the stent printing model, set the corresponding parameters, extrude through the fine nozzle, and superimpose the fiber layers to form the PCL stent.

[0052] ②Preparation of GelMA with low degree of substitution and high degree of substitution:

[0053] 1. Prepare 0.25M carbonate-bicarbonate buffer (CB buffer): add 0.3975g sodium carbonate and 0.7325g sodium bicarbonate to deionized water, then measure the pH of the solution, if the pH is less than 9.0, add HCl , if the pH is greater than 9.0 then add NaOH to bring the final pH to 9.0.

[0054] 2. Preparation reaction of GelM...

Embodiment 2

[0067] ① Preparation of PLA scaffolds by 3D printing:

[0068] The printer used for 3D printing is the OPUS seven-channel bioprinting system. The average molecular weight of the PLA used is 100,000. The diameter of the 3D printed fibers is 200 μm, and the distance between the fibers is 200 μm. The printing pressure is 100 Psi and the printing speed is 250 mm / min. . The specific steps of 3D printing are as follows: design the printing model of the bracket, set the corresponding parameters, extrude through the fine nozzle, and superimpose the fiber layers to form the PLA bracket.

[0069] ②According to the existing literature, glycidyl methacrylate (GMA) was used to modify hyaluronic acid (HA) to obtain hyaluronic acid with a low degree of substitution (30%) and a high degree of substitution (70%);

[0070] ③ The final preparation method of the composite scaffold of hyaluronic acid and PLA with different degrees of substitution and crosslinking, including the following steps:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com